Gauge used for measuring inner groove diameter of elongated hole

A technology for slender holes and inspection tools, applied in the field of inspection, can solve problems such as the inability to measure the diameter of the undercut, affect the machining accuracy of the inner taper hole, and the actual size is unstable, and achieve a simple structure, improved processing quality, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

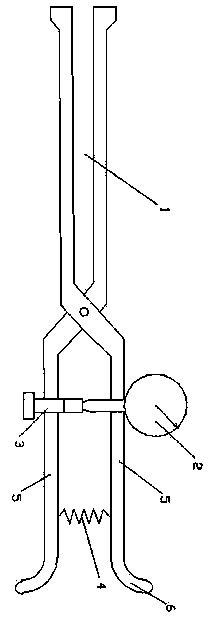

[0015] refer to figure 1 , is a checking tool for measuring the diameter of the inner groove of a slender hole, including a caliper 1, a dial indicator 2, an adjustment rod 3 and a spring 4, the caliper 1 is a pincer structure, and is composed of two measuring rods 5 hinged , one of the measuring rods 5 of the calliper 1 is fixedly equipped with a dial gauge 2, and the other measuring rod 5 is fixedly mounted with an adjusting rod 3, and the adjusting rod 3 corresponds to the position of the dial gauge 2, so The length of the adjusting rod 3 relative to the measuring rod 5 can be adjusted, and the measuring ends 6 of the two measuring rods 5 are connected by a spring 4 .

[0016] The adjusting rod 3 and the measuring rod 5 are connected by threads.

[0017] Described spring 4 adopts compression spring.

[0018] When measuring, install the dial indicator 2 on the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com