Feeding device of stone sawing machine

A technology of feeding device and stone sawing machine, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of increasing the conveying load of the stone sawing machine, increasing the processing steps of sawing stone, and the high scrap rate of stone processing. Ideal processing effect, strong humanized design, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

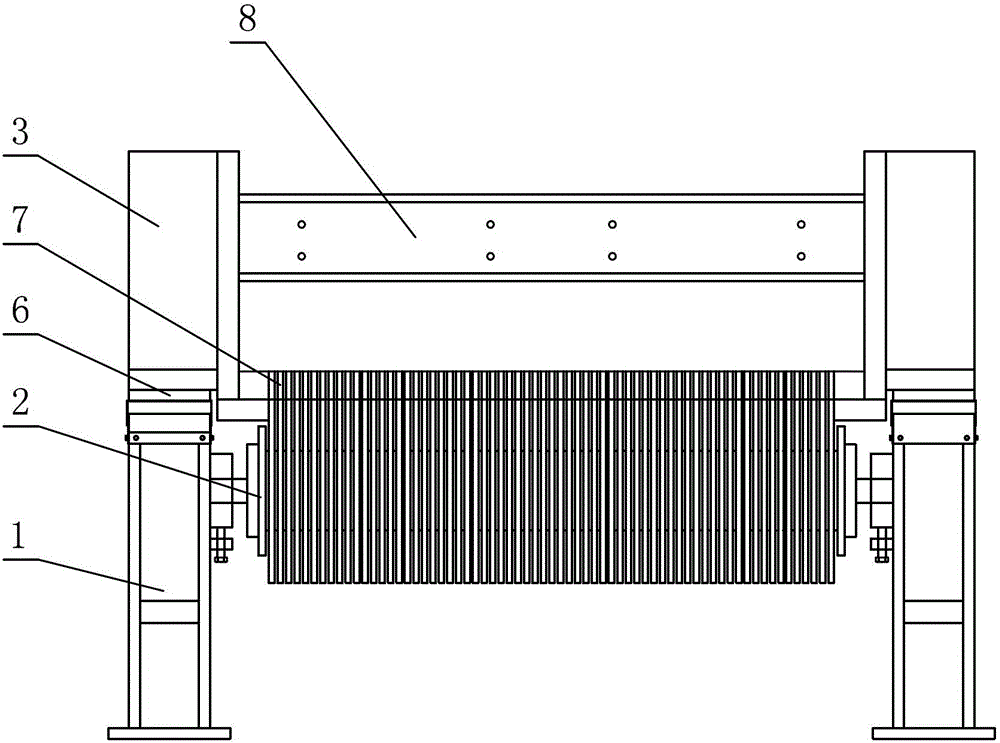

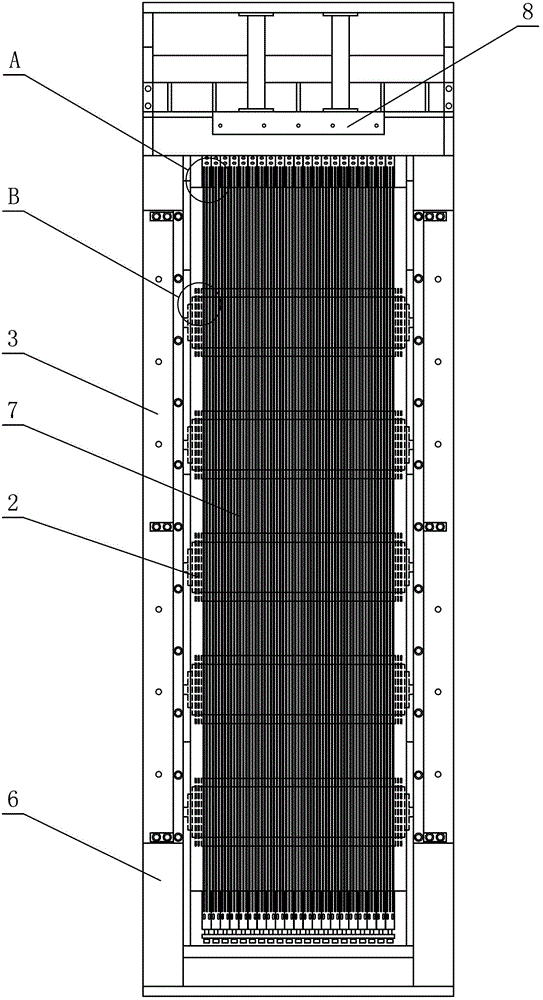

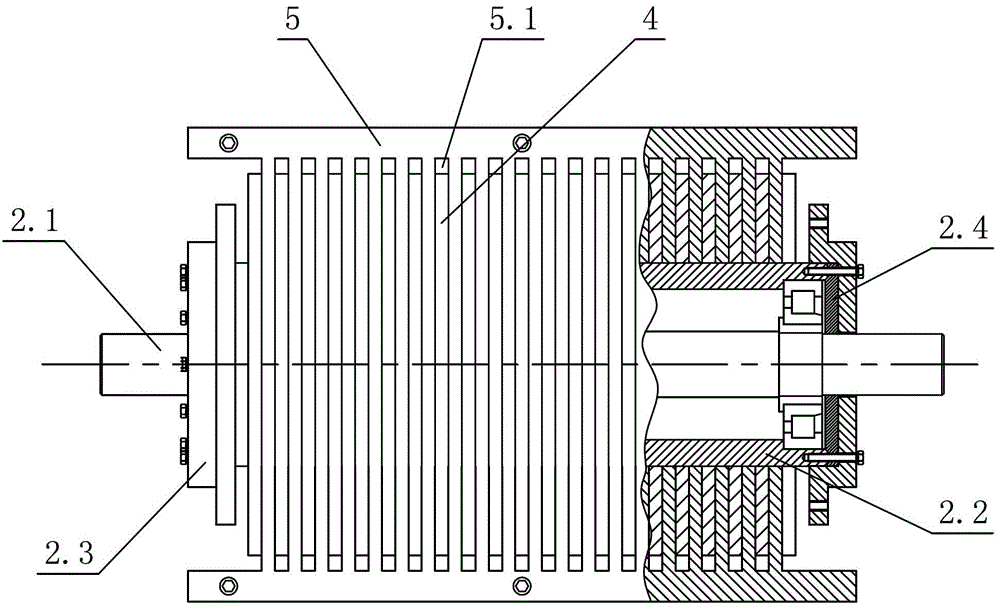

[0020] see Figure 1-Figure 5 , the feeding device of the stone sawing machine includes a left-right symmetrically arranged workbench base 1, a feed roller 2 connected between the workbench bases 1, and a guide rail (not shown in the figure) above the workbench base 1. can be marked) and the vertical plate 3 of the stone pressing frame, the bottom of the vertical plate 3 of the stone pressing frame is provided with a slider fixing plate 6, and the slider fixing plate 6 is provided with a slider corresponding to the guide rail (not marked in the figure), the vertical plate of the stone pressing frame 3 is slidably arranged on the guide rail through the slider fixing plate 6, and a number of rollers 4 are uniformly arranged on the feeding roller 2, and gap grooves 4.1 are arranged between adjacent rollers 4.

[0021] The feeding roller 2 includes a rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com