Preparing method of single-layer or few-layer molybdenum disulfide nanometer material

A technology of molybdenum disulfide and nanomaterials, which is applied in the field of metal molybdenum, can solve the problems of low output of molybdenum disulfide nanomaterials, low stripping efficiency, and weak electrical properties of products, and achieve high stripping efficiency, large output, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

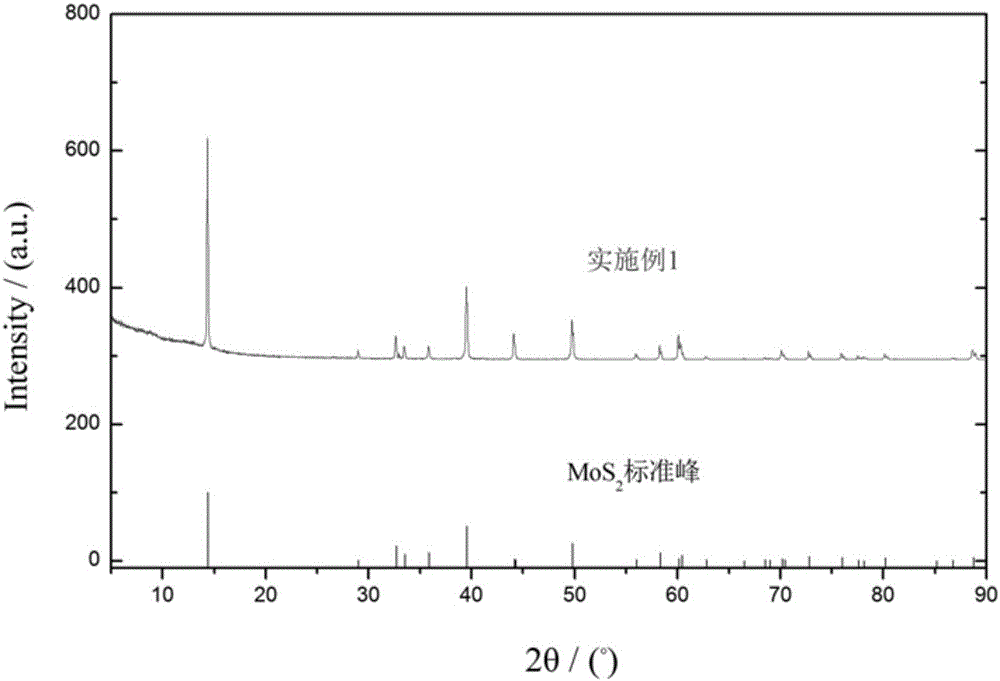

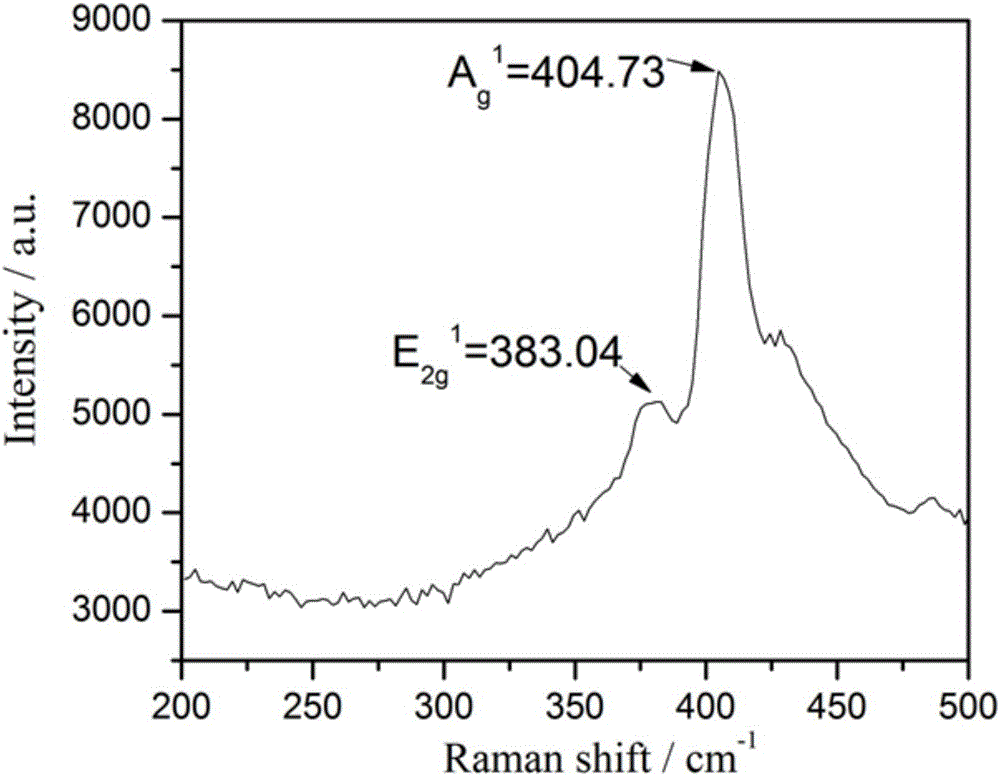

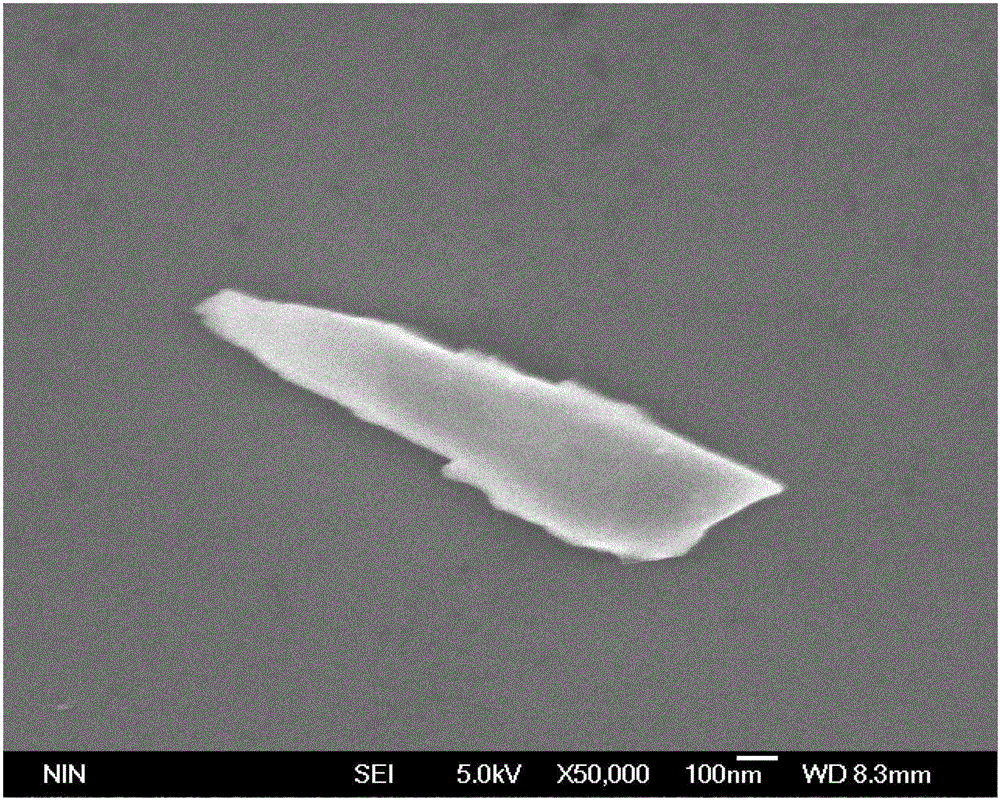

Embodiment 1

[0044] This embodiment provides a method for preparing a single-layer or few-layer molybdenum disulfide nanomaterial, which specifically includes the following steps:

[0045] Take 10g of molybdenum disulfide powder and grind it to a 200-mesh sieve, add it to an ethanol solution with a mass concentration of 10% and containing 100g of polyphenylene sulfide, heat it in a water bath to 30°C and stir for 12 hours to obtain a mixed solution.

[0046] Add 5gKMnO to the above mixture 4 powder, heated to 50°C in a water bath and stirred for 18 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 3g layered molybdenum disulfide powder.

[0047] Put the obtained layered molybdenum disulfide powder and 1.5g of picric acid into the high-pressure reaction kettle evenly, vacuumize and pass in argon, heat the reaction kettle to 500°C to explode, and take out the explosion reaction after cooling to room temperature with the furnace. In this way, single-layer or ...

Embodiment 2

[0050] This embodiment provides a method for preparing a single-layer or few-layer molybdenum disulfide nanomaterial, which specifically includes the following steps:

[0051] Take 10g of molybdenum disulfide powder and grind it to a 200-mesh sieve, add it to an ethanol solution with a mass concentration of 20% and containing 200g of polyphenylene sulfide, heat it in a water bath to 50°C and stir for 5 hours to obtain a mixed solution.

[0052] Add 10g KMnO to the above mixture 4 powder, heated to 80°C in a water bath and stirred for 8 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 3.2g layered molybdenum disulfide powder.

[0053] Put the obtained layered molybdenum disulfide powder and 3.2g of picric acid into the high-pressure reaction kettle evenly, evacuate and pass in argon, heat the reaction kettle to 480°C to explode, and take out the explosion reaction after cooling to room temperature with the furnace. In this way, single-layer or...

Embodiment 3

[0055] This embodiment provides a method for preparing a single-layer or few-layer molybdenum disulfide nanomaterial, which specifically includes the following steps:

[0056] Take 10g of molybdenum disulfide powder and grind it to a 200-mesh sieve, add it to an ethanol solution with a mass concentration of 30% and containing 300g of polyphenylene sulfide, heat it in a water bath to 40°C and stir for 8 hours to obtain a mixed solution.

[0057] Add 15gKMnO to the above mixture 4 powder, heated to 70°C in a water bath and stirred for 12 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 2.8g layered molybdenum disulfide powder.

[0058] Put the obtained layered molybdenum disulfide powder and 5.6g of picric acid into the high-pressure reaction kettle evenly, evacuate and pass in argon, heat the reaction kettle to 450°C to explode, and take out the explosion reaction after cooling to room temperature with the furnace. In this way, single-layer or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com