Method for machining cylindrical mirror

A processing method and technology of cylindrical mirrors, applied in metal processing equipment, manufacturing tools, optical surface grinders, etc., can solve the problems of low processing precision of cylindrical mirrors, achieve good application prospects, reduce processing scrap rate, and improve surface accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

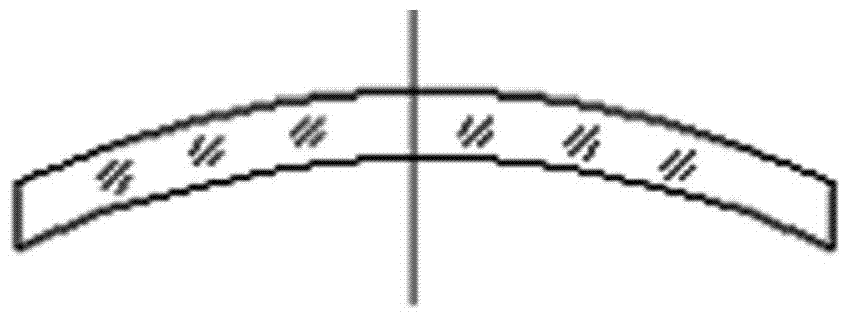

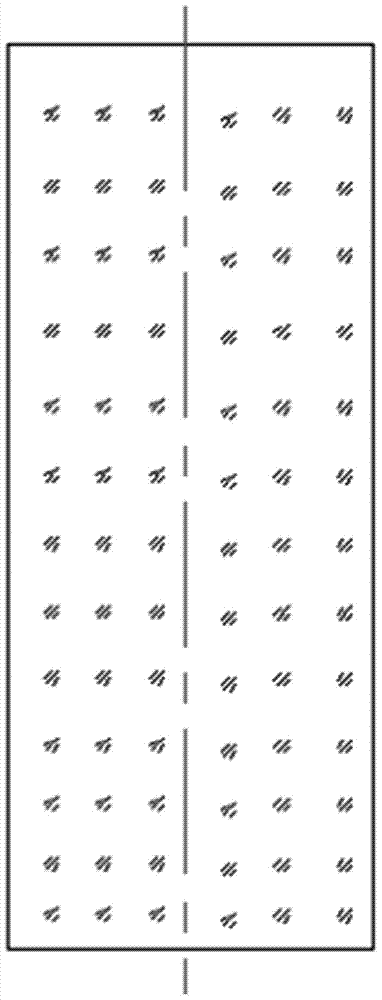

[0043] The shape of the cylindrical mirror to be processed in this embodiment is as follows figure 1 , 2 As shown, the process requirements are:

[0044] Dimensions, length 237.7, width

[0045] Cylindrical curvature radius, concave surface R-107.5, convex surface R+107.5;

[0046] Surface accuracy Rt≤0.4μm, Ra≤0.04μm;

[0047] Center deviation χ≤1.2';

[0048] Center thickness dimension 8±0.1;

[0049] Surface blemish grade B=Ⅴ.

[0050] The processing method of the cylindrical mirror of the present embodiment comprises the following steps:

[0051] Process the first side R+107.5:

[0052] 1) Take a quadrangular prism blank, which is 237.7 in length and 237.7 in width Thickness 22, milling a long side adjacent to the cylindrical surface to be processed, controlling the parallelism of this surface to be 0.002, and using this surface as the blank reference surface;

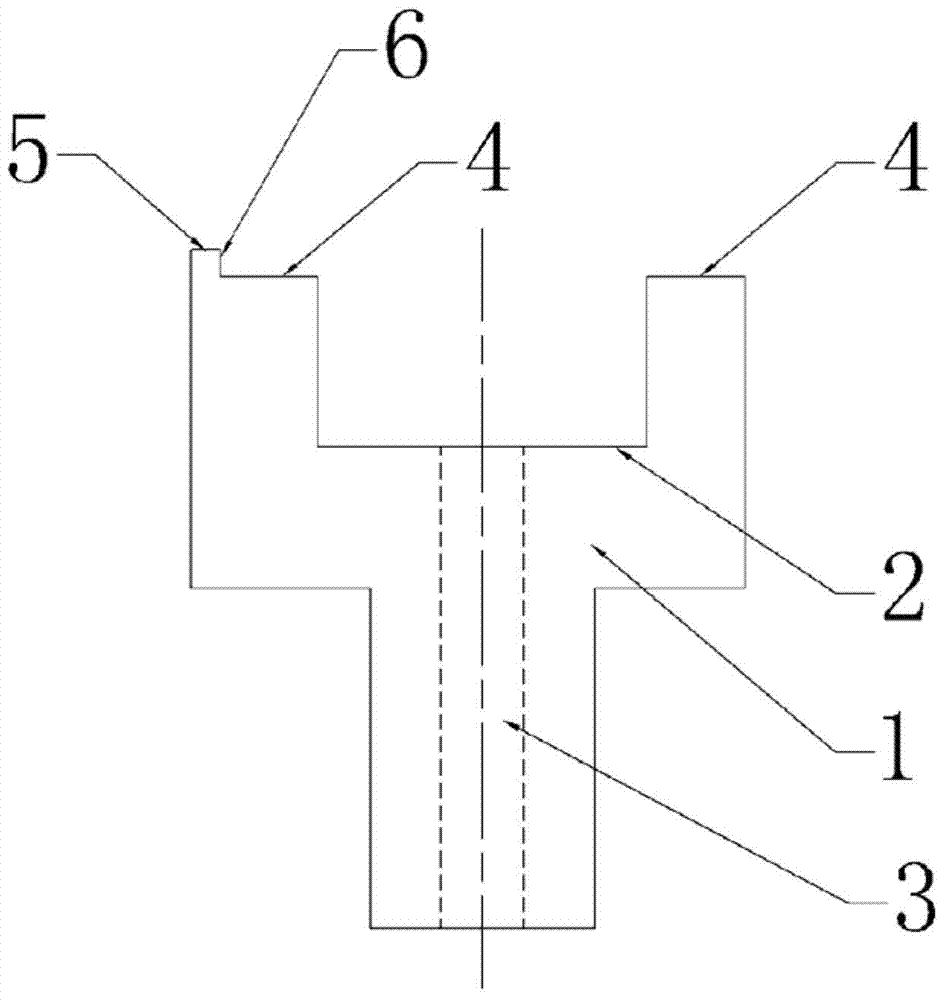

[0053] Get the used frock of this embodiment, described frock is as image 3 , 4 As shown, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com