Low-cost honeycomb curved face machining method

A surface processing, low-cost technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost of honeycomb surface processing, weak stability of honeycomb cells, collapse of honeycomb cells, etc., to save The effect of preparation time and cost, reduction of processing scrap rate, and reduction of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

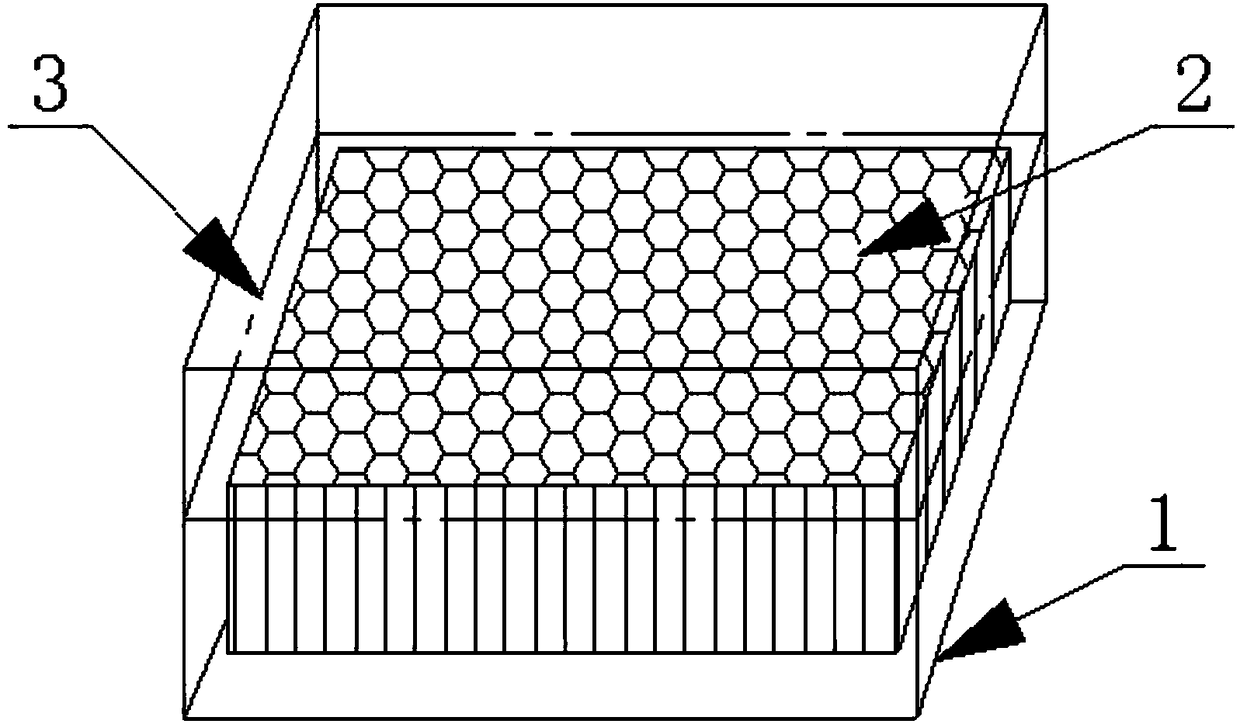

Image

Examples

Embodiment 1

[0025] (1) Place the aluminum honeycomb block (400mm×400mm×200mm) to be processed flat in the container, and fix it, fill the aluminum honeycomb cells with water (3°C), and ensure that the aluminum honeycomb block is submerged in water.

[0026] (2) Put the container into the cold storage to cool down, so that the water in the container is frozen, and the water is filled in the aluminum honeycomb cells in a solid form, and the aluminum honeycomb and the ice are integrated, and the aluminum honeycomb filled with ice cubes is removed from the mold. According to the size of the product, it is first sawn into a blank and then directly clamped on the CNC machine tool. It is subjected to various mechanical cutting processes with conventional tools (the ambient temperature of the processing is -6°C) to obtain the designed product shape.

[0027] (3) After the product processing is completed, the aluminum honeycomb product filled with ice cubes is melted at room temperature in a contai...

Embodiment 2

[0030] (1) Place the aramid paper honeycomb block (530mm×410mm×80mm) to be processed flat in the container and fix it. Fill the cells of the aramid paper honeycomb with water (2° C.), and ensure that the aramid paper honeycomb block is immersed in the water.

[0031] (2) Put the container into the cold storage to cool down, so that the water in the container is frozen, and the water is filled in the honeycomb cells of the aramid paper in a solid form, and the honeycomb of the aramid paper is integrated with the ice, and the aramid fiber filled with ice cubes The paper honeycomb is removed from the mold, sawed into a blank according to the size of the product, and then directly clamped on the CNC machine tool. It is subjected to various mechanical cutting processes with conventional tools (the ambient temperature of the processing is -7°C), and the designed product shape is obtained. .

[0032] (3) After the product processing is completed, the aramid paper honeycomb product f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com