Electric vehicle reducer gear shaft assembly structure

A technology of assembly structure and reducer, applied in the direction of vehicle gearbox, gear transmission, belt/chain/gear, etc., can solve the problem of not meeting the strength, durability, NVH requirements of electric vehicle reducer, gear precision heat treatment, large deformation, Increase the volume and weight of the reducer to achieve the effects of improving machining accuracy and consistency, reducing machining reject rate, and improving strength life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

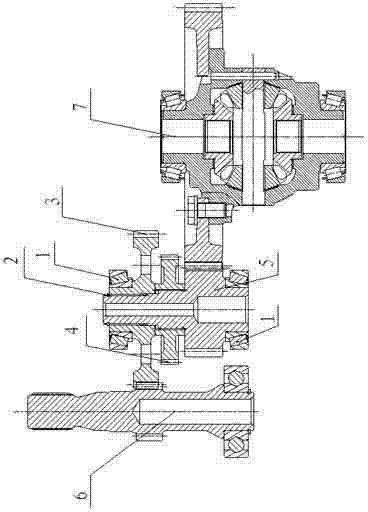

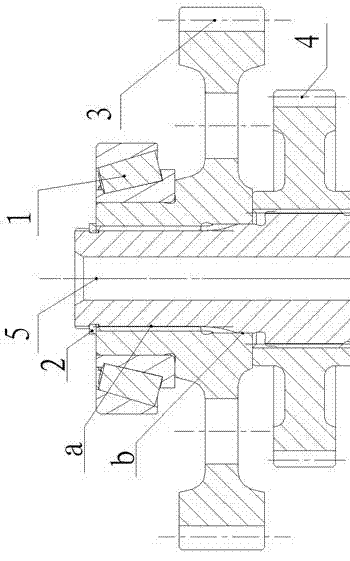

[0023] Depend on Figure 1-2 as shown, figure 1 Among them, 6 is the input shaft assembly, 5 is the output shaft, and 7 is the differential assembly. On the output shaft 5, a ratchet wheel 4 is sequentially pressed, and the output gear 3 meshing with the input shaft assembly 6 is installed. The taper bearing 1 is press-fitted on the shaft shoulder on 3, and the taper bearing is also arranged on the output shaft shoulder close to the meshing part of the output shaft 5 and the differential assembly 7; the output shaft and the output gear are press-fitted The outer end is provided with a graded circlip 2; the part where the output shaft 5 is connected to the output gear 3 is respectively provided with a spline fit a structure and a shaft hole fit b structure, wherein the spline fits a to transmit torque, and the shaft hole fits b Ensure accurate positioning.

[0024] The assembly steps of the gear shaft assembly structure of the electric vehicle reducer are as follows: ①Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com