Broadband micro-perforated board sound absorber, absorber performance prediction method and absorber structure design method

A technology for micro-perforated plates and performance prediction, which is applied in computing, sound-generating equipment, instruments, etc., and can solve the problems that local resonance effects cannot be formed, and broadband micro-perforated plate sound absorbers have not yet been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

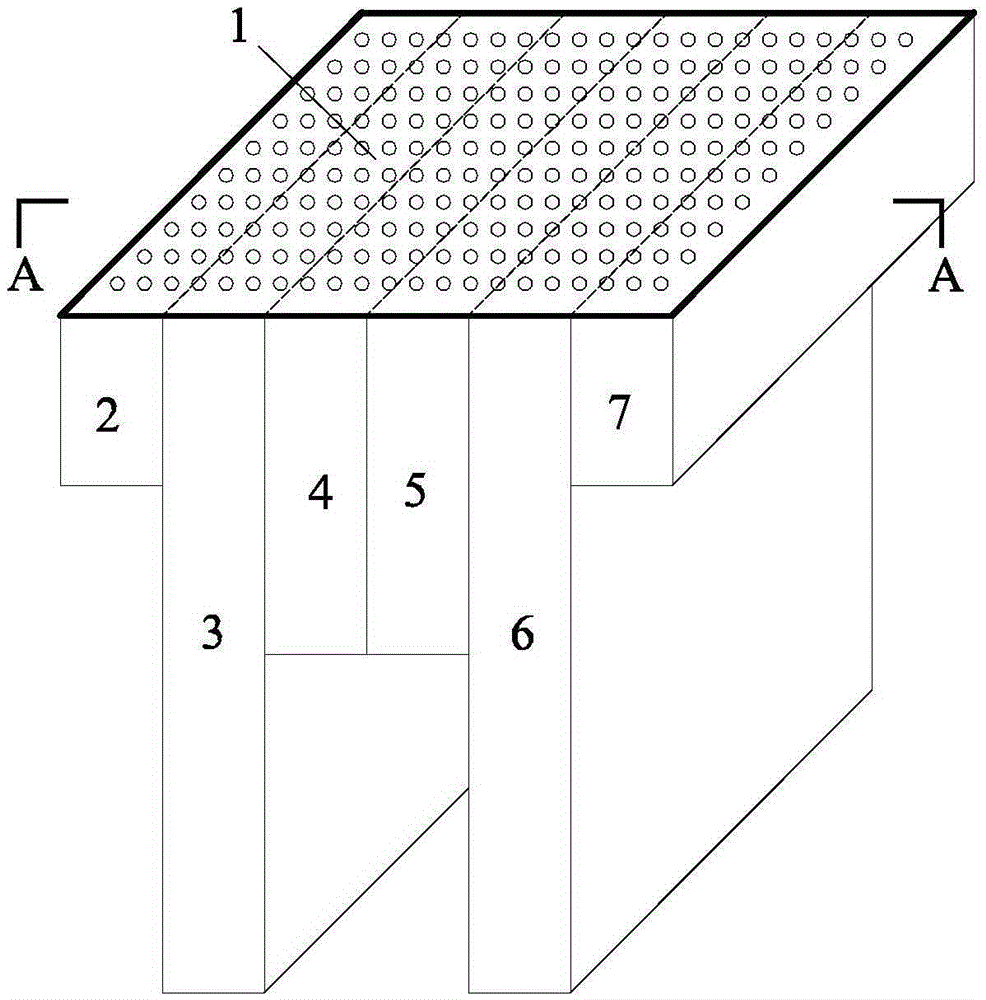

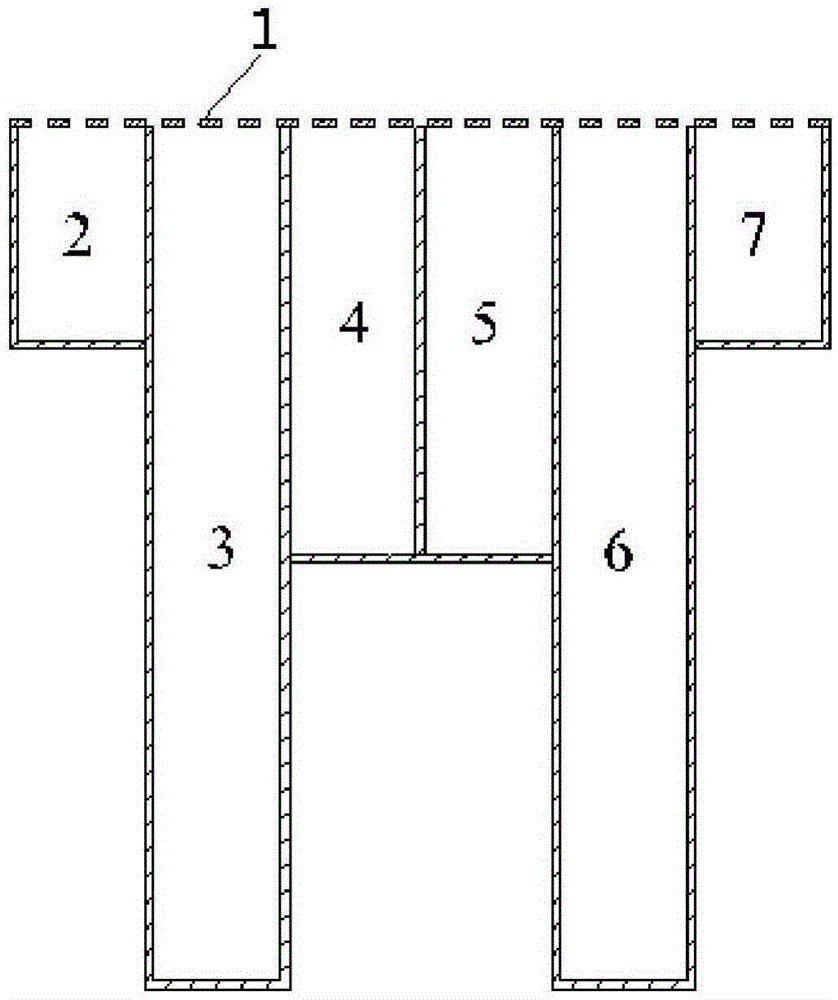

[0046] A broadband micro-perforated sound-absorbing body, comprising: a micro-perforated plate 1, sub-back cavities with different depths are arranged on the micro-perforated plate 1, and the sub-back cavities stand on the micro-perforated plate 1, and the corresponding Adjacent to the side of the microperforated plate 1. In this embodiment, six sub-chambers with different depths are provided on the micro-perforated plate 1 .

Embodiment 2

[0048] A method for predicting the performance of a broadband micro-perforated plate sound absorber, the performance is determined by the sound absorption coefficient spectrum α(θ e ) characterization, the sound absorption coefficient spectrum α(θ e ) is obtained by formula 1,

[0049] α ( θ e ) = 1 - | A 0 P e | 2 - 1 cosθ e Σ n ≠ 0 | A n P e ...

Embodiment 3

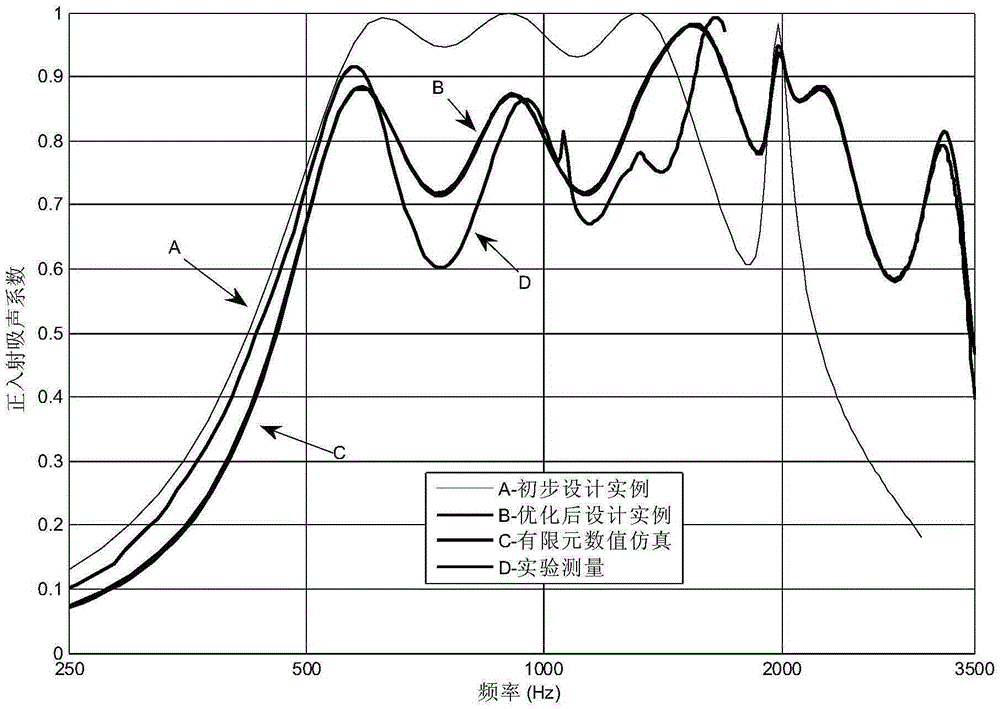

[0066] A structural design method for sound-absorbing body design using a performance prediction method, comprising the following steps:

[0067] Step 1 obtains the sound spectrum to be absorbed, and then obtains the target effective sound absorption spectrum range in the sound absorption coefficient spectrum, and it is generally considered that the sound absorption frequency band with a sound absorption coefficient above 0.45 is the effective sound absorption spectrum range;

[0068] Step 2 Select the material of the micro-perforated plate and the sub-back cavity, set the surface acoustic impedance of the micro-perforated plate to 0.5-1.5 times the air acoustic impedance, and use the calculation method of the acoustic impedance of the micro-perforated plate to determine the parameters of the micro-perforated plate, the perforation diameter d and the thickness of the plate The initial value of t and the perforation rate i;

[0069] Step 3 Design the depth matrix of the sub-bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com