High-precision processing method of long-strip reflecting mirror

A processing method and reflector technology, which is applied to metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of low processing precision of long reflectors, achieve good application prospects, facilitate operation, and avoid waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

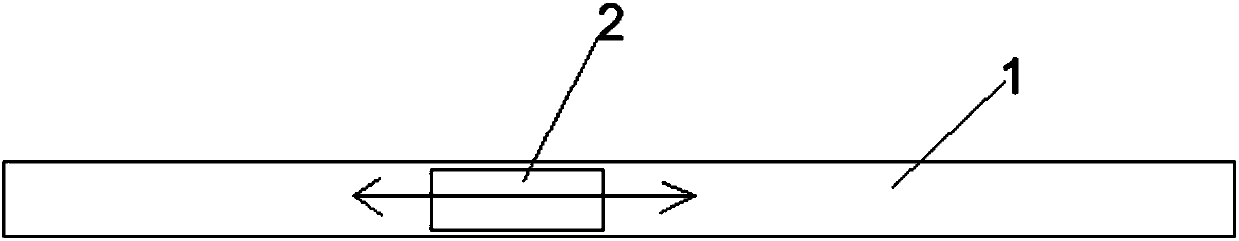

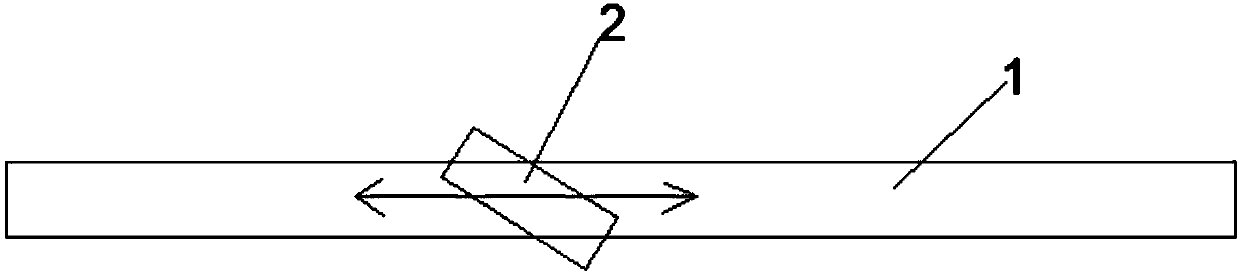

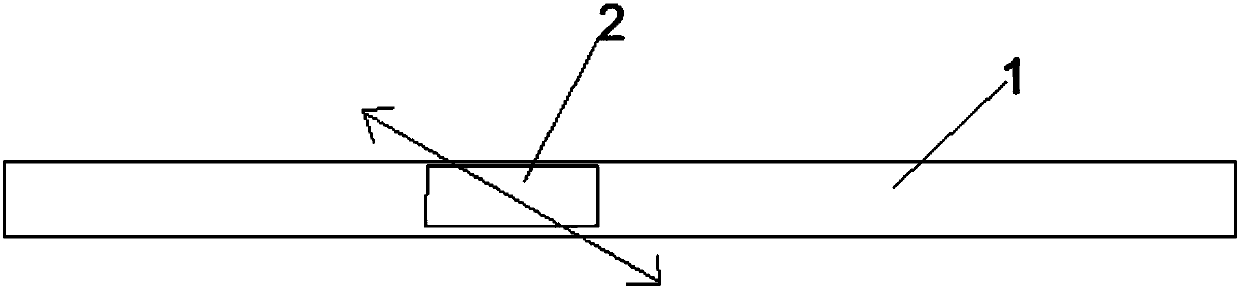

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] A method for processing a strip reflector, comprising the following steps:

[0044] 1. DMG milling molding

[0045] 1) Take a rectangular cylindrical blank, and mill the long side adjacent to the surface to be processed. The weight-reducing groove required by the drawing is 13mm long, 6mm wide, and 10mm deep;

[0046] 2) Heat to melt the wax. After waxing the side of the blank opposite to the surface to be processed, turn the surface to be processed upwards, and the reference surface of the blank is close to the limit structure of the tooling. Bond the blank to the tooling and wait for the wax to cool After that, form the blank tooling;

[0047] 3) Install the blank tooling on the workpiece axis of the DMG milling equipment, fix the dial indicator on the Z axis of the milling equipment, position the blank reference plane, control the parallelism within 0.005, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com