Performance Evaluation Method of Progressive Multifocal Freeform Surface Lens

A progressive multifocal and evaluation method technology, applied in the field of optical performance, can solve problems such as increasing the defective rate of progressive multifocal lenses, and achieve the effect of shortening the design cycle, reducing the processing reject rate, and being highly implementable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

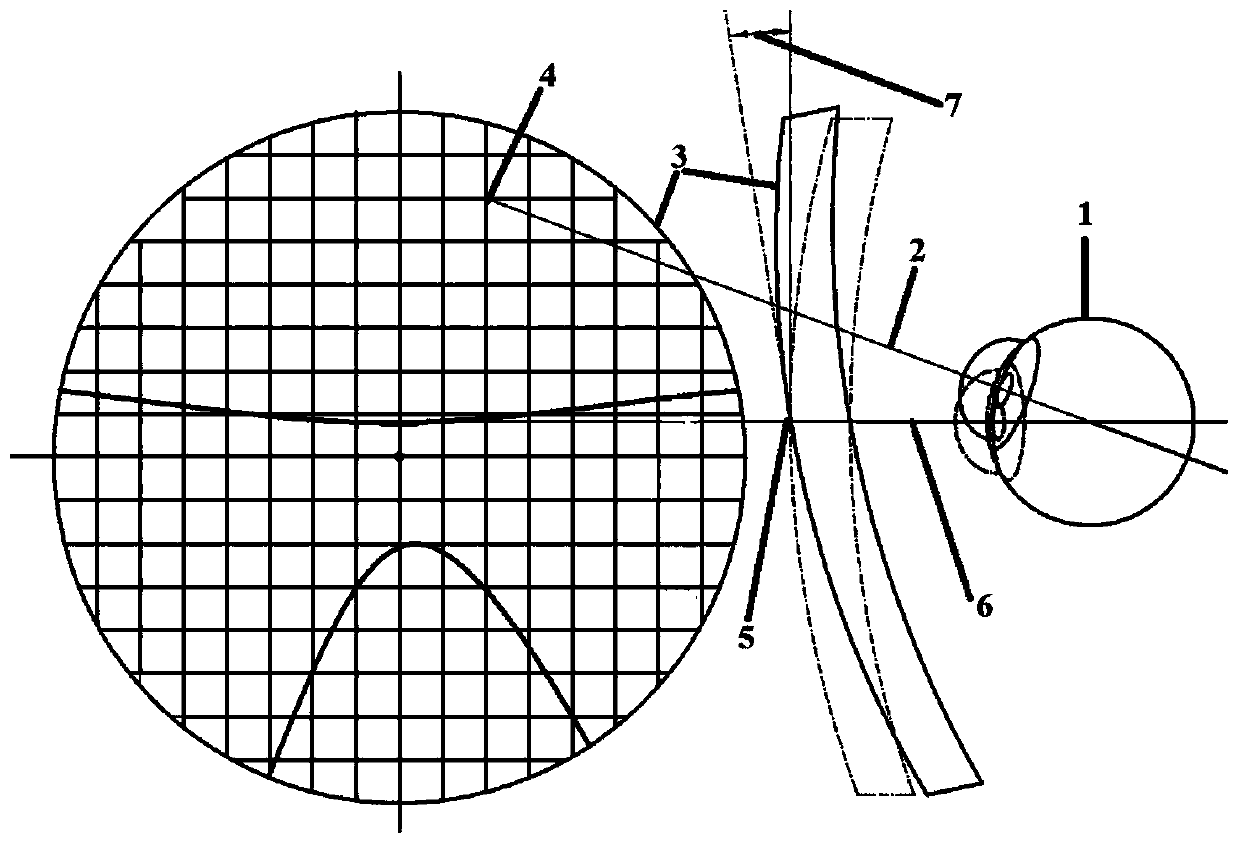

[0027] Such as figure 1 Shown is a schematic diagram of the performance evaluation of progressive multifocal free-form surface lenses. Place the lens 3 directly in front of the human eye 1, the horizontal line passing the eyeball center of the human eye 1 is the optical axis 6, the intersection of the optical axis 6 and the front surface of the lens 3 is the front surface vertex 5, and the front surface vertex 5 of the lens 3 is away from the human The length of the eyeball center is 27mm. According to the facial features of the wearer, the lens 3 is inclined at a certain angle 7 along the vertical line of the optical axis 6, and the range is 10-12°. This is used to simulate different wearing states, that is, the face shape.

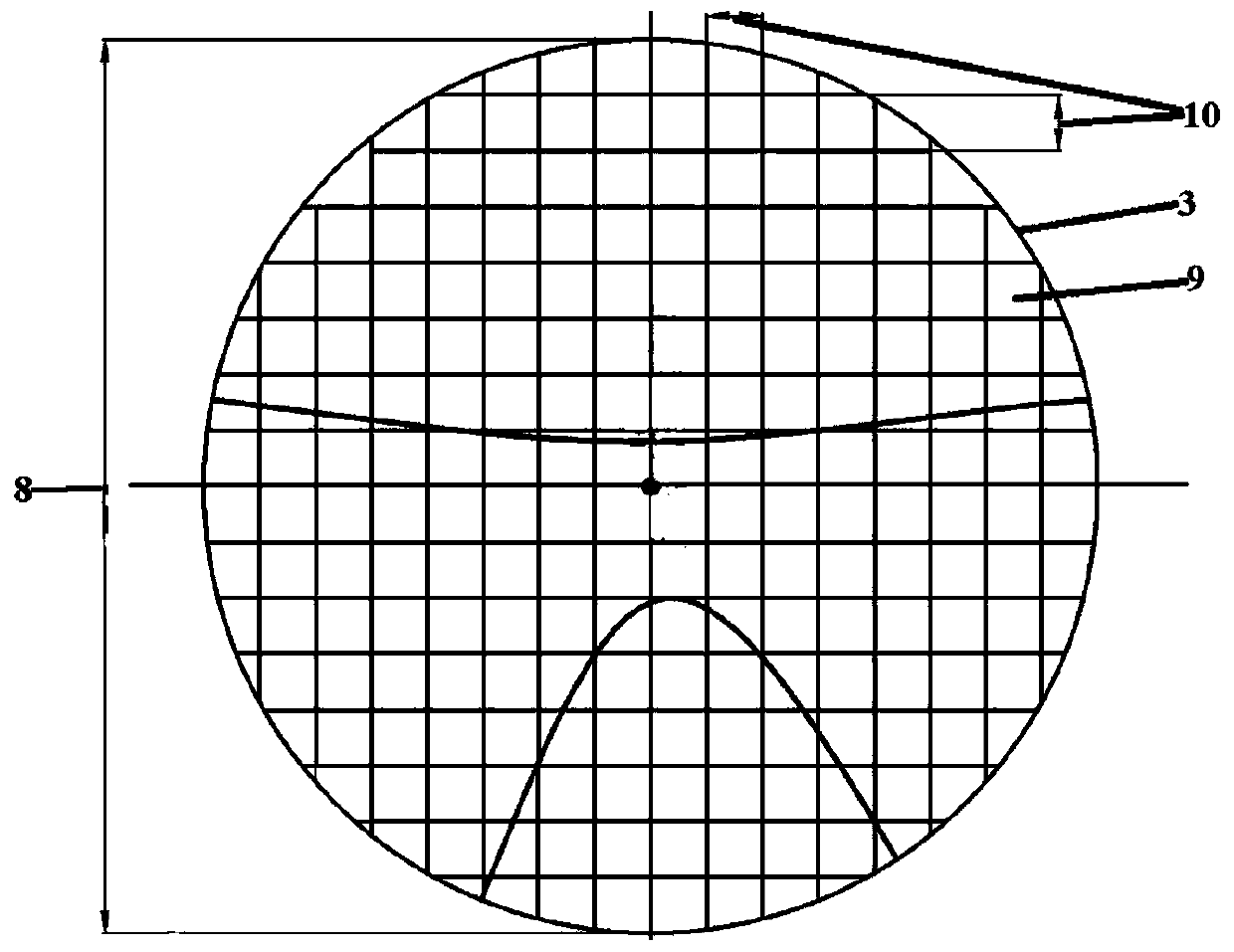

[0028] Such as figure 2 The grid division standard diagram is shown. The diameter 8 of the lens 3 is R, which is divided according to the radius r of the pupil of the eye of different wearers. The grid 9 is square and the side length of the grid is r. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com