Steel strip water-cooled pressure plate quenching device capable of adjusting cooling final temperature

A technology of terminal temperature and quenching device, applied in the field of heat treatment, can solve the problems of polluted environment, complex structure and high quenching cost, and achieve the effects of low quenching cost, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

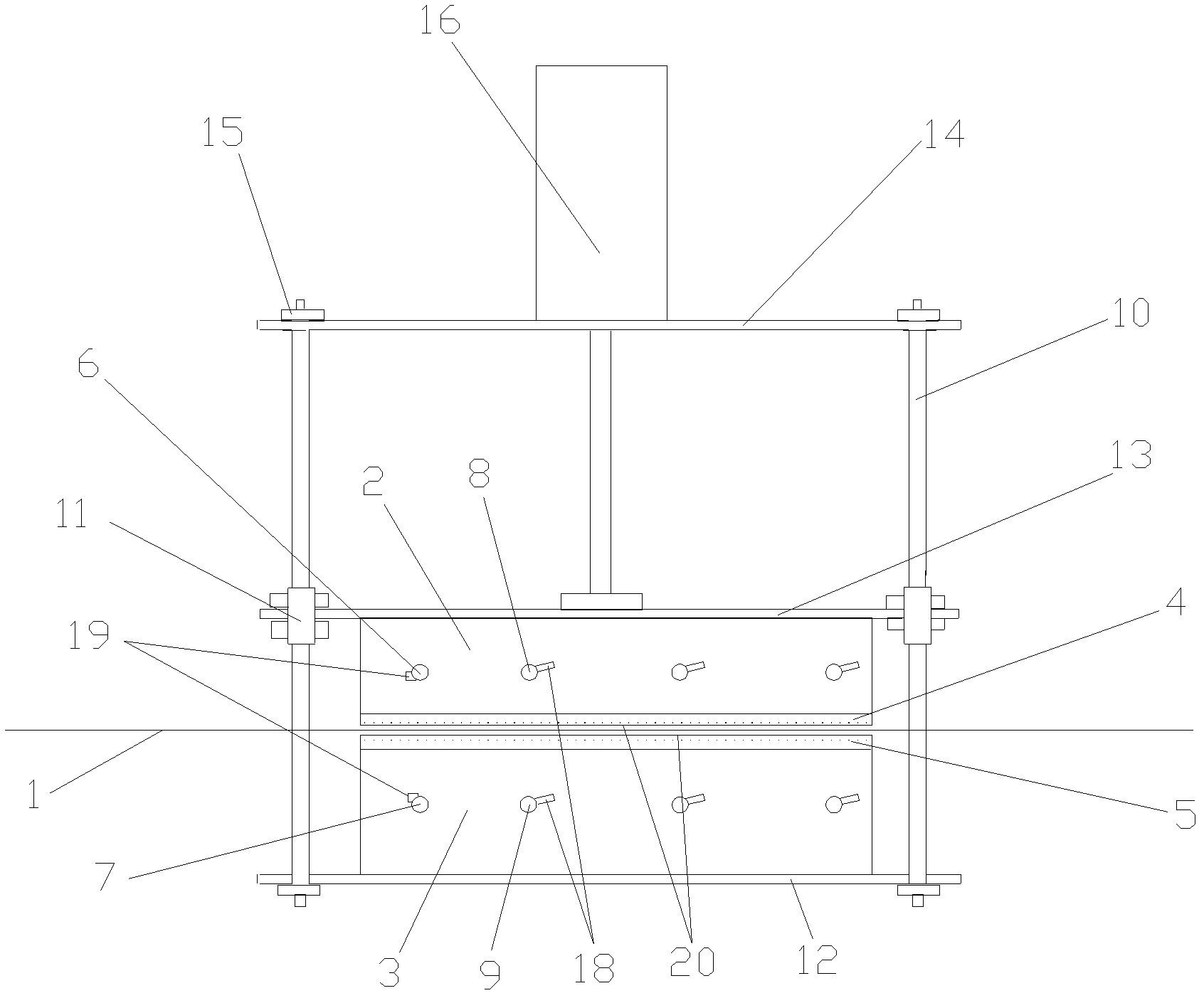

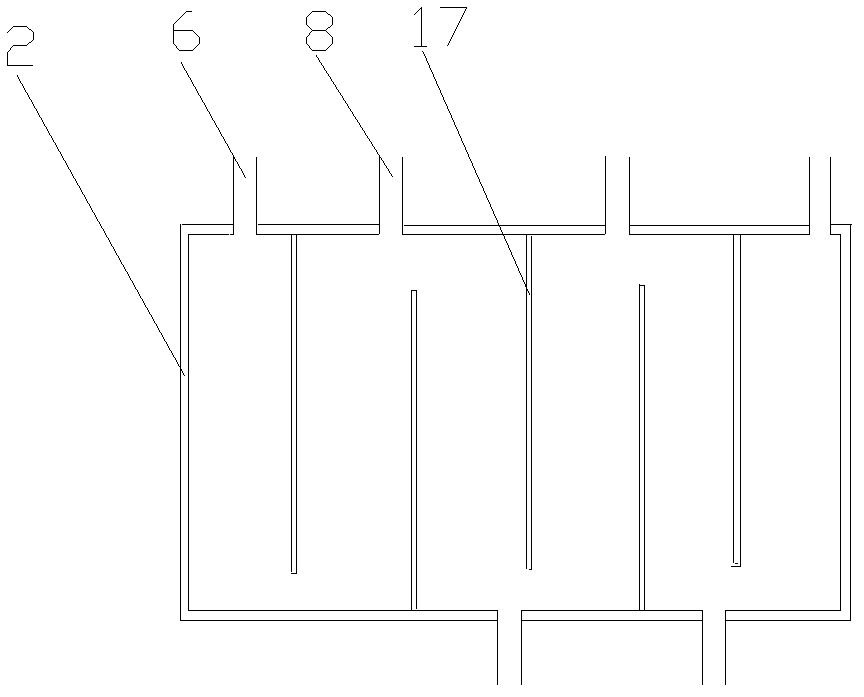

[0018] Such as figure 1 with figure 2 As shown, a steel strip water-cooled press plate quenching device with adjustable cooling end temperature includes an upper fixed plate 14, a lower fixed plate 12, a column 10 connecting the upper fixed plate 14 and the lower fixed plate 12, and the upper fixed plate 14 An upper water tank 2 is arranged on the top, an upper pressing plate 4 is provided at the bottom of the upper water tank 2, a lower water tank 3 is arranged on the lower fixing plate 12, and a lower pressing plate 5 is arranged on the top of the lower water tank 3, and the upper pressing plate 4 and A steel strip 1 for cooling and quenching through the heat conduction of the upper pressing plate 4 and the lower pressing plate 5 is threaded between the lower pressing plates 5, and the upper water tank 2 is provided with an upper water inlet 6 and at least two upper water outlets arranged side by side in the horizontal direction 8. The lower water tank 3 has a lower water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com