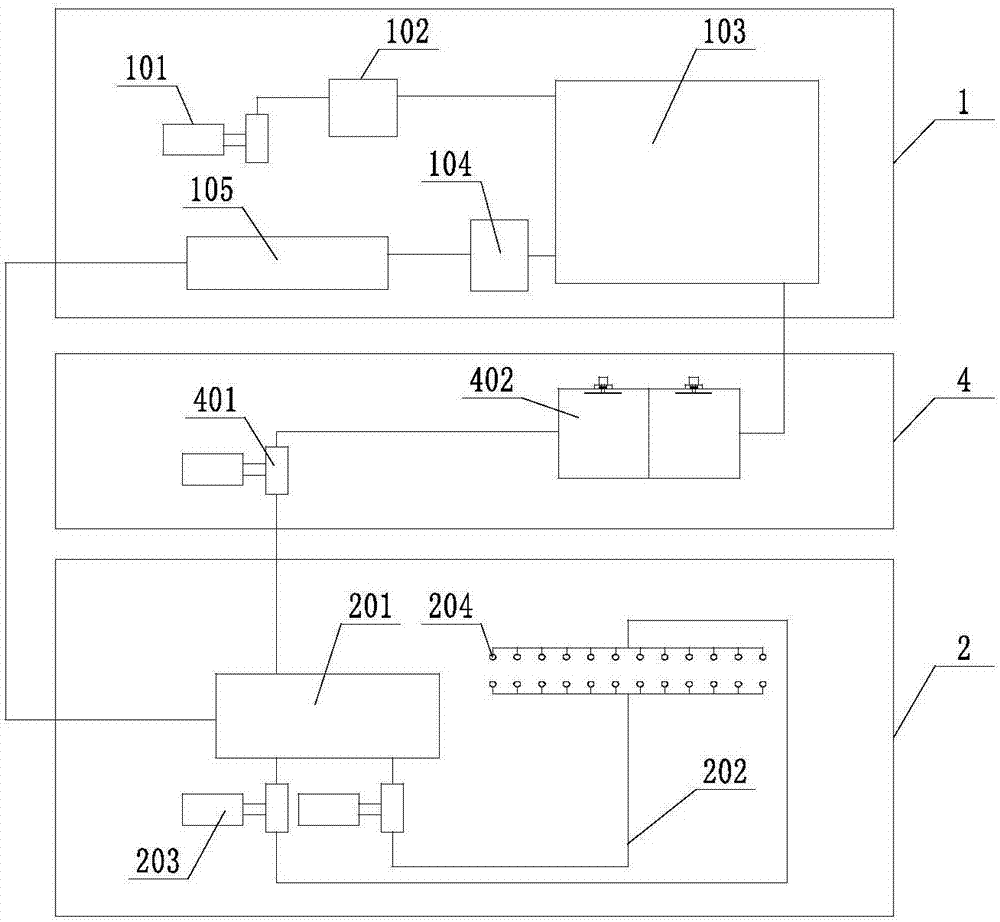

Online aluminum alloy plate quenching process and equipment

An aluminum alloy plate and quenching equipment technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of unfavorable quenching solid solution performance, long production cycle, and high quenching cost, so as to ensure quenching solid solution performance and reduce quenching. cost, the effect of avoiding waste of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

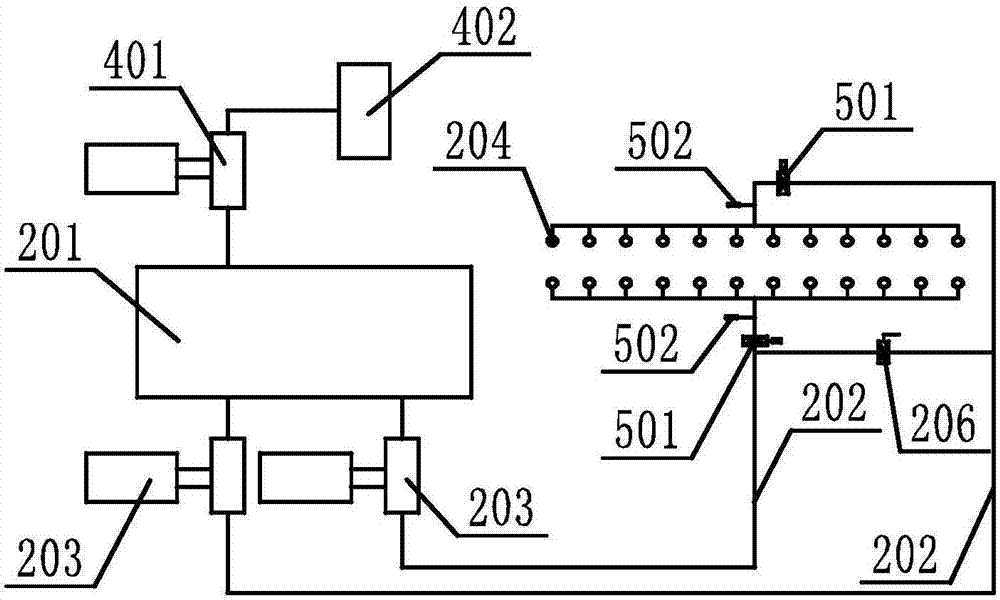

[0047] An aluminum alloy plate online quenching process is characterized in that it comprises the following steps:

[0048] A. Rolling: Roll the aluminum alloy plate to the size required by the process, and control the temperature of the rolled aluminum alloy plate to not be lower than 460°C, and the thickness of the aluminum alloy plate to be 250mm;

[0049] B. Spraying preparation: The rolled aluminum alloy plate enters the entrance of the spraying area at a speed of 160m / min through the conveying device, and at the same time starts the conveying device in the spraying area to control the speed of the conveying device in the spraying area 9m / s;

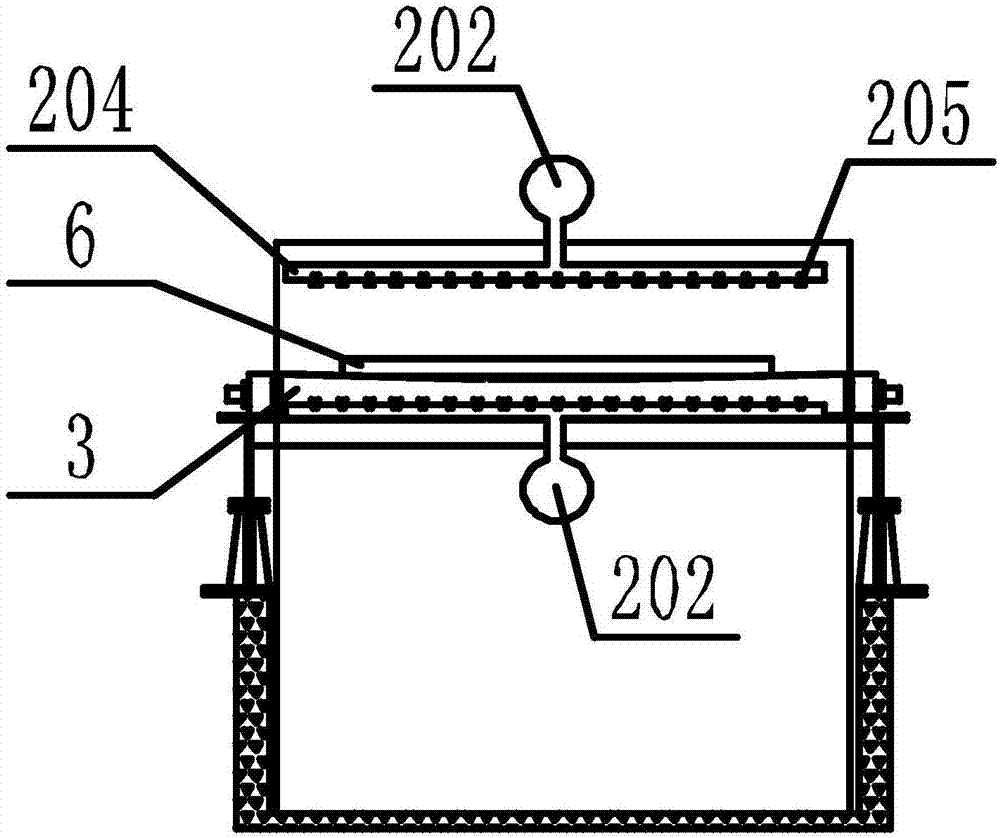

[0050] C. Rapid spraying: the rolled aluminum alloy plate enters and passes through the spray area, and sprays the upper and lower sides of the aluminum alloy plate with deionized water at the same time, and the spray water pressure on the upper plate surface is controlled to 3.8 kg water pressure. The spray water pressure on the l...

Embodiment 2

[0053] Embodiment 2: an aluminum alloy plate online quenching process, is characterized in that, comprises the following steps:

[0054] A. Rolling: Roll the aluminum alloy plate to the size required by the process, and control the temperature of the rolled aluminum alloy plate to not be lower than 460°C, and the thickness of the aluminum alloy plate to be 60mm;

[0055] B. Spraying preparation: The rolled aluminum alloy plate enters the entrance of the spraying area at a speed of 200m / min through the conveying device, and at the same time starts the conveying device in the spraying area to control the speed of the conveying device in the spraying area 11m / s;

[0056] C. Rapid spraying: the rolled aluminum alloy plate enters and passes through the spray area, and sprays the upper and lower sides of the aluminum alloy plate with deionized water at the same time, and the spray water pressure on the upper plate surface is controlled to 3.8 kg water pressure. The spray water pres...

Embodiment 3

[0059] Embodiment 3: an aluminum alloy plate online quenching process, is characterized in that, comprises the following steps:

[0060] A. Rolling: Roll the aluminum alloy plate to the size required by the process, and control the temperature of the rolled aluminum alloy plate to not be lower than 460°C, and the thickness of the aluminum alloy plate is 120mm;

[0061] B. Spraying preparation: The rolled aluminum alloy plate enters the entrance of the spraying area at a speed of 180m / min through the conveying device, and at the same time starts the conveying device in the spraying area to control the speed of the conveying device in the spraying area 10m / s;

[0062] C. Rapid spraying: the rolled aluminum alloy plate enters and passes through the spray area, and sprays the upper and lower sides of the aluminum alloy plate with deionized water at the same time, and the spray water pressure on the upper plate surface is controlled to 3.8 kg water pressure. The spray water pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com