Evaluation method of free cambered lens with high curvature and large caliber and design processing method thereof

An evaluation method and a large-caliber technology, applied in the fields of glasses/goggles, optics, instruments, etc., which can solve the problems of inability to accurately evaluate the quality of lenses and large deviation of theoretical values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In the first embodiment, the optometry obtained the parameters of the lens to be processed: the power of the aspheric lens is 8 diopters, the aspheric coefficient k=-5, the diameter is 72 mm, and the refractive index is 1.55.

[0060] The evaluation method of a high-curvature large-aperture free-form surface lens provided in the first embodiment, the specific steps are:

[0061] (1) In this embodiment, the maximum curvature k of each point on the lens is calculated according to the initial sagittal height distribution data z(x,y) of the lens according to the method disclosed in Chinese patent (200510033935.0) max (x,y) and minimum curvature k min (x,y), and the corresponding direction of maximum curvature θ max (x,y) and the direction of minimum curvature θ min (x,y), the calculation steps are as follows:

[0062] (a) In the Cartesian coordinate system o-xyz, a point P(x i ,y i ,z i ) projection on the xoy plane is P 0 (x i ,y i ,0), ν is the point P(x i ,y i...

Embodiment 2

[0101] In this embodiment, the power of the aspheric lens is 10 diopters, the aspheric coefficient k=-5, the diameter is 72 mm, and the refractive index is 1.55.

[0102] The implementation steps of embodiment two are as embodiment one, and the implementation steps of comparison reference example two are as comparison reference one, the data that obtains by described steps, drawing accompanying drawing is as follows:

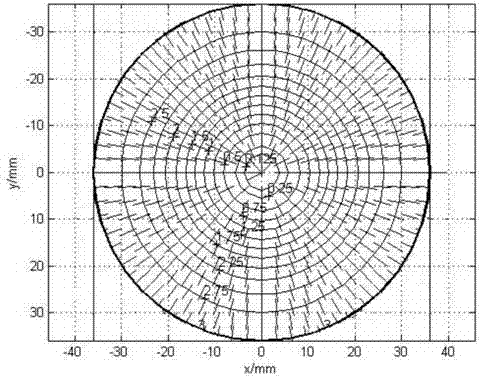

[0103] Figure 9 It is the spherical light distribution diagram of the aspheric lens of the second embodiment of the present invention.

[0104] Figure 10 It is the astigmatism distribution diagram of the aspheric lens of the second embodiment of the present invention.

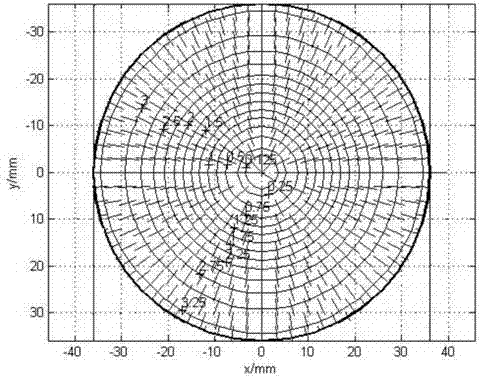

[0105] Figure 11 It is the distribution diagram of the spherical light intensity of the aspheric lens of the reference example 2 for comparison.

[0106] Figure 12 It is the astigmatism distribution diagram of the aspheric lens of the comparison reference example 2.

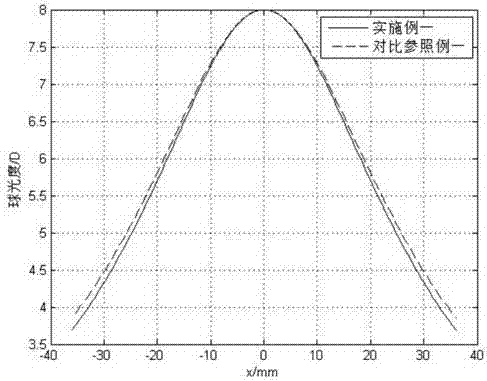

[0107] Figure 13...

Embodiment 3

[0119] In this embodiment, the parameters of the progressive multifocal lens designed by the Winthrop method are as follows: the spherical power of the far vision zone is 6 diopters, the additional diopter is 1 diopter, the diameter is 60 mm, and the refractive index is 1.55.

[0120] The implementation steps of embodiment three are as embodiment one, and the implementation steps of comparison reference example three are as comparison reference one, the data that obtains by described steps, drawing accompanying drawing is as follows:

[0121] Figure 17 It is the spherical light distribution diagram of the progressive addition lens of the third embodiment of the present invention.

[0122] Figure 18 It is the astigmatism distribution diagram of the progressive addition lens of the third embodiment of the present invention.

[0123] Figure 19 It is a graph of spherical power distribution of the progressive multifocal lens of Reference Example 3 for comparison.

[0124] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com