Necking die for water sealing neck machining and necking machining method

A processing method and mold technology, which is applied in the necking mold and necking processing field of processing the water sealing neck of the liner, can solve the problem that holes are easy to appear in the relative position of the workpiece, the depth of the water sealing neck cannot meet the requirements, and the disassembly and installation are time-consuming and laborious and other problems, to achieve the effect of reducing the processing scrap rate, reducing the scrap rate, and avoiding slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

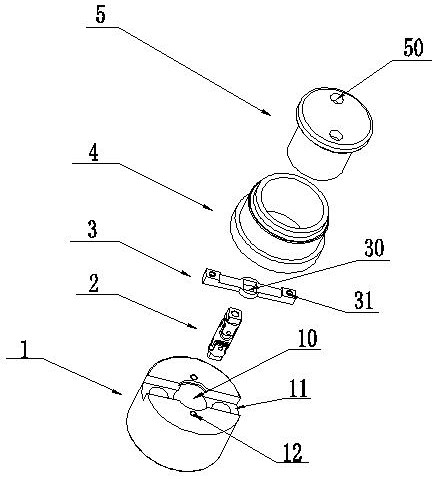

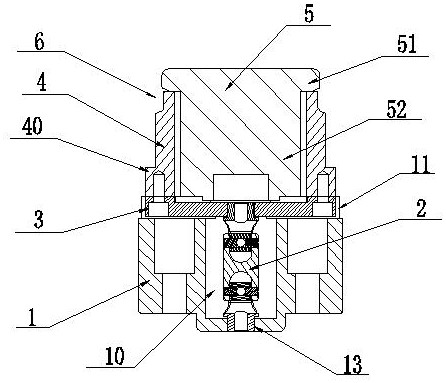

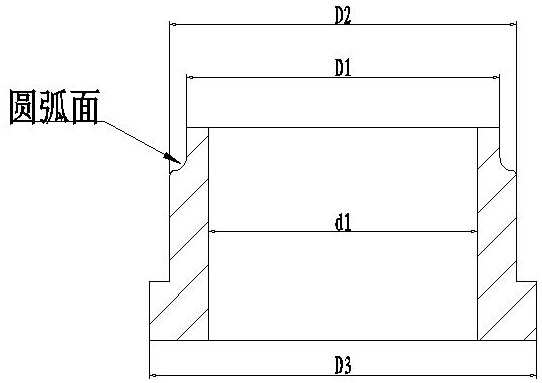

[0029] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figure 1-6 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0030] Refer to attached figure 1 , 2 . A necking mold for processing a water sealing neck, which includes a mold base 1, a universal joint 2, a connecting rod 3, a synchronous mold 4 and a positioning mold 5; the mold base 1 is fixedly connected with a machine transmission shaft, and the machine, transmission shaft , the connecting structure of the drive shaft and the mold base 1 is the prior art, and will not be repeated; the middle part of the mold base 1 is provided with an accommodation hole 10, and the center of the accommodation hole 10 bottom of the mold base 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com