Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce processing scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for machining cylindrical mirror

ActiveCN104290002AImprove processing efficiencyImprove machining accuracyOptical surface grinding machinesGrinding feed controlWaxSurface type

The invention discloses a method for machining a cylindrical mirror. The method for machining the cylindrical mirror comprise the steps that a blank is obtained, and the reference surface of the blank is milled; the blank adheres to a tool with wax; the tool with the blank is arranged on a workpiece shaft of a milling device, and the reference surface of the blank is measured with a dial indicator and is clamped; programmed milling is conducted on the cylindrical surface to be machined; the surface type data of the machined cylindrical surface are measured; the surface type data are compared, if the Rt value is larger than 1 micron, correction milling is conducted, and if the Rt value is smaller than 1 micron, polishing is conducted; if the Rt value and the Ra value of the machined cylindrical surface of the polished workpiece meet expected requirements, the workpiece is detached from the tool, cleaning is conducted, and then the cylindrical mirror is obtained. By the adoption of the method for machining the cylindrical mirror, the machining efficiency and the machining precision of the cylindrical mirror are improved, the high-precision cylindrical mirror can be machined, the machining difficulty and the detection difficulty are effectively lowered, generation of waste is avoided, the machining rejection rate is reduced, the technologies are simple, operation is convenient, and good application prospect is achieved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

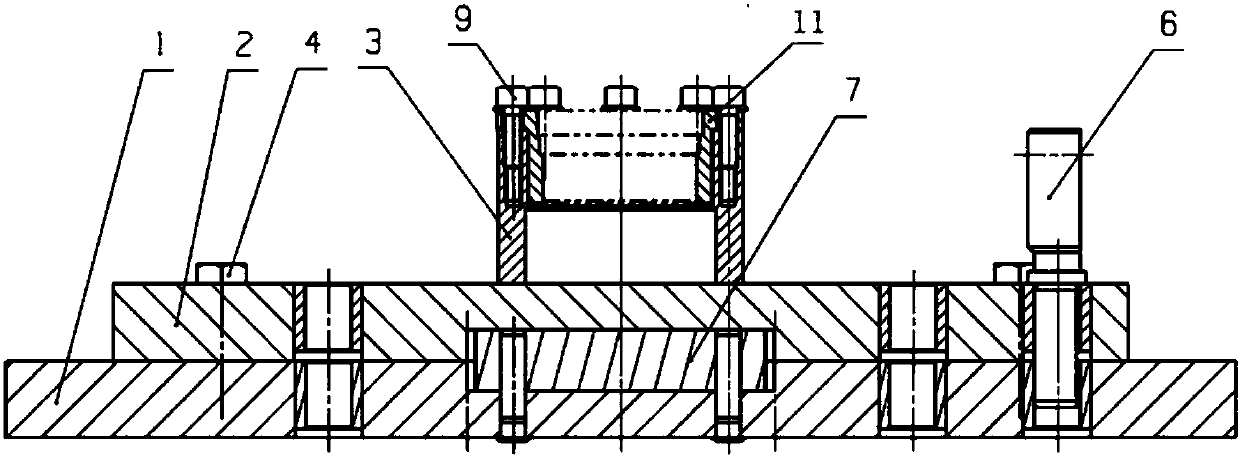

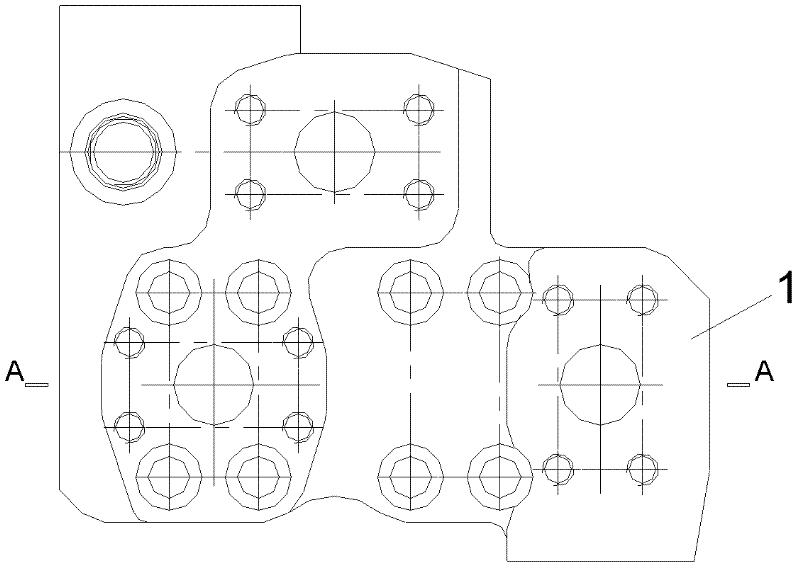

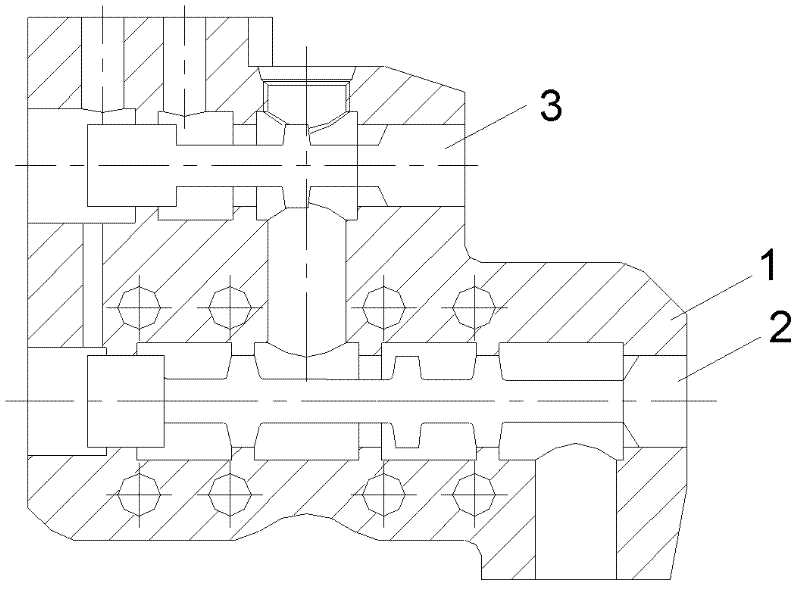

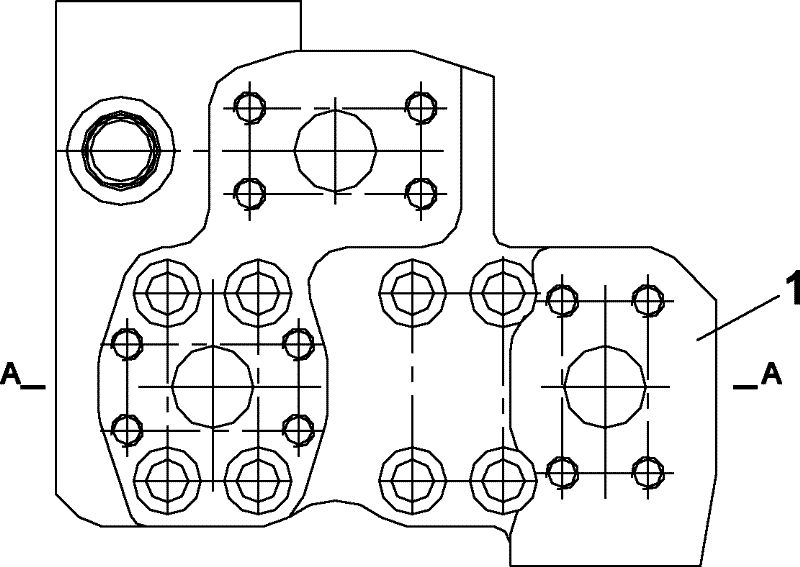

Machining method for forming holes in peripheral surface of housing of timing gear and special combination drilling machine for machining method

ActiveCN103586717AGuaranteed positionHigh precisionThread cutting machinesOther manufacturing equipments/toolsWorkstationMachine tool

The invention relates to a machining method for forming holes in the peripheral surface of a housing of a timing gear and a special combined drilling machine for the machining method on machining. A workpiece clamping table in the special combination drilling machine is arranged on a bottom plate of a machine tool by an oil cylinder which is perpendicularly arranged in the middle of the workpiece clamping table; a plurality of hydraulic chucks and positioning pins which are symmetric to one another are arranged on the workpiece clamping table; five machining workstations are arranged surrounding the workpiece clamping table; two multi-spindle tools which are arrayed vertically and are placed horizontally are arranged on each machining workstation; drilling bits or screw taps are respectively arranged in the upper and lower multi-spindle tools; the housing of the timing gear is positioned by a combining surface and two positioning pins; four corners of the housing of the timing gear are compressed by using the hydraulic chucks; the workpiece clamping table drives the housing of the timing gear to ascend and descend; and drilling and tapping on the peripheral surface of the housing of the timing gear can be simultaneously finished under the action of the drilling bits and the screw taps of the multi-spindle tools. By using the machining method and the special combination drilling machine, the peripheral surface of the housing of the timing gear is machined, the uniformity and the accuracy of holes are guaranteed, and the product quality and the machining efficiency are effectively improved.

Owner:杭州德曼汽车零部件有限公司

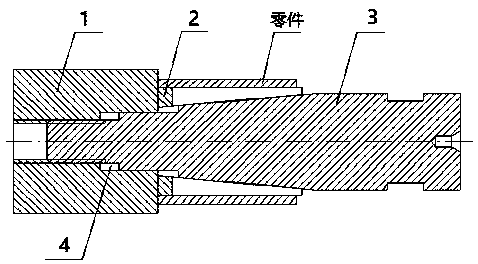

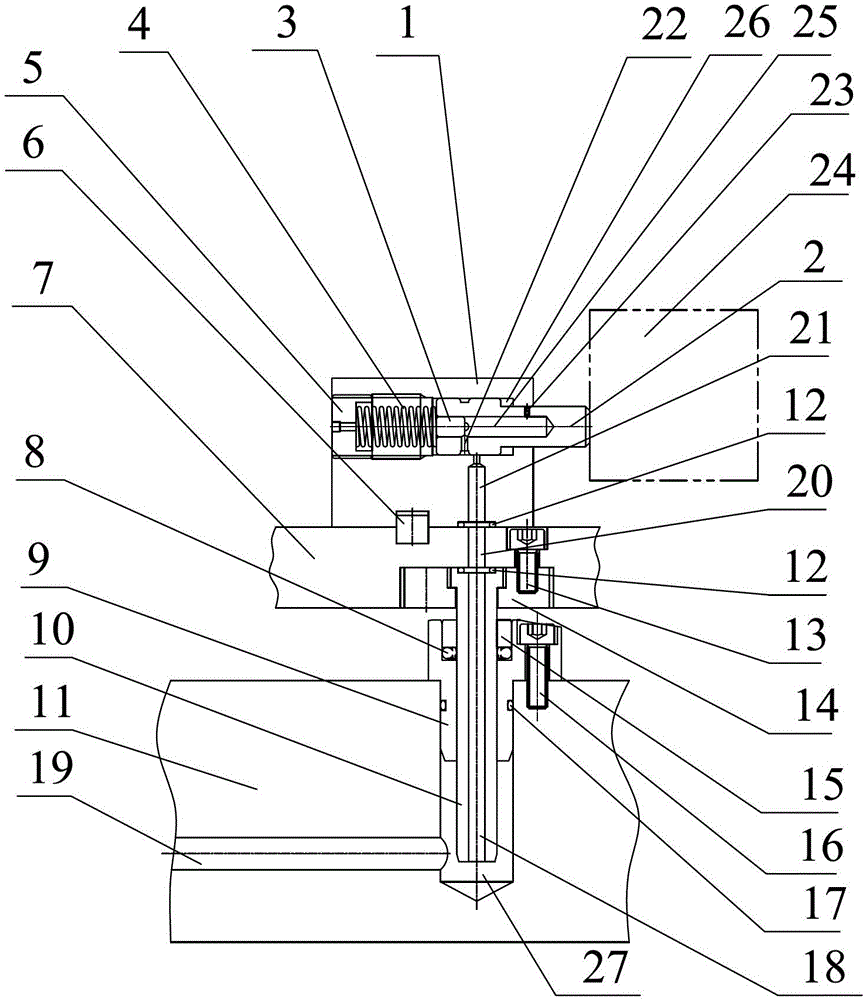

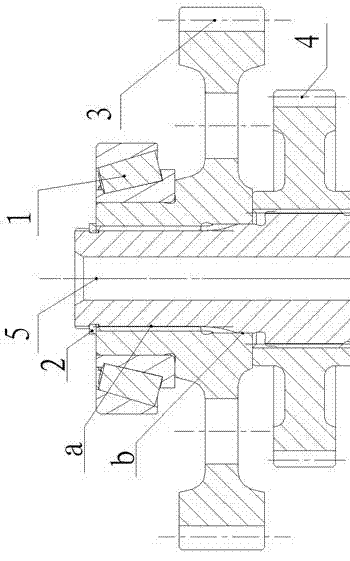

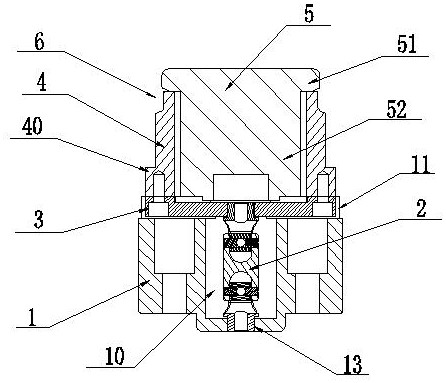

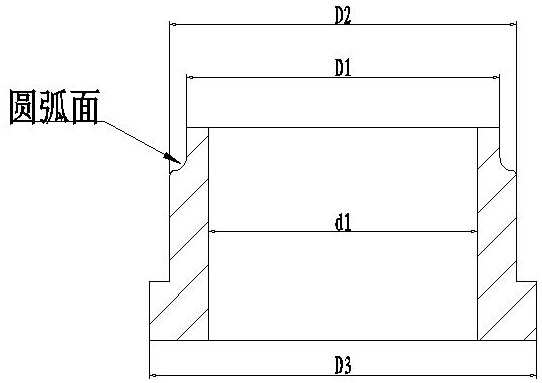

Thin-wall rotary type component cylindrical lathe cutting clamping method and device

The invention discloses a thin-wall rotary type component cylindrical lathe cutting clamping method and device. According to the method, an inner hole of a thin-wall rotary type component is tightened, and the purpose of clamping the thin-wall rotary type component is achieved; the clamping device used in the method comprises a base, an elastic hollow shaft and a top rod with a threaded conical surface, wherein a guide hole is formed in the center of the base; the guide hole is in threaded connection with the top rod of the threaded conical surface; the elastic hollow shaft is arranged at theperiphery of the top rod with the threaded conical surface. The device is relatively simple in structure, convenient in clamping operation and reliable in clamping mode, the situation that the thin-wall rotary type component is deformed or scraped in cylindrical latch cutting operation is avoided. Not only is the processing precision improved, but also the processing rejection rate is reduced, andthe processing cost is reduced.

Owner:GUIZHOU HONGLIN MACHINERY

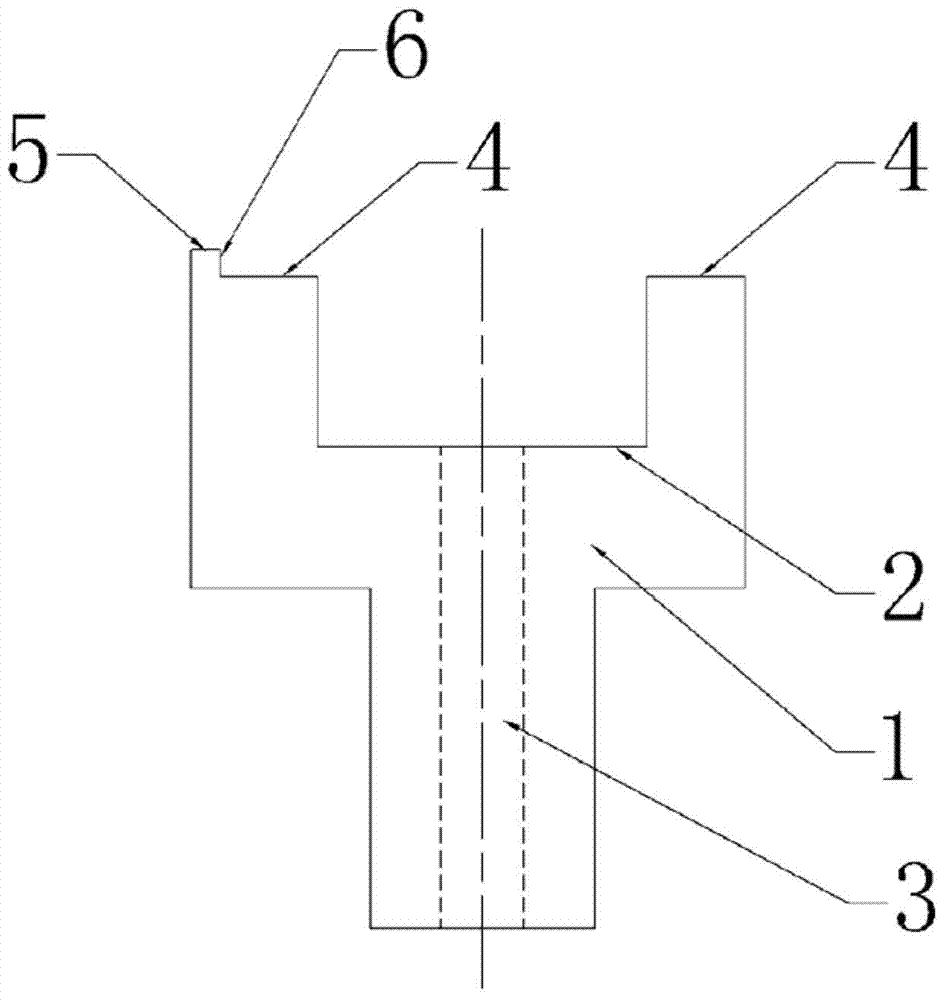

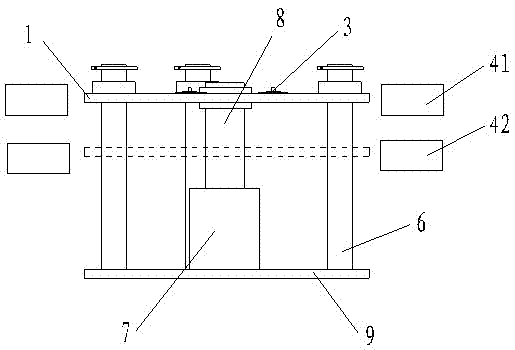

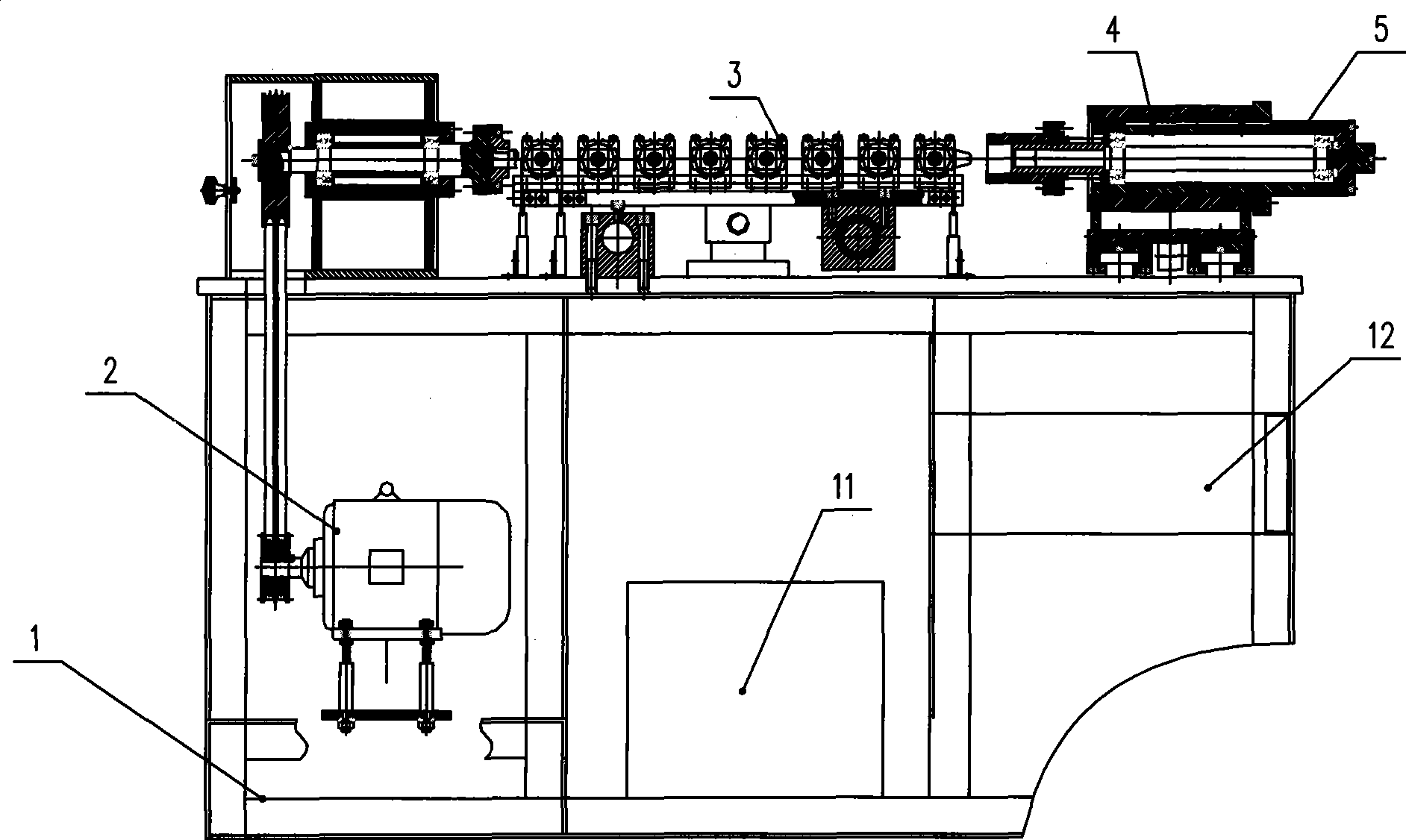

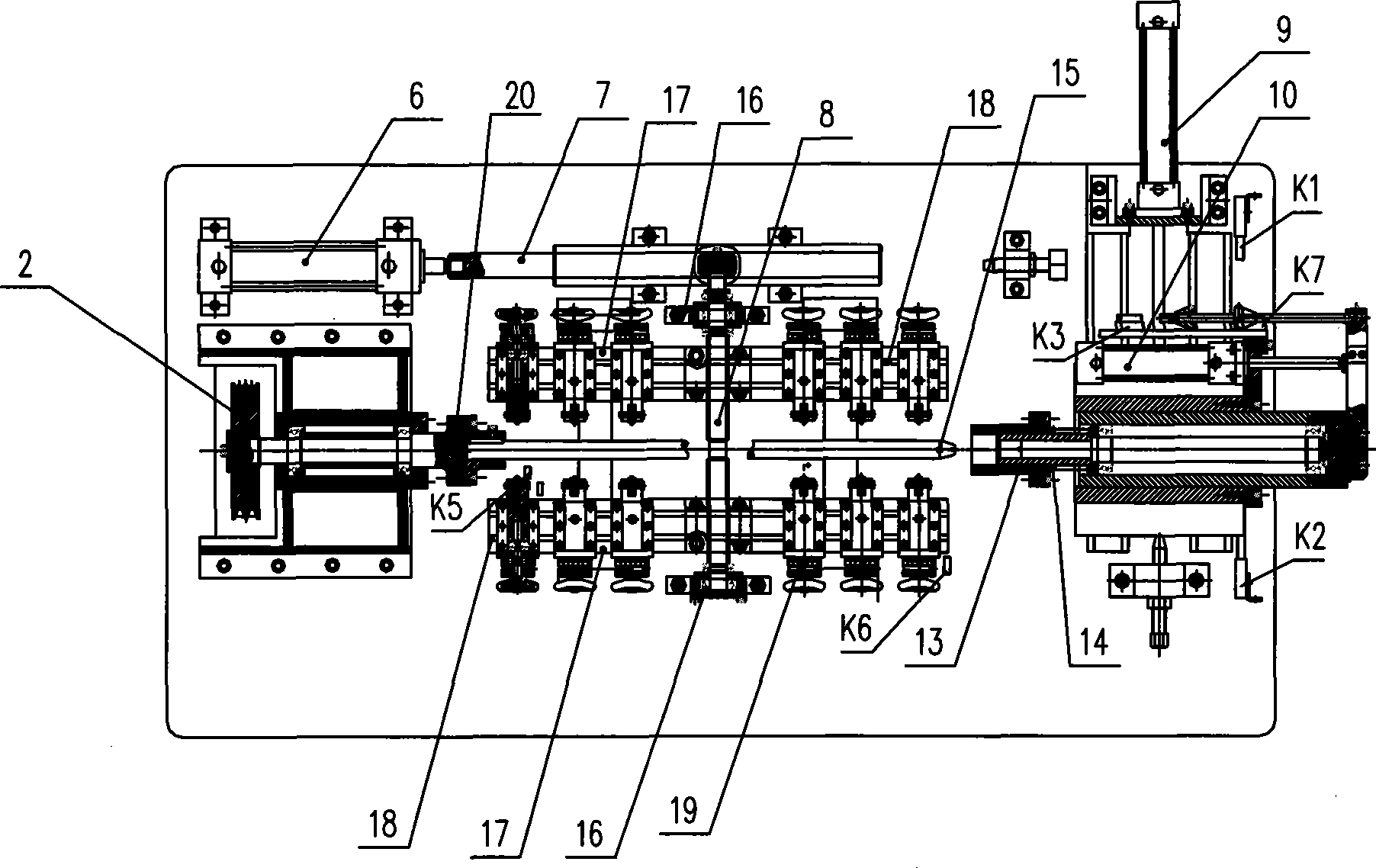

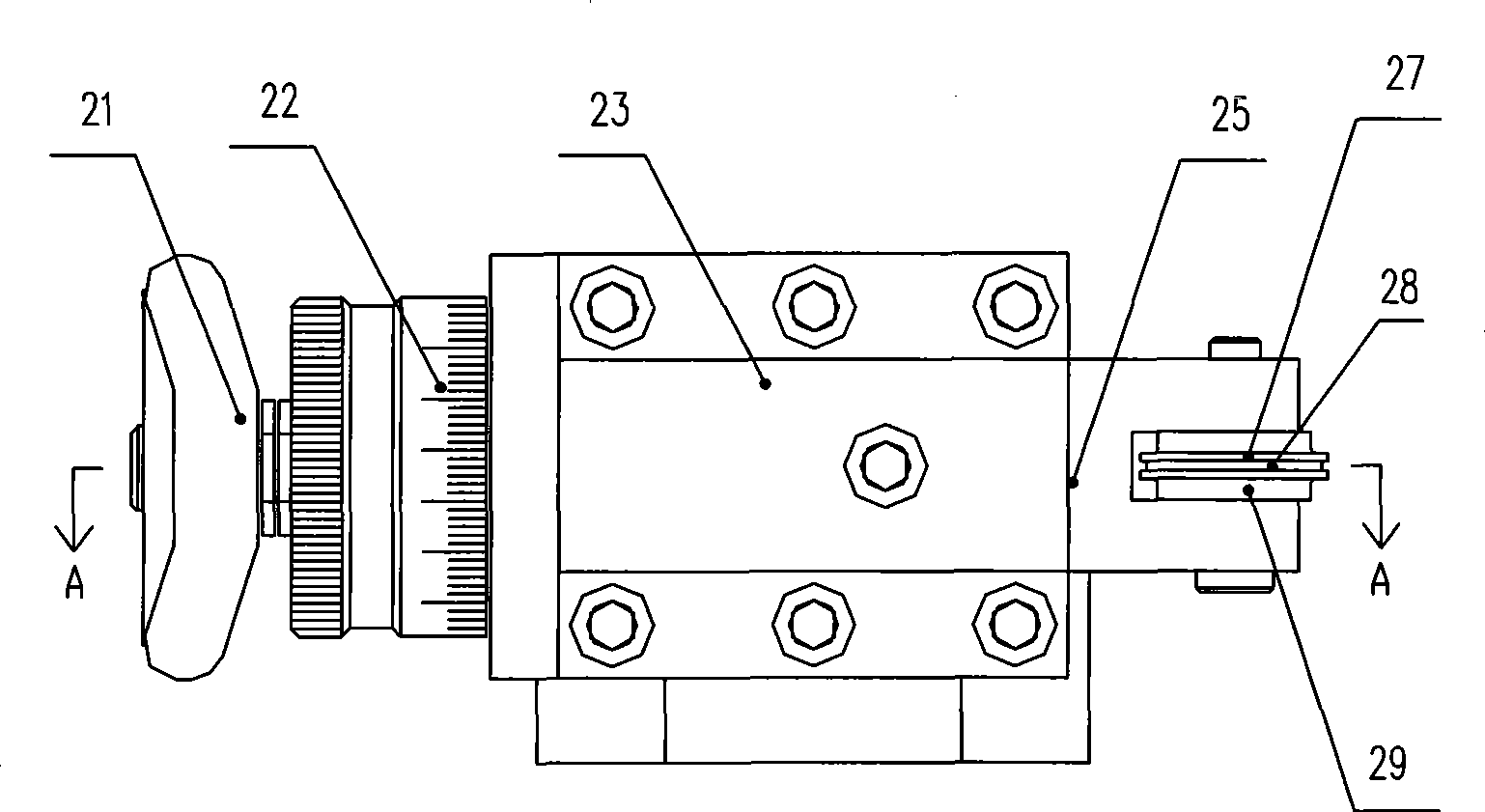

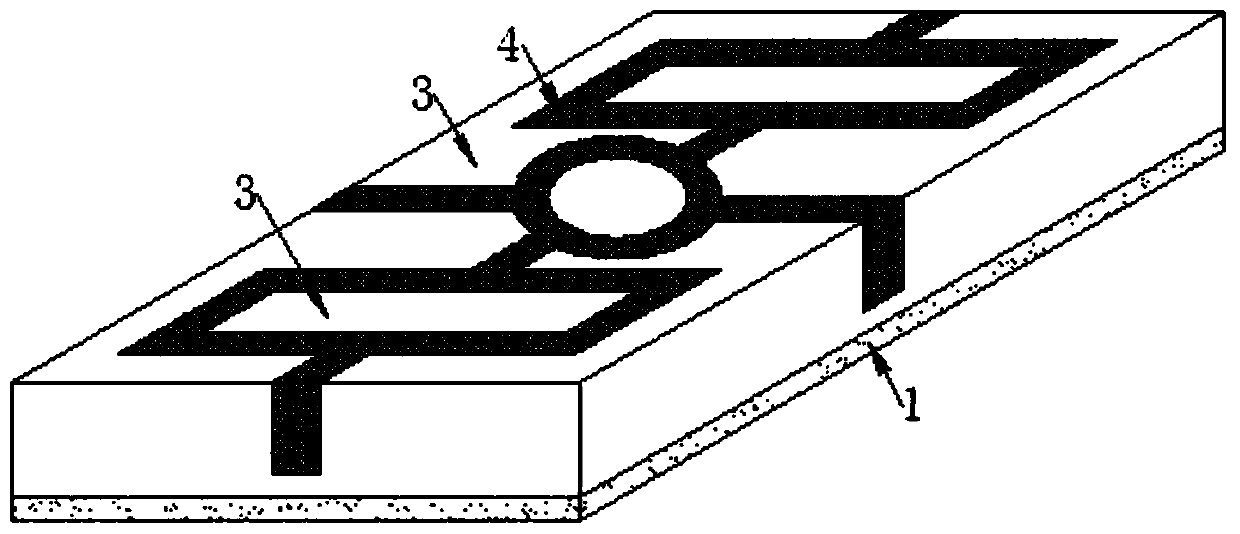

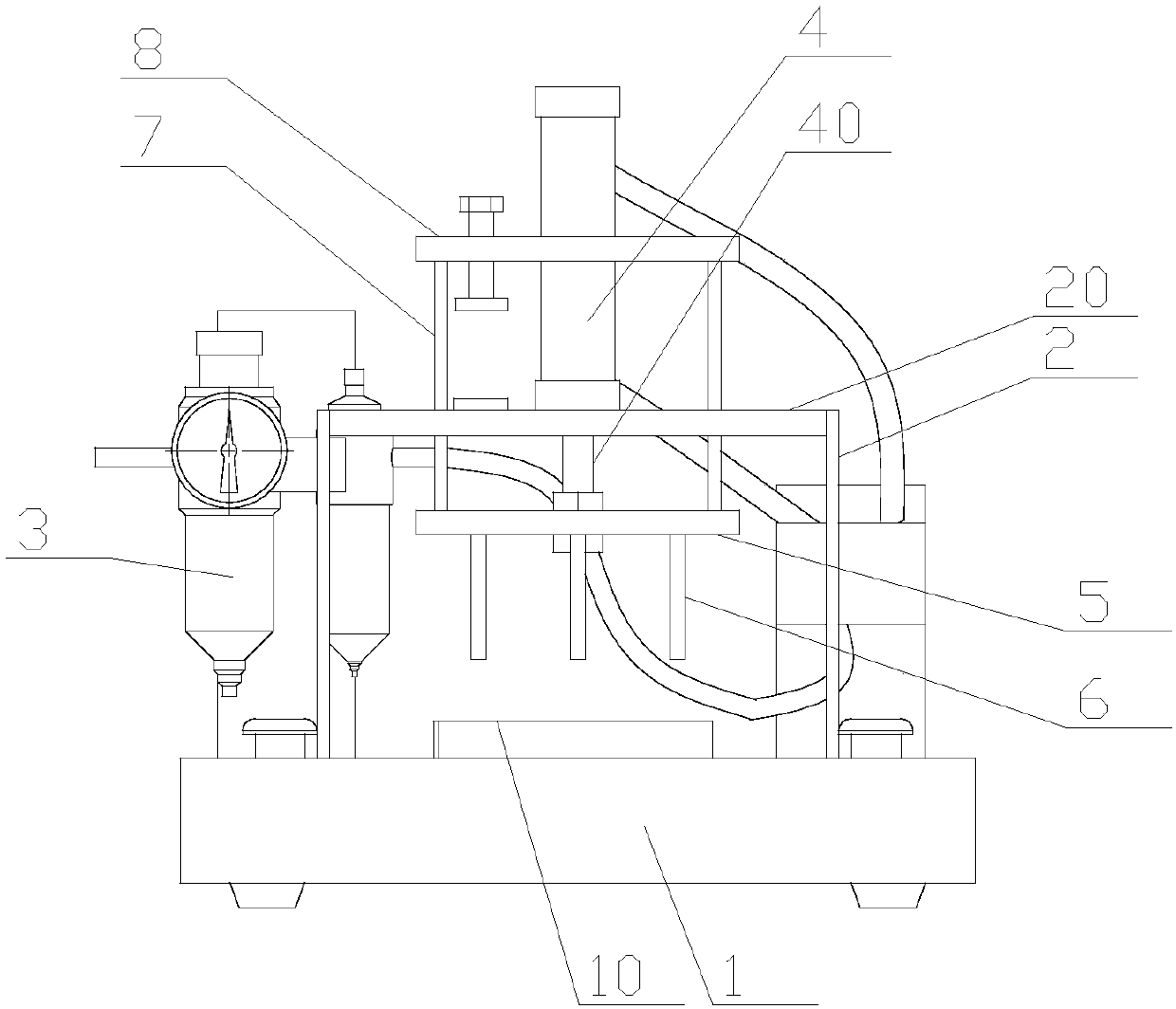

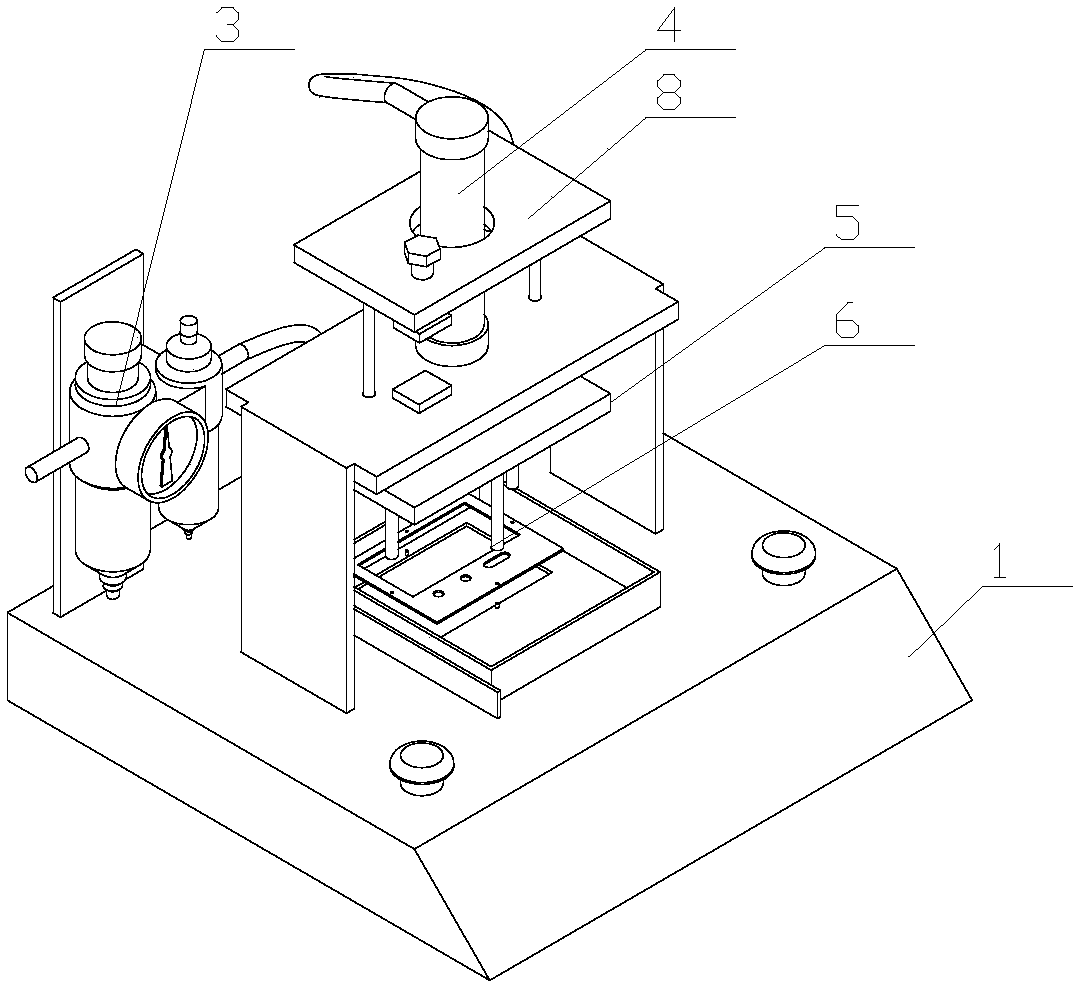

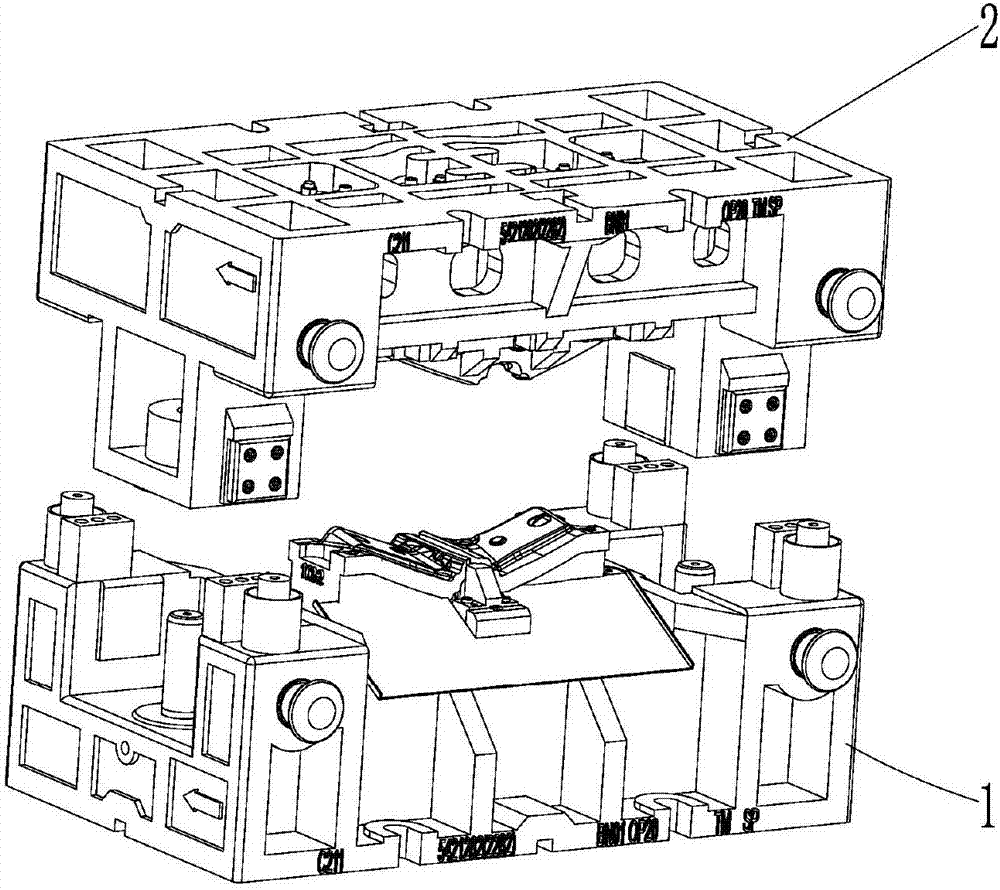

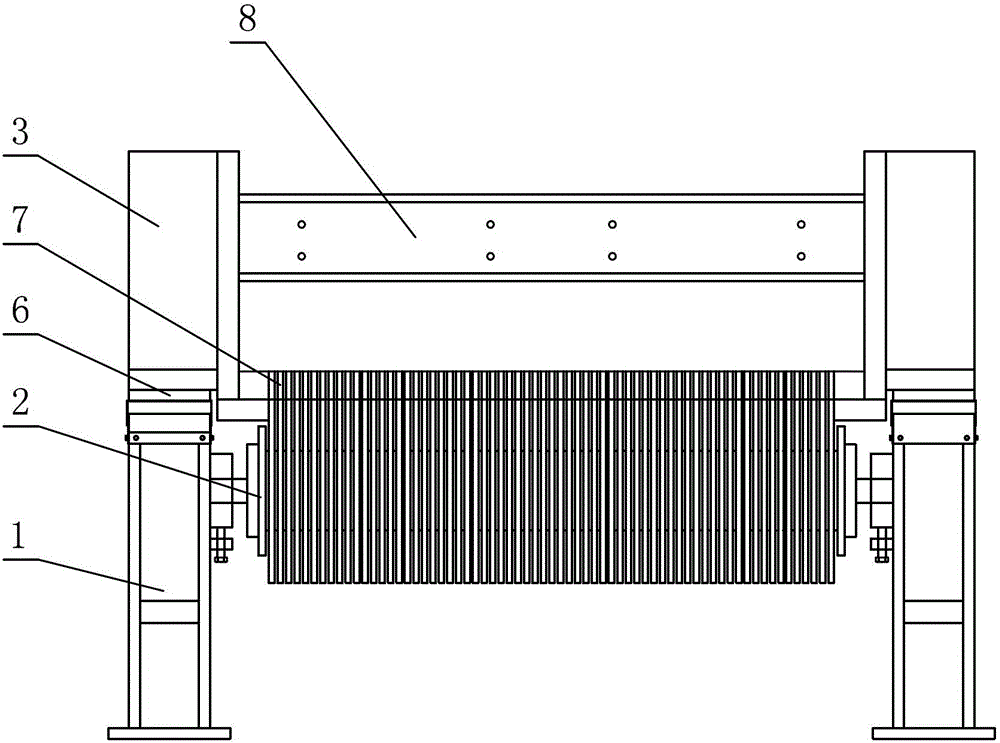

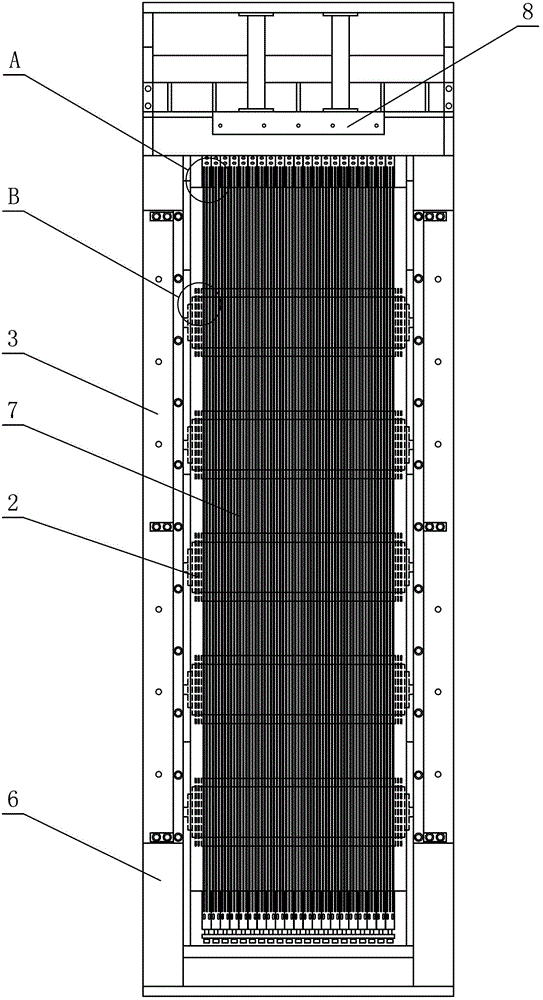

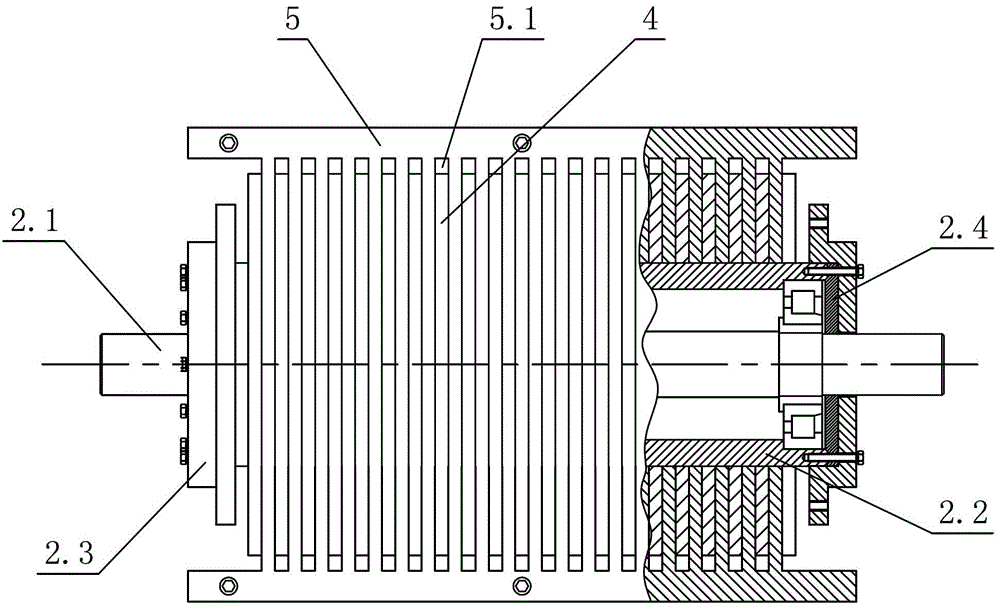

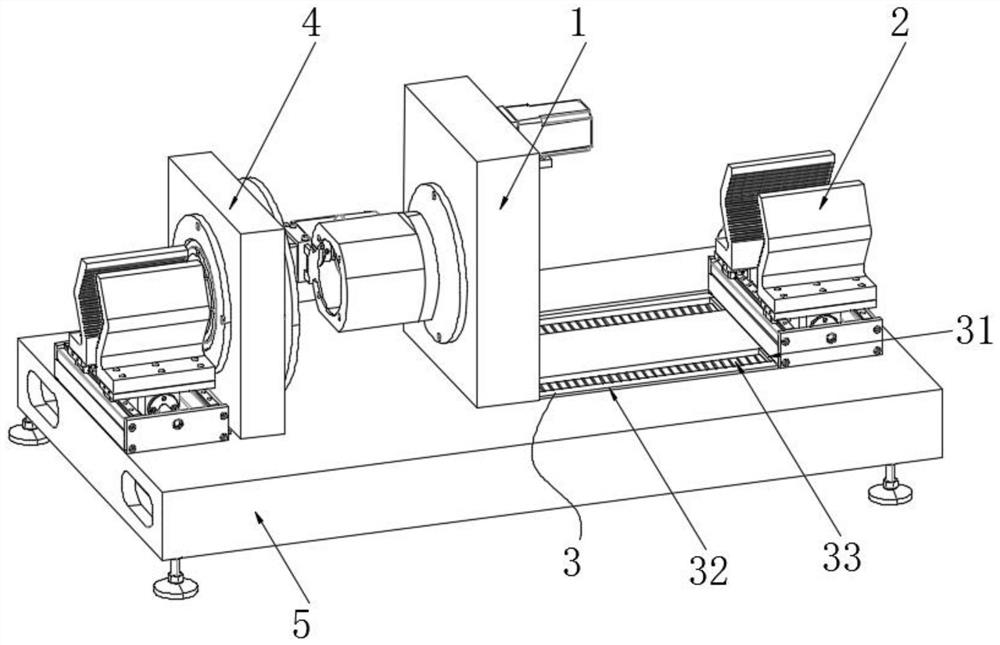

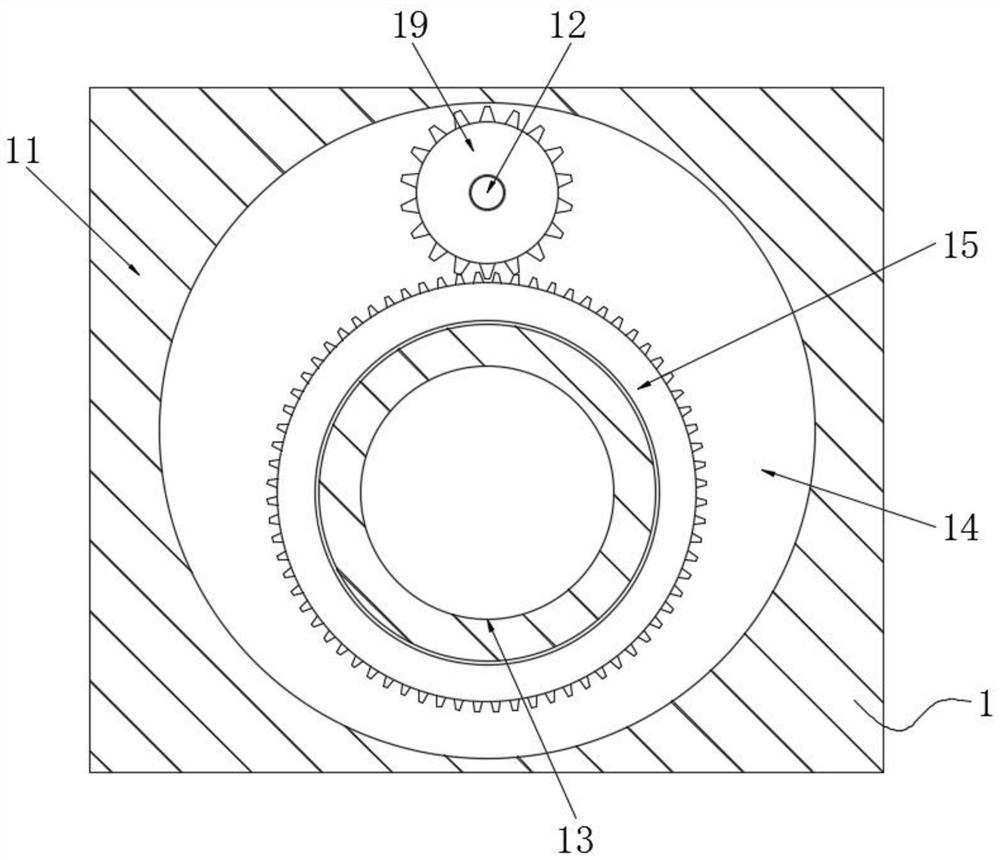

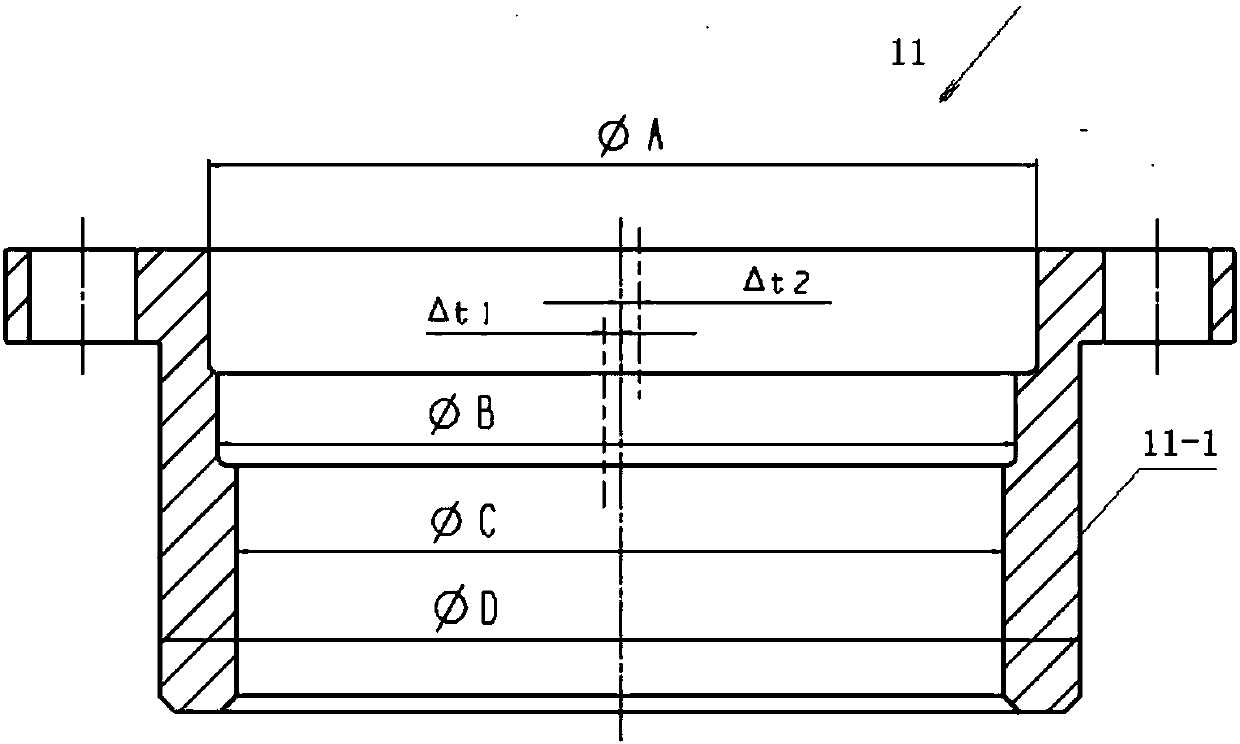

Metal axial-flow fan roller riveting and forming machine

ActiveCN101457765AImprove processing efficiencyHigh concentricityPump componentsPumpsProcess equipmentAutomation

The invention relates to processing equipment of a metal crossflow fan. A rolling-riveting shaping machine of the metal crossflow fan comprises a frame (1) and a rolling-riveting shaft rotating mechanism, a rolling-riveting mechanism (3) and a fastening mechanism (4) which are arranged on the frame (1). The rolling-riveting shaping machine of the metal crossflow fan has the advantages that: full-automation operation is employed, and an operator only needs to carry out operation on feeding and discharging; the processing efficiency is high; the coaxiality of each middle disc of the vane is very consistent, and the situation of radial jumping can not appear; moreover, the reject rate of processing is very low.

Owner:ZHEJIANG LANGDI GROUP

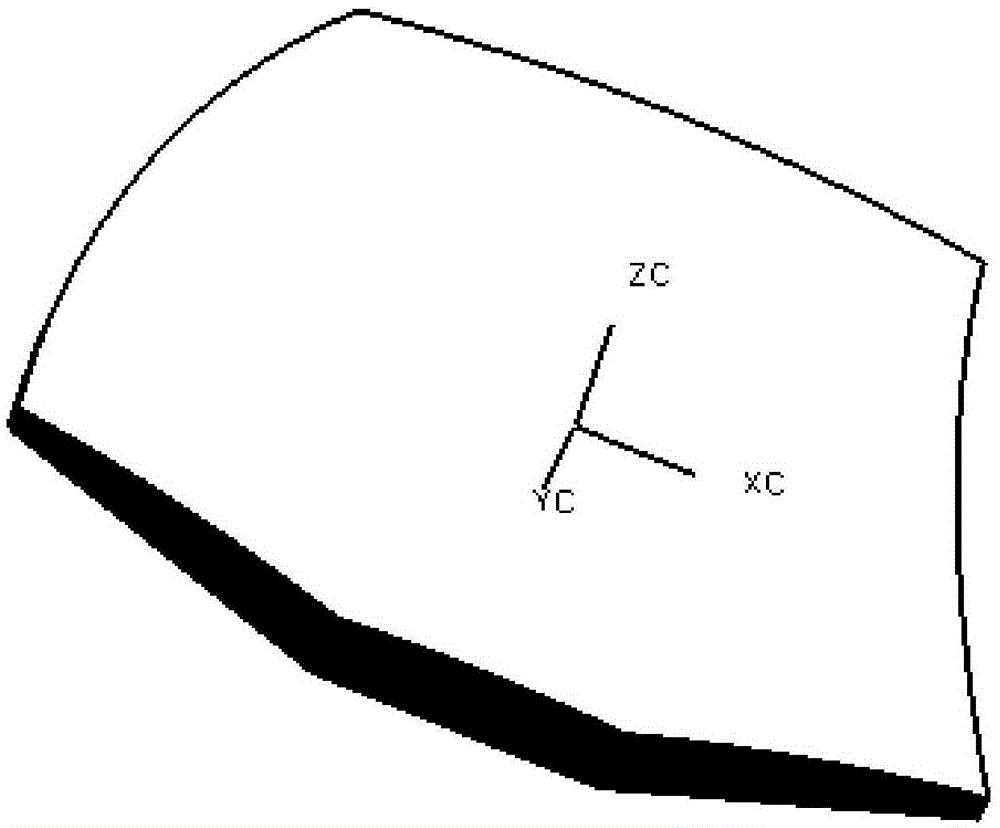

Special-shaped lens machining method based on computer aided manufacturing (CAM)

ActiveCN105538085AAvoid it happening againGet rid of precisionOptical surface grinding machinesModularityEngineering

The invention discloses a special-shaped lens machining method based on computer aided manufacturing (CAM). The special-shaped lens machining method based on CAM comprises the steps that a rotary symmetrical lens blank model is established, and the rotary symmetrical lens blank model is cut into a target special-shaped lens model; a right-handed coordinate system is adopted, the origin of coordinates is determined, the distance d between the zero point of the Z coordinate and an installation surface, used for being matched with a tool, on a lens blank meets the equation of d=delta Z-H, and H is the height of the tool; a cutter path is generated through CAM; post-processing is conducted, an NC program code is generated, and a tool axis and a cooling liquid control code are converted, so that a machining program is obtained; the lens blank is installed on the tool, and the outer circle of the lens blank is polished, so that the tool provided with the lens blank is obtained; and the outline of the lens blank is milled and ground according to the machining program till the boundary dimension and angle of the lens blank meet the design requirements. By the adoption of the special-shaped lens machining method based on CAM, machine-forming of the outline of a special-shaped lens is achieved, and the defects that the precision of manual milling and grinding is poor, and the efficiency of manual milling and grinding is low are overcome; the limitation that a machine tool is provided with modular software is broken through, and the machining efficiency and machining precision are improved; the rejection rate of machining is decreased; the technique is simple, operation is convenient, and the special-shaped lens machining method has good application prospects.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

High-precision processing method of long-strip reflecting mirror

InactiveCN107775453AImprove processing efficiencyImprove machining accuracyOptical surface grinding machinesWaste productSurface type

The invention provides a high-precision processing method for a long-strip reflecting mirror. The method includes the following steps that a semi-finished product is obtained, the reference plane of the semi-finished product is milled through a DMG ultrasonic-wave milling machine, a weight-reduction positioning hole is milled, and through the combination of manual polishing and QED magnetorheological polishing, the to-be-polished optical surface is programmed; optical surface type data is measured, and based on the requirement of a drawing, surface type correction is conducted. According to the high-precision processing method for the long-strip reflecting mirror, the processing efficiency and accuracy of the long-strip reflecting mirror are improved, and the high-precision long-strip reflecting mirror can be processed. The processing difficulty and the detection difficulty are effectively reduced, production of waste products is avoided, the rejection rate of processing is reduced, the process is simple, operation is convenient, and the method has a good application prospect.

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

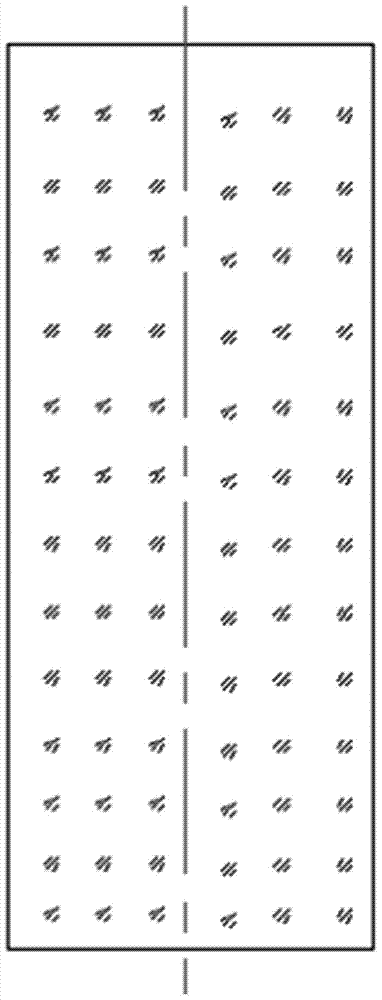

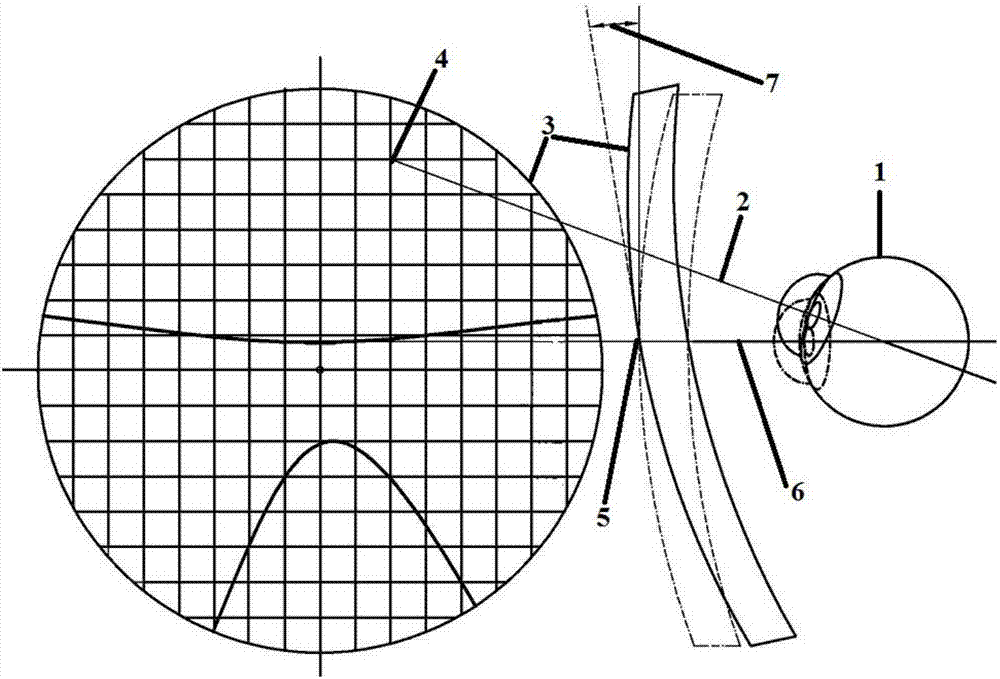

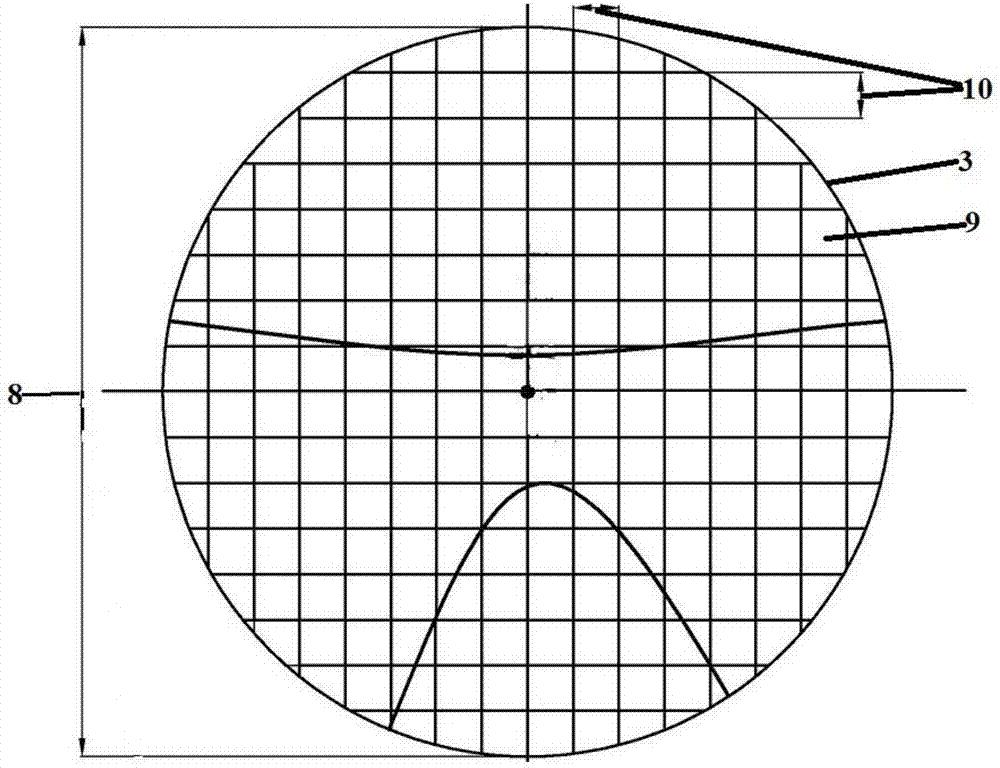

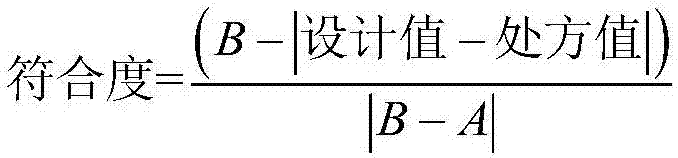

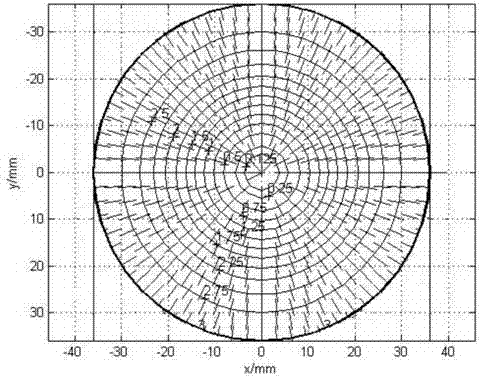

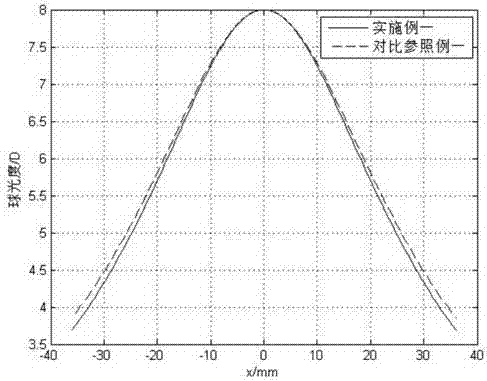

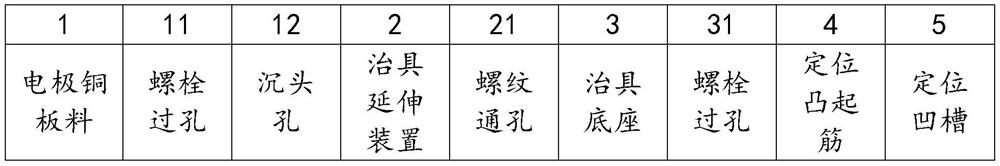

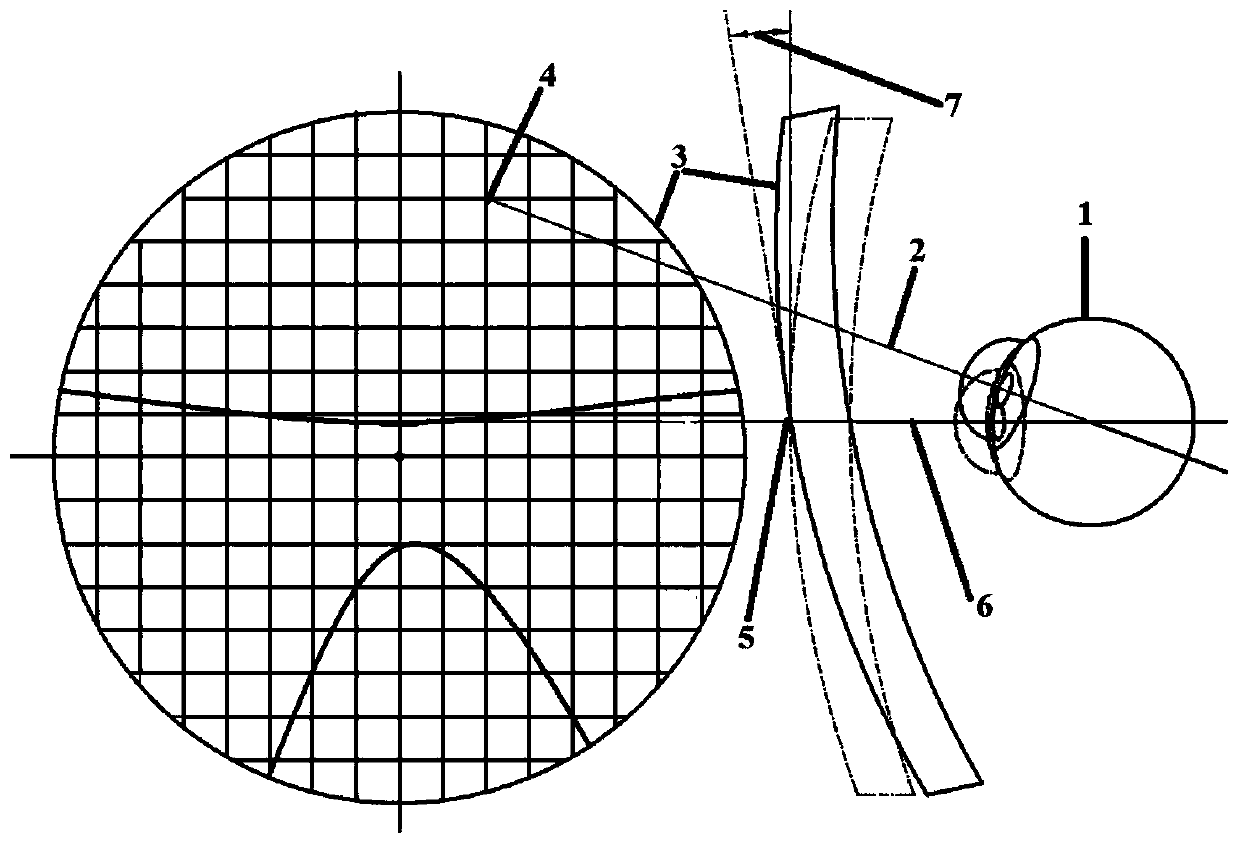

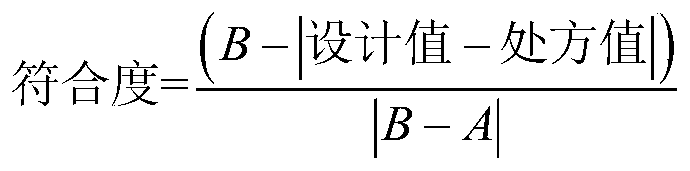

Progressive addition freeform-surface lenses performance evaluation method

InactiveCN106932921AShorten the design cycleReduce processing scrap rateOptical partsOptical axisAxial distribution

The invention relates to a progressive addition freeform-surface lenses performance evaluation method. The method is a method for evaluating focal power, astigmatism and axial distribution of lenses when a person wears progressive addition freeform-surface lenses in the multiple optical axes state from the perspective of multiple optical axes in the design stage. According to the invention, the influence of optical axis change on focal power, astigmatism and axial distribution of lenses when a person wears progressive addition freeform-surface lenses to see faraway and near places and perimeter zone in the multiple optical axes state is provided, and conformity and weighting factor of different areas of the lenses also can be provided. After normalization processing, weight factor thresholds of focal power of lenses' lattice points, astigmatism and axial distribution of the progressive addition freeform-surface lenses in the multiple optical axes state are calculated for evaluation. According to the weight factor thresholds, the difference between the progressive addition freeform-surface designed in the multiple optical axes state and a prescription is obtained, and errors of parameters in the design process are understood. By the evaluation method, design period can be shortened, rejection rate of processing can be reduced, and product qualification ratio can be raised.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

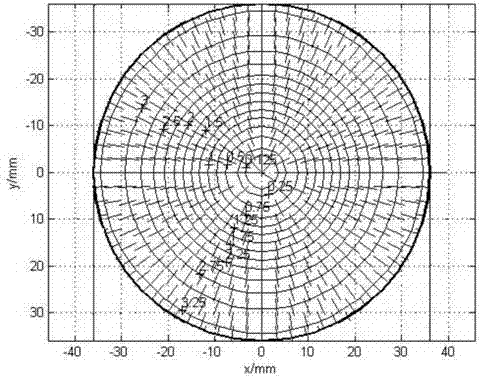

Evaluation method of free cambered lens with high curvature and large caliber and design processing method thereof

ActiveCN103487947AReduce processing scrap rateImprove pass rateOptical partsEvaluation resultRejection rate

The invention discloses an evaluation method of a free cambered lens with high curvature and large caliber and a design processing method thereof. With the adoption of the technical scheme, an ordinary free cambered lens can be evaluated, besides, the free cambered lens with the high curvature and the large caliber can be evaluated; and for a high-degree lens or a lens edge position, an evaluation result is more close to a theoretical value, not only can spherical photometric values and astigmatic degree values of all points of the lens be given, but also astigmatic directions of all points can be given. At the same time, the method can evaluate the lens accurately in a design process, design parameters are adjusted according to the evaluation result and by combining actual processing errors, and processing is performed again, so that the processing rejection rate can be decreased, the product yield is increased, and industrial popularization and application are facilitated.

Owner:SUZHOU UNIV +1

Cold machining method of Inconel 706

The invention relates to a cold machining method, in particular to a cold machining method of Inconel 706 and aims to solve the problem that the surface quality of workpieces machined by the prior part are defective and safety accidents occur easily. The cold machining method includes: firstly, measuring; secondly, laying a test ring into a mould spigot; thirdly, turning the upper end of the test ring by an end-turning tool; and fourthly, turning outer periphery of the test ring by an external turning tool. Surface quality of workpieces machined by the cold machining method is higher, machining rejection rate is lower, quality of fine machined surfaces of Inconel 706 parts is higher, and unsatisfactory waste products are decreased. The cold machining method is used for cold machining of Inconel 706.

Owner:HARBIN TURBINE

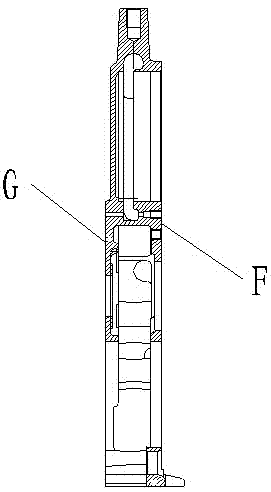

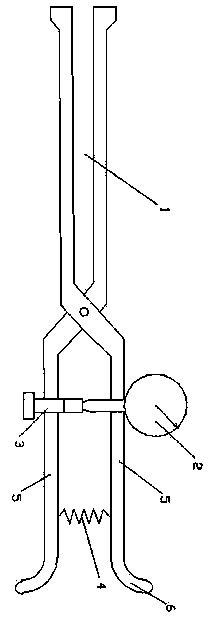

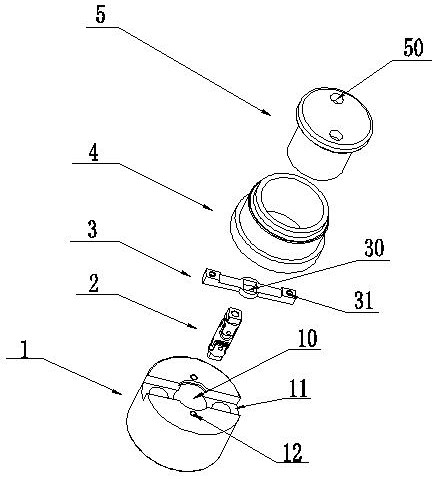

Movable elastic airtight detecting device

ActiveCN102941505AReduce processing scrap rateThe overall structure is simple and reliableMeasurement/indication equipmentsMetal working apparatusEngineeringSmall hole

The invention relates to a movable elastic airtight detecting device which comprises a fixture and a tray. An air guide base is fixed on the fixture, and an airway communicated with a mounting hole of the air guide base is opened on the fixture; an air guide bar in a sliding matching inside the air guide base is fixed under the tray, and a first through hole communicated with a second through hole on the tray and the airway on the fixture is opened in the air guide bar; a base is fixed on the tray, a horizontal stepped hole and a third through hole communicated with the stepped hole are arranged in the base, and the other end of the third through hole is communicated with the second through hole; an ejecting rod is in a sliding matching inside the stepped hole, the front end of the ejecting rod stretches out of the base from a small hole of the stepped hole, and a spring is arranged between the back end and the base; and a second vent hole is arranged in the ejecting rod, and a first vent hole and a third vent hole which are communicated with the second vent hole are opened on the side wall of the ejecting rod. According to the device, a workpiece can be pushed to a locating point on the tray accurately, so that the processing rejection rate can be reduced greatly.

Owner:WUXI BEST PRECISION MACHINERY

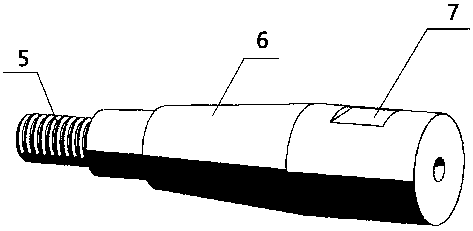

Gauge used for measuring inner groove diameter of elongated hole

InactiveCN105021107ASimple structureEasy to useMechanical diameter measurementsBiochemical engineeringCalipers

The invention relates to a gauge used for measuring the inner groove diameter of an elongated hole, which comprises a caliper gauge, a dial indictor, an adjustment lever and a spring, wherein the caliper gauge is of a pincer-shaped structure and formed by hinging two measuring rods, one of the measuring rods of the caliper gauge is fixedly provided with the dial indicator, the other measuring rod is fixedly provided with the adjustment lever, the adjustment lever corresponds to the dial indicator in position, the length of the adjustment lever relative to the measuring rods can be adjusted, and measuring ends of the two measuring rods are connected through the spring. The gauge provided by the invention is simple in structure, convenient to use, convenient for measurement at any time in processing at the production field, can improve the processing quality and reduce the processing rejection rate, and has the characteristics of high detection efficiency and high universality.

Owner:成都九龙柜业有限公司

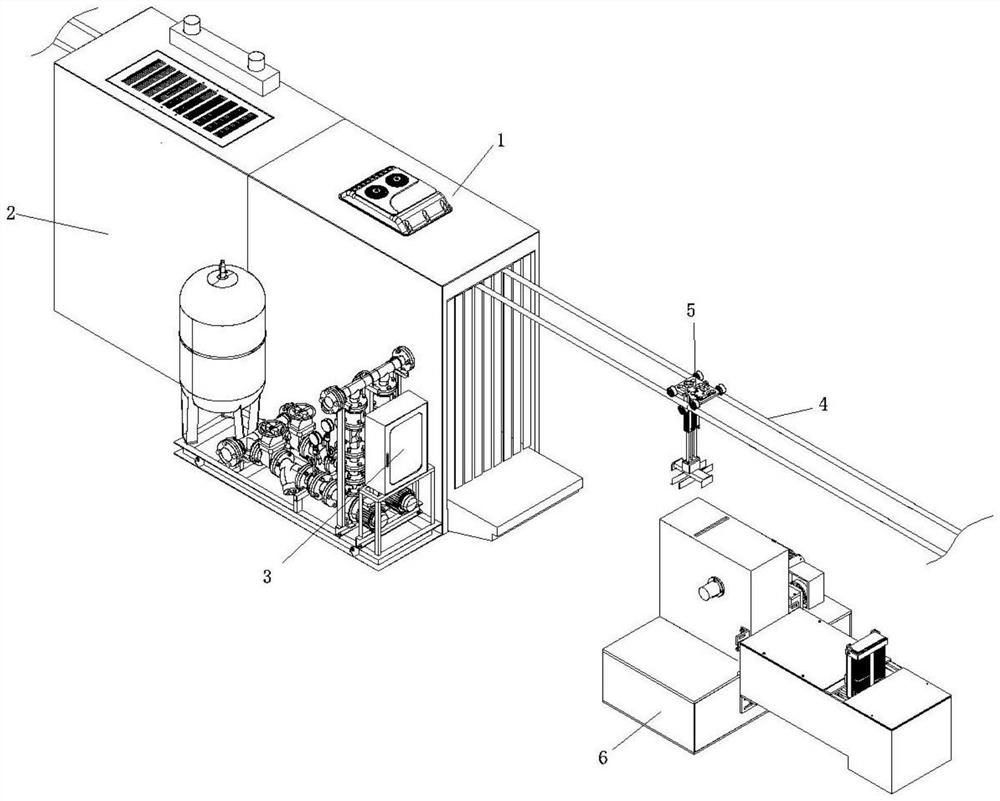

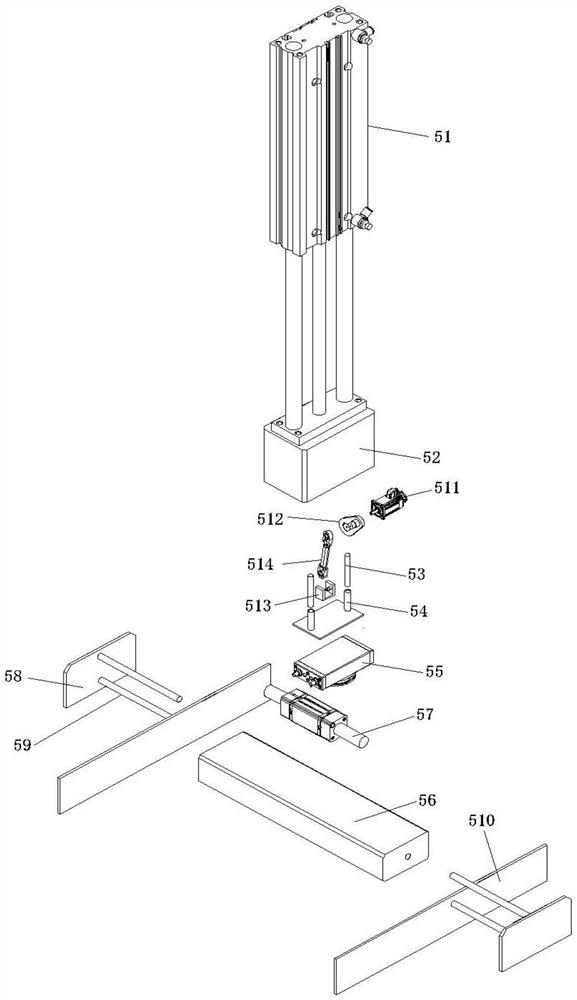

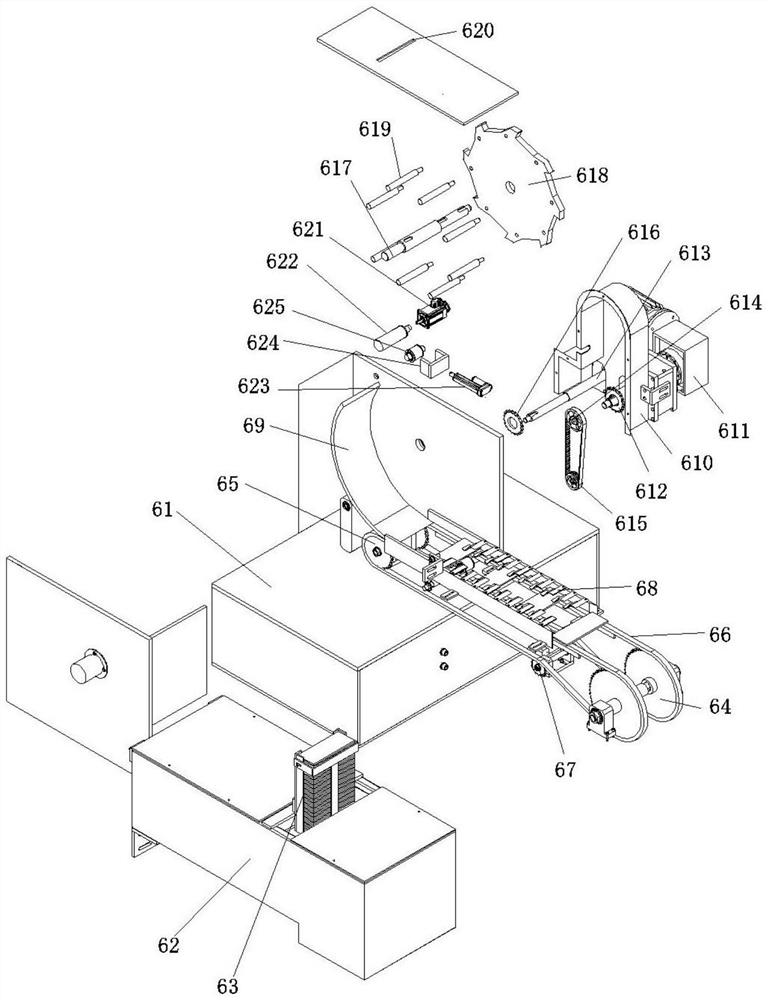

Industrial automatic coating production line

ActiveCN114226108ATimely detection of hanging flow phenomenonHigh degree of automationSpray boothsConveyor partsProcess engineeringManufacturing line

The invention discloses an industrial automatic coating production line which comprises a coating machine, a drying machine, a control box, a hoisting conveyor, a moving mechanism and a feeding mechanism. The dryer is arranged on the left side of the coating machine and is communicated with the coating machine; the control box is arranged on the outer side of the coating machine; the hoisting conveyor is arranged above the inner side of the coating machine and the inner side of the drying machine in the left-right direction, and the hoisting conveyor is electrically connected with the control box; the moving mechanism is mounted at the moving end of the hoisting conveyor; the feeding mechanism is arranged on the lower right portion of the hoisting conveyor. According to the industrial automatic coating production line, workpieces can be hoisted, conveyed and automatically fed in the industrial automatic coating production process, the automation degree is high, compared with mechanical arm carrying, the occupied production space is small, in the coating process, the sprayed workpieces can be vibrated up and down, workers can conveniently find the workpiece surface hanging phenomenon in time, and the coating efficiency is improved. The machining rejection rate is reduced.

Owner:昆山市圣吉川工业自动化设备有限公司

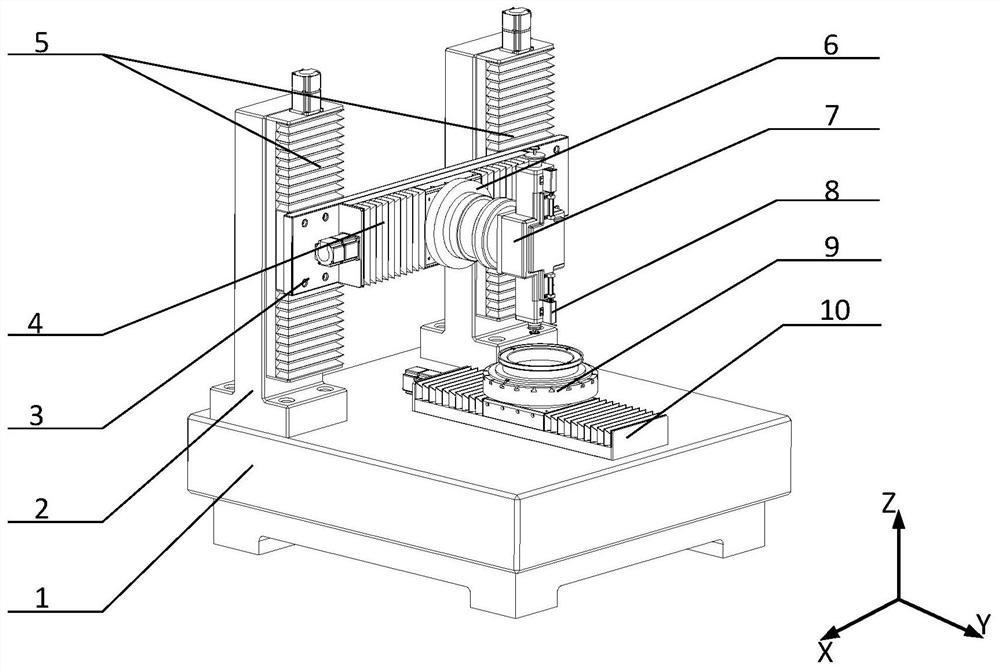

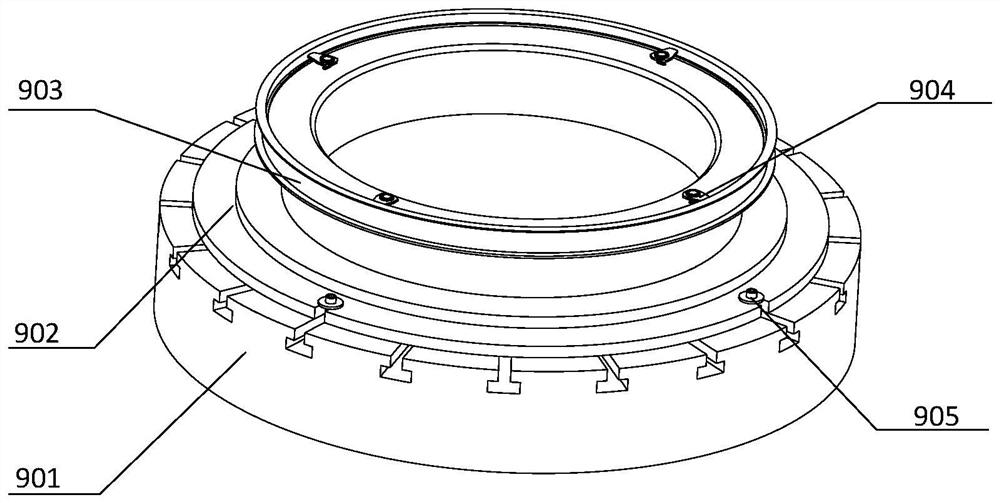

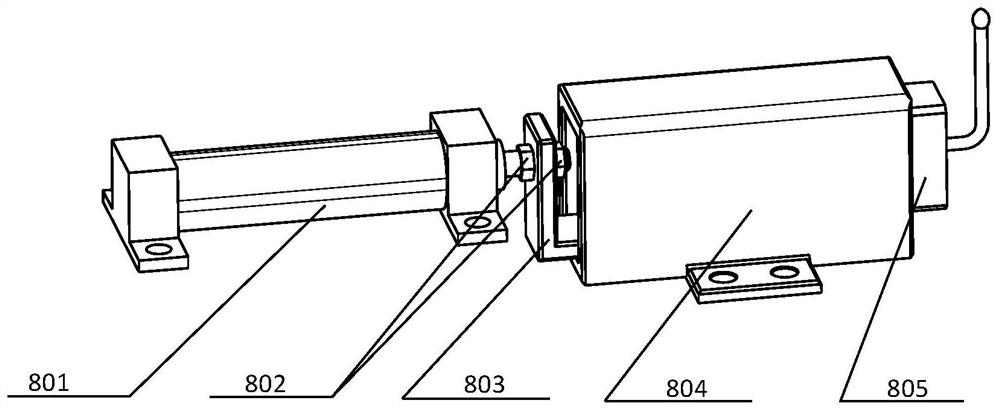

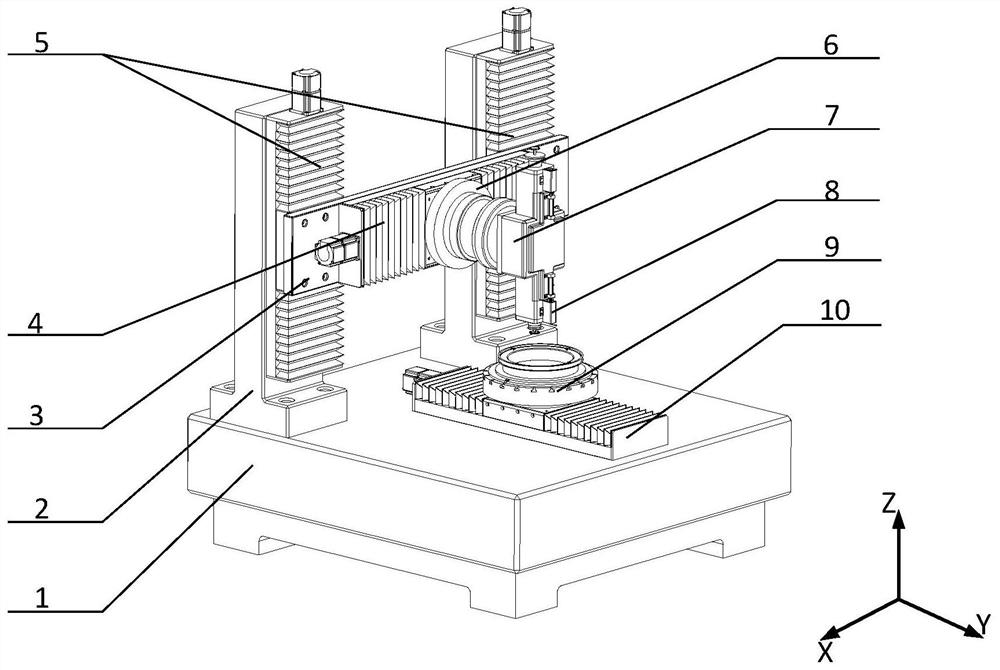

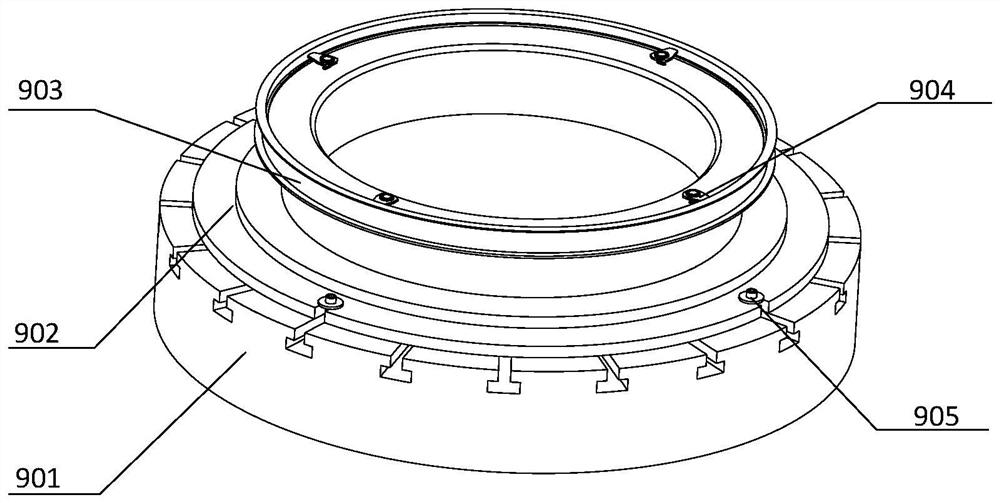

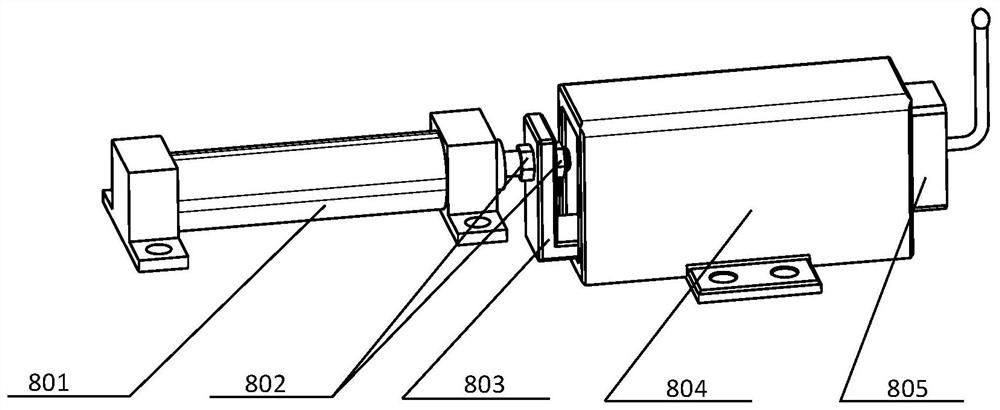

Annular workpiece milling, grinding and measuring integrated machining machine tool and control method thereof

ActiveCN112025315AReduce labor intensityReduce processing stepsProgramme controlComputer controlRotary stageEngineering

The invention discloses an annular workpiece milling, grinding and measuring integrated machining machine tool which comprises a machine tool base, a Z-axis mounting support, an X-axis mounting panel,an X-axis moving device, a Z-axis moving device, a B-axis rotating table, a milling and grinding operation system, a measuring mechanism, a workbench and a Y-axis moving device. The Z-axis mounting support is fixed to the machine tool base, the Z-axis moving device is fixed to the Z-axis mounting support, the X-axis mounting panel is fixed to the Z-axis moving device and is driven by the Z-axis moving device to move up and down in the Z-axis direction, and the X-axis moving device is fixed to the X-axis mounting panel. The B-axis rotating table is fixed to the X-axis moving device and drivenby the X-axis moving device to move leftwards and rightwards in the X-axis direction, the milling and grinding operation system is fixed to the B-axis rotating table, the measuring mechanism is fixedto the end of the milling and grinding operation system, the workbench is fixed to the Y-axis moving device and driven by the Y-axis moving device to move forwards and backwards in the Y-axis direction, and the Y-axis moving device is fixed to the machine tool base. Meanwhile, the invention discloses a control method of the annular workpiece milling, grinding and measuring integrated machining machine tool.

Owner:JILIN UNIV

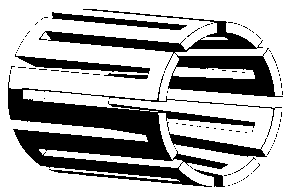

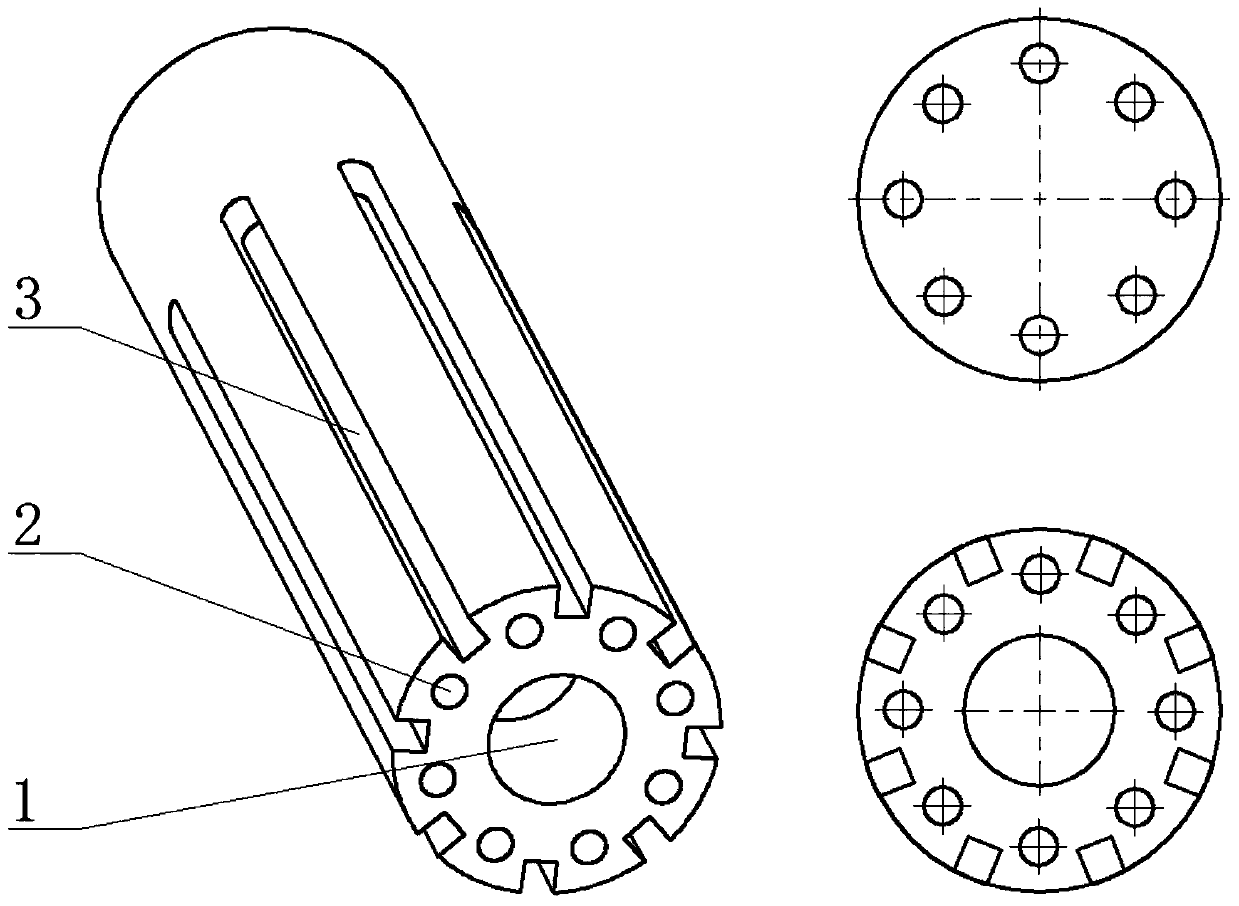

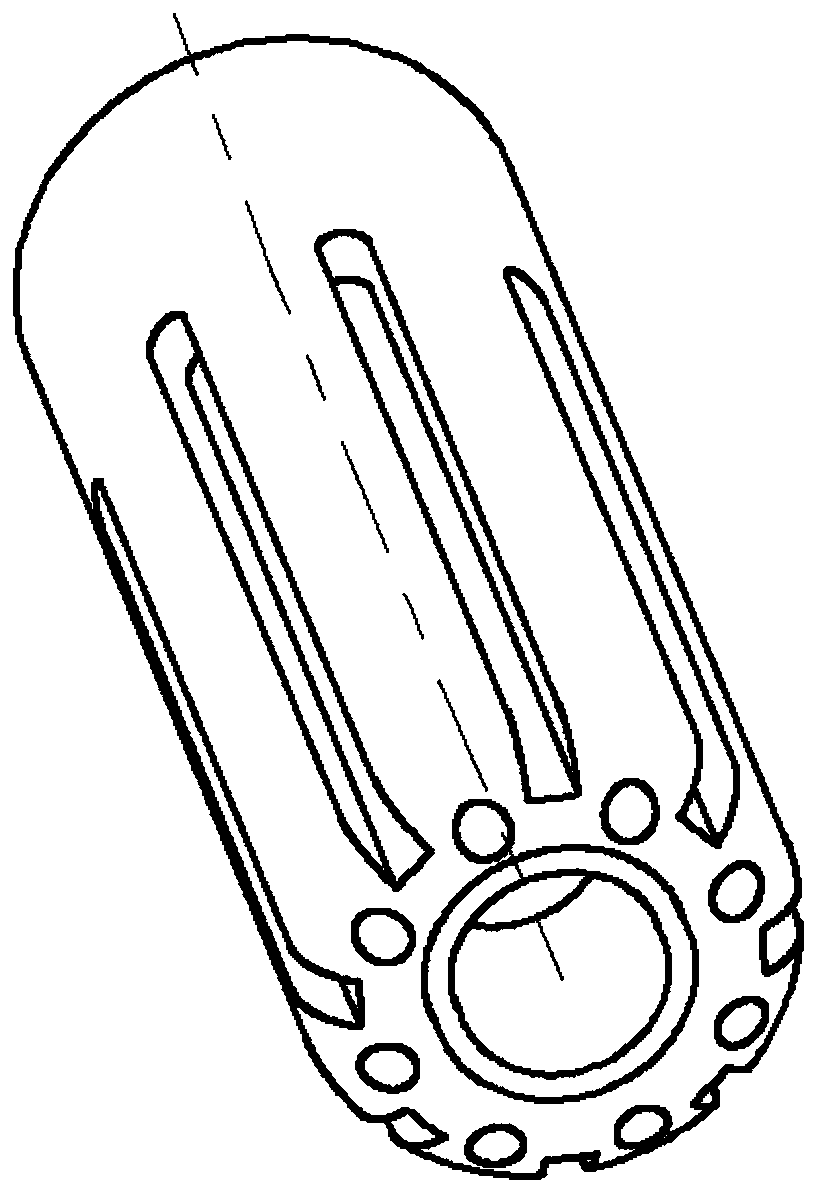

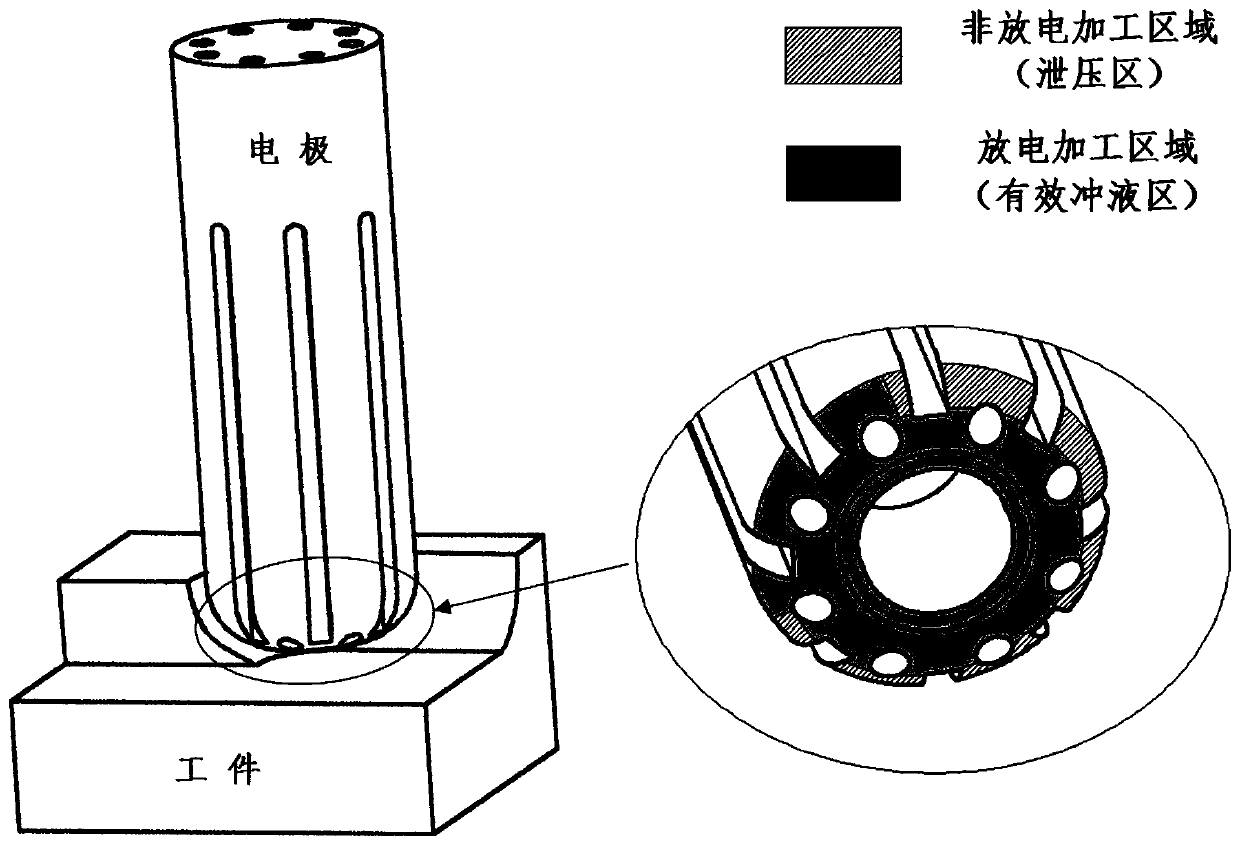

Anti-short-circuit porous high-efficiency flushing electrode for arc discharge machining

ActiveCN108620699BEasy to passRealize strong flushingElectrical-based machining electrodesMachined surfaceEngineering

A short circuit prevention porous efficient liquid flushing electrode for arc discharge machining is characterized in that the electrode is cylindrical; the central area of the bottom of the electrodeis provided with a blind hole along the electrode axis; a plurality of inner liquid flushing through holes are distributed in one periphery of the outer side area of the bottom of the electrode in the axial direction; the side face of the electrode is provided with a plurality of liquid flushing chip discharge grooves, so that the side face of the electrode forms a discontinuous surface; each liquid flushing chip discharge groove is open in the bottom face of the electrode; and the openings of the liquid flushing chip discharge grooves and the inner liquid flushing through holes are formed ina staggered mode. According to the electrode, the decompression effect on work liquid from a non-discharge machining area can be reduced effectively, strong inner liquid flushing of the discharge machining area is maintained, a short circuit phenomenon is prevented, the quality of the machined surface is promoted, the machining rejection rate is lowered, and uniformity of electrode loss and the precision of the machining size are improved.

Owner:SHANGHAI JIAO TONG UNIV

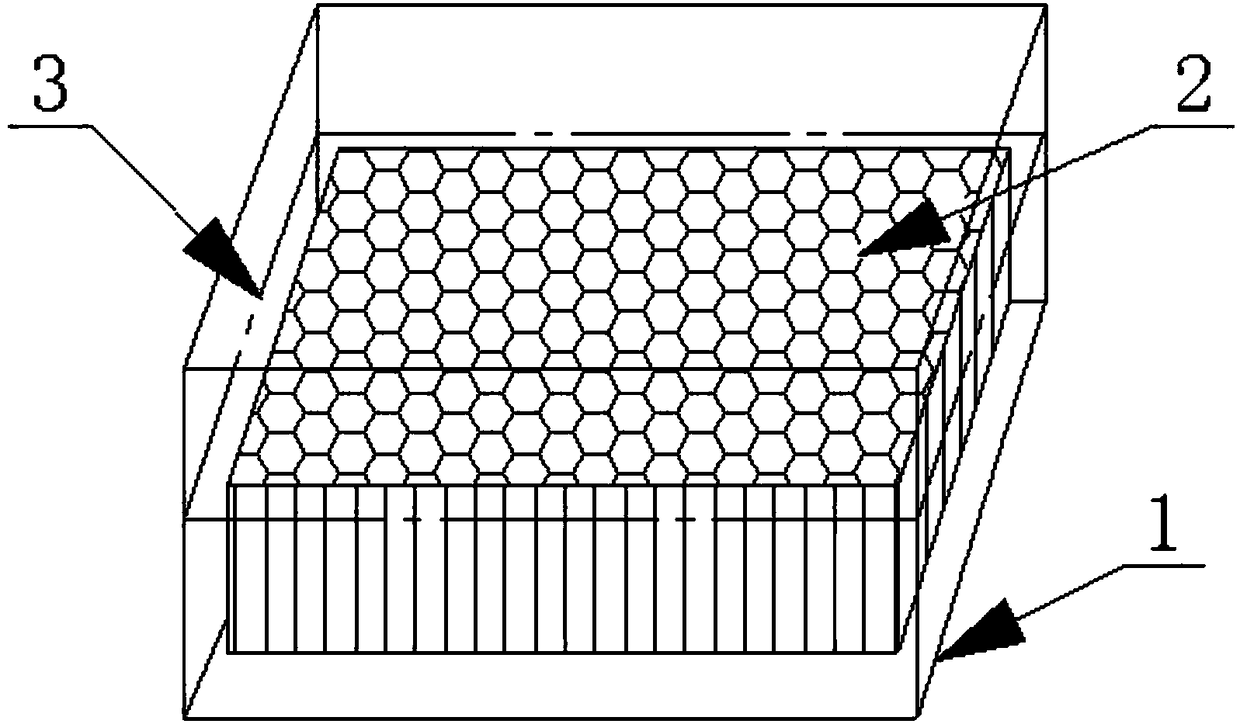

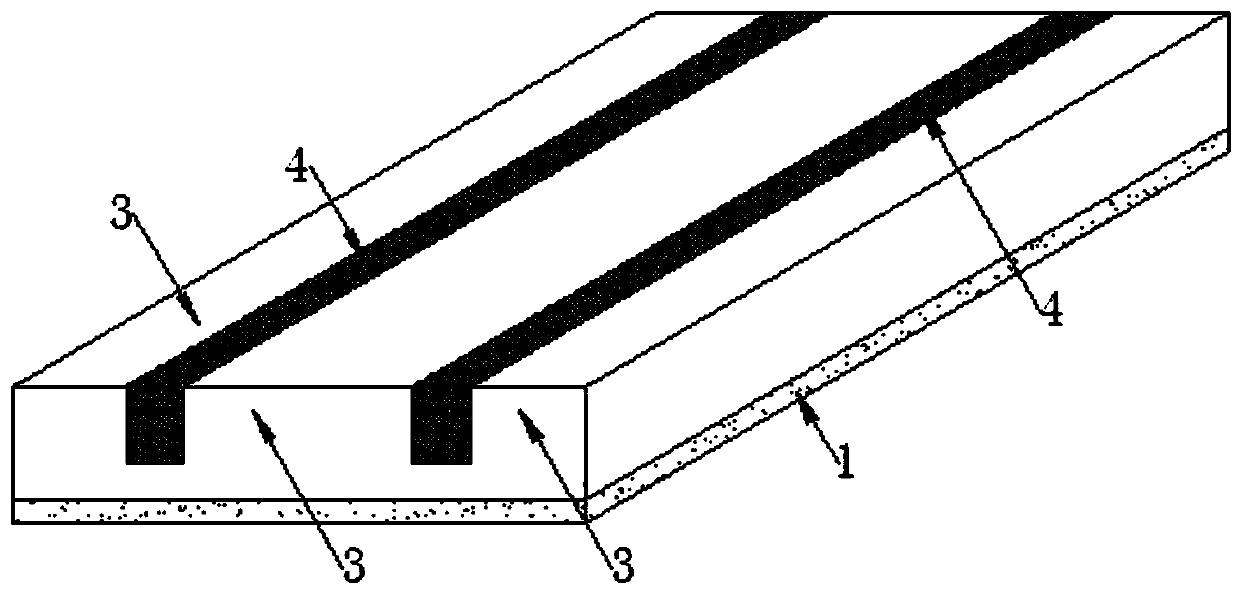

Low-cost honeycomb curved face machining method

InactiveCN108297163AReduce distortionAvoid dependenceMetal sawing devicesMetal working apparatusNumerical controlHoneycomb

The invention relates to a low-cost honeycomb curved face machining method. The low-cost honeycomb curved face machining method includes the steps that water and to-be-machined honeycomb blocks are placed into a container, and the honeycomb blocks are completely immersed in the water; the water in the container is iced, the honeycomb blocks filled with ice blocks are subjected to demolding and taken out, and are clamped to a numerical control machine tool after being firstly sawn into blank pieces, and mechanical cutting and machining are performed on the blank pieces; then thawing is performed, and after the ice blocks in honeycomb hole grids fall off, honeycomb products are taken out and dried; and the water is recycled and reused, and cutting particles generated in the machining processare collected and treated. According to the low-cost honeycomb curved face machining method, on the basis of the water phase changing icing principle, the honeycomb hole grids are filled with water in a manner that the water is in a solid state manner, a honeycomb and ice are integrated, the honeycomb can be directly clamped on a machining platform like a metal block, depending of the honeycomb curved face products on an auxiliary mold is effectively reduced, the mold preparing time is shortened, and the mold preparing cost is reduced.

Owner:DONGHUA UNIV +1

Electric vehicle reducer gear shaft assembly structure

InactiveCN104265840AImprove machining accuracyGood processing consistencyToothed gearingsAssembly machinesNoise, vibration, and harshnessGear wheel

An electric vehicle reducer gear shaft assembly structure comprises an input shaft assembly, an output shaft and a differential mechanism assembly and is characterized in that a ratchet wheel and an output gear which is meshed with the input shaft assembly are sequentially installed on the output shaft in a press fitting mode; a cone bearing is installed on a shaft shoulder of the output gear in a press fitting mode; an output shaft shoulder which is close to a meshed position of the output shaft and the differential mechanism assembly is provided with a cone bearing; a graded snap spring is arranged on the press fitting external side portion of the output shaft and the output gear. The electric vehicle reducer gear shaft assembly structure is impact and light. According to the electric vehicle reducer gear shaft assembly structure, the length of a gear shaft string is shortened, the axial length, the size and the weight of a reducer is reduced, and the gear accuracy is improved due to a gear structure design; the gear machining and assembling error caused by spline is avoided and accordingly the gear accuracy is improved due to a gear machining and assembling scheme; meanwhile the NVH (Noise Vibration and Harshness) performance, the gear intensity service life and the cone bearing service life are improved.

Owner:BRILLIANCE AUTO

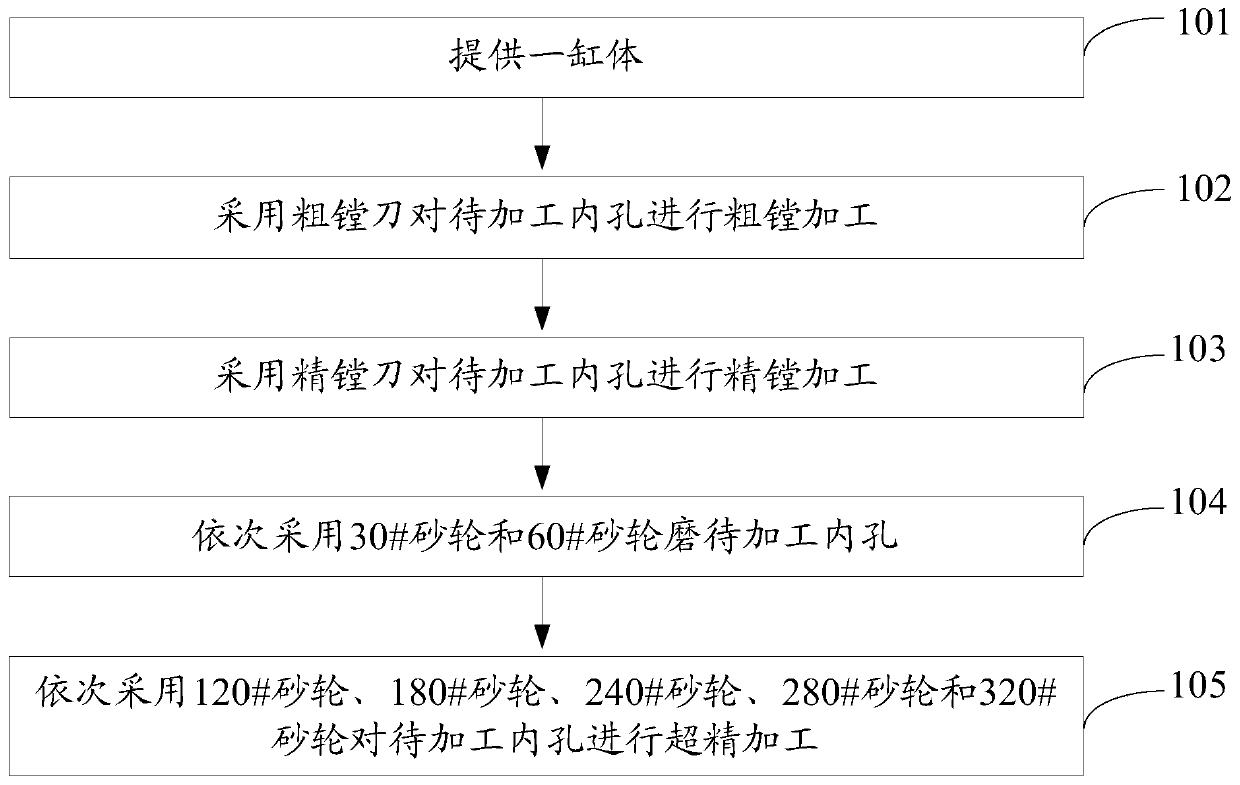

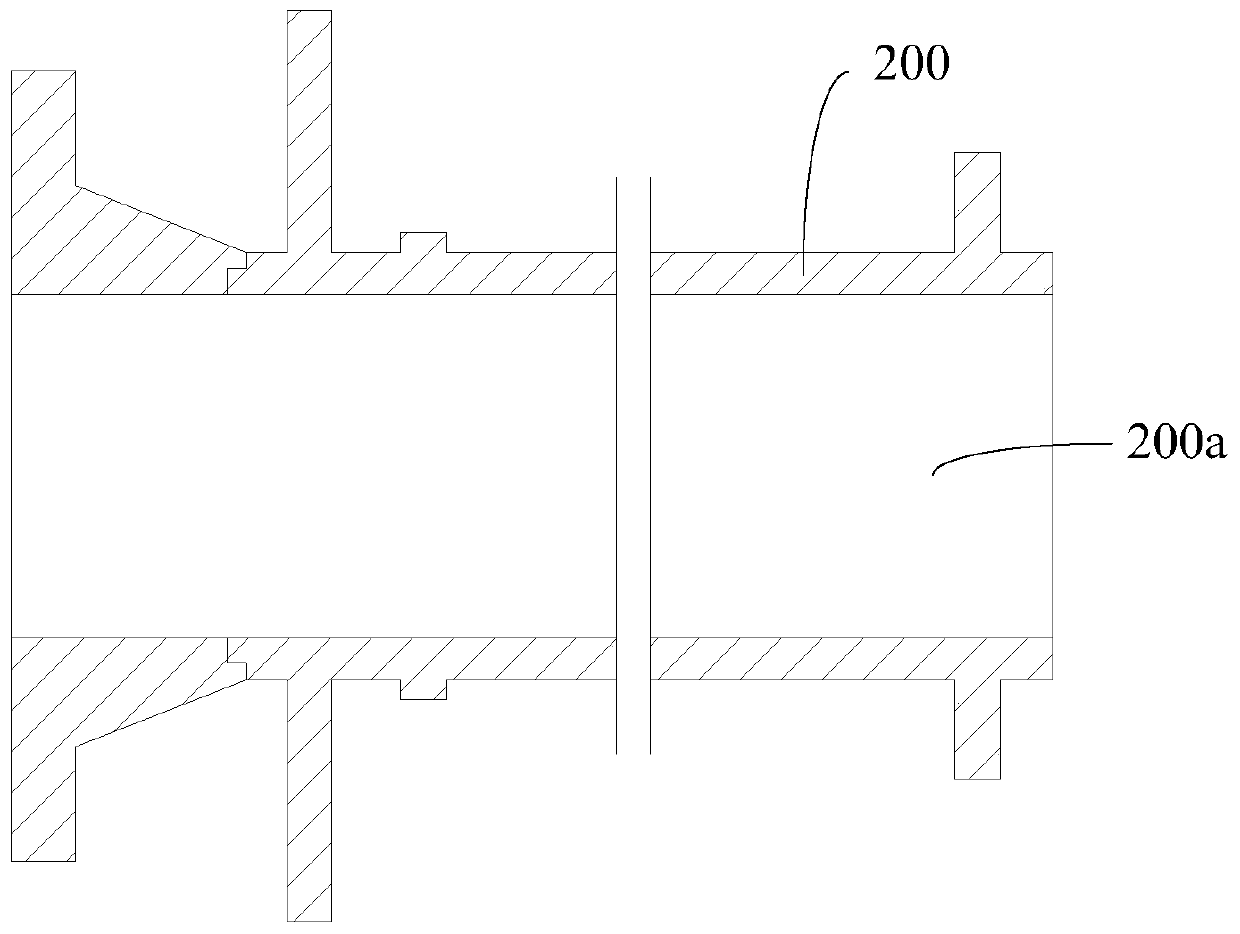

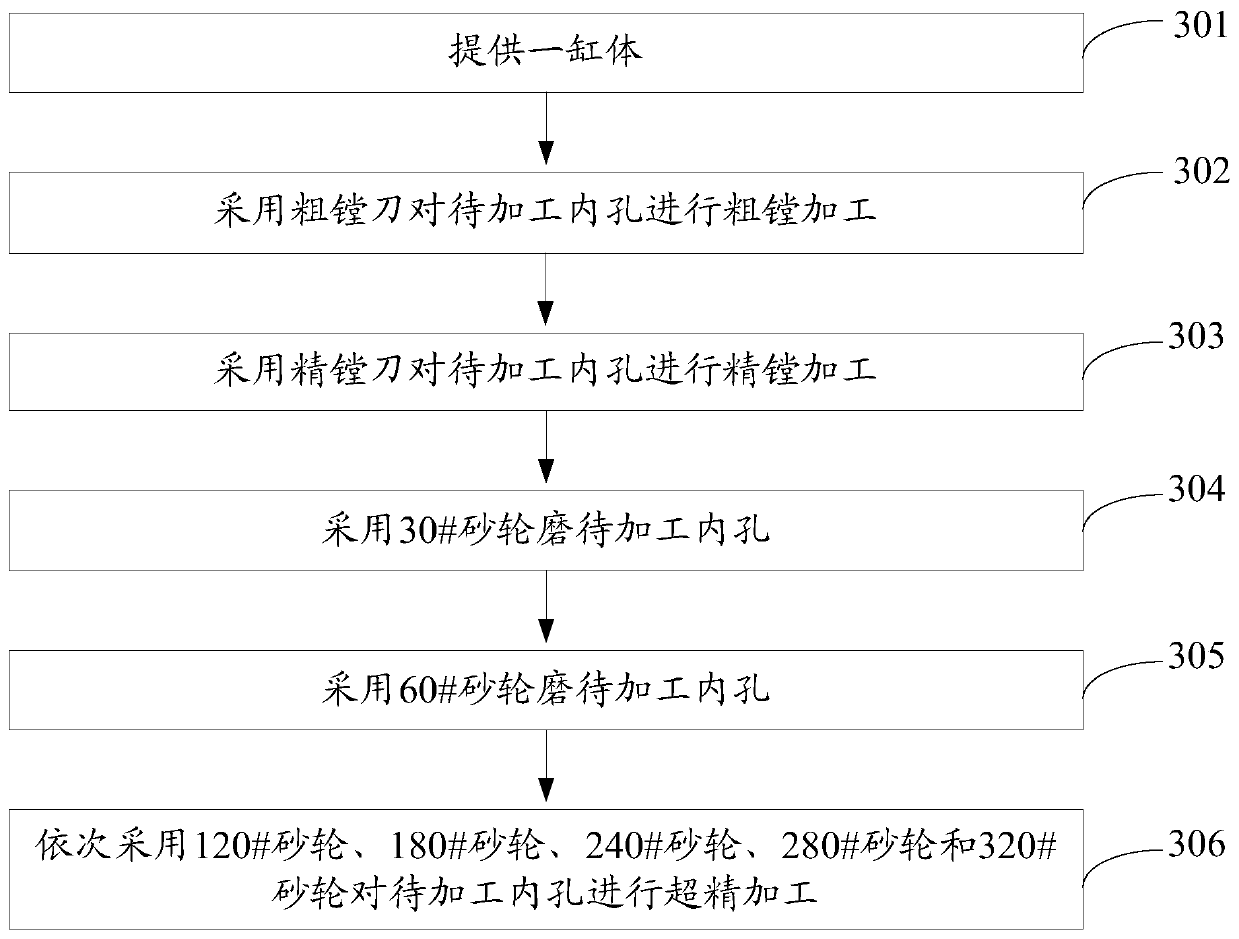

Processing method for inner hole of cylinder block

The invention discloses a processing method for an inner hole of a cylinder block and belongs to the technical field of machining. The processing method comprises the following steps: providing a cylinder block with a to-be-processed inner hole; carrying out heavy boring processing on the to-be-processed inner hole by using a heavy boring cutter; carrying out fine boring processing on the to-be-processed inner hole by using a fine boring cutter; grinding the to-be-processed inner hole by using a 30# grinding wheel and a 60# grinding wheel successively; and carrying out superfinishing processing on the to-be-processed inner hole by using a 120# grinding wheel, a 180# grinding wheel, a 240# grinding wheel, a 280# grinding wheel and a 320# grinding wheel successively to obtain the inner holeof the cylinder block needed to be processed, wherein the surface roughness of the processed inner hole of the cylinder block is not smaller than Ra0.2 and the cylindricity is not smaller than 0.02 mm. By adopting the processing method for the inner hole of the cylinder block, the processing precision and the surface quality of the to-be-processed inner hole can be improved, so that the processingrejection rate of the cylinder block is reduced.

Owner:WUHAN MARINE MACHINERY PLANT

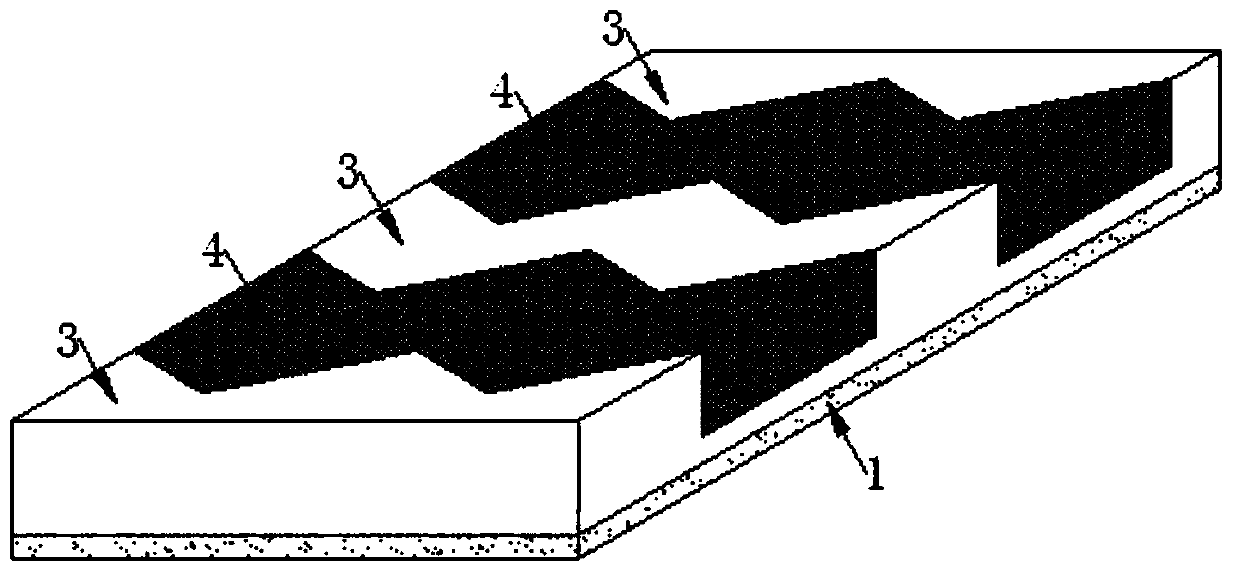

Split bin type fireproof heat preservation plate production technology

PendingCN110984414AGuaranteed firmnessReduce breakageSynthetic resin layered productsConstructions elementsThermodynamicsEngineering

The invention relates to the technical field of building heat preservation materials, in particular to a split bin type fireproof heat preservation plate production technology. The split bin type fireproof heat preservation plate production technology comprises the following steps that an enhancing layer is laid or bonded to any surface of the upper surface or the lower surface of a heat preservation plate body; a groove is machined in the heat preservation plate body, and the depth of the groove is not smaller than 2 / 3 of the thickness of the heat preservation plate body; the groove is filledwith A-level materials, and a fireproof isolation belt is formed; and an enhancing layer is laid or bonded to the face opposite to the face with the enhancing layer. The technology is simple, the machining rejection rate is low, the occupied space is small, the mechanical degree is high, and the labor intensity is low; and a produced split bin type fireproof heat preservation plate is good in fireproof effect, integrally firm and high in strength, and product uniformity is good.

Owner:山东创伟外墙保温材料集团有限公司

Necking die for water sealing neck machining and necking machining method

The invention discloses a necking die for water sealing neck machining and a necking machining method. Through the necking die and the necking machining method, the requirement for machining water sealing necks with different depths is met, and the scrap ratio is lowered. The necking die comprises a die holder, a universal joint, a connecting rod, a synchronous die body and a locating die body, wherein a containing hole is formed in the middle of the die holder, and a through groove is formed in the center of the upper portion of the die holder; the universal joint is arranged in the containing hole, and the connecting rod is arranged in the through groove; one end of the universal joint is fixed to the middle of the connecting rod, and the other end of the universal joint is fixed to thecenter of the bottom of the die holder; the synchronous die body is located on the upper portion of the connecting rod, and the center of the connecting rod is coaxial with the center of the synchronous die body; the locating die body is arranged above the synchronous die body, and the lower portion of the locating die body penetrates through and is fixedly connected with the die holder and is coaxial with the die holder; and a groove ring for machining a water sealing neck is formed by an opening in the upper end of the synchronous die body and the upper portion of the locating die body. During machining, the synchronous die body eccentrically and synchronously rotates, stripping of a workpiece can be guaranteed while a deeper water sealing neck forming effect is achieved; and due to themovement of the synchronous die body in the radial direction, the workpiece is prevented from slipping and stopping rotation, and the machining quality is guaranteed while the water sealing neck can meet the preset requirement.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

Novel electric energy meter nameplate installation system

InactiveCN109894839AEven by forceReduce processing scrap rateMetal working apparatusMultiple pointEngineering

The invention discloses a novel electric energy meter nameplate installation system which comprises a base, a supporting frame, a power source, a power rod, a crimping plate, a plurality of crimping columns and a plurality of guide columns; the supporting frame is fixedly connected to the top surface of the base, and a horizontal plate is arranged at the top of the supporting frame, the guide columns are vertically arranged and penetrate through the horizontal plate, the top surface of the crimping plate is fixedly connected with the bottom ends of the guide columns, and the crimping columns are fixedly connected to the bottom surface of the crimping plate; and the power rod is vertically arranged and fixedly connected to the top surface of the horizontal plate, the power rod is provided with an output shaft, the output shaft extends below the horizontal plate and is fixedly connected with the crimping plate, and the power source is fixedly connected to the base and communicates with the power rod. According to the novel electric energy meter nameplate installation system, nameplates are pressed by using the crimping columns to act at multiple points at the same time, so that the novel electric energy meter nameplate installation system further has the characteristics of uniform stress on the nameplates, low processing rejection rate, low production cost and short production period.

Owner:魏凤

Automotive reinforced part trimming die

PendingCN107952863APrevent movementPrevent deformationVehicle componentsEjection devicesHeight differenceEngineering

The invention provides an automotive reinforced part trimming die. The automotive reinforced part trimming die comprises a lower die assembly and an upper die assembly. The lower die assembly comprises a lower die base, two locating blocks and a plurality of limiting assemblies. The upper die assembly comprises an upper die base, two trimming blocks and two material press blocks. The locating blocks and the material press blocks are cooperated to tightly press a die release product of an automotive reinforced part, the material press blocks are pushed by the locating blocks and the die releaseproduct to move in the process that the upper die assembly and the lower die assembly get close to each other, a height difference exists between each trimming block and the corresponding material press block, shearing force is generated on the die release product to cut leftover materials off. An existing machining method is improved through the die cutting mode, the safety of workers is improved in the machining process, the dust pollution caused by machining is reduced, and the machining environment is improved.

Owner:重庆安亚模具制造有限公司

Feeding device of stone sawing machine

ActiveCN103144210AReduce processing scrap rateImprove flatnessWorking accessoriesStone-like material working toolsEngineeringRejection rate

The invention discloses a feeding device of a stone sawing machine, which comprises a workbench base arranged symmetrically right and left, and a feeding drum connected in the middle of the workbench base, wherein a guide rail and a stone pressure rack stand plate are arranged above the workbench base; the stone pressure rack stand plate is slidingly arranged on the guide rail; the feeding device is characterized in that a plurality of rolling wheels are uniformly arranged on the feeding drum; and a gap groove is formed between every two adjacent rolling wheels. According to the feeding device, the rolling wheels are arranged on the feeding drum of the stone sawing machine, the gap groove is formed between every two adjacent rolling wheels, the feeding workbench and saw blades are connected with the gap grooves in a matching manner respectively, stone blocks to be processed are fixed on the feeding workbench, and the feeding workbench makes rectilinear movement under guiding of the feeding drum and the gap grooves, so that the stone blocks can make rectilinear motion and be in a smooth placement state all the time; cutting and processing of the saw blades are facilitated; the processing rejection rate of the processed stone blocks is low; the smoothness of the processed stone blocks is high; and the rolling wheels on the feeding drum can adjust a gap distance according to a cutting demand of a user.

Owner:广东威德力机械实业股份有限公司 +1

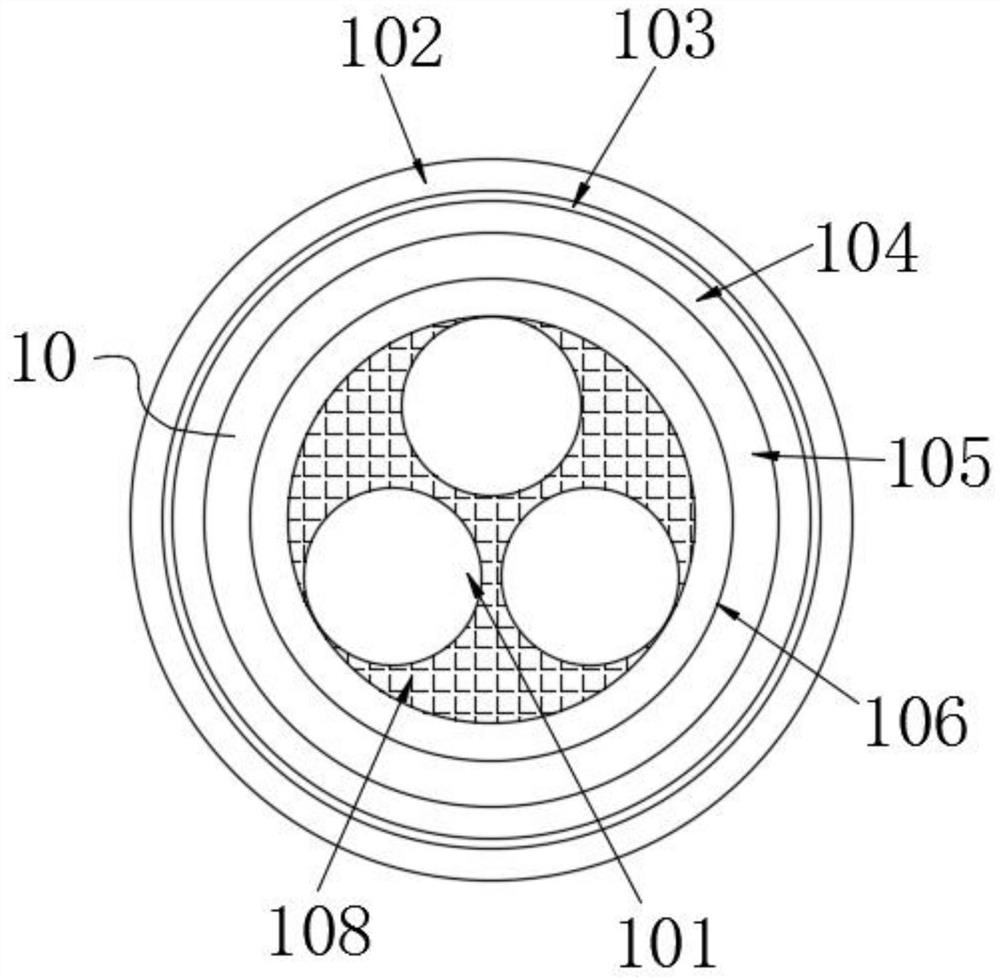

Crosslinked polyethylene insulated halogen-free low-smoke flame-retardant polyolefin sheath power cable

ActiveCN112091741AControl the amount of sandingImprove grinding accuracyRevolution surface grinding machinesGrinding drivesPolyolefinPower cable

The invention discloses a cross-linked polyethylene insulated halogen-free low-smoke flame-retardant polyolefin sheath power cable which comprises a cable body. The cable body comprises a cable core body, a sheath, a flame-retardant layer, a lining layer, a shielding layer, a halogen-free wrapping layer and a flame-retardant filling rope. According to the crosslinked polyethylene insulated halogen-free low-smoke flame-retardant polyolefin sheath power cable, an output shaft of a servo motor II rotates to drive a polishing wheel to rotate, a linear motor II on the right side of a fixed frame IIslides on the surface of a linear slideway II to drive a mounting frame to shift, and a sliding block I connected with the mounting frame slides on the surface of a sliding rail I, so that the polishing wheel is close to the surface of the cable body to polish the surface of the cable body, the surface of the cable body is polished by means of surface contact of the polishing wheel and the cablebody, and the polishing amount of the polishing wheel to the cable body can be controlled precisely by controlling the distance of the linear motor II shifting on the linear slideway II, so that the polishing precision of the cable is improved greatly, and the processing rejection rate of the cable is reduced.

Owner:居盛文

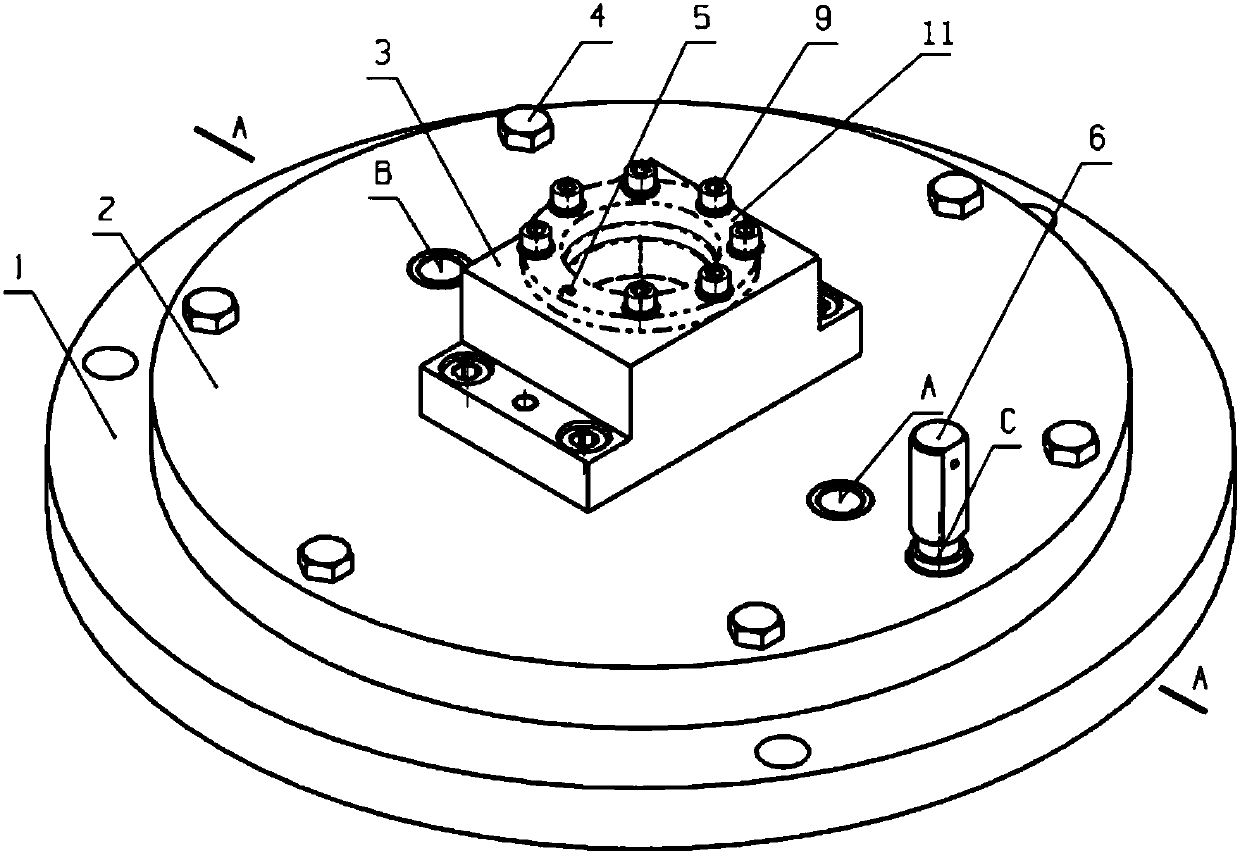

Clamping device for machining small eccentric stepped circular hole parts

InactiveCN107649907AGuaranteed sizeWarranty requirementsPositioning apparatusMetal-working holdersEngineering

The invention discloses a clamping device for machining small eccentric stepped circular hole parts. The device comprises a base, an indexing plate, a positioning base, an indexing guide plate, an indexing bolt and indexing adjusting mechanisms, wherein the indexing guide plate is a rectangular plate body; the base is in a circular truncated cone shape; a first groove used for installing the indexing guide plate is formed in the top surface of a top seat; a first indexing bolt hole is formed in the base; the indexing plate is in a circular truncated cone shape; a second groove which is combined with the indexing guide plate is formed in the bottom surface of the indexing plate; a second indexing bolt hole is formed in the indexing plate; the positioning seat is provided with a central holewhich is combined with the small eccentric stepped round hole parts to be machined; the indexing guide plate is fixed in the first groove formed in the top surface of the base; the positioning seat is fixed on the top surface of the indexing plate; a second groove formed in the bottom surface of the indexing plate is combined with the indexing guide plate, and the indexing plate is located on thetop surface of the base; the indexing bolt is inserted into one certain second indexing bolt hole in the indexing plate and a first indexing bolt hole corresponding to the second indexing bolt hole;and the various indexing adjusting mechanisms are used for fixedly connecting the base with the indexing plate.

Owner:CHENGDU ENGINE GROUP

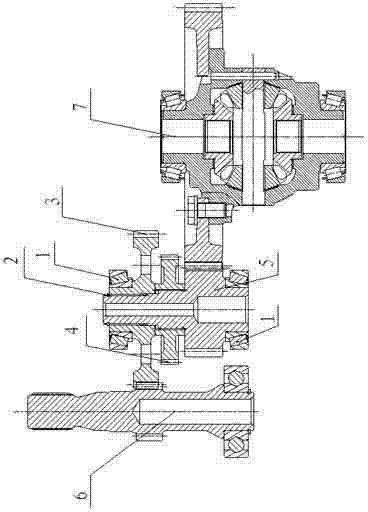

Application of aluminum alloy material in hydraulic valve body and aluminum alloy hydraulic switching valve

InactiveCN102418015AExpand the scope of useBroaden the field of applicationValve housingsRare-earth elementImpurity

The invention discloses application of an aluminum alloy material in a hydraulic valve body and an aluminum alloy hydraulic switching valve. Particularly the aluminum alloy material is applied to manufacture of the hydraulic valve body. The aluminum alloy comprises the following components in percentage by weight: 2.0-6.0% of Cu, 0.05%% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of rare-earth element Pr and the balance of Al and trace impurity elements. According to the invention, great breakthrough on the production materials of the tradition hydraulic valve is made, the weight of the valve body is greatly reduced, the corrosion resistance of the valve body is improved and the valve body is easy to process.

Owner:曾琦

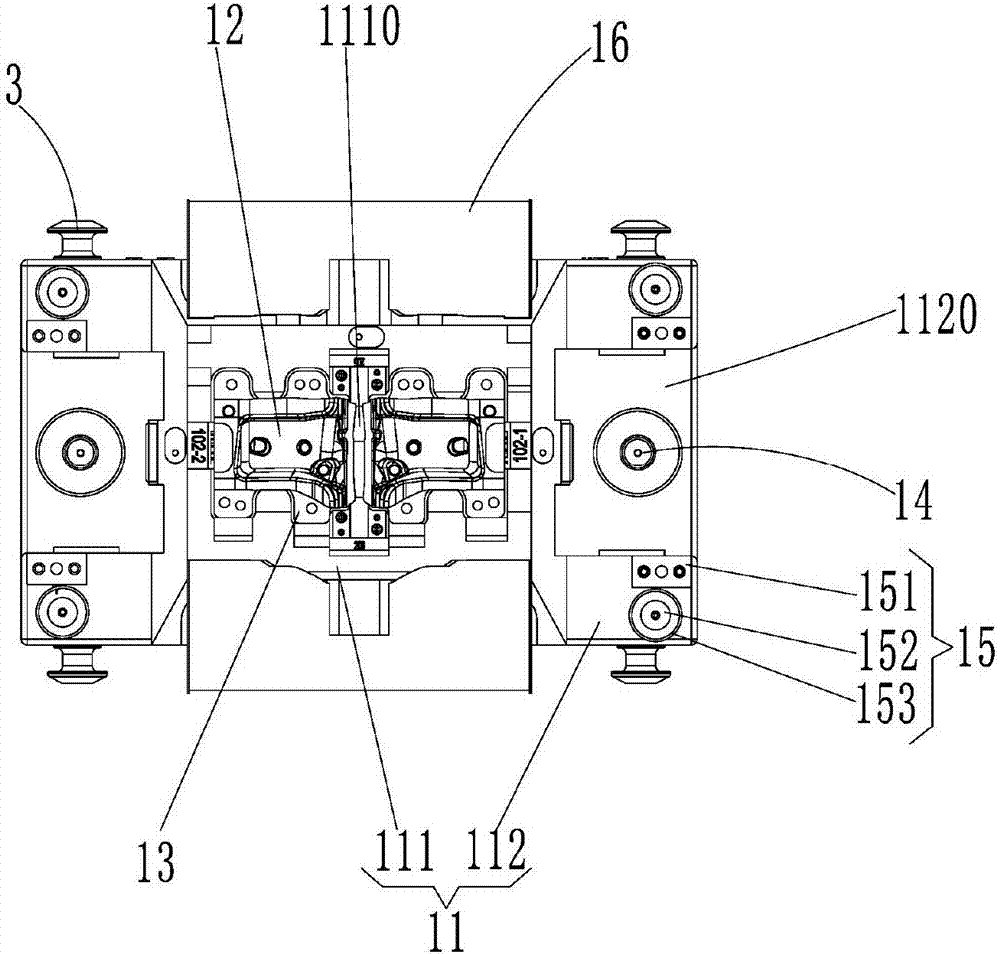

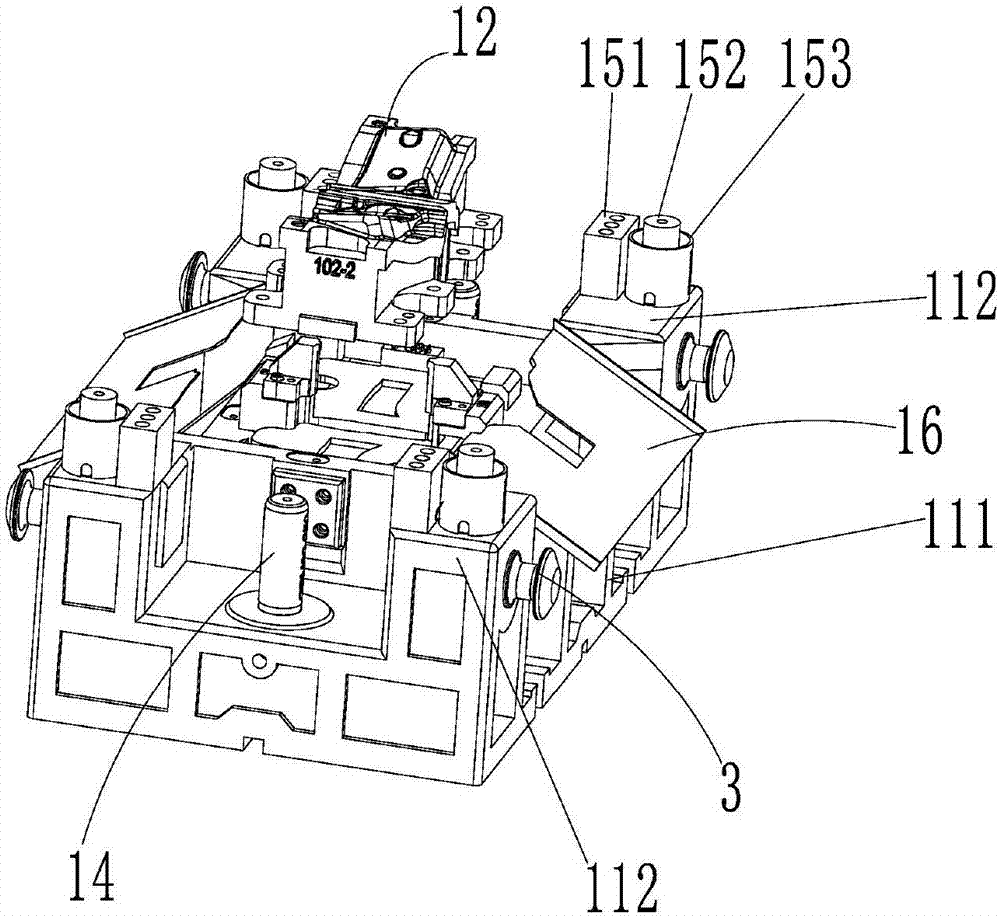

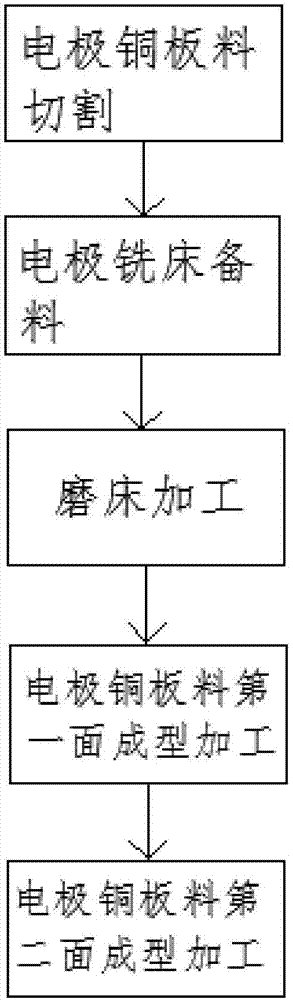

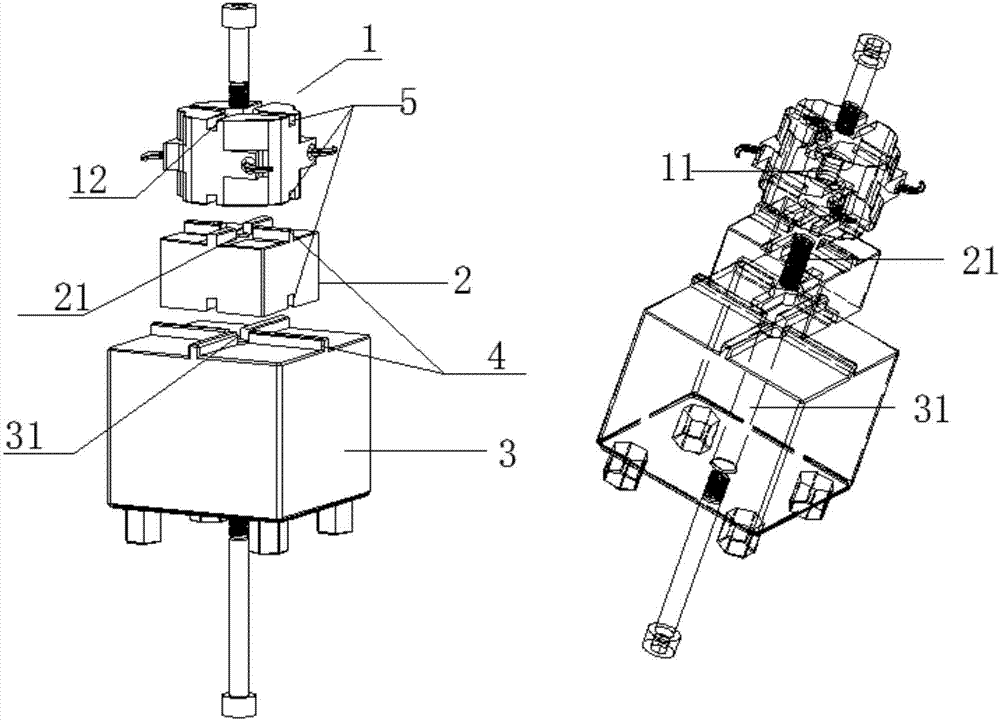

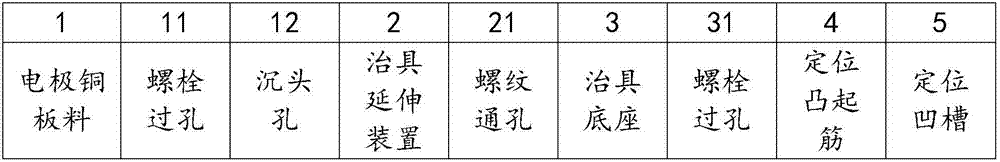

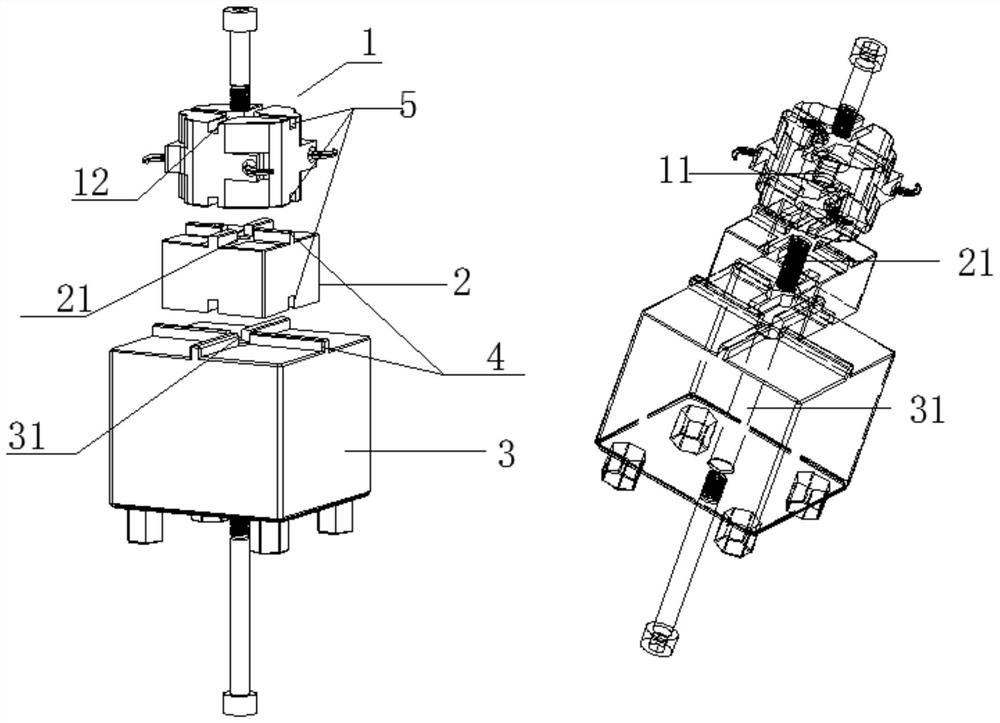

Processing method of integrated horn submarine gate electrode

ActiveCN107414427AGuaranteed coincidenceCause processing errorElectrical-based machining electrodesPositioning apparatusCopperProcessing cost

The invention provides a processing method of an integrated horn submarine gate electrode. The method comprises the following steps: cutting an electrode copper plate material, preparing materials of an electrode milling machine, processing via a grinding machine, forming and processing a first side of the electrode copper plate material and forming and processing a second side of the electrode copper plate material, wherein the step of processing via the grinding machine is characterized by processing positioning grooves used for subsequently clamping in the upper end surface and the lower end surface of the electrode copper plate material. The processing method is simple in steps, short in period and low in processing cost. A clamping fixture used in the electrode processing method comprises a fixture base and a fixture extending device, wherein the fixture base and the fixture extending device are provided with positioning convex ribs, positioning grooves and central through holes; through cooperation of the central holes and positioning structures, the electrode material to be processed is stably fixed on the clamping fixture, so that the processing accuracy is ensured. The processing method and the clamping fixture are suitable for clamping and processing various types of electrodes.

Owner:苏州沃思诺精密模具有限公司

A processing method for an integral horn submerged electrode

ActiveCN107414427BReduce the amount that can be processedSave raw materialsElectrical-based machining electrodesPositioning apparatusEngineeringMachining process

Owner:苏州沃思诺精密模具有限公司

Performance Evaluation Method of Progressive Multifocal Freeform Surface Lens

InactiveCN106932921BShorten the design cycleReduce processing scrap rateOptical partsOptical axisAxial distribution

The invention relates to a progressive addition freeform-surface lenses performance evaluation method. The method is a method for evaluating focal power, astigmatism and axial distribution of lenses when a person wears progressive addition freeform-surface lenses in the multiple optical axes state from the perspective of multiple optical axes in the design stage. According to the invention, the influence of optical axis change on focal power, astigmatism and axial distribution of lenses when a person wears progressive addition freeform-surface lenses to see faraway and near places and perimeter zone in the multiple optical axes state is provided, and conformity and weighting factor of different areas of the lenses also can be provided. After normalization processing, weight factor thresholds of focal power of lenses' lattice points, astigmatism and axial distribution of the progressive addition freeform-surface lenses in the multiple optical axes state are calculated for evaluation. According to the weight factor thresholds, the difference between the progressive addition freeform-surface designed in the multiple optical axes state and a prescription is obtained, and errors of parameters in the design process are understood. By the evaluation method, design period can be shortened, rejection rate of processing can be reduced, and product qualification ratio can be raised.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

An integrated milling, grinding and measuring machine tool for circular workpieces and its control method

ActiveCN112025315BReduce labor intensityReduce processing stepsProgramme controlComputer controlRotary stageEngineering

The invention discloses an integrated processing machine tool for milling, grinding and measuring ring-shaped workpieces, which comprises a machine tool base, a Z-axis mounting support, an X-axis mounting panel, an X-axis moving device, a Z-axis moving device, a B-axis rotating table, and a milling and grinding operation System, measuring mechanism, worktable and Y-axis moving device; the Z-axis mounting support is fixed on the machine base, the Z-axis moving device is fixed on the Z-axis mounting support, the X-axis mounting panel is fixed on the Z-axis moving device and Drive it to move up and down along the Z-axis direction through the Z-axis moving device, the X-axis moving device is fixed on the X-axis installation panel, and the B-axis rotating table is fixed on the X-axis moving device and driven by the X-axis moving device to move left and right along the X-axis direction Mobile, the milling and grinding operation system is fixed on the B-axis rotary table, the measuring mechanism is fixed on the end of the milling and grinding operation system, the worktable is fixed on the Y-axis moving device and driven by the Y-axis moving device to move back and forth along the Y-axis direction, Y The axis moving device is fixed on the base of the machine tool. The invention also discloses a control method of a milling, grinding and measuring integrated processing machine tool for an annular workpiece.

Owner:JILIN UNIV

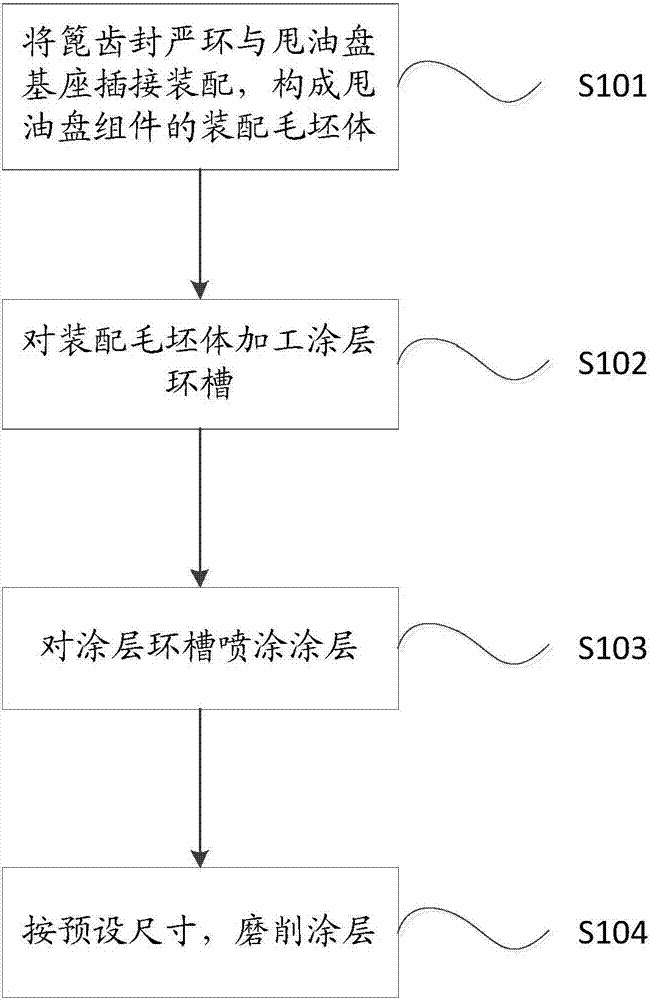

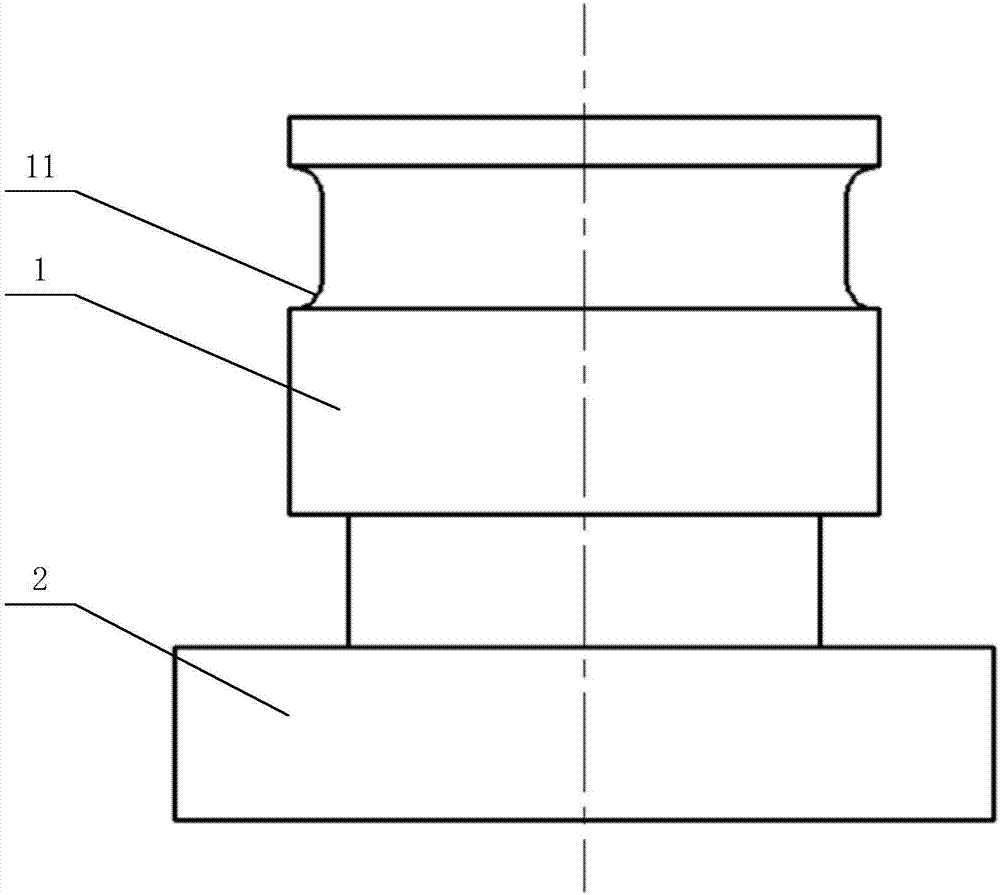

Manufacturing method of oil flinger assembly of aircraft engine

InactiveCN107088737AHigh dimensional accuracyImprove uniformityAircraft componentsAviationEngineering

The invention relates to the field of aviation technology, in particular to a method for manufacturing an oil thrower assembly of an aircraft engine. The manufacturing method of the oil slinger assembly of the aircraft engine comprises: plugging and assembling the grate tooth sealing ring and the oil slinger base to form the assembly blank body of the oil slinger assembly; processing the coating ring on the assembly blank body groove; spray coating on the coating ring groove; grind the coating according to the preset size. Through the application of this method, the processing of the coating ring groove, spraying coating and grinding coating are all carried out on the basis of plugging and assembling the grate sealing ring and the base of the oil slinger to form an assembly blank body. This makes the above-mentioned processing steps all take the assembled blank body as the overall processing object and the clamping positioning reference. Therefore, the application of the present application significantly improves the machining accuracy of the oil flinger assembly of the aircraft engine and reduces the reject rate.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com