Clamping device for machining small eccentric stepped circular hole parts

A technology of clamping device and small eccentricity, which is applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of meeting the requirements of size and position relationship, increasing the cost of clamping device, consuming processing time, etc., and achieving improvement The effects of processing accuracy, reducing the burden on the warehouse, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

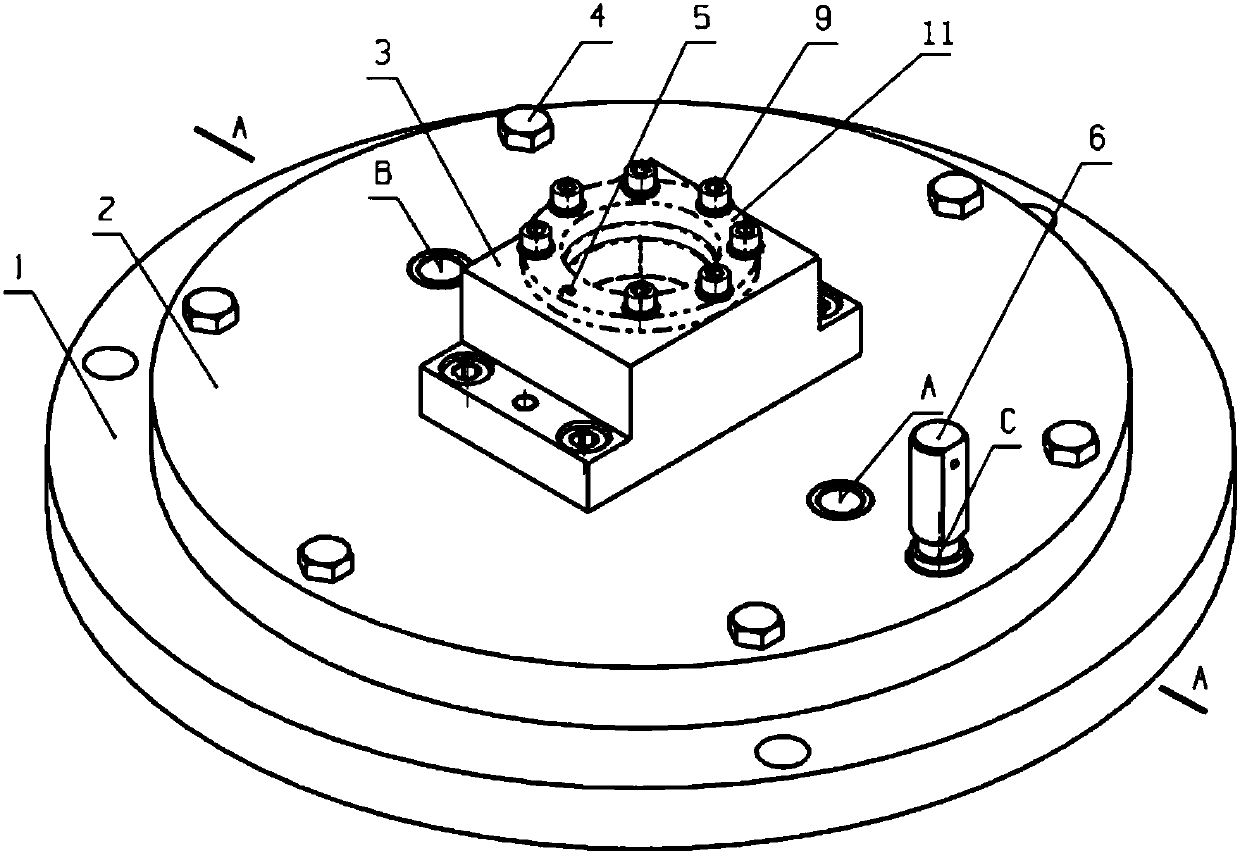

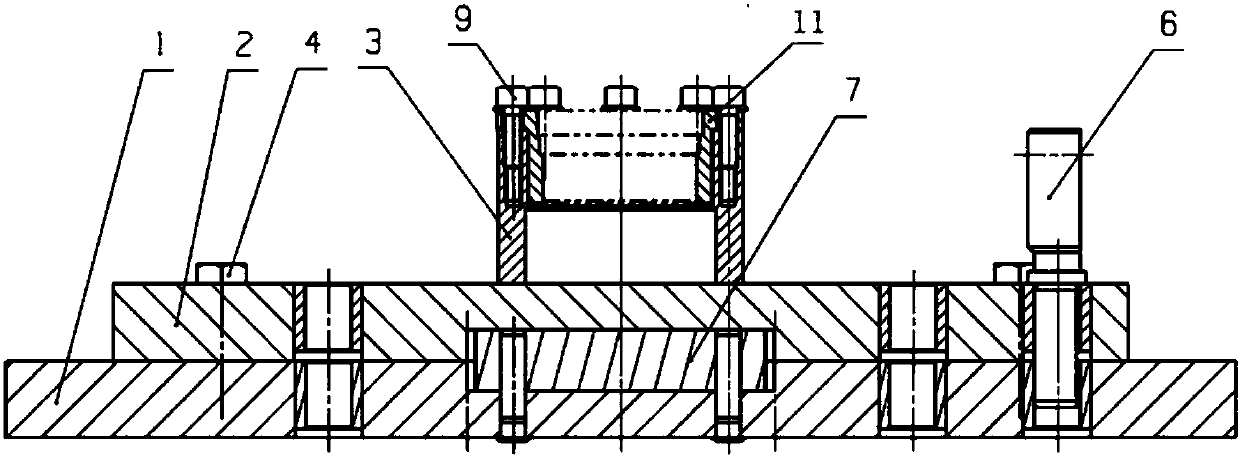

[0021] The clamping device and usage method for processing small eccentric stepped round hole parts according to the present invention will be further described below through examples and in conjunction with the accompanying drawings.

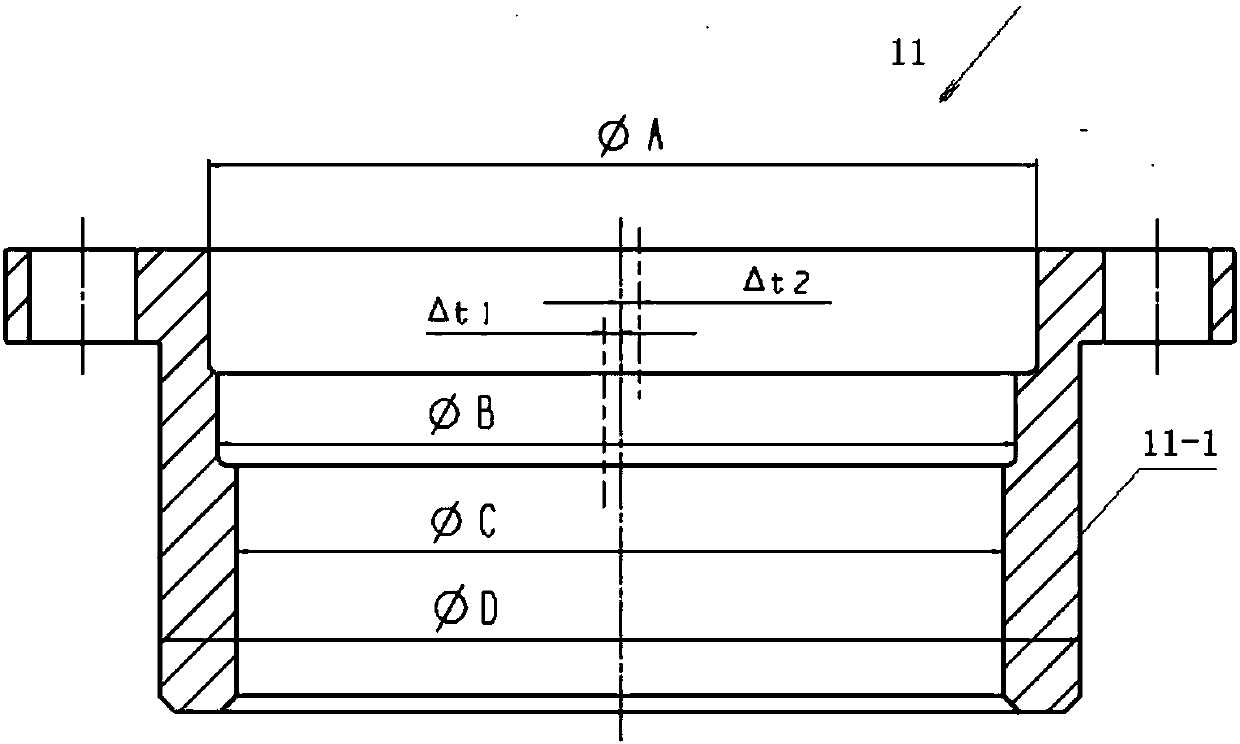

[0022] The clamping device described in this embodiment is used for figure 1 The processing of the small eccentric stepped round hole parts shown is from figure 1 It can be seen that in this part, the centerline of the circular hole with the lower aperture of ΦC is on a straight line with the centerline of the positioning outer cylindrical surface 1-1, which is a non-eccentric hole, and the centerline of the circular hole with the upper and middle aperture of ΦB is located at the positioning On the left side of the center line of the outer cylindrical surface 1-1, the eccentric distance △t1=0.2mm, the center line of the circular hole with the upper aperture diameter ΦA is located on the right side of the center line of the outer cylindrical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com