Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce quenching costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

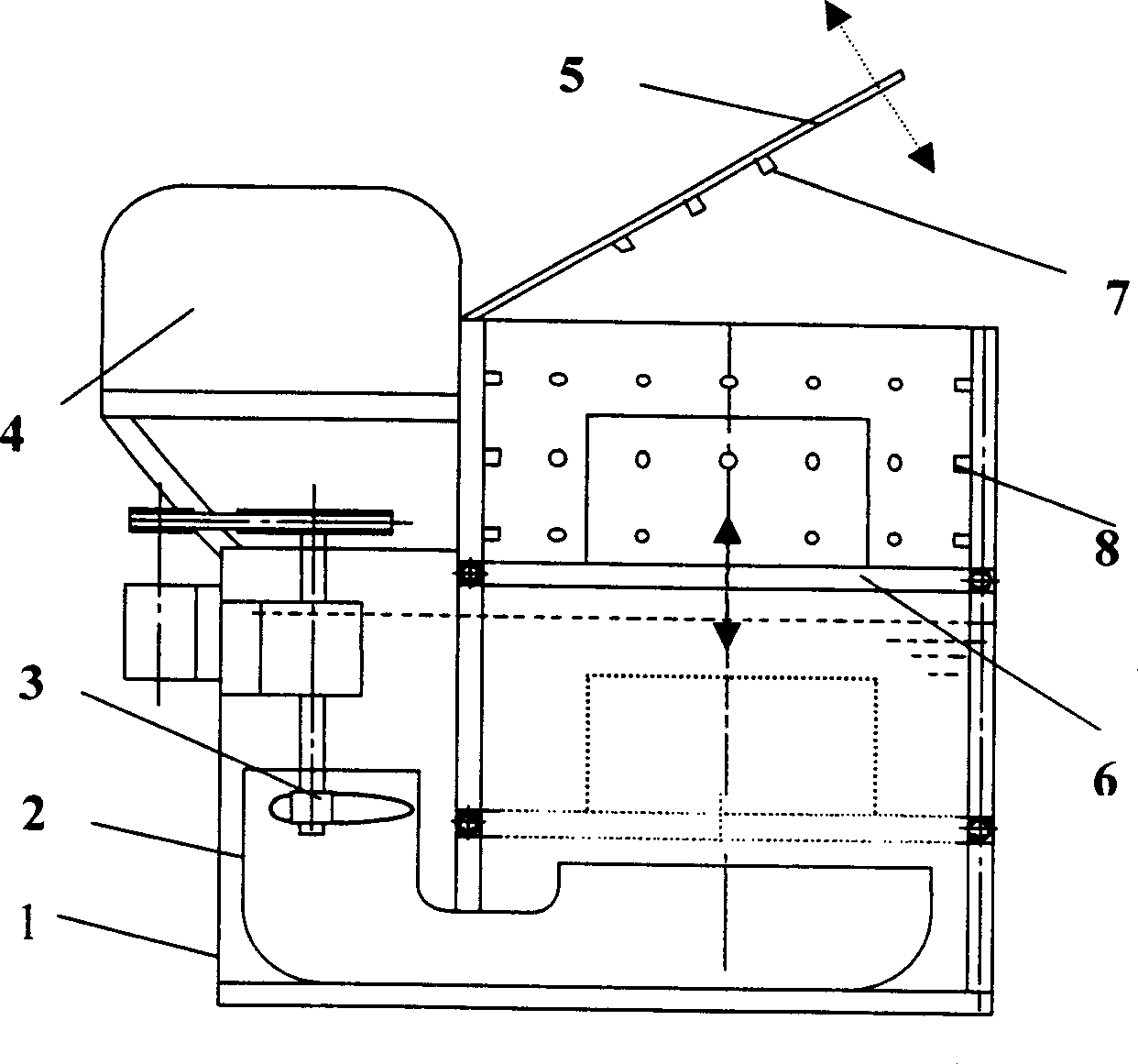

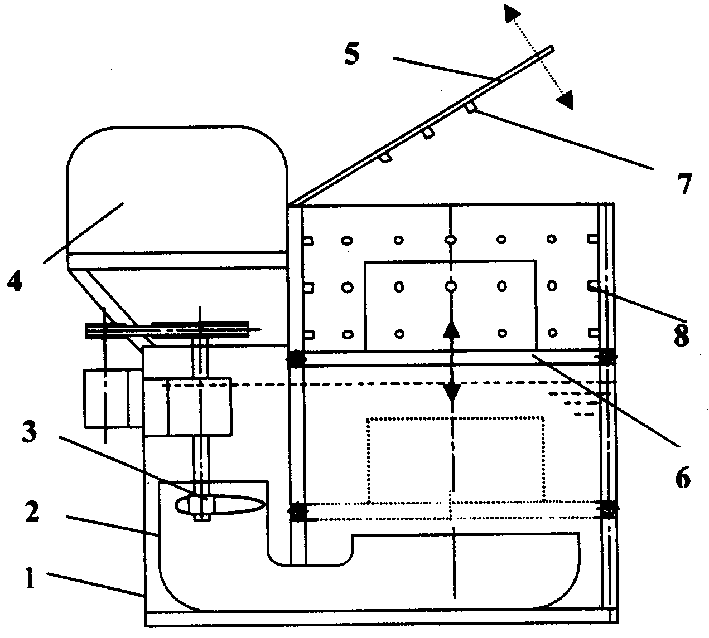

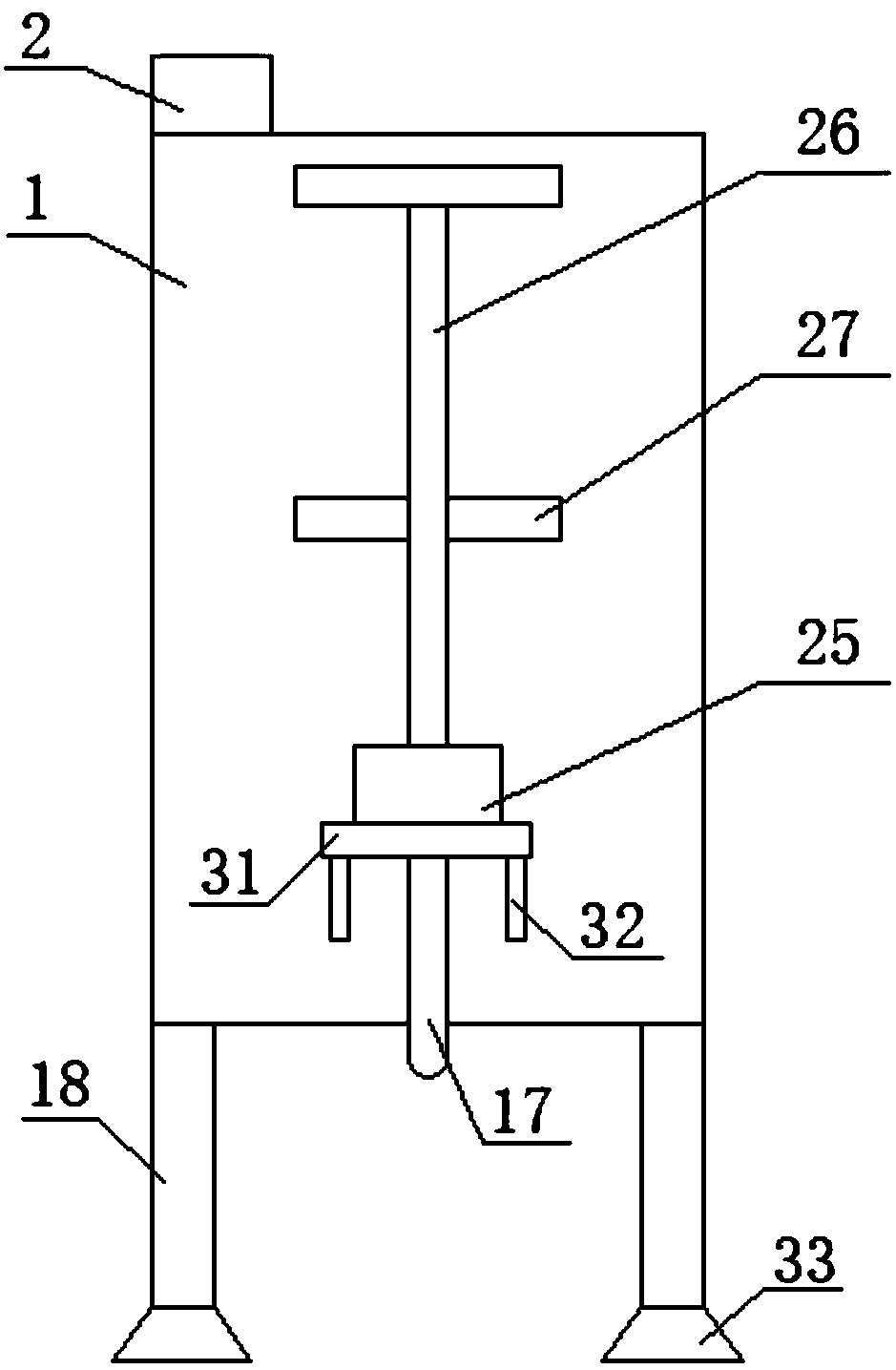

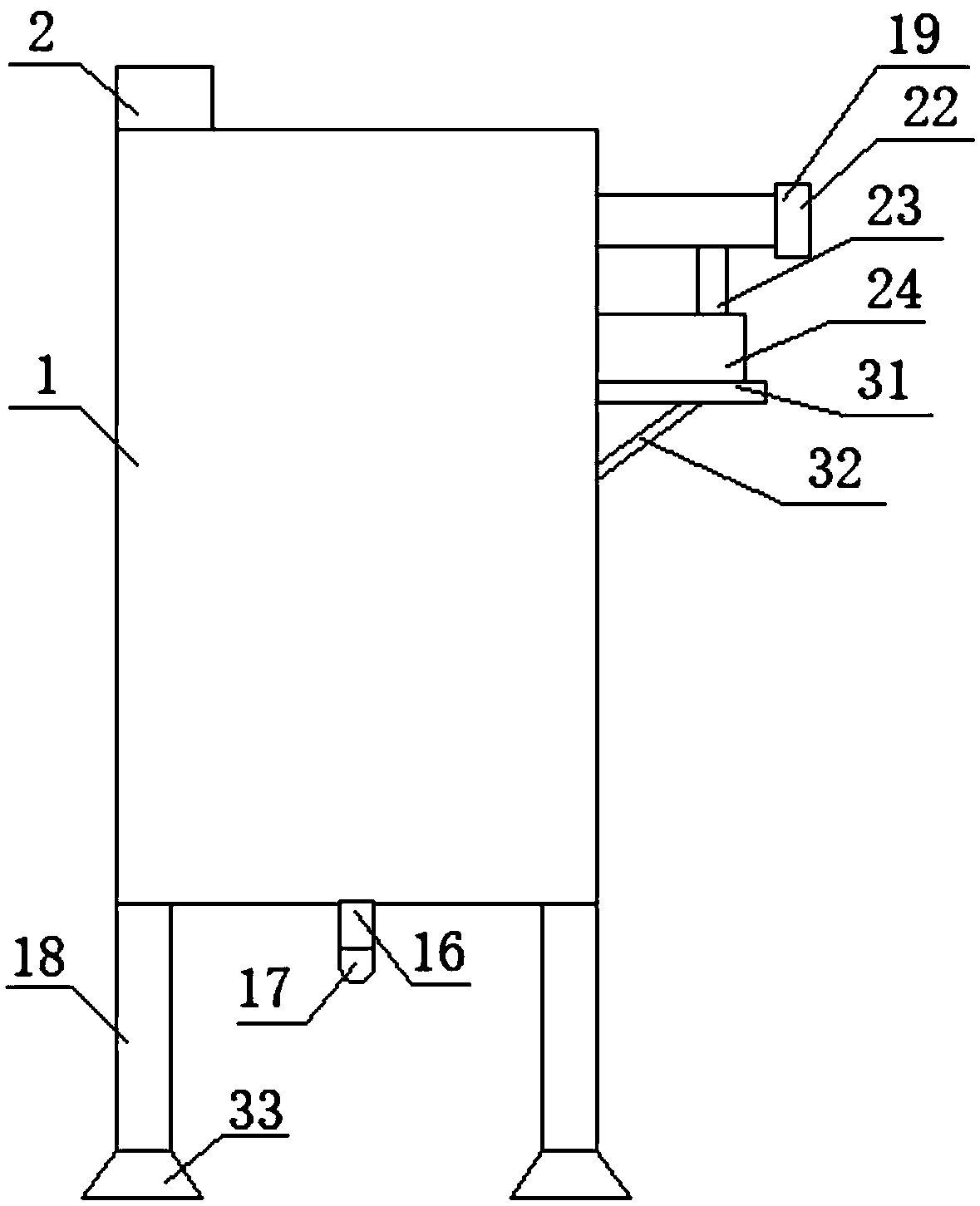

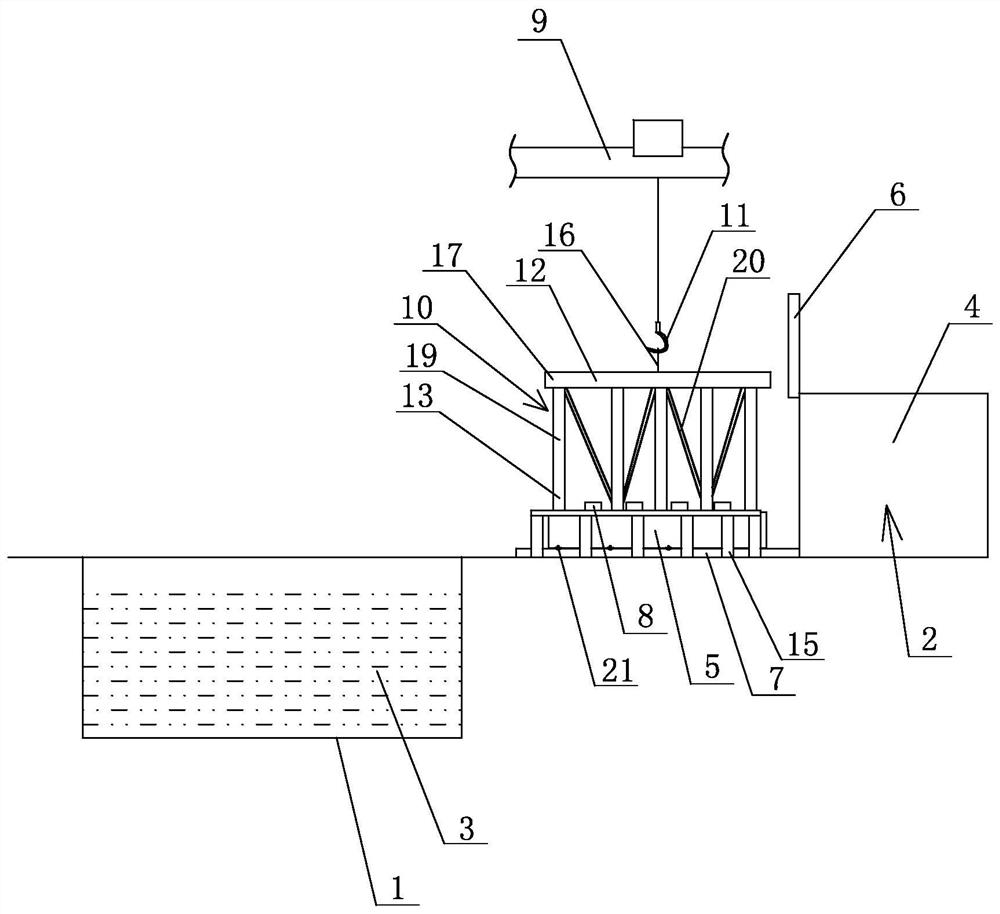

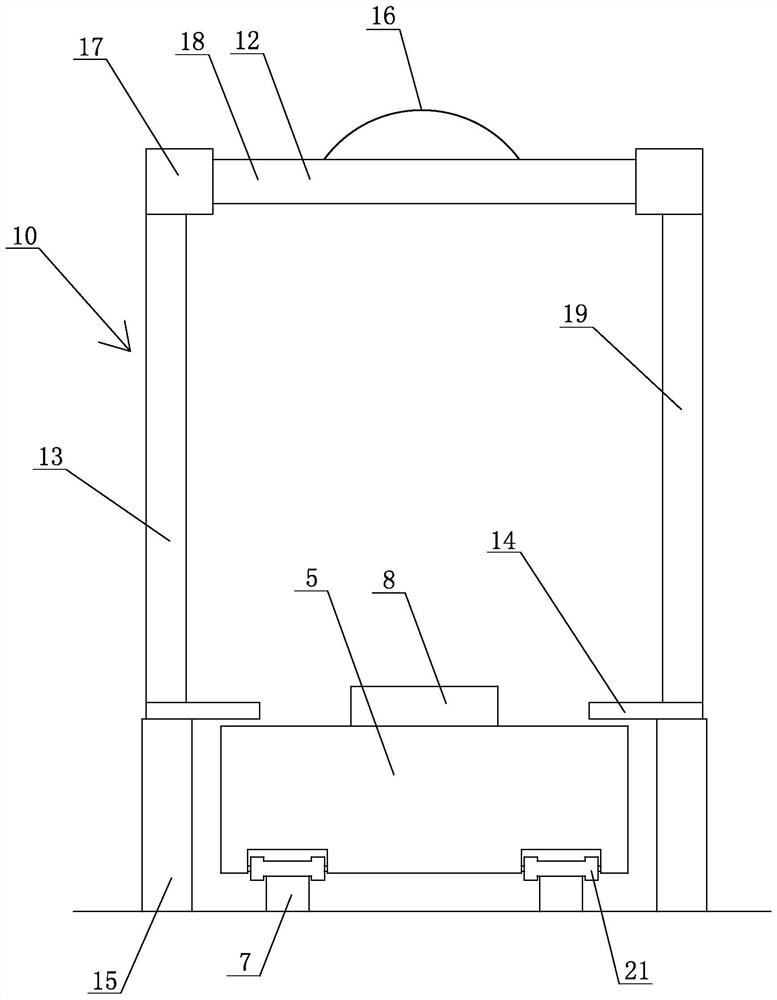

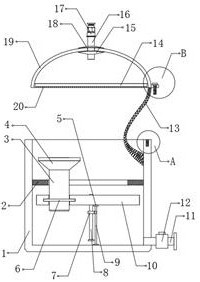

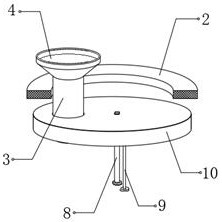

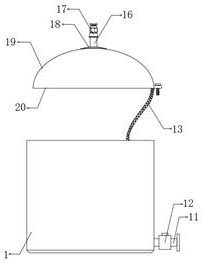

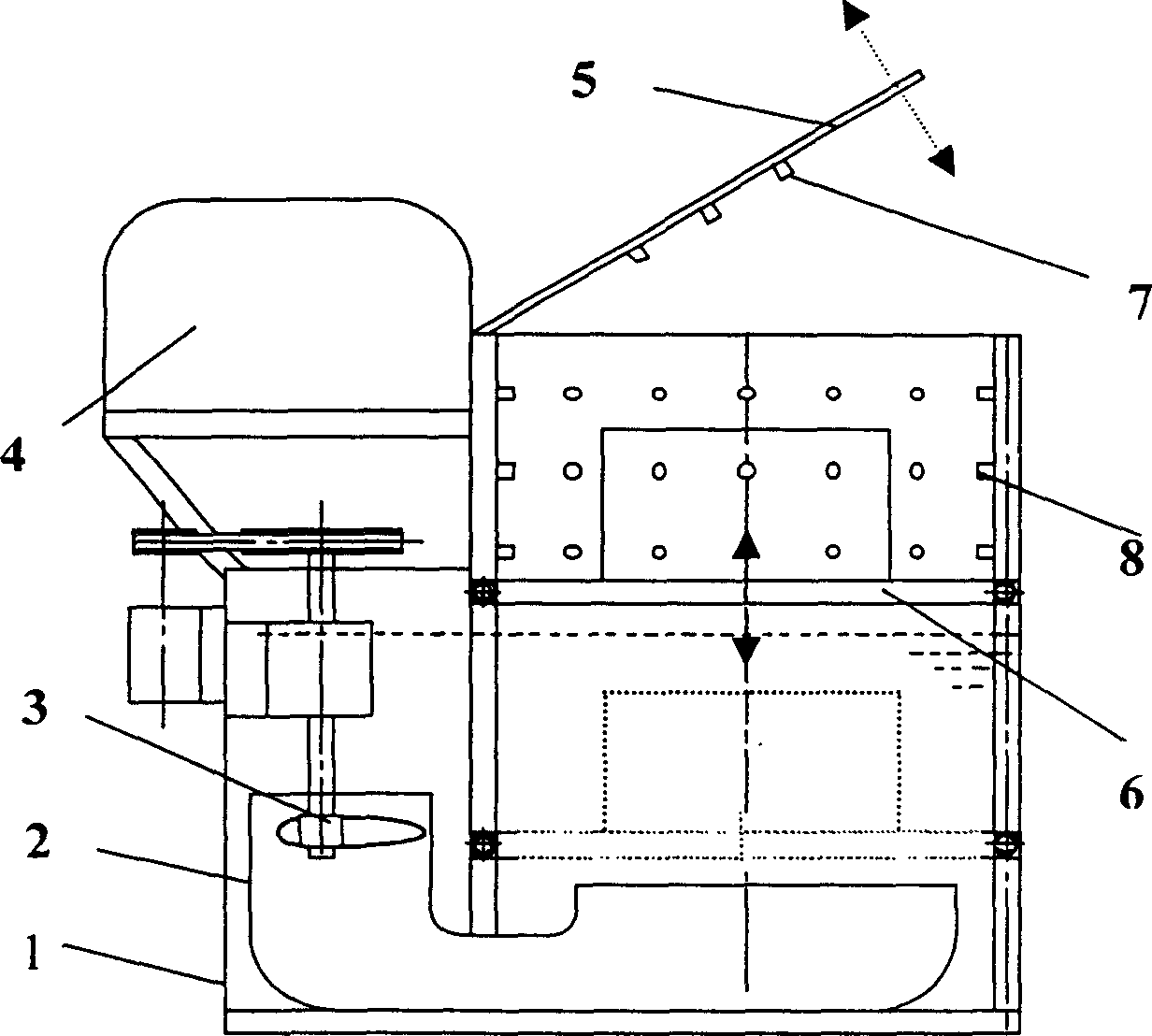

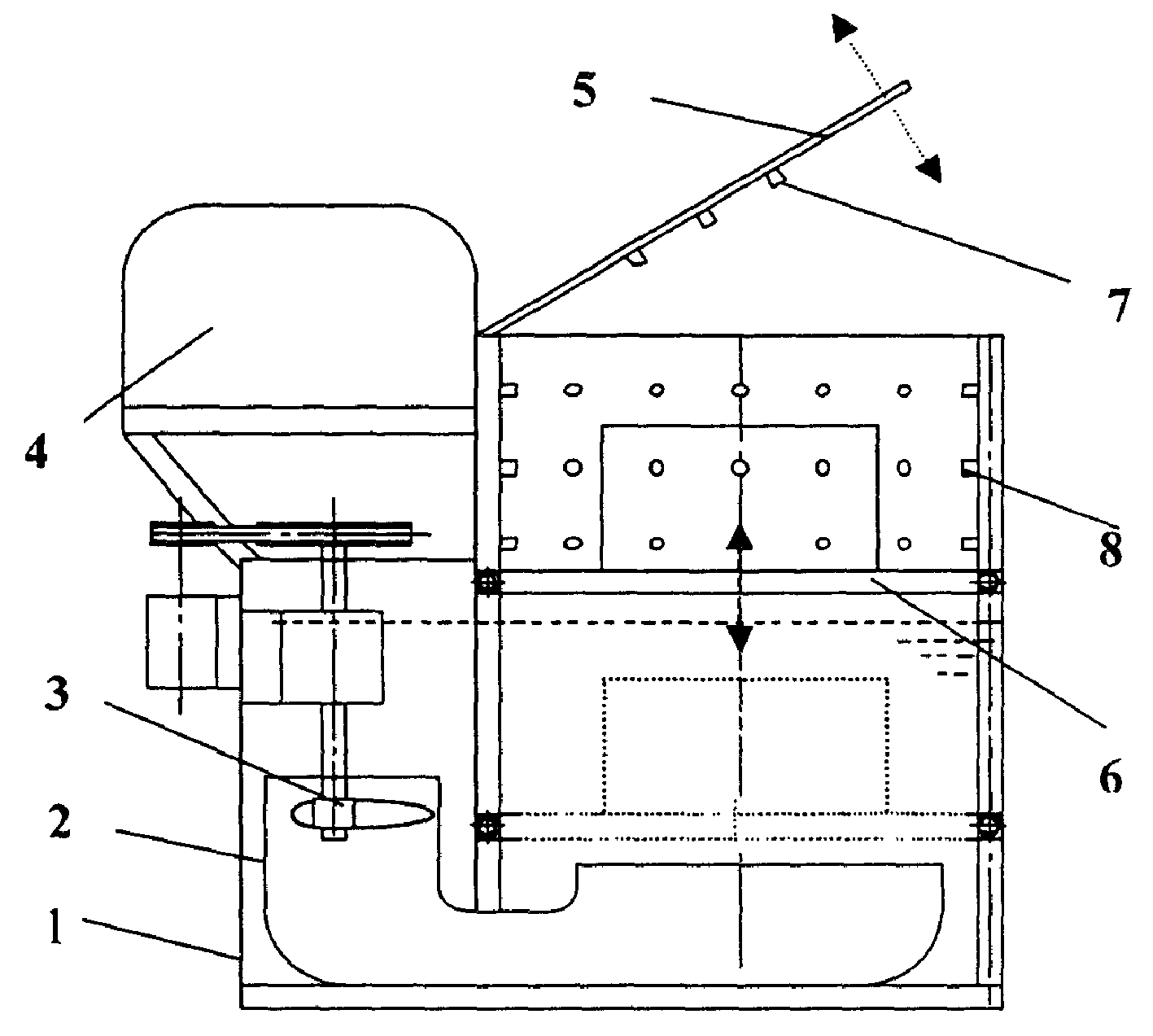

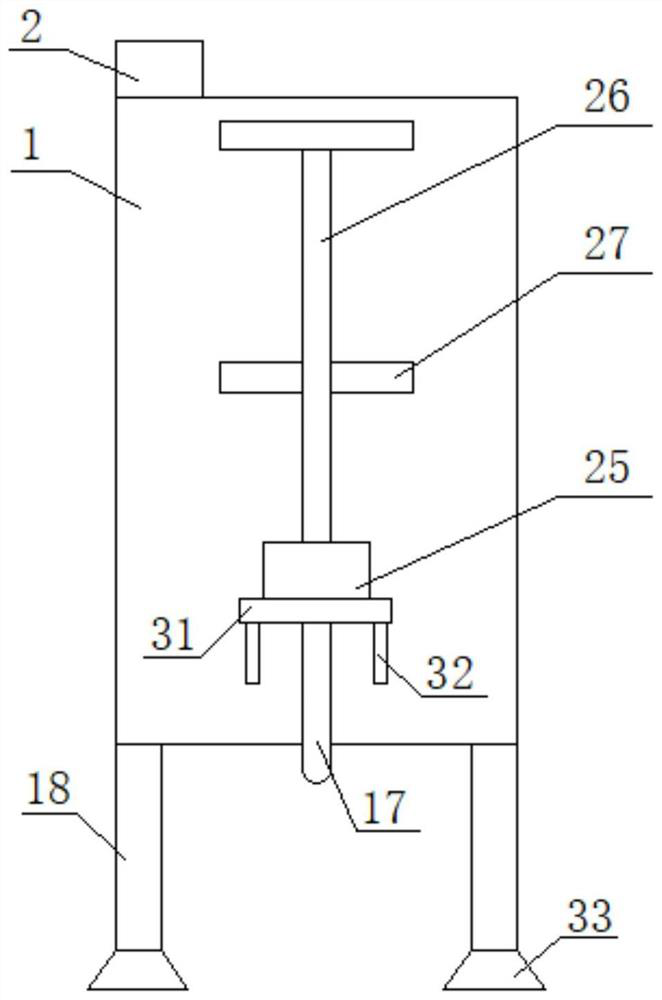

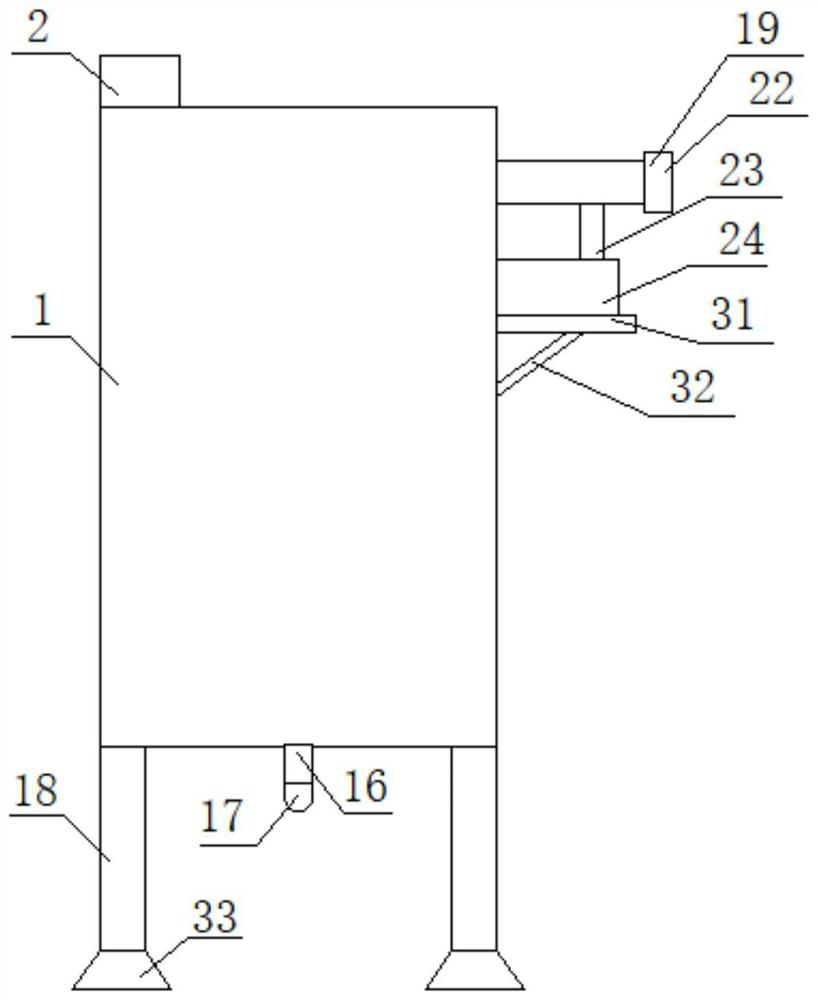

Periodical stepped quenching cooling equipment

InactiveCN1403601AReduce quenching costsSolve pollution and production safety issuesQuenching devicesPropellerQuenching

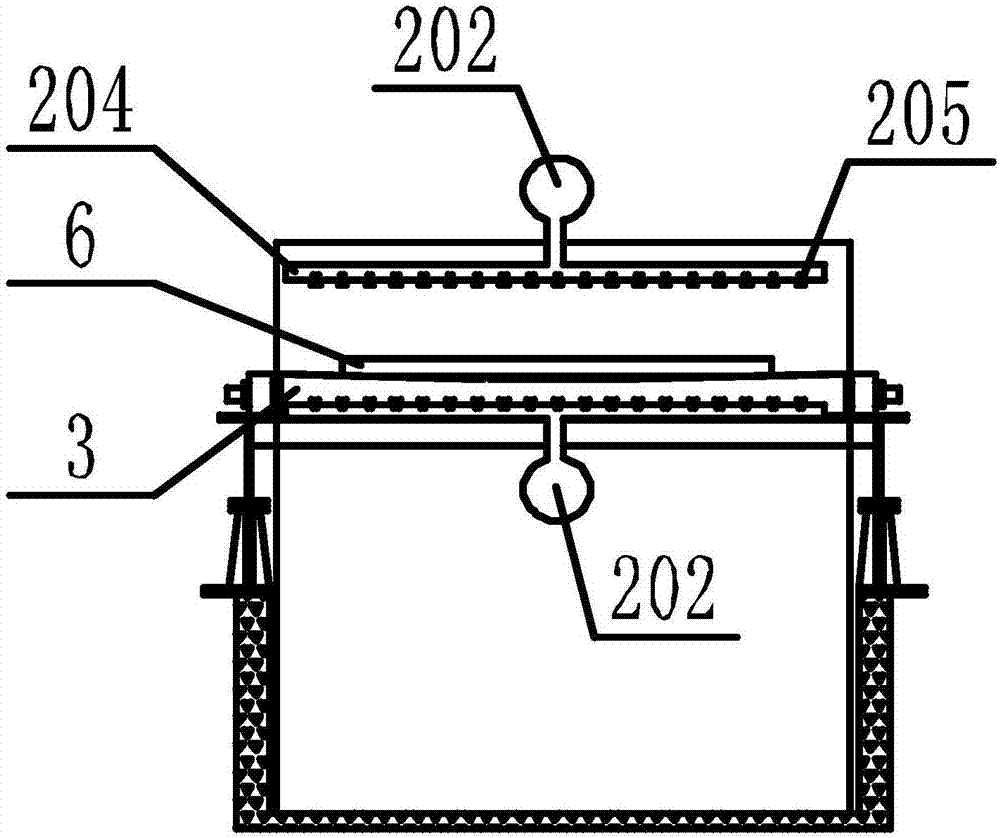

The present invention relates to heat treatment of metal material. The periodical stepped quenching cooling equipment of the present invention includes tank, U-shaped fluid guiding tube, propeller stirrer set beside the tank and with propeller extending below the liquid surface, elevating platform and this driving system, cover plate, one nozzle below the cover plate and one other nozzle over the liquid surface. The propeller is inserted into one opening of the fluid guiding tube and the other opening of the fluid guiding tube is set below the soaked quenched part. The present invention makes it possible to regulate the cooling strength of the quenching based on the requirement, has low quenching cost, no pollution of nitrate and oil to atmosphere and high production safety.

Owner:SHANGHAI JIAO TONG UNIV

Special quenching agent for large shaft and preparation method of quenching agent

The invention discloses a special quenching agent for a large shaft and a preparation method of the quenching agent, belonging to the field of quenching agents. The quenching agent is prepared from the following components: sodium chloride, sodium hydroxide, sodium citrate, cis-butenedioic acid, mesotrione, lotus root starch, acrylic acid, p-cresol, metribuzin and water. Through adding reasonable components and strictly controlling the component proportion, when used for quenching a shaft which is made of 45# steel and has the diameter of 1.8-3.5m, the quenching agent has the following advantages that the workpiece cooling speed is high within the temperature range of 650-450 DEG C, and the cooling speed is low at the temperature of below 400 DEG C, so that a favorable quenching effect can be obtained, and a quenching crack condition can also be avoided. The preparation method of the quenching agent has the advantages that all components in the quenching agent are completely dispersed and uniformly distributed by controlling temperatures and adding sequences of raw materials, the quenching agent is similar to a colloid in shape, and the cooling speed at the temperature of below 400 DEG C is lowered.

Owner:深圳市新元特钢有限公司

Water-based polymer quenching liquid for high-chromium cast iron

InactiveCN106916926AReduce cooling rateNo pollution in the processQuenching agentsWater basedQuenching

The invention discloses water-based polymer quenching liquid for high-chromium cast iron. The water-based polymer quenching liquid for the high-chromium cast iron is prepared from the following components in percentage by mass: 3 to 10 percent of polyoxyethylene-propylene polyether, 4 to 8 percent of polyvinyl alcohol resin, 0.4 to 1.2 percent of dipropylene glycol, 0.8 to 1.1 percent of zinc chloride, 0.3 to 0.6 percent of magnesium nitrate, 4 to 5 percent of polyoxy enamine, and the balance of water. A preparation method of the quenching liquid comprises the concrete steps of pouring the polyoxyethylene-propylene polyether, the polyvinyl alcohol resin and the water with the total weight being 30 to 35 percent into a heating container, controlling the temperature of the heating container to range from 60 to 80 DEG C, standing for 1 to 2 hours in a vacuum environment after uniformly stirring, then adding all residual components in the heating container, stirring for 50 to 60 minutes, controlling the temperature in the heating container to range from 50 to 55 DEG C during a stirring period, and obtaining the quenching liquid. The water-based polymer quenching liquid for the high-chromium cast iron provided by the invention is remarkably improved in quenching degree, comparable to nickel-molybdenum high-chromium cast iron, and better in hardness distribution uniformity.

Owner:TOYO GRINDING BALL MAANSHAN

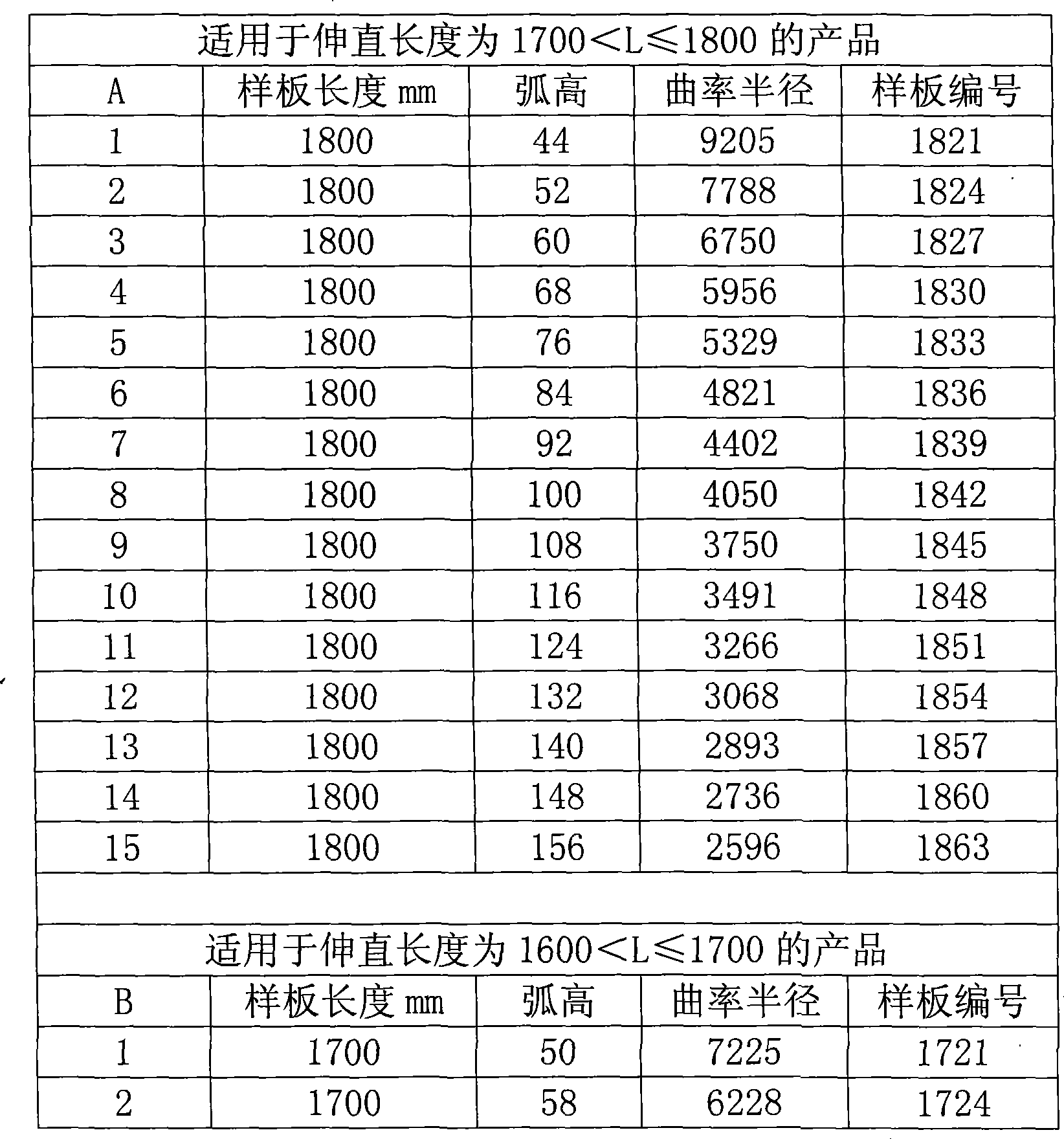

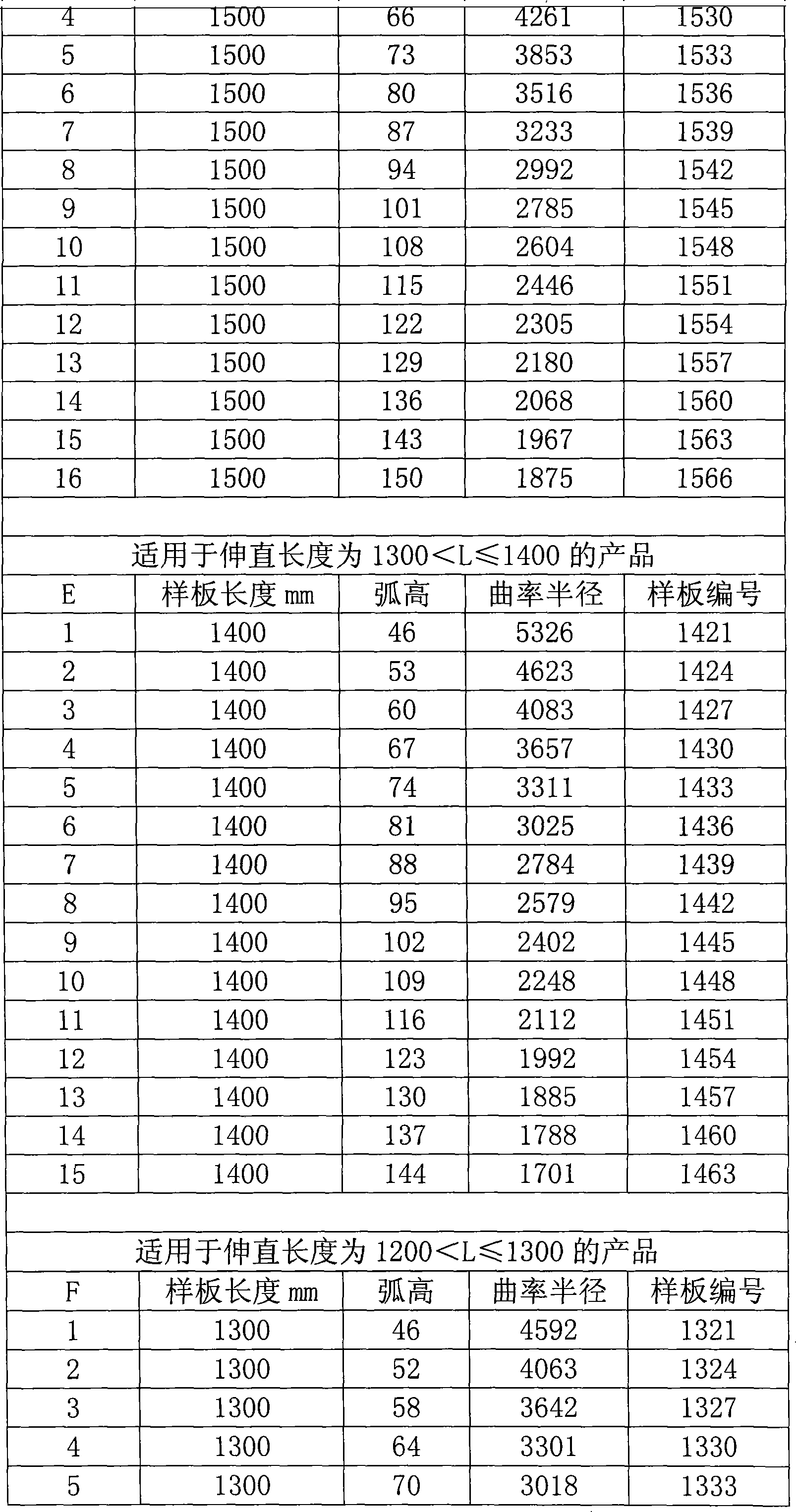

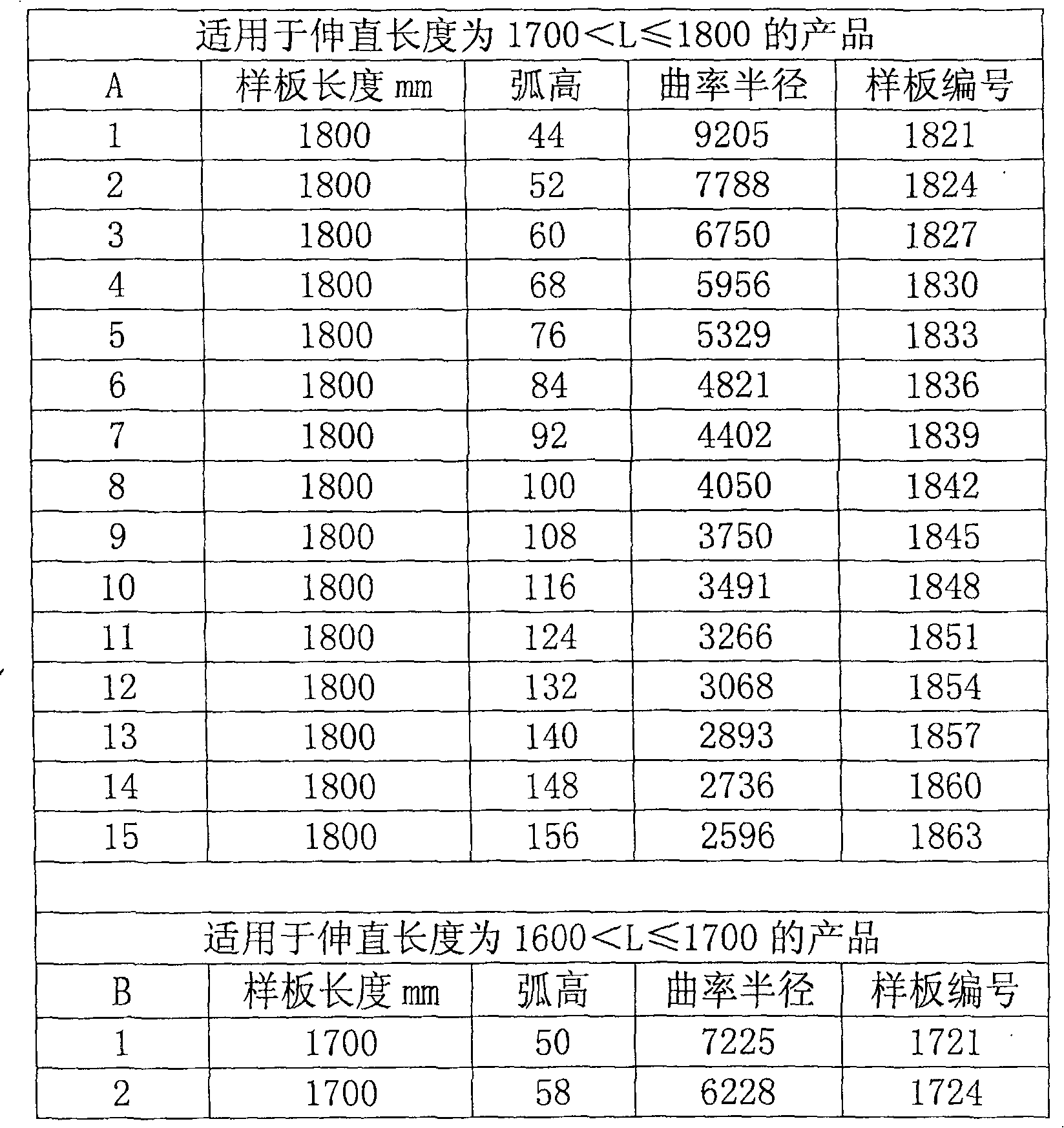

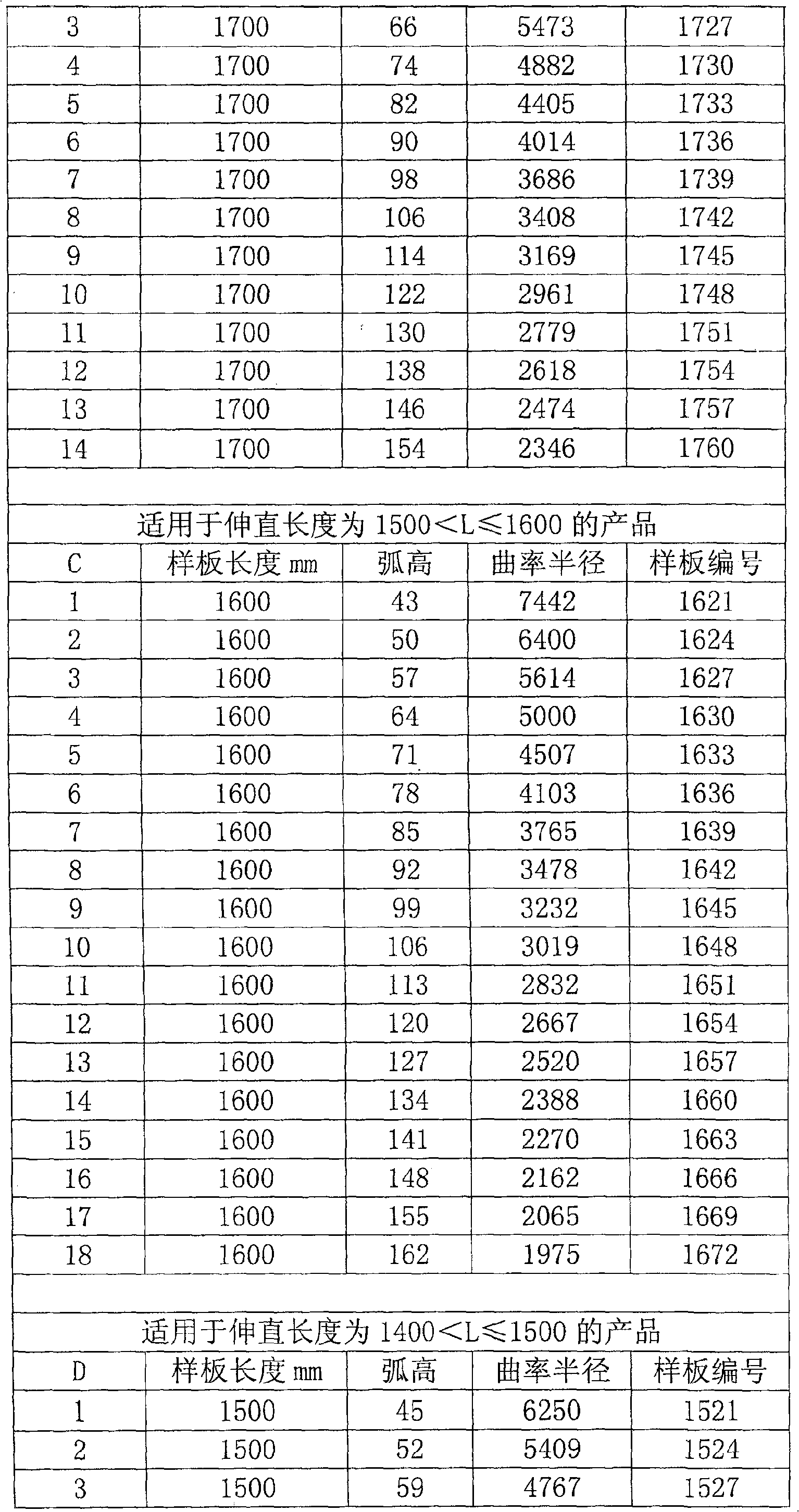

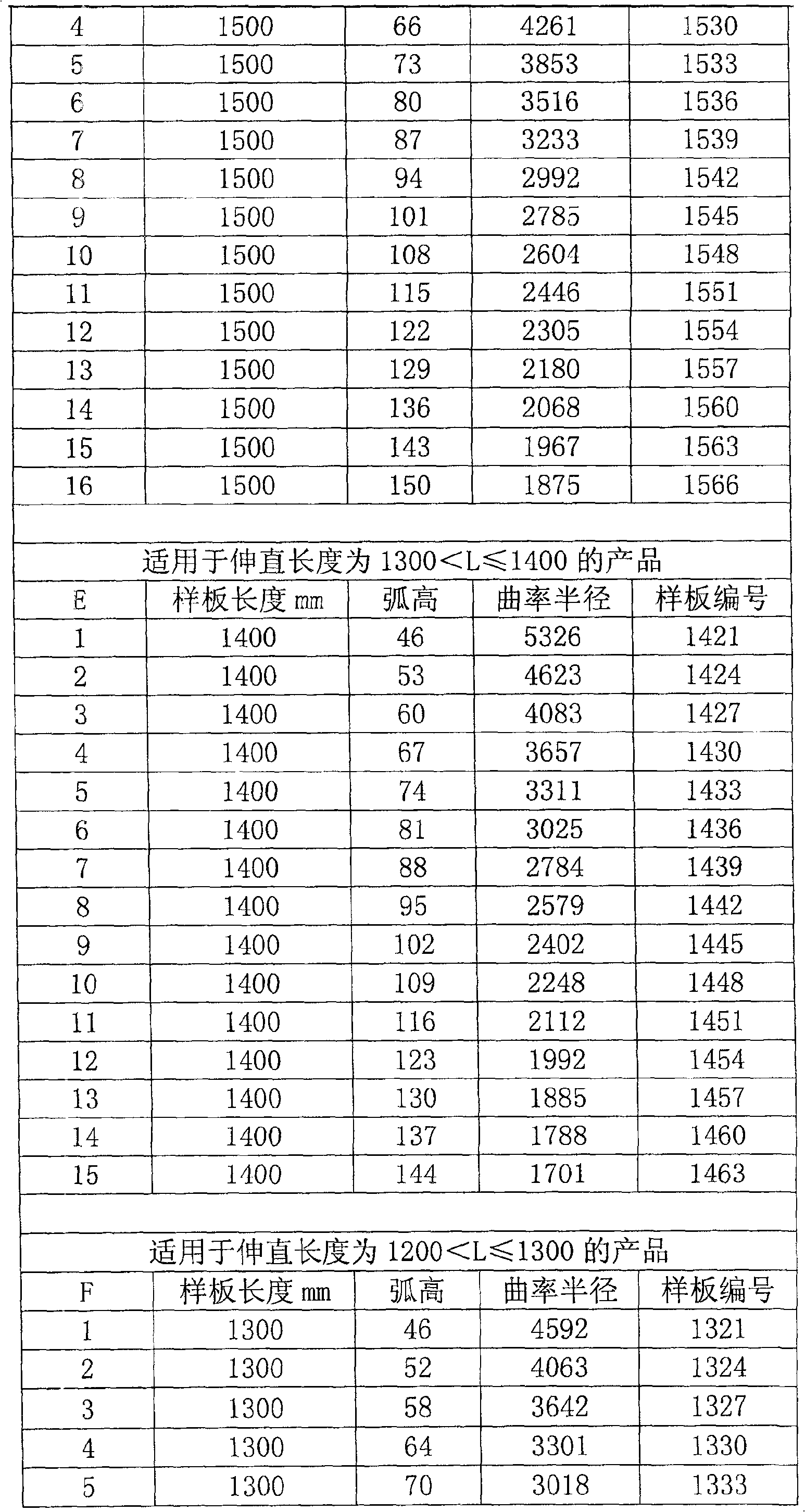

Method for quenching band spring by using standard jig

InactiveCN101245406AReduce in quantityEasy to manufactureFurnace typesHeat treatment furnacesEngineeringQuenching

The invention provides a method for using a standard sample plate to quench a leaf spring and aims at significantly reducing the quantity of the sample plates of the leaf spring and cost for quenching the leaf springs with constant sections and improving the production efficiency. The method of the invention is characterized in that the length and the height of arc of the leaf springs with constant sections are aggregated, calculated and analyzed and the leaf springs with constant sections are classified according a certain length and then a plurality of standard sample plates are made according to a certain curvature interval of each category; when in quenching, the leaf springs with constant sections and the curvature in the interval, the standard sample plate with the most similar radius of the curvature is served as a quenching sample plate to quenching the leaf spring. As a result, the standard sample plates accounting for 1 / 40 to 1 / 20 of the current more than 8000 kinds of leaf springs with constant sections can successfully realize the quenching so as to simplify the making, management and maintenance of the sample plates and shorten the production period at the same time.

Owner:东风汽车底盘系统有限公司

Preparation method for automobile plate spring

ActiveCN111809034AReduce usageReduce lossSolid state diffusion coatingFurnace typesTemperingIndustrial engineering

The invention discloses a preparation method for an automobile plate spring. The preparation method is characterized in that the automobile plate spring is manufactured by adopting a spring steel blank containing molybdenum, vanadium and trace chromium and nickel elements, and the preparation method comprises the following steps that spring steel is forged to obtain a blank, the blank is hot-rolled into an automobile plate spring steel plate with variable cross-section characteristics, eye coiling is carried out, constant-temperature treatment is carried out, water-cooling quenching is carriedout, air cooling is carried out, surface accurate grinding is carried out, shot blasting treatment is carried out, gas co-permeation is carried out, overlay coating is carried out, and a finished product is obtained after drying. According to the preparation method, after a hot rolling process, waste heat is repeatedly utilized by means of a constant temperature device to complete forming and heat treatment of the plate spring, the heating time is shortened, the energy loss is greatly reduced, in the heat treatment process, water is adopted as a cooling medium, the problem of environmental pollution is reduced, tempering and surface gas co-permeation treatment are simultaneously carried out, the cost is greatly reduced, the surface quality of the plate spring is improved, and the corrosion resistance and the fatigue performance are improved.

Owner:四川丰元机械制造有限公司 +1

Carrier roller processing technique conducive to reducing heat treatment defects

InactiveCN104152640ASimple process routeReduce quenching costsFurnace typesHeat treatment furnacesQuenchingTreatment quality

The invention discloses a carrier roller processing technique conducive to reducing heat treatment defects. The carrier roller processing technique comprises a quenching step and a tempering step, wherein the quenching step comprises the procedures of preheating, heat preservation and shock cooling; in the preheating procedure, a carrier roller is heated to 630-650 DEG C, and heat preservation lasts for no fewer than 5 h; in the heat preservation procedure, the hot carrier roller obtained in the preheating procedure is transferred into a heating furnace at the temperature above 870 DEG C to be heated to 840-870 DEG C, and heat preservation lasts for no fewer than 2 h; the shock cooling is water-cooling and air-cooling alternated circulating cooling, and tempering is performed once after each circulating cooling procedure. According to the technique, water cooling and air cooling are performed alternately to replace conventional oil-quenching shock cooling under the condition of achieving heat treatment quality objectives; such a change in the technique not only reduces the quenching cost, but also reduces the dependence on oil quenching agents. Besides, the implementation of the technique is favorable for environment protection and the route of the technique is favorable for uniformity of heat treatment hardness on the surface and the depth of the carrier roller.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Method for preparing environment-friendly water-soluble hardening agent

ActiveCN103981343AReduce internal stressImprove cooling effectFurnace typesProcess efficiency improvementWater solubleHardening effect

The invention discloses a method for preparing an environment-friendly water-soluble hardening agent and belongs to the field of preparation of hardening agents. The invention belongs to divisional application, and the original Chinese patent application number of is 201310350402.X. According to the preparation method, all components of the hardening agent are guaranteed to be completely dispersed and uniformly distributed by virtue of controlling the feeding sequence of the raw materials and temperature and stirring time, so that the hardening agent meets the hardening requirement, can be used for strictly controlling the cooling speed of large shafts to prevent hardening crack, greatly lowering the initial cooling speed and the cooling speed at a temperature of below 400DEG C and lowering the internal stress of workpieces, has fast enough cooling speed for 650-450DEG C, and guarantees the hardening effect while guaranteeing the product not to be cracked by hardening; after being hardened, large workpieces are not cracked by hardening.

Owner:马鞍山金泉工业介质科技有限公司

Carrier roller heat treatment technology

InactiveCN104152641ALow degree of surface oxidation decarburizationUniform cooling rateFurnace typesHeat treatment furnacesSkin coolingHeat carrier

The invention discloses a carrier roller heat treatment technology. The carrier roller heat treatment technology comprises a quenching treatment step and a tempering step. According to the quenching treatment step, preheating, heat preservation and shock cooling working procedures are sequentially carried out on a forming carrier roller with billet materials of 40 Cr, and the water cooling and air cooling interphase circulating cooling mode is adopted by shock cooling; according to the preheating step, the carrier roller is heated to 630 DEG C to 650 DEG C, and heat preservation is carried out on the carrier roller for five or more hours; according to the heat preservation step, the heat carrier roller obtained in the preheating step is moved into a heating furnace with the temperature higher than 870 DEG C to be heated to 840 DEG C to 870 DEG C, and heat preservation is carried out on the heat carrier roller for two or more hours. The process route is simple, the shock cooling mode that water cooling and air cooling are alternatively carried out is adopted, and under the condition that the heat treatment quality target is achieved, an existing adopted oil quenching shock cooling mode is replaced. Due to changes of the process, the quenching cost is saved, meanwhile, the dependency on oil quenching agents is reduced, and due to implementation of the process, environmental protection is benefited.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

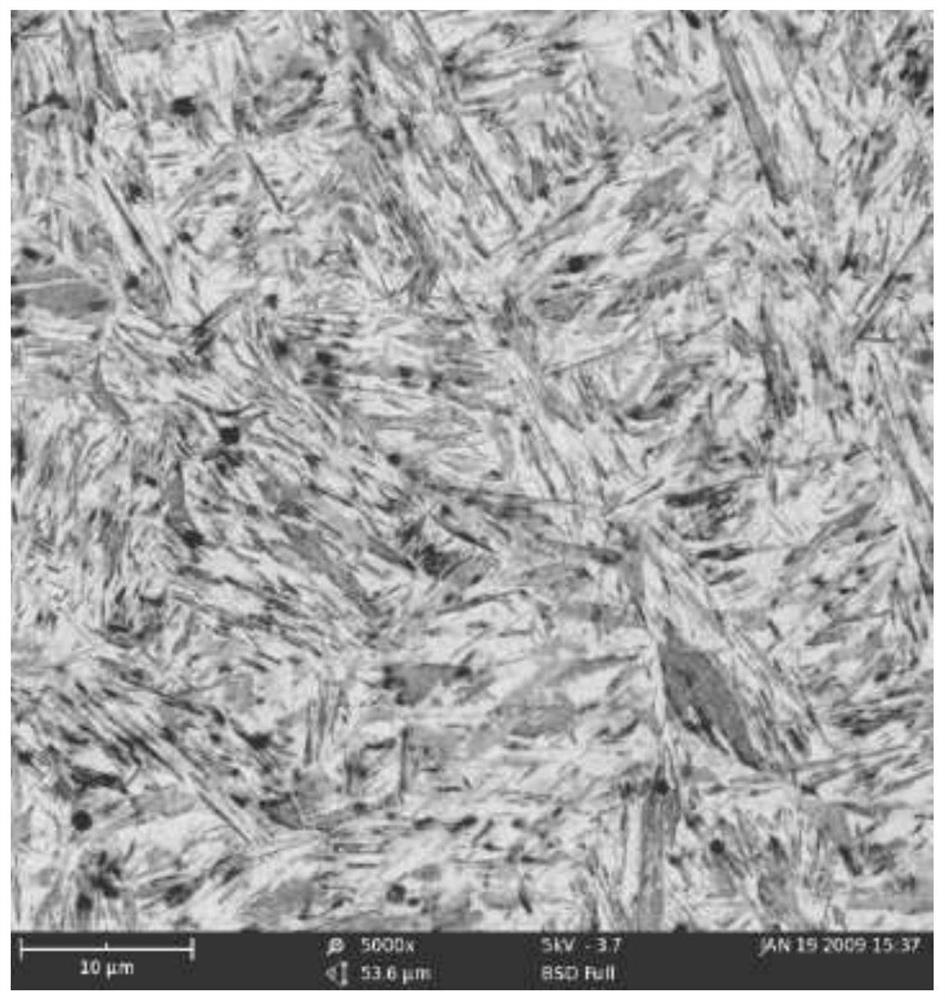

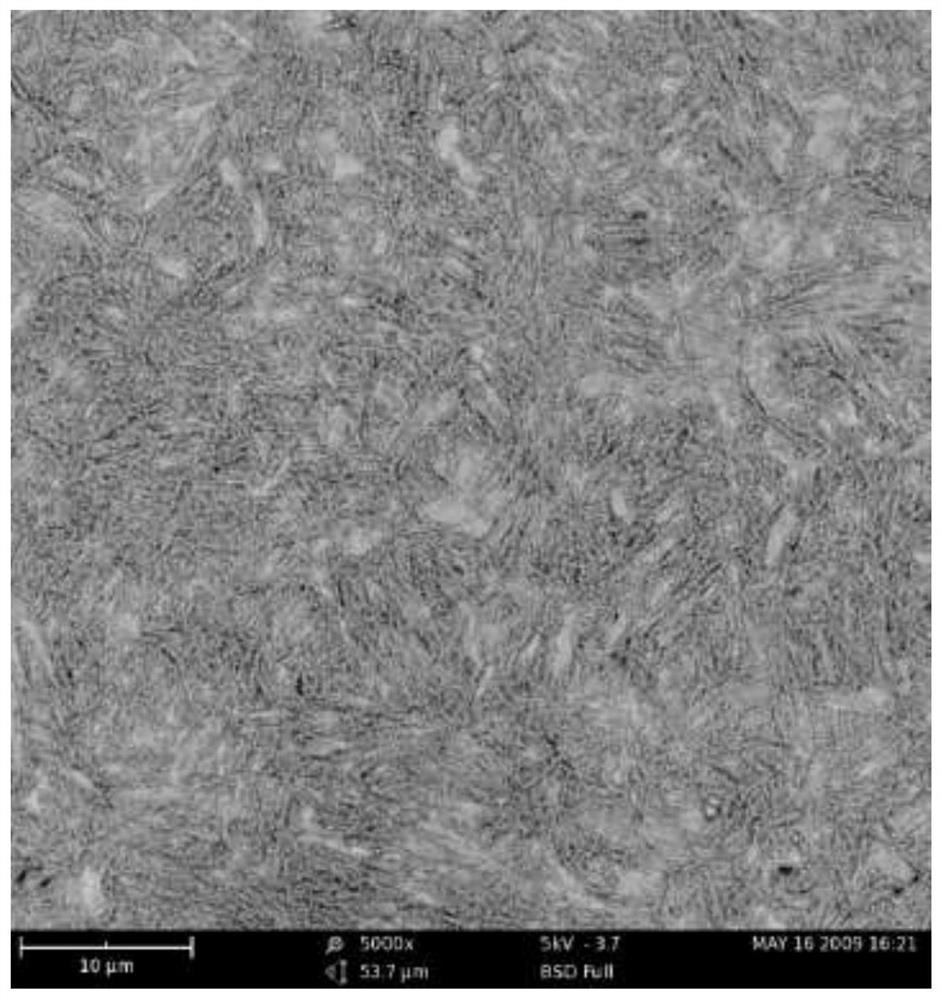

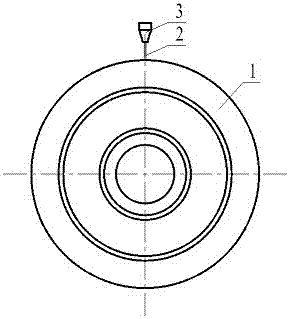

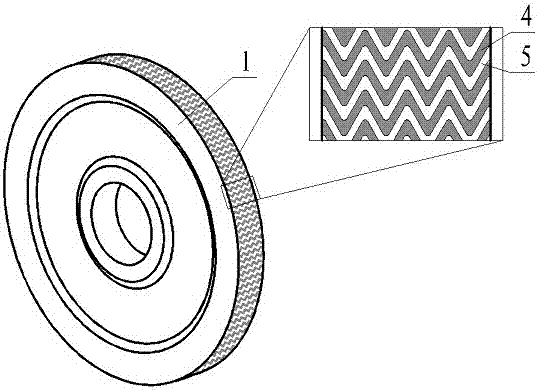

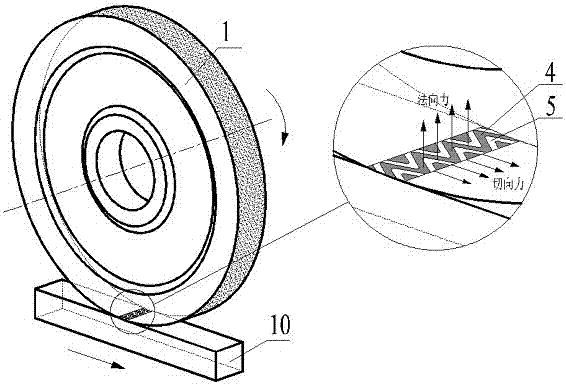

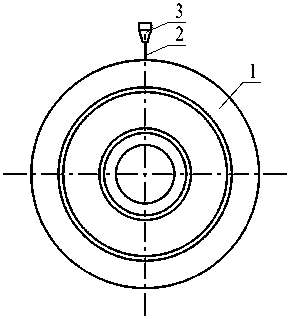

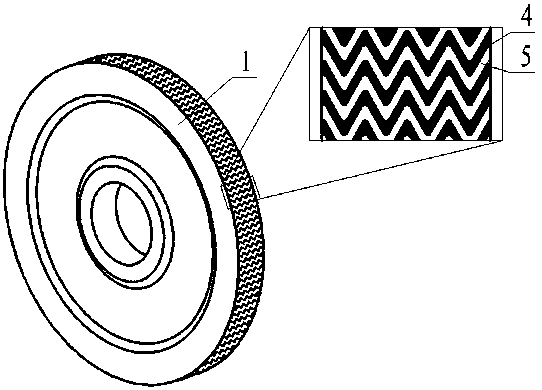

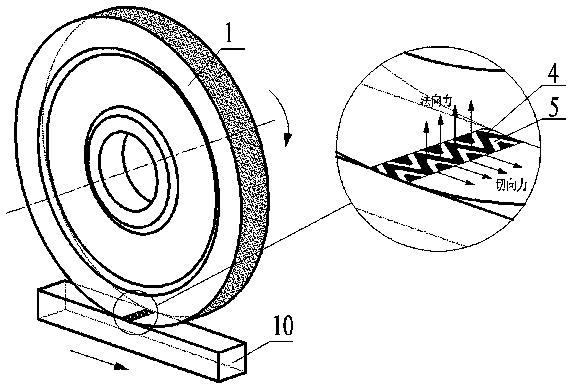

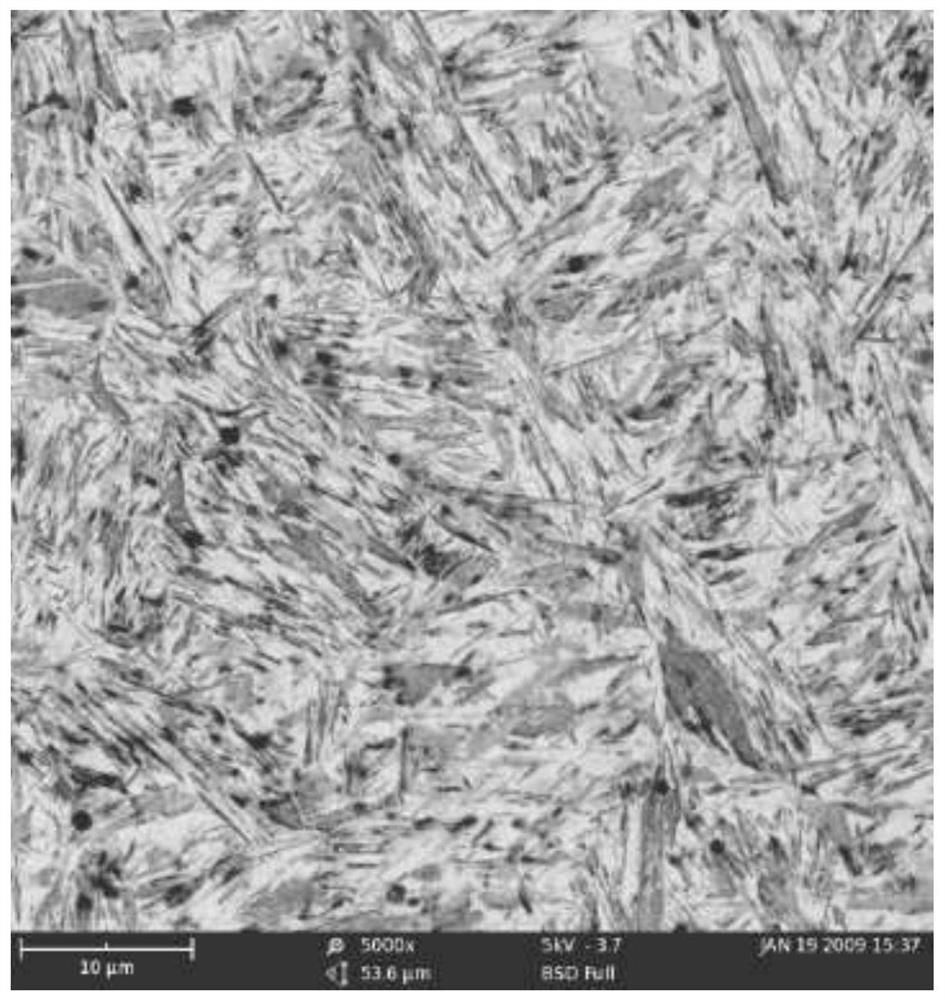

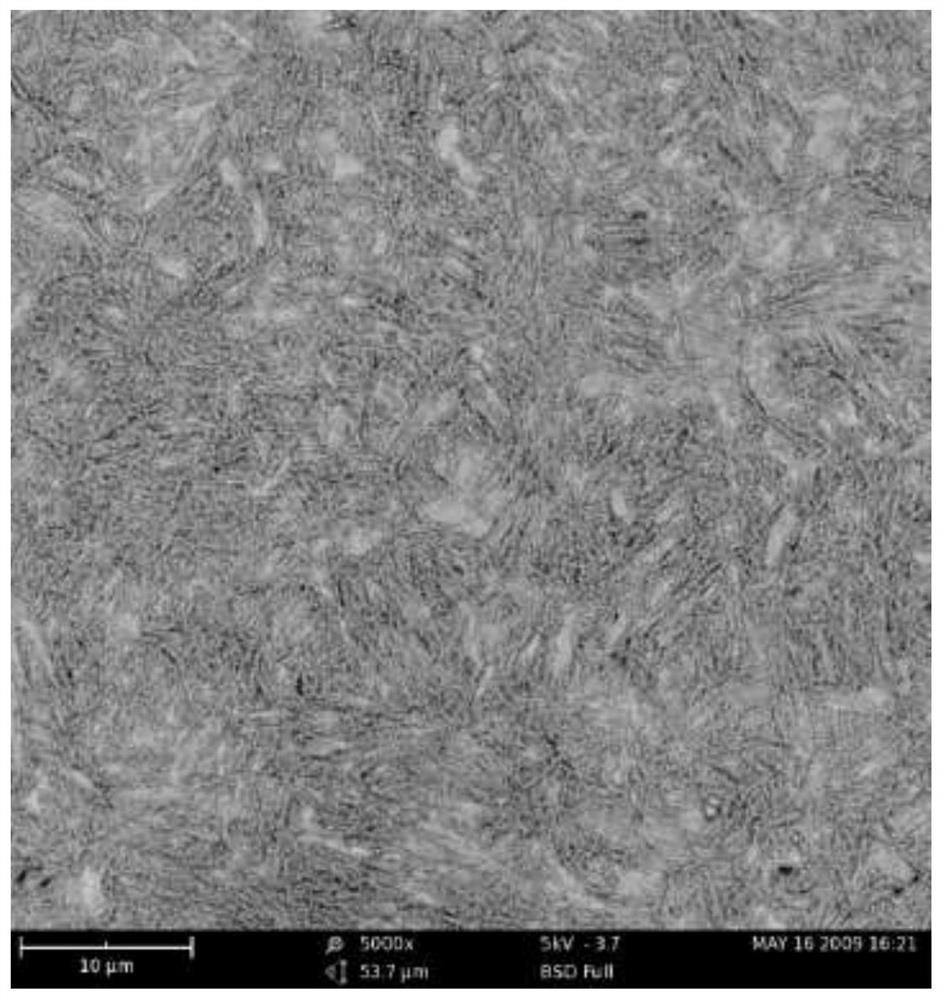

Preparation method of grinding wheel with discretely reinforced hub electroplated with super hard abrasive

ActiveCN107971939AHigh hardnessReduce the impactGrinding devicesUltimate tensile strengthGrinding wheel

The invention discloses a preparation method of an grinding wheel with a discretely reinforced hub electroplated with super hard abrasive. The preparation method comprises the steps that a nozzle of aquenching gun is moved in a wavy shape in the axial direction of a grinding wheel hub, and the temperature of materials, irradiated by plasma arc, of the external circumference surface of the grinding wheel hub is increased quickly, and decreased to form a wavy quenched zone; the quenching gun is returned to the original position, and the grinding wheel hub is rotated for an arc length around itsown axis for machining a second wavy quenched zone; the materials which are not irradiated by the plasma arc between the two quenched zones still maintain the original matrix structures; so repeatedly, till the whole external circumference surface of the grinding wheel hub forms the structure that the quenched zones and the matrix structures are arranged alternately in a wavy shape; and the grinding wheel hub discretely reinforced is electroplated with super hard abrasive to form the grinding wheel with the discretely reinforced hub electroplated with the super hard abrasive. The preparationmethod disclosed by the invention facilitates improvement of the bonding strength of the grinding wheel hub and a nickel coating, and the convergence of interface cracks is reduced; and the bearing capacity of the nickel coating is improved, and the service life of the electroplated grinding wheel is prolonged.

Owner:湖南远东机械制造股份有限公司

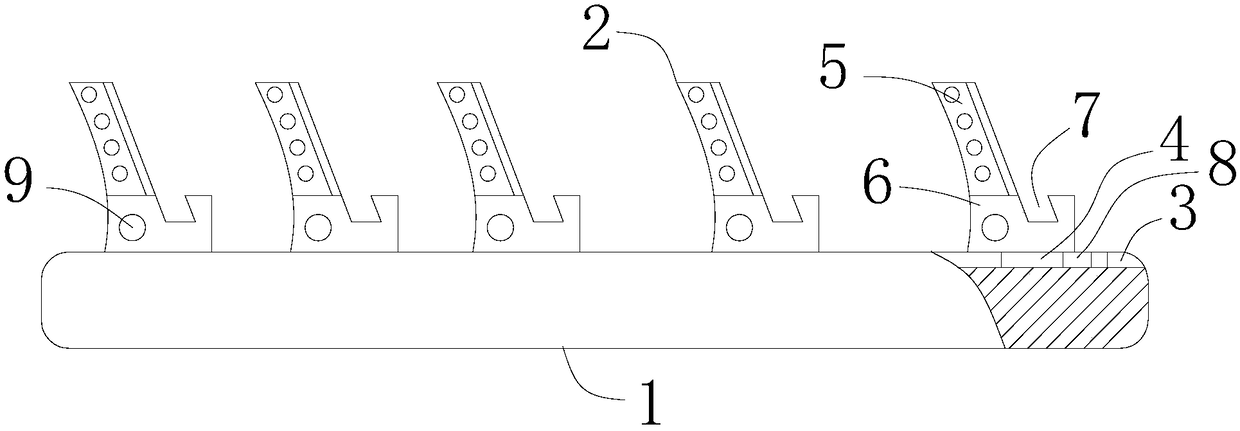

Bracket for gear quenching

InactiveCN108486352AEvenly heatedAvoid damageFurnace typesHeat treatment furnacesGear wheelEngineering

The invention relates to a gear machining auxiliary tool, in particular to a bracket for gear quenching. The bracket for gear quenching aims at solving the technical problem that the gear production cost is high since a gear is prone to damage during quenching treatment in the prior art. The bracket for the gear quenching is characterized in that locating blocks are uniformly arranged on a base; the locating blocks are connected with the base in a sliding manner; in addition; and the locating blocks comprise abutting and connecting parts and locating parts. An included angle between each gearand a horizontal plane is 30-60 degrees due to the abutting and connecting parts, so that the gears are obliquely located on the base, a space occupied by each gear on the base is reduced, more gearscan be placed on the base, and the quenching cost of the gears is lowered. The gears are located through the locating blocks, and the contact area between each gear and the base is reduced, so that the gears are heated uniformly, the gears are not prone to cracking after being quenched, and the machining cost of the gears is lowered.

Owner:平湖市永成齿轮配件厂

Automobile gear assembly uniform quenching device

ActiveCN109402349AEasy to useQuenching treatment to achieveFurnace typesProcess efficiency improvementActivated carbonFixed frame

The invention discloses an automobile gear assembly uniform quenching device which comprises a quenching box. One side of the top surface of the quenching box is provided with a feeding port, and thebottom of a feed channel is provided with a groove. A first fixed frame and a second fixed frame are respectively fixed at the bottom of the feed channel and on the inner wall of the quenching box. Asecond connecting rod is internally provided with a cavity, a spring is fixed inside the cavity, and the surface of a guide plate is provided with through holes. The lower end of the guide plate is located on the outer wall of the quenching box and provided with a discharging port. An outlet pipe is installed in the middle at the bottom of the quenching box. One side of a filter net located in anexhaust pipe is in insertion connection with an activated carbon adsorption cylinder, a water pump is installed on the outer wall of the back surface of the quenching box, and a rotary nozzle is installed at the bottom of a branch water pipe. The device facilitates recycling of a coolant to save resources, and the quenching of a gear assembly is more uniform and convenient. At the same time, gas generated by quenching is treated and discharged to protect the environment.

Owner:徐州优力同创科技股份有限公司

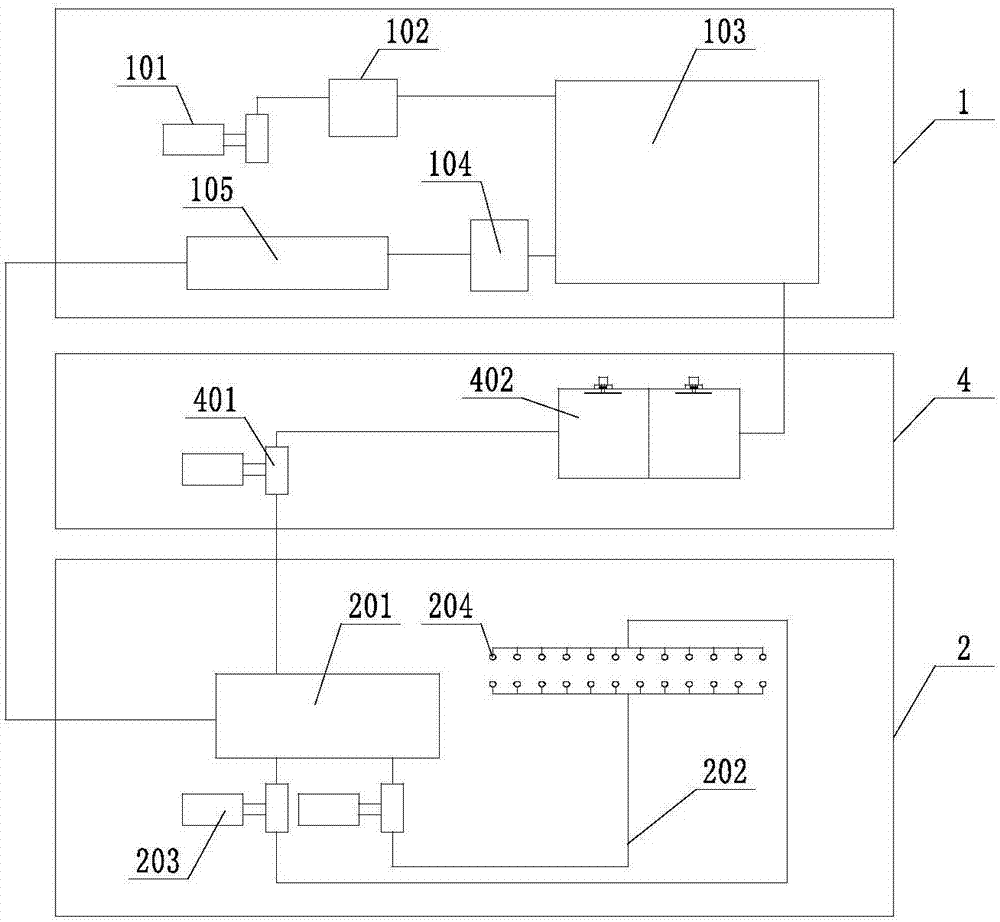

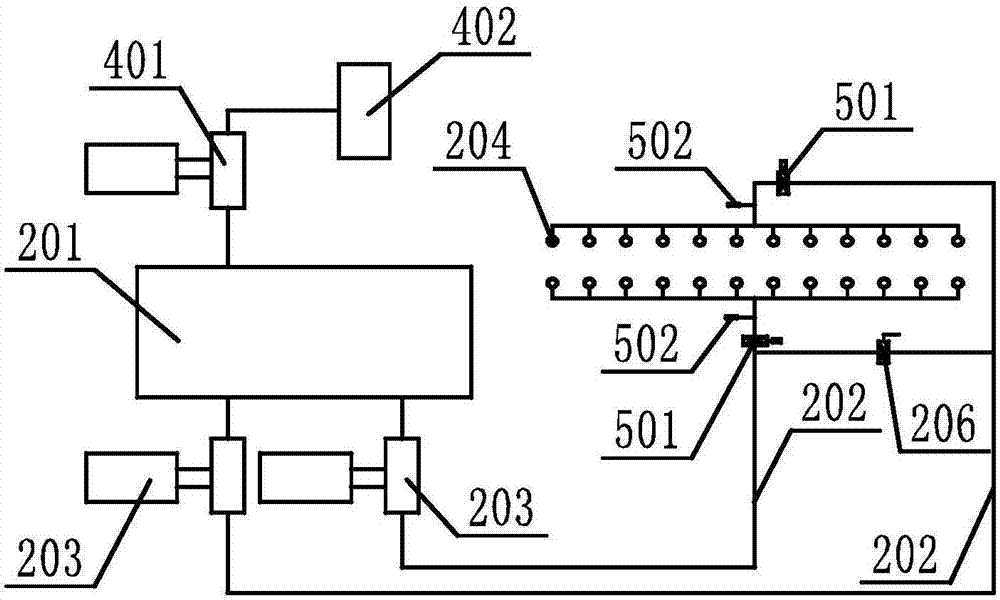

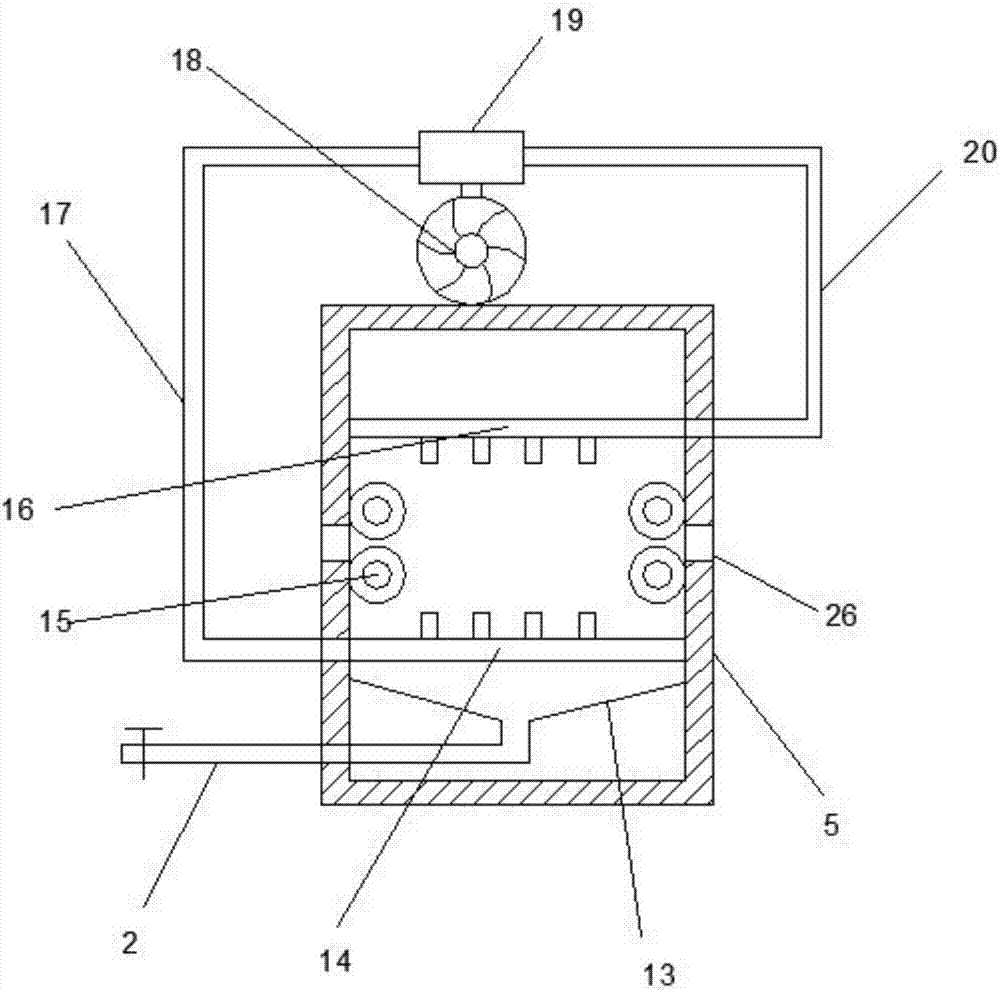

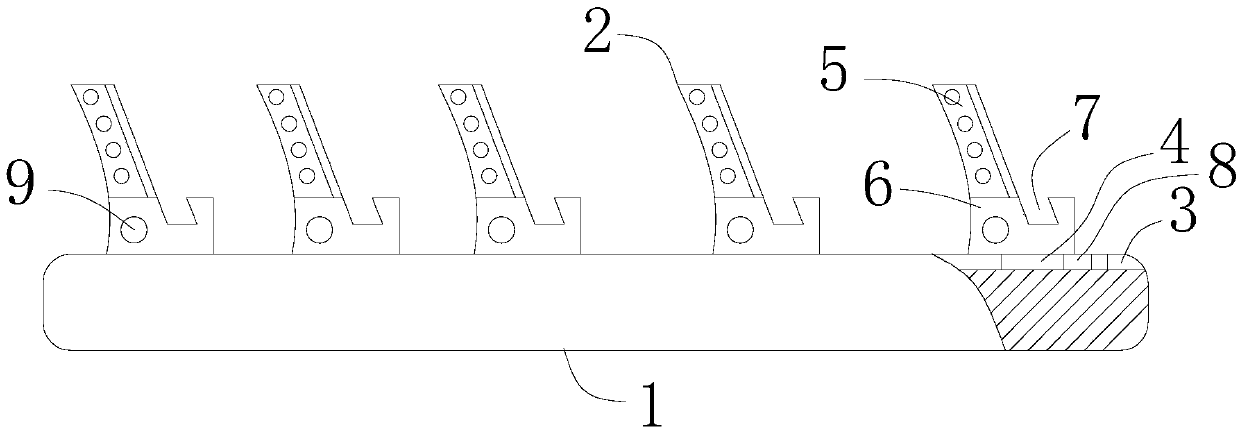

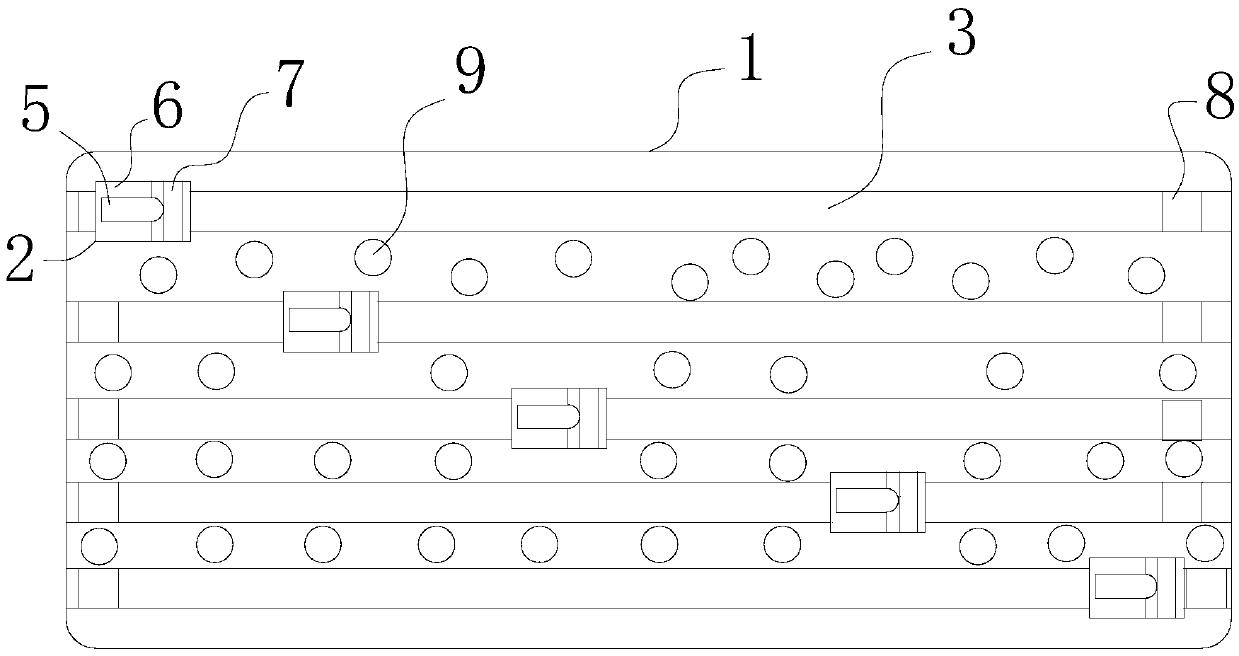

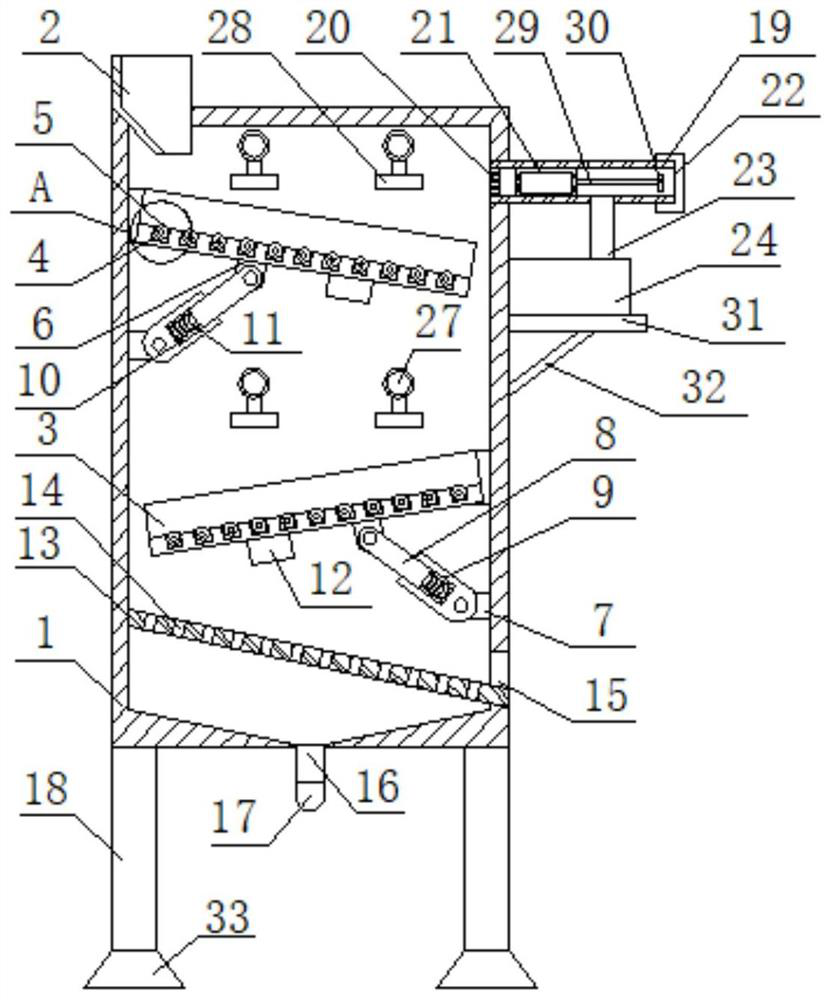

Online aluminum alloy plate quenching process and equipment

The invention belongs to the technical field of metal machining, and in particular, relates to an online aluminum alloy plate quenching process. The process comprises the steps of: (A) rolling; (B) spraying preparation: a rolled aluminum alloy plate is fed in an inlet of a spraying area through a conveying device at a speed of 160-200 m / min; and meanwhile, the conveying device in the spraying area is started to control the speed within 9-11 m / s; (C) rapid spraying: the upper and lower surfaces of the aluminum alloy plate are sprayed at the same time; the spraying water pressure of the upper surface is controlled as 3.8 kg; and the spraying water pressure of the lower surface is controlled as 3 / 5 kg; and (D) postcooling: the aluminum alloy plate is reversely fed in the spraying area; and meanwhile, the spraying water pressure of the upper and lower surfaces is reduced to perform postcooling on raw materials. The process needs no secondary heating; a rolling process is directly adjusted online; the afterheat of the plate is maintained to quickly feed in quenching equipment to finish the quenching process; the energy consumption waste caused by secondary heating is prevented; the quenching cost is greatly reduced; and the quenching solid solution performance of the product is guaranteed.

Owner:江苏国铝高科铝业有限公司

Heat treatment method of non-ferrous metal hot roll

ActiveCN107447096ASimple heat treatment methodHigh strengthFurnace typesHeat treatment furnacesEconomic benefitsHigh intensity

The invention discloses a heat treatment method of a non-ferrous metal hot roll, and relates to the technical field of metal processing. The method comprises the following steps: 1) preheating: the roll is placed in a high-temperature furnace for preheating treatment after being demolded and cleaned; 2) secondary normalization; 3) quenching: double-frequency induction quenching is performed on the working surface of the roll, and the cooling mode is a combination of oil cooling and air cooling; 4) tempering; 5) annealing. The heat treatment method of the non-ferrous metal hot roll is simple and feasible; the treated non-ferrous metal hot roll is high in strength and good in thermal cracking resistance and electrochemical corrosion resistance, and has excellent accident resistance, fatigue resistance and abrasion resistance, thereby meeting operating requirements of practical production and application; the service life of the non-ferrous metal hot roll is effectively prolonged, and production efficiency and economic benefits are increased.

Owner:安徽昕悦铸造科技有限公司

Quenching treatment device for machining of aluminum strips

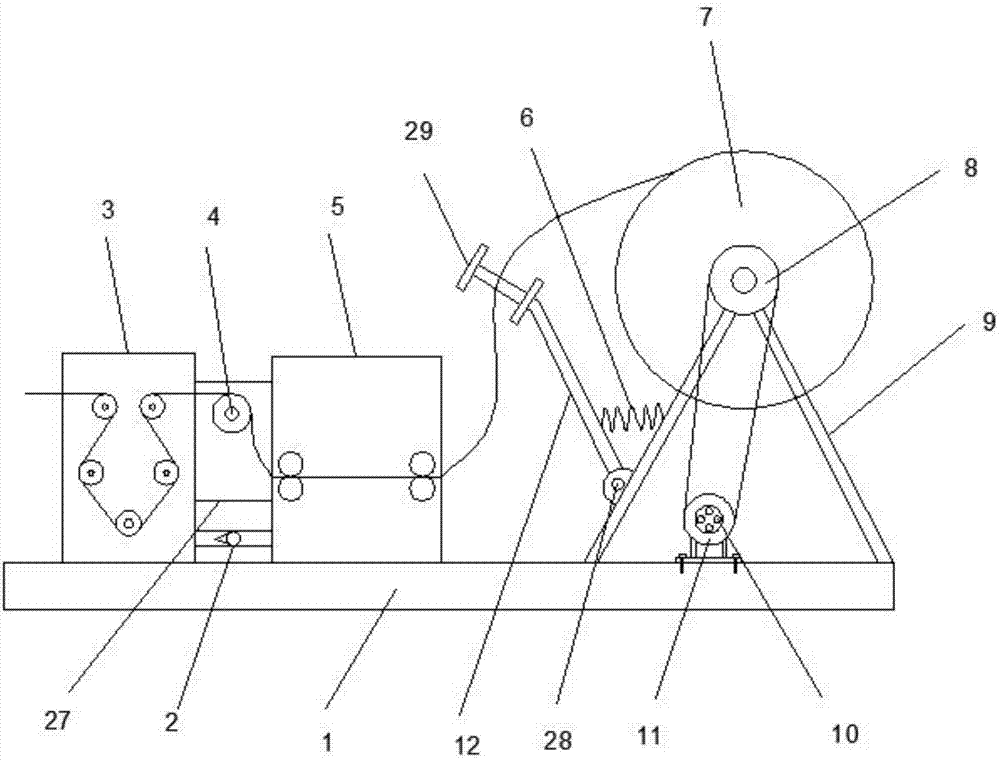

InactiveCN107058696AReasonable structureImprove winding qualityFurnace typesProcess efficiency improvementDrive motorPulp and paper industry

The invention discloses a quenching treatment device for machining of aluminum strips. The quenching treatment device comprises a base. The upper side of the left end of the base is connected with a quenching box. A liquid injection port is connected to the interior of the top end of the quenching box. The upper end of the liquid injection port is connected with a liquid guide pump. The lower end of the liquid guide pump is connected with a refrigerating device. The middle of the upper end of the base is connected with a drying box. An induced draft fan is fixed to the top end of the drying box. The upper end of the induced draft fan is connected with a flow divider valve. The right end of the flow divider valve is connected with a wind feed pipe. The lower end of the wind feed pipe is connected with a wind feed plate. The left end of the flow divider valve is connected with a wind discharge pipe. The lower end of the wind discharge pipe is connected with a wind discharge plate. The right side of the upper end of the base is connected with a supporting frame. The upper end of the supporting frame is provided with a winding wheel. The middle of the winding wheel is coaxially connected with a driven belt pulley. The lower end of the driven belt pulley is connected with a driving belt pulley through a belt. The middle of the driving belt pulley is connected with a driving motor. By adopting the quenching treatment device for machining of the aluminum strips, drying treatment of quenched aluminum strips is realized; and meanwhile, cyclic utilization of quenching liquid is realized, and waste of quenching liquid is avoided.

Owner:张子和

Quenching process and device for low-impurity ultra-low-carbon stainless steel

PendingCN111961816AReduce contact timeGuaranteed quenching effectQuenching agentsQuenching devicesEngineeringSS - Stainless steel

The invention discloses a quenching process and device for low-impurity ultra-low-carbon stainless steel. The method includes the steps that: firstly, a blank is put into a heating furnace and heatedto 1060-1200 DEG C; secondly, a sliding seat at the bottom of the heating furnace is pulled out, when the sliding seat is pulled out, the two sides of the bottom of the blank slide to the two sides ofa hanging basket, and thus the hanging basket can lift the blank; thirdly, the hanging basket is lifted through a crane, and in the process of lifting the hanging basket, the blank can be lifted by the hanging basket and thus be separated from the sliding seat of the heating furnace; fourthly, the blank is moved to the position above a quenching bath through the hanging basket, and then lowered,so that the high-temperature blank is put into quenching oil in the quenching bath, and the blank is completely submerged in the quenching oil for quenching; fifthly, the initial temperature of the quenching oil is 80-130 DEG C; and sixthly, quenching is conducted for 1 to 3 minutes and then completed. Through the quenching process and device, the product performance is improved, and potential safety hazards are reduced.

Owner:江阴市天虹金属铸造有限公司

Method for quenching band spring by using standard jig

InactiveCN100591779CReduce in quantityEasy to manufactureFurnace typesHeat treatment furnacesEngineeringQuenching

The invention provides a method for using a standard sample plate to quench a leaf spring and aims at significantly reducing the quantity of the sample plates of the leaf spring and cost for quenchingthe leaf springs with constant sections and improving the production efficiency. The method of the invention is characterized in that the length and the height of arc of the leaf springs with constant sections are aggregated, calculated and analyzed and the leaf springs with constant sections are classified according a certain length and then a plurality of standard sample plates are made according to a certain curvature interval of each category; when in quenching, the leaf springs with constant sections and the curvature in the interval, the standard sample plate with the most similar radius of the curvature is served as a quenching sample plate to quenching the leaf spring. As a result, the standard sample plates accounting for 1 / 40 to 1 / 20 of the current more than 8000 kinds of leaf springs with constant sections can successfully realize the quenching so as to simplify the making, management and maintenance of the sample plates and shorten the production period at the same time.

Owner:东风汽车底盘系统有限公司

A heat treatment method for non-ferrous metal hot roll

ActiveCN107447096BSimple heat treatment methodHigh strengthFurnace typesHeat treatment furnacesElectrochemical corrosionQuenching

The invention discloses a heat treatment method of a non-ferrous metal hot roll, and relates to the technical field of metal processing. The method comprises the following steps: 1) preheating: the roll is placed in a high-temperature furnace for preheating treatment after being demolded and cleaned; 2) secondary normalization; 3) quenching: double-frequency induction quenching is performed on the working surface of the roll, and the cooling mode is a combination of oil cooling and air cooling; 4) tempering; 5) annealing. The heat treatment method of the non-ferrous metal hot roll is simple and feasible; the treated non-ferrous metal hot roll is high in strength and good in thermal cracking resistance and electrochemical corrosion resistance, and has excellent accident resistance, fatigue resistance and abrasion resistance, thereby meeting operating requirements of practical production and application; the service life of the non-ferrous metal hot roll is effectively prolonged, and production efficiency and economic benefits are increased.

Owner:安徽昕悦铸造科技有限公司

Quenching agent for improving wear resistance of bearing ring component and preparation method of quenching agent

InactiveCN108359777AImprove wear resistanceImprove quenching effectFurnace typesQuenching agentsQuenchingP-Cresol

The invention provides a quenching agent for improving the wear resistance of a bearing ring component and a preparation method of the quenching agent and relates to the technical field of quenching agents. The quenching agent provided by the invention is prepared from the following raw materials of: sodium molybdate, p-cresol, amino silicon oil, decyl Polyglucoside, sodium ethylene diamine tetracetate, sodium chloride, barium chloride, oleamide, a preservative agent, a defoaming agent, a bactericide, polyvinyl acetate, sodium hydroxide and deionized water. The quenching agent for improving the wear resistance of the bearing ring component can greatly improve the wear resistance of the bearing ring component, is good in quenching effect and low in quenching cost, can reduce the quenching speed, can prevent formation of relatively large internal stress inside the bearing ring component, and prevents cracking of the bearing ring component.

Owner:HEFEI YUANDA BEARING FORGING

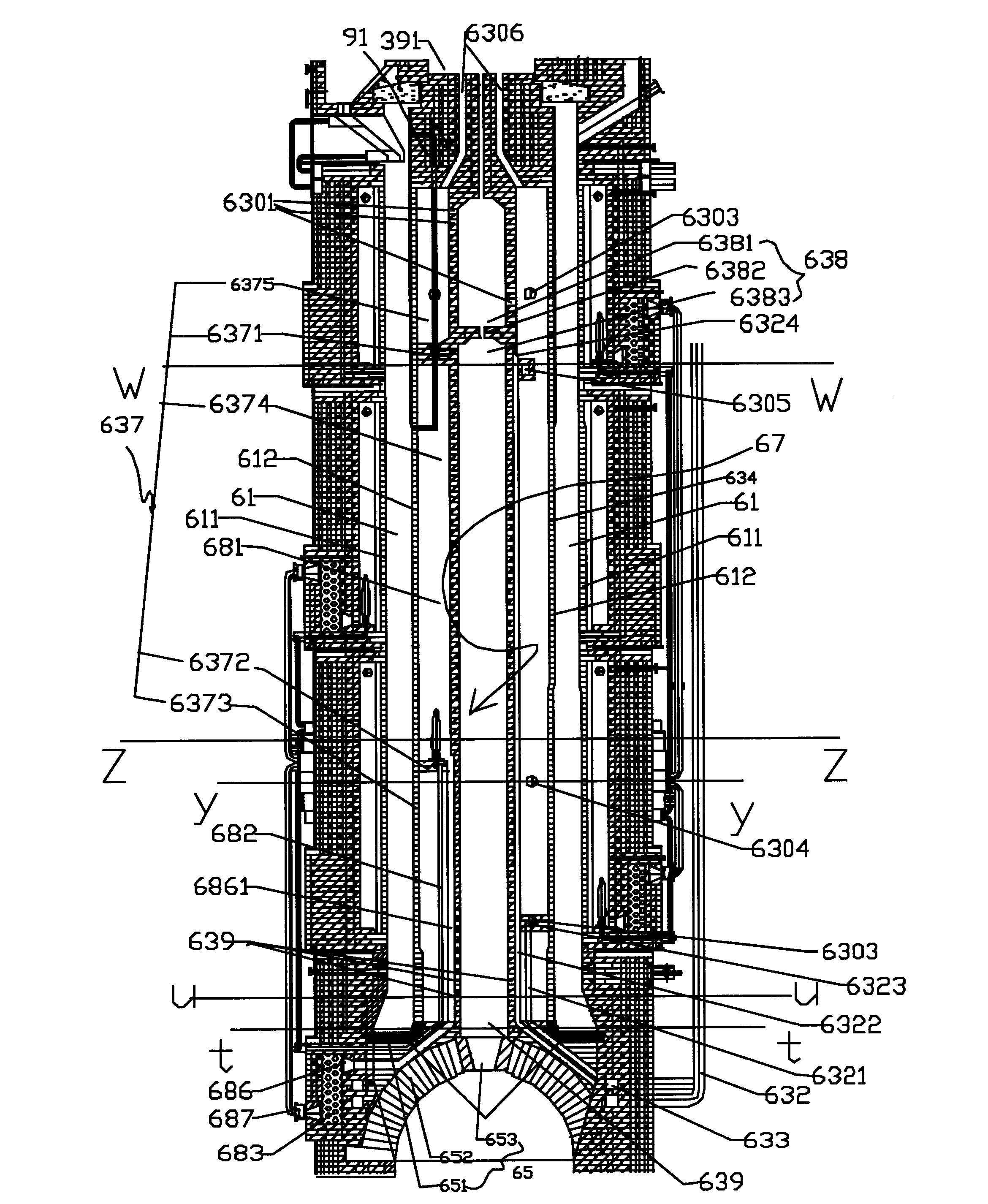

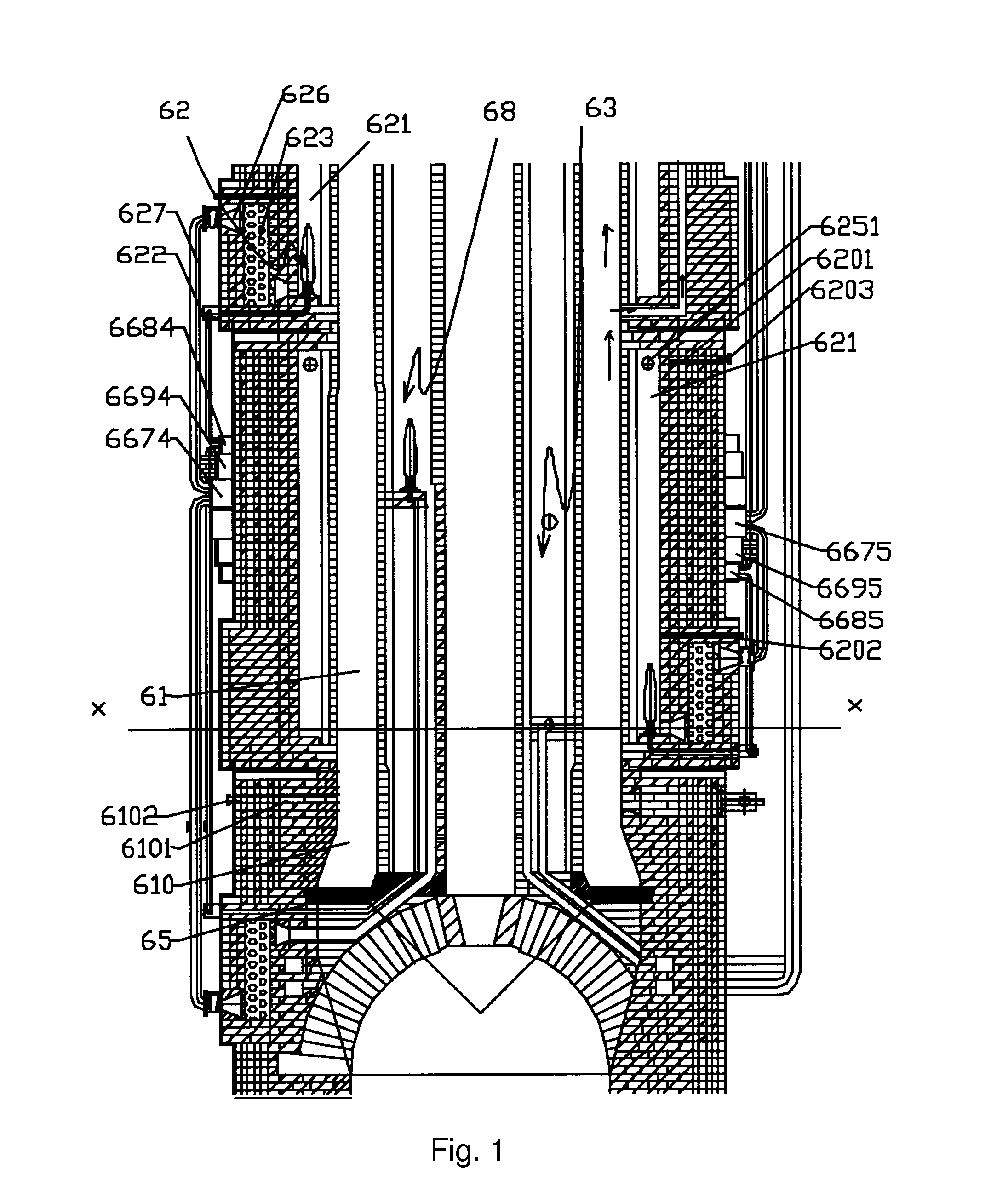

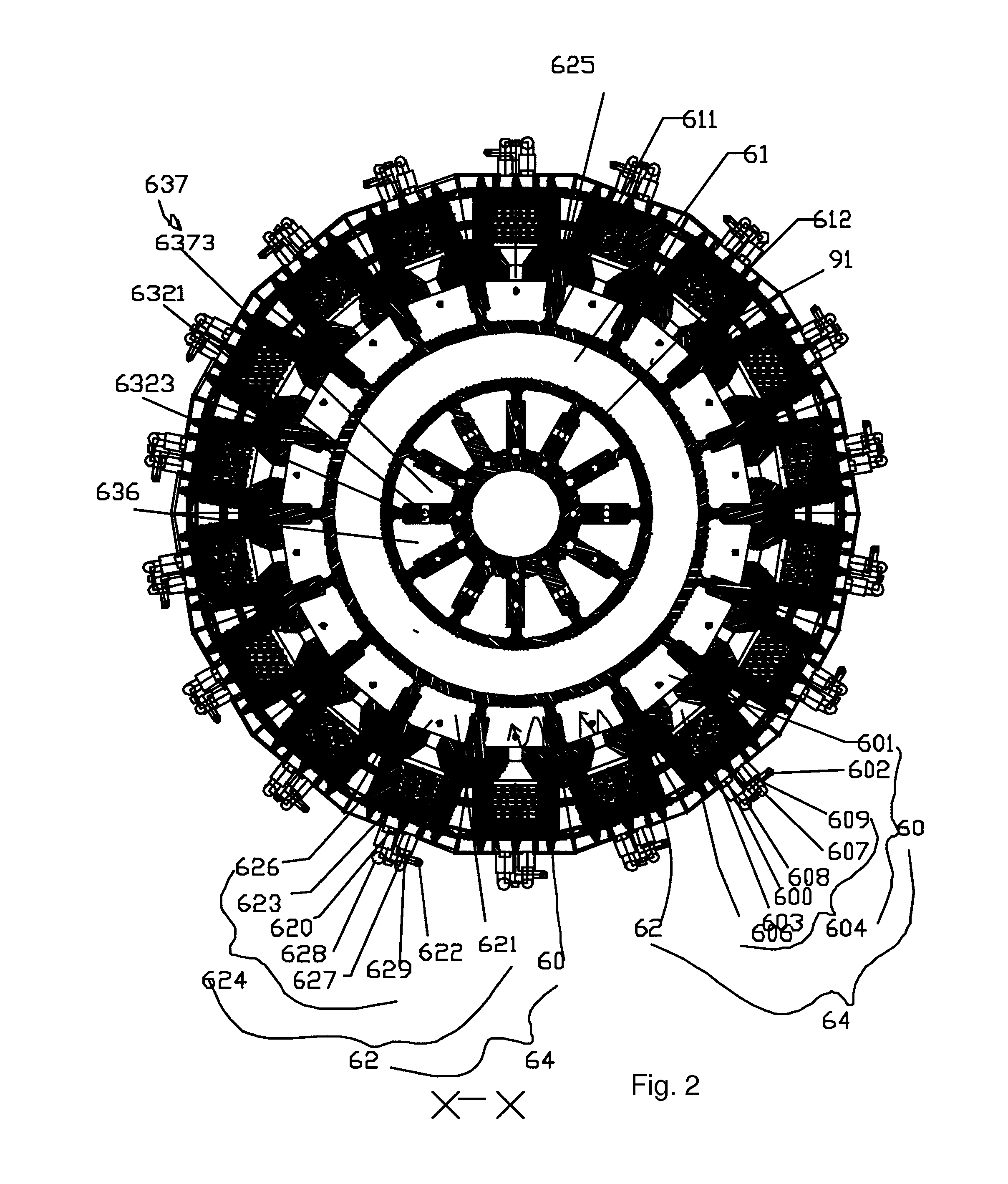

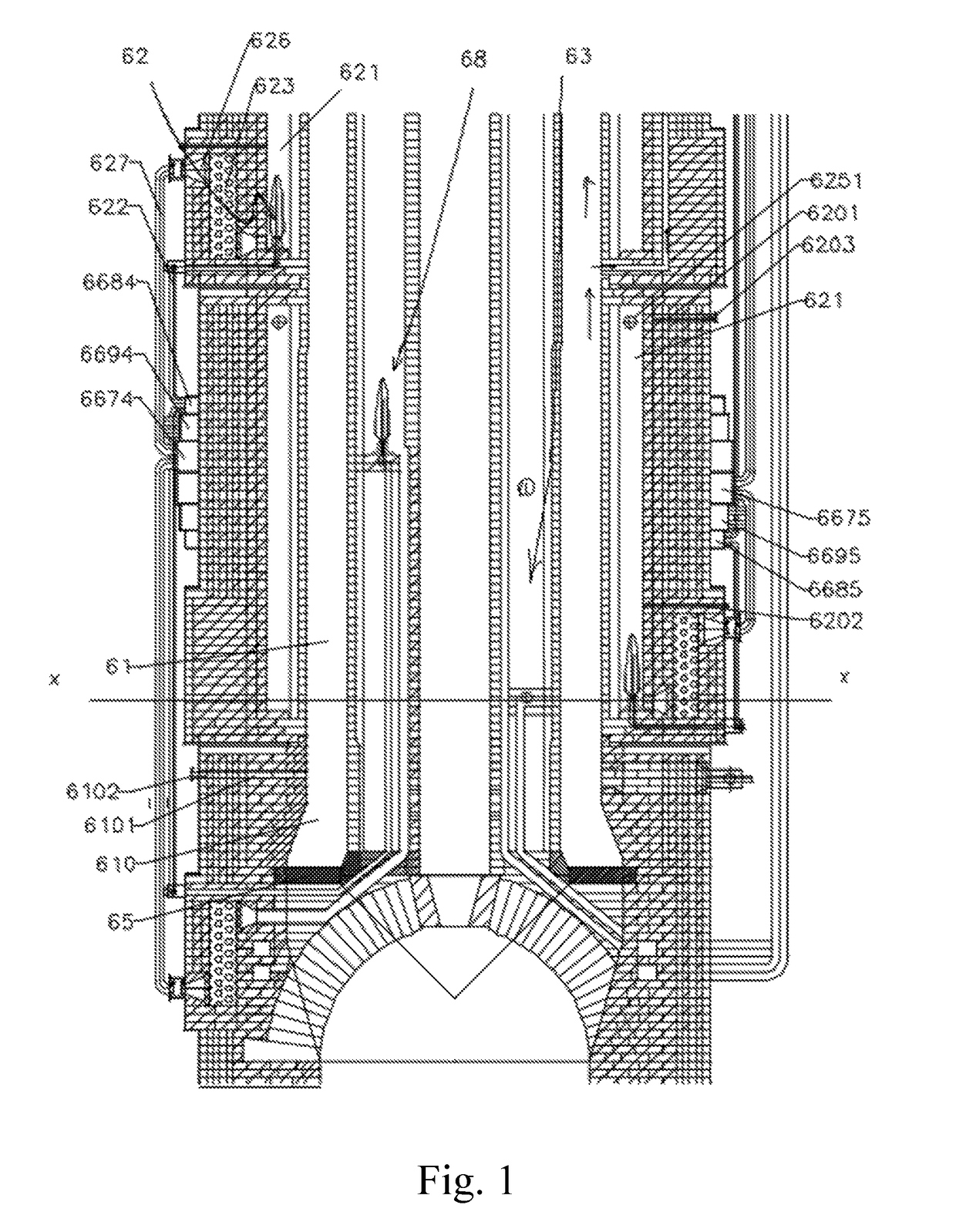

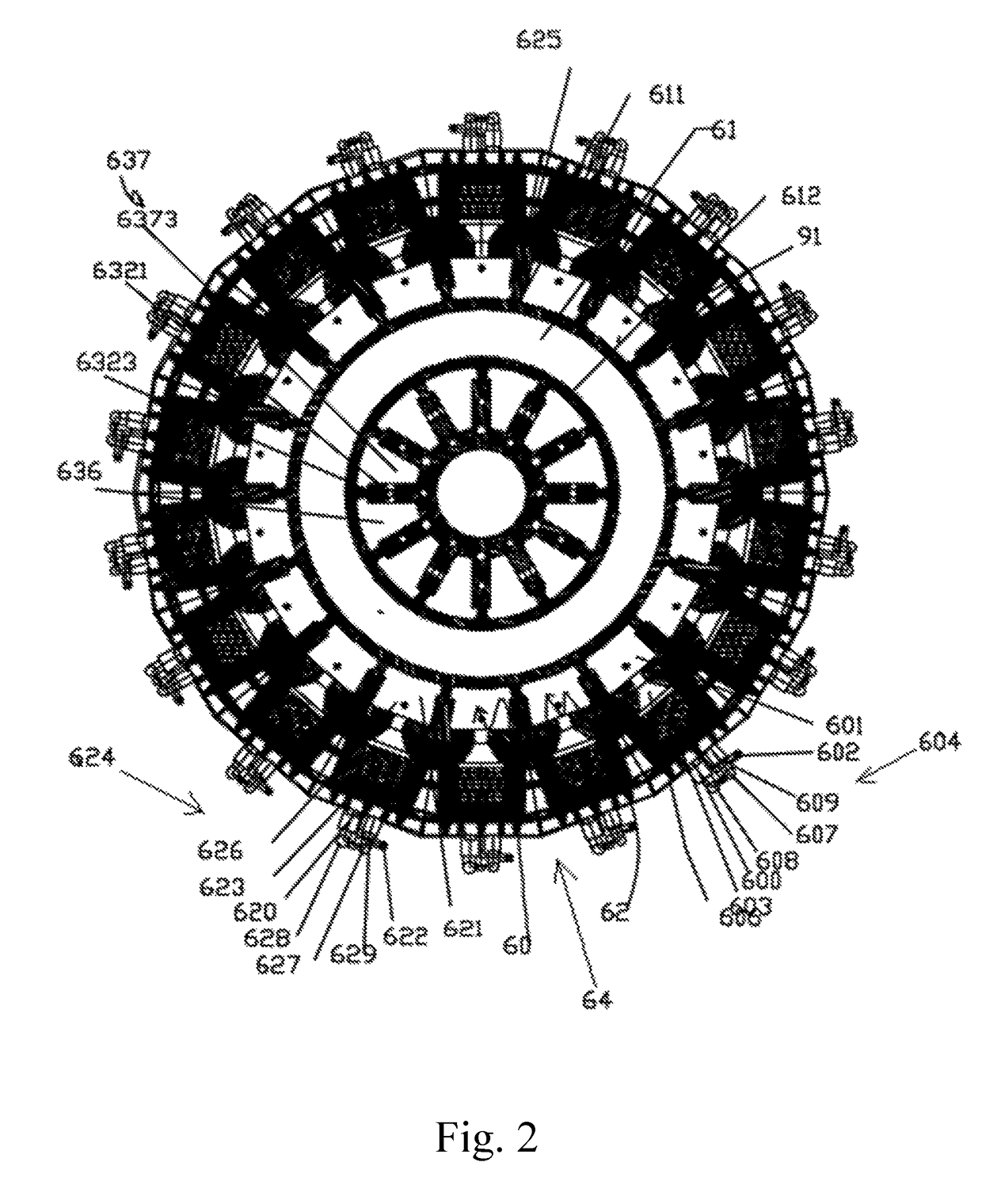

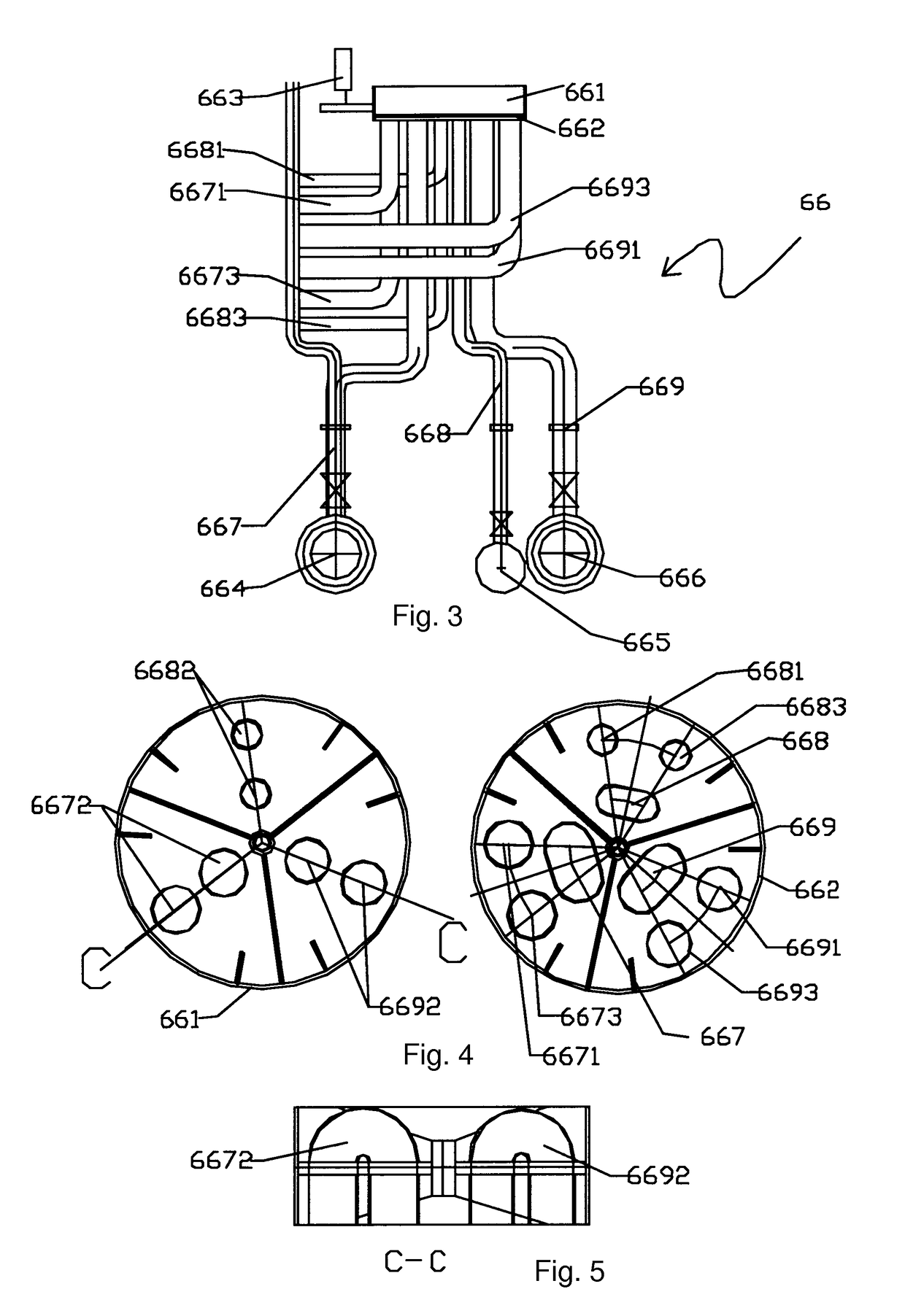

External Gas Heating Device of Coal Pyrolyzing Furnace

InactiveUS20150197693A1Ensure heat energyEnsure temperatureCoke quenchingCombustible gas coke oven heatingCombustion chamberGas heater

An external gas heating device of a coal pyrolyzing furnace is positioned on the middle part of a furnace body and around the outer wall of a carbonizing chamber and comprises more than one group of first gas heater and second gas heater that have the same structure and a gas reversing device. The gas reversing device supplies air and purified gas into a combustion chamber of the first gas heater to be combusted and meanwhile sucks hot waste gas from a combustion chamber of the second gas heater. In the same way, the gas reversing device supplies air and purified gas into the combustion chamber of the second gas heater to be combusted and meanwhile sucks hot waste gas from the combustion chamber of the first gas heater. In the present invention, the aims of energy conservation and consumption reduction are fulfilled, and the coking cost is saved.

Owner:SHANXI XINLI ENERGY TECH

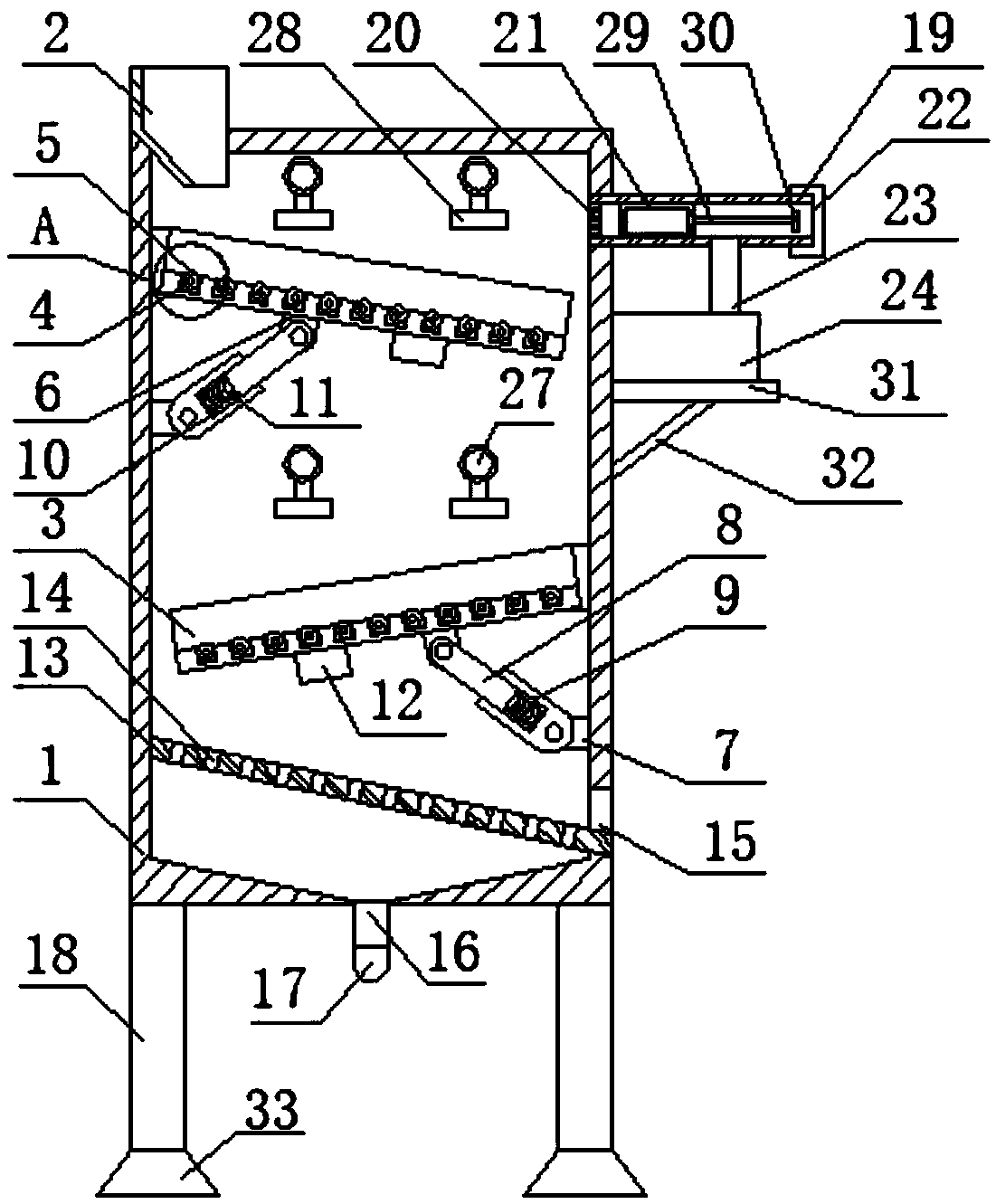

A metal workpiece quenching equipment that can quickly extract mist

ActiveCN111893271BIncrease profitAvoid shakingDirt cleaningQuenching devicesMechanical engineeringQuenching

The invention discloses a metal workpiece quenching device capable of quickly extracting mist, comprising a quenching box, the inner wall in the middle of the quenching box is fixedly connected with a limit ring, and the middle position of the inner wall at the bottom of the quenching box is fixedly connected with a support rod. The top of the support bar is fixedly connected with a support block. When the present invention is in use, the quenching liquid is poured into the bottom of the quenching box through the guide bucket, the density of the floating block is lower than that of the quenching liquid, and it rises together with the liquid level, and the addition of the quenching liquid is stopped after the floating block is stuck at the bottom of the limit ring. During the rising of the floating block, the lifting rod slides along the inner wall of the sleeve to limit the path of the floating block to avoid shaking. The workpiece to be quenched is inserted into the quenching box through the guide bucket and the intubation tube, and the quenching liquid rises into the intubation tube Inside, as the volume of the workpiece immersed in the quenching liquid increases, the liquid level inside the cannula rises synchronously, fully immersing the workpiece, improving the utilization rate of the quenching liquid, and reducing the quenching cost.

Owner:SHANDONG JINZHU MATERIALS TECH +1

External gas heating device of coal pyrolyzing furnace

InactiveUS10144873B2Reduce quenching costsEfficient combustionCoke quenchingCombustible gas coke oven heatingCombustion chamberGas heater

Disclosed is an external gas heating device of a coal pyrolyzing furnace. The external gas heating device is positioned on the middle part of a coal pyrolyzing furnace body and around the outer wall of a carbonizing chamber and comprises more than one group of first gas heater and second gas heater that have the same structure and a gas reversing device. The gas reversing device supplies air and purified gas into a combustion chamber of the first gas heater to be combusted and meanwhile sucks hot waste gas from a combustion chamber of the second gas heater. In the same way, the gas reversing device supplies air and purified gas into the combustion chamber of the second gas heater to be combusted and meanwhile sucks hot waste gas from the combustion chamber of the first gas heater.

Owner:SHANXI XINLI ENERGY TECH

A bracket for gear quenching

InactiveCN108486352BSmall footprintReduce quenching costsFurnace typesHeat treatment furnacesGear wheelQuenching

The invention relates to a gear machining auxiliary tool, in particular to a bracket for gear quenching. The bracket for gear quenching aims at solving the technical problem that the gear production cost is high since a gear is prone to damage during quenching treatment in the prior art. The bracket for the gear quenching is characterized in that locating blocks are uniformly arranged on a base; the locating blocks are connected with the base in a sliding manner; in addition; and the locating blocks comprise abutting and connecting parts and locating parts. An included angle between each gearand a horizontal plane is 30-60 degrees due to the abutting and connecting parts, so that the gears are obliquely located on the base, a space occupied by each gear on the base is reduced, more gearscan be placed on the base, and the quenching cost of the gears is lowered. The gears are located through the locating blocks, and the contact area between each gear and the base is reduced, so that the gears are heated uniformly, the gears are not prone to cracking after being quenched, and the machining cost of the gears is lowered.

Owner:平湖市永成齿轮配件厂

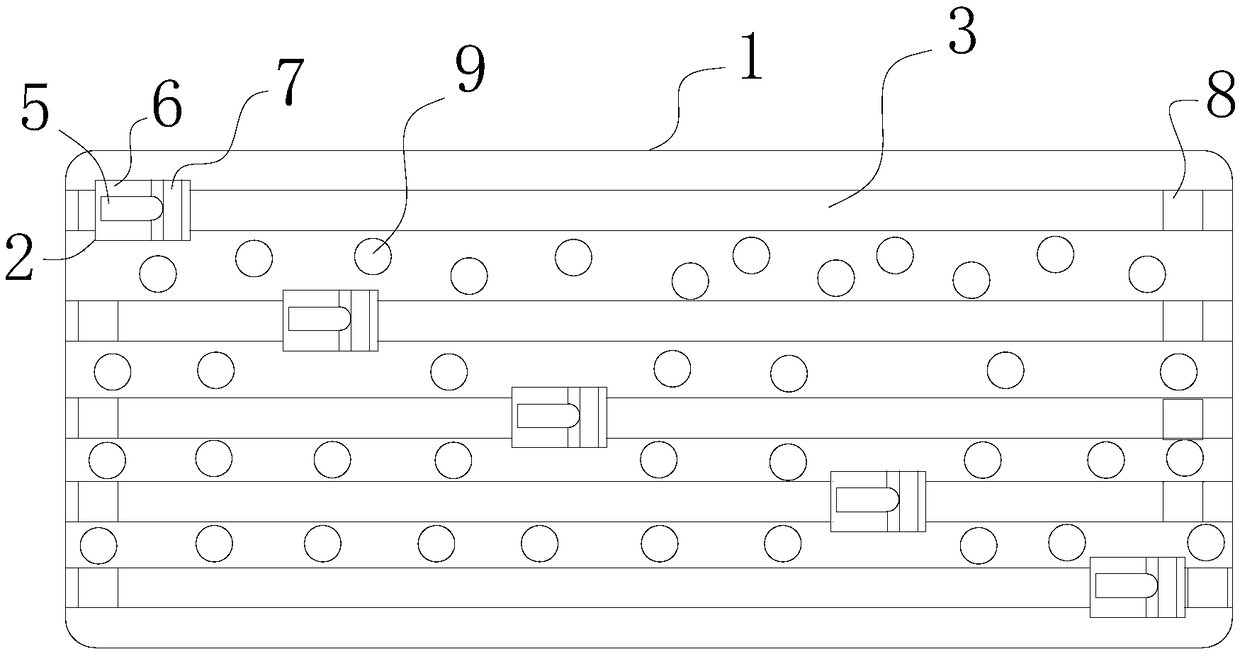

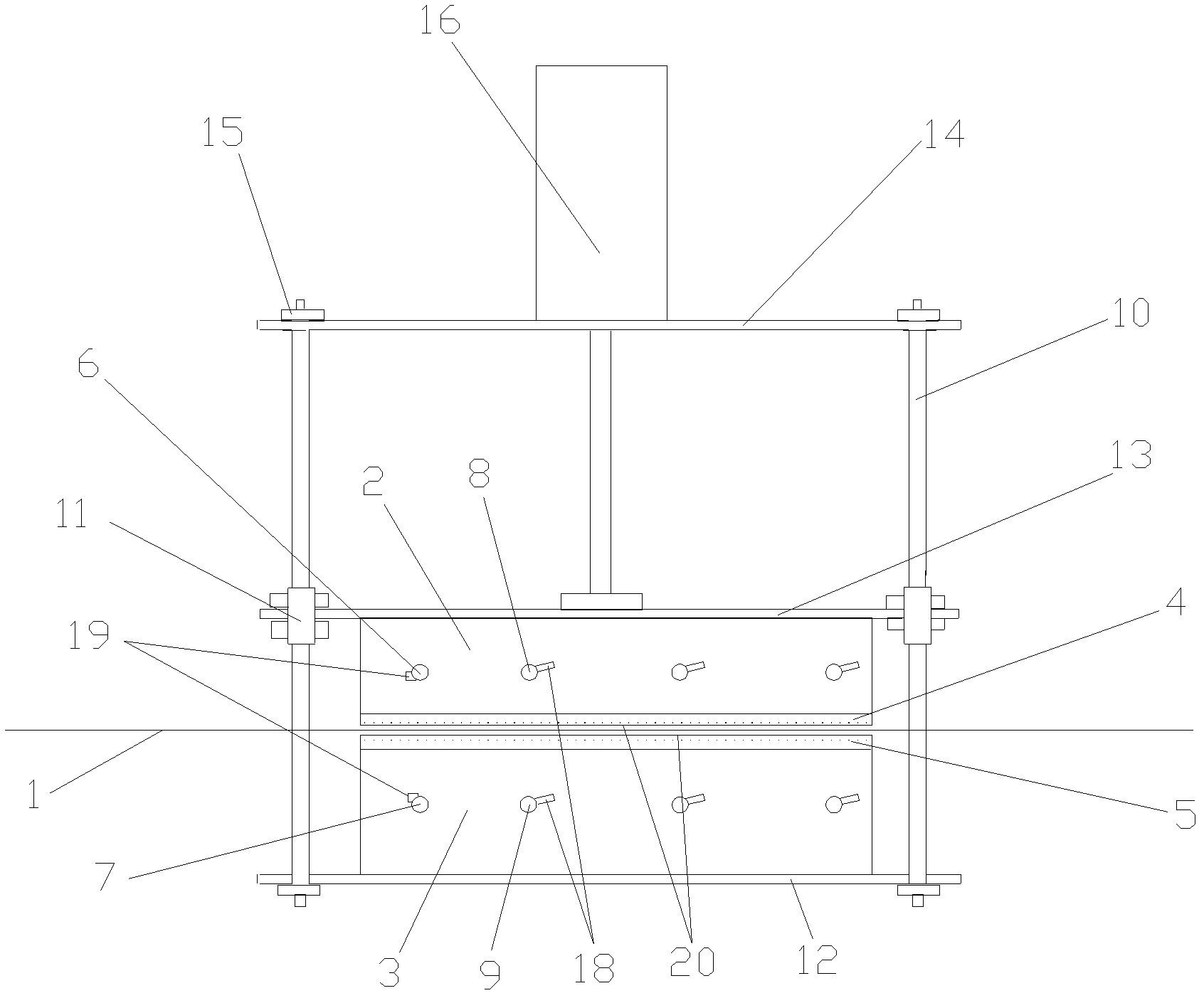

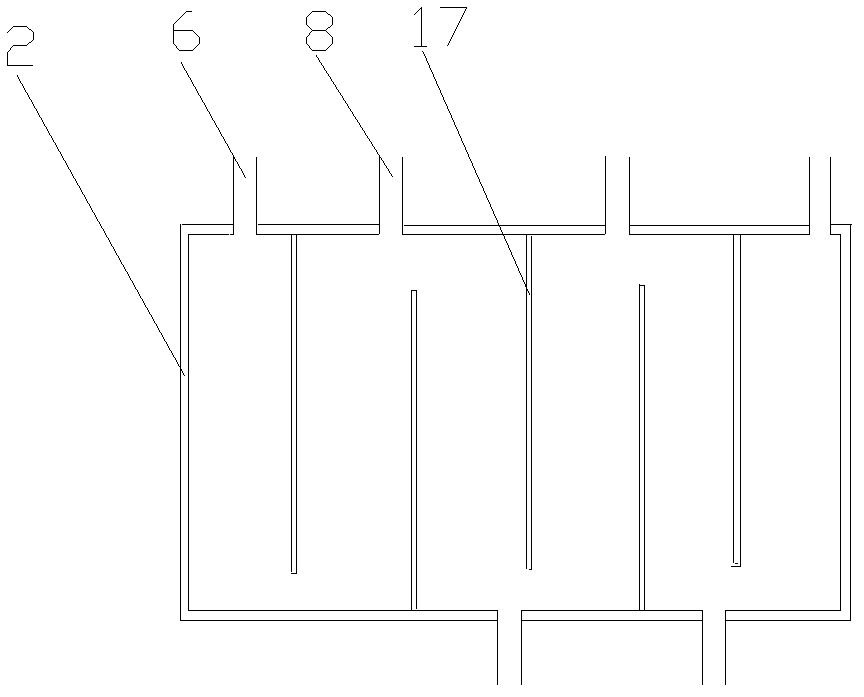

Steel strip water-cooled pressure plate quenching device capable of adjusting cooling final temperature

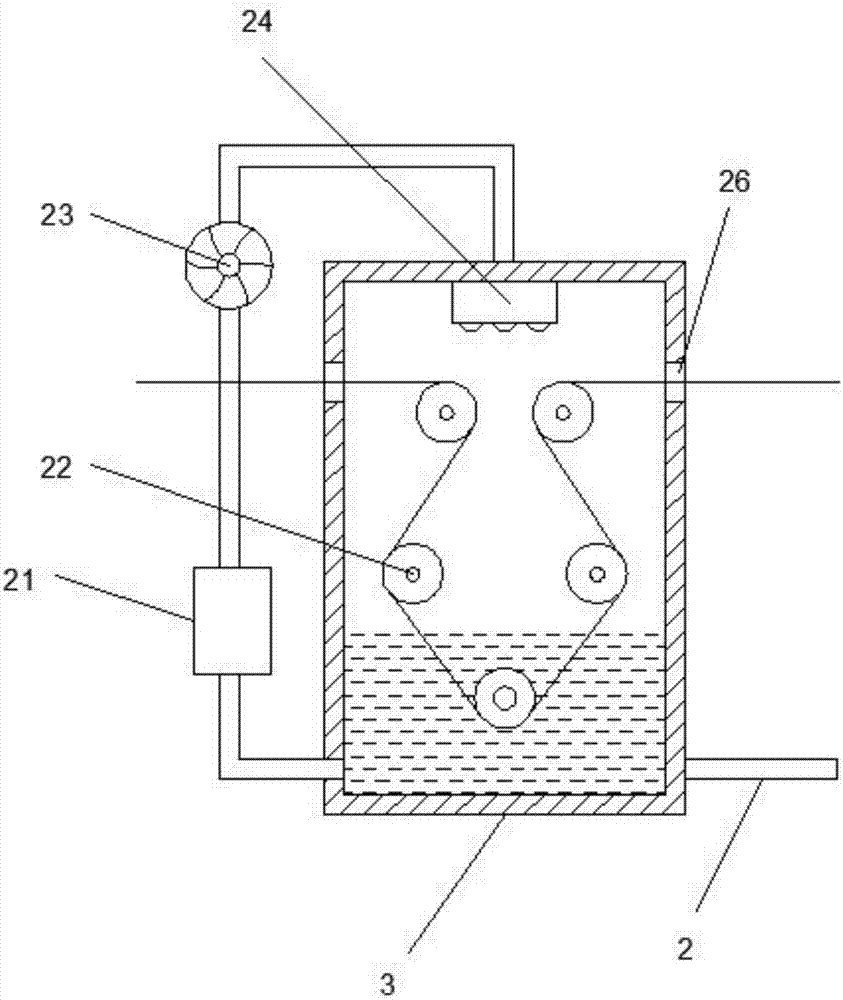

ActiveCN102399957BWill not polluteSimple structureFurnace typesHeat treatment furnacesPulp and paper industryQuenching

The invention provides a steel strip water-cooled pressure plate quenching device capable of adjusting cooling final temperature. The device comprises an upper fixed plate, a lower fixed plate and an upright post for connecting the upper fixed plate and the lower fixed plate; the upper fixed plate is provided with an upper water tank, and an upper pressure plate is arranged at the bottom of the upper water tank; the lower fixed plate is provided with a lower water tank, and a lower pressure plate is arranged on the top of the lower water tank; a steel strip cooled and quenched by heat conduction of the upper fixed plate and the lower fixed plate passes through a space between the upper fixed plate and the lower fixed plate, and the upper water tank is provided with an upper water inlet and at least two upper water outlets formed in parallel in the horizontal direction; the lower water tank is provided with a lower water inlet and at least two lower water outlets formed in parallel in the horizontal direction; and valves are arranged on the upper water outlets and the lower water outlets. The device can be used for adjusting the cooling final temperature of the steel strip, is simple in structure, convenient to operate and low in quenching cost, and cannot pollute the environment.

Owner:ZHEJIANG BAINAI STEEL STRIP

A kind of preparation method of electroplating superabrasive grinding wheel of discreet strengthened hub

The invention discloses a preparation method of an grinding wheel with a discretely reinforced hub electroplated with super hard abrasive. The preparation method comprises the steps that a nozzle of aquenching gun is moved in a wavy shape in the axial direction of a grinding wheel hub, and the temperature of materials, irradiated by plasma arc, of the external circumference surface of the grinding wheel hub is increased quickly, and decreased to form a wavy quenched zone; the quenching gun is returned to the original position, and the grinding wheel hub is rotated for an arc length around itsown axis for machining a second wavy quenched zone; the materials which are not irradiated by the plasma arc between the two quenched zones still maintain the original matrix structures; so repeatedly, till the whole external circumference surface of the grinding wheel hub forms the structure that the quenched zones and the matrix structures are arranged alternately in a wavy shape; and the grinding wheel hub discretely reinforced is electroplated with super hard abrasive to form the grinding wheel with the discretely reinforced hub electroplated with the super hard abrasive. The preparationmethod disclosed by the invention facilitates improvement of the bonding strength of the grinding wheel hub and a nickel coating, and the convergence of interface cracks is reduced; and the bearing capacity of the nickel coating is improved, and the service life of the electroplated grinding wheel is prolonged.

Owner:湖南远东机械制造股份有限公司

Periodical stepped quenching cooling equipment

InactiveCN1250750CSolve pollutionSolve the problem of large fluctuations affecting product qualityQuenching devicesPropellerEngineering

The present invention relates to heat treatment of metal material. The periodical stepped quenching cooling equipment of the present invention includes tank, U-shaped fluid guiding tube, propeller stirrer set beside the tank and with propeller extending below the liquid surface, elevating platform and this driving system, cover plate, one nozzle below the cover plate and one other nozzle over the liquid surface. The propeller is inserted into one opening of the fluid guiding tube and the other opening of the fluid guiding tube is set below the soaked quenched part. The present invention makes it possible to regulate the cooling strength of the quenching based on the requirement, has low quenching cost, no pollution of nitrate and oil to atmosphere and high production safety.

Owner:SHANGHAI JIAOTONG UNIV

A kind of aluminum alloy material and quenching treatment method

Owner:佛山市昌美铝业有限公司

A uniform quenching device for automobile gear components

ActiveCN109402349BEasy to useQuenching treatment to achieveFurnace typesProcess efficiency improvementActivated carbonGear wheel

The invention discloses an automobile gear assembly uniform quenching device which comprises a quenching box. One side of the top surface of the quenching box is provided with a feeding port, and thebottom of a feed channel is provided with a groove. A first fixed frame and a second fixed frame are respectively fixed at the bottom of the feed channel and on the inner wall of the quenching box. Asecond connecting rod is internally provided with a cavity, a spring is fixed inside the cavity, and the surface of a guide plate is provided with through holes. The lower end of the guide plate is located on the outer wall of the quenching box and provided with a discharging port. An outlet pipe is installed in the middle at the bottom of the quenching box. One side of a filter net located in anexhaust pipe is in insertion connection with an activated carbon adsorption cylinder, a water pump is installed on the outer wall of the back surface of the quenching box, and a rotary nozzle is installed at the bottom of a branch water pipe. The device facilitates recycling of a coolant to save resources, and the quenching of a gear assembly is more uniform and convenient. At the same time, gas generated by quenching is treated and discharged to protect the environment.

Owner:徐州优力同创科技股份有限公司

A special quenching agent for large shaft and its manufacturing method

The invention discloses a special quenching agent for a large shaft and a preparation method of the quenching agent, belonging to the field of quenching agents. The quenching agent is prepared from the following components: sodium chloride, sodium hydroxide, sodium citrate, cis-butenedioic acid, mesotrione, lotus root starch, acrylic acid, p-cresol, metribuzin and water. Through adding reasonable components and strictly controlling the component proportion, when used for quenching a shaft which is made of 45# steel and has the diameter of 1.8-3.5m, the quenching agent has the following advantages that the workpiece cooling speed is high within the temperature range of 650-450 DEG C, and the cooling speed is low at the temperature of below 400 DEG C, so that a favorable quenching effect can be obtained, and a quenching crack condition can also be avoided. The preparation method of the quenching agent has the advantages that all components in the quenching agent are completely dispersed and uniformly distributed by controlling temperatures and adding sequences of raw materials, the quenching agent is similar to a colloid in shape, and the cooling speed at the temperature of below 400 DEG C is lowered.

Owner:深圳市新元特钢有限公司

Quenching treatment method of seamless stainless steel pipe for fluid

InactiveCN111020161ACool evenlyReduce quenching costsFurnace typesHeat treatment furnacesSteel tubePipe

The invention discloses a quenching treatment method of a seamless stainless steel pipe for a fluid, and belongs to the technical field of steel pipe quenching. The method comprises the following steps of immersing the bottom of the steel pipe heated until the temperature is above the austenite temperature into a quenching medium, rotating the steel pipe at the same time, and spraying the outer portion of the steel pipe until the temperature of the steel pipe falls below the martensite transformation temperature. Compared with an existing quenching treatment method adopting outer sprinkling and inner spraying or outer immersion and inner spraying, the method of bottom immersion and rotating outer spraying is adopted, the quenching cooling speed is high, cooling is uniform, the cost is low,quenching cracking phenomena can be effectively reduced, the surface quality of the stainless steel pipe is improved, and the cracking rejection rate of the seamless stainless steel pipe is reduced.

Owner:NANJING WORLD SPECIAL STEEL

A kind of manufacturing method of automobile leaf spring

ActiveCN111809034BReduce usageReduce lossSolid state diffusion coatingFurnace typesHeat treatingChromium

The invention discloses a method for preparing an automobile leaf spring. The automobile leaf spring is manufactured by using a spring steel billet material containing molybdenum, vanadium and trace amounts of chromium and nickel elements. Spring steel plate, rolled lugs, constant temperature treatment, water cooling and quenching, air cooling, surface fine grinding, shot blasting treatment, gas co-infiltration, coating, and finished product after drying. This invention uses the waste heat repeatedly after the hot rolling process with the help of a constant temperature device Complete the forming and heat treatment of the leaf spring, reduce the heating time, and greatly reduce the energy loss. In the heat treatment process, water is used as the cooling medium, which reduces the environmental pollution problem. Cost reduction, improved surface quality of leaf springs, increased corrosion resistance and fatigue properties.

Owner:四川丰元机械制造有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com