Method for preparing montmorillonite nano-sheets through gas phase stripping

A technology of montmorillonite nanosheets and vapor phase exfoliation, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low exfoliation efficiency, and achieve the effect of improving exfoliation efficiency, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 1 g of Naki montmorillonite, put it in a beaker, put it into a blast drying oven, dry it at 60°C for 8 hours, take out the montmorillonite, and cool it to room temperature for later use. Put the dried montmorillonite into a 200 mL conical flask, add 50 mL of liquid nitrogen to the conical flask, and let it stand after the liquid nitrogen is completely vaporized. Repeat the above gasification-standstill steps for a total of 5 times to obtain montmorillonite nanosheets.

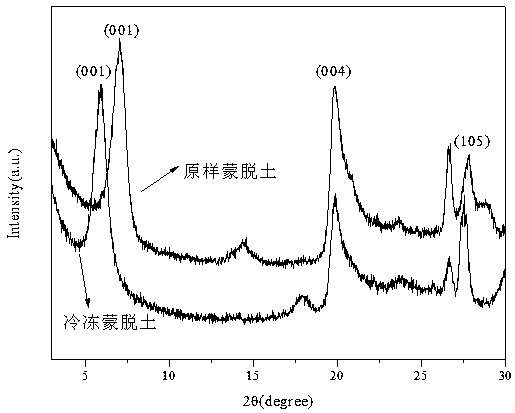

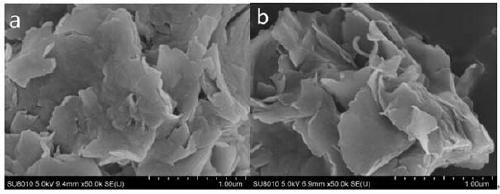

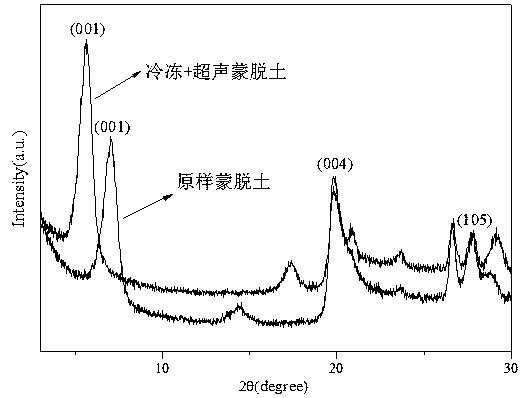

[0023] figure 1 are the XRD patterns of the montmorillonite as-is used in this example and the montmorillonite nanosheets after stripping, figure 1 The characteristic peak (001) shifts after the middle montmorillonite is peeled off. According to the Bragg equation 2dsinθ=λ, the montmorillonite layer spacing before peeling is d=1.263nm, and the montmorillonite layer spacing after peeling is d=1.506nm, indicating that the montmorillonite layer spacing is d=1.506nm. The soil was successfully strippe...

Embodiment 2

[0026] Weigh 1 g of Naki montmorillonite, put it in a beaker, put it into a blast drying oven, dry it at 60°C for 8 hours, take out the montmorillonite, and cool it to room temperature for later use. Put the dried montmorillonite into a 200 mL conical flask, add 50 mL of liquid nitrogen to the conical flask, and let it stand after the liquid nitrogen is completely vaporized. Repeat the above gasification-standing step for a total of 10 times to obtain montmorillonite nanosheets. The obtained montmorillonite has a calculated interlayer spacing of 1.503 nm.

Embodiment 3

[0028] Weigh 1 g of Naki montmorillonite, put it in a beaker, put it into a blast drying oven, dry it at 60°C for 8 hours, take out the montmorillonite, and cool it to room temperature for later use. Put the dried montmorillonite into a 200 mL conical flask, and put the montmorillonite into a 150W ultrasonic cleaner for ultrasonic vibration for 10 min to obtain montmorillonite nanosheets. The calculated interlayer spacing of the obtained montmorillonite was 1.523 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com