Application of aluminum alloy material in hydraulic valve body and aluminum alloy hydraulic switching valve

A technology of aluminum alloy materials and hydraulic valves, which is applied in valve details, valve devices, valve housing structures, etc., can solve the problems of heavy valve body, poor corrosion resistance, and difficult processing, and achieve good processing performance and corrosion resistance Good, the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

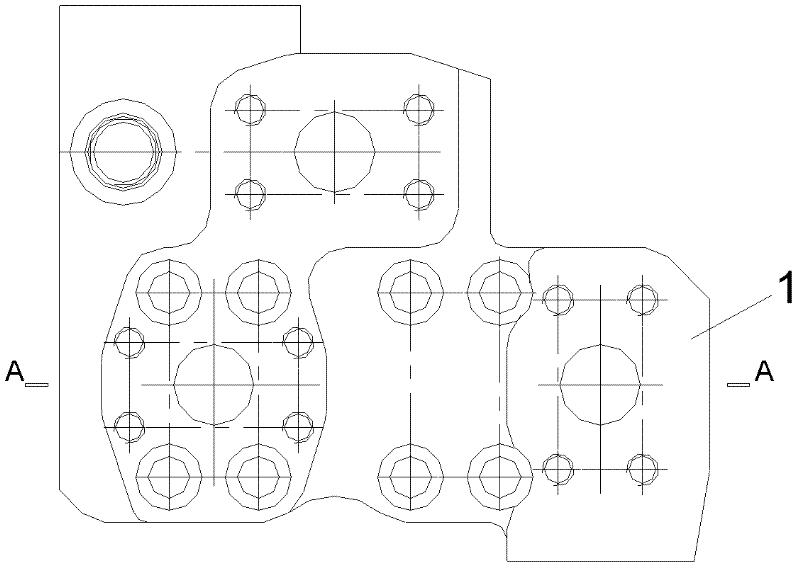

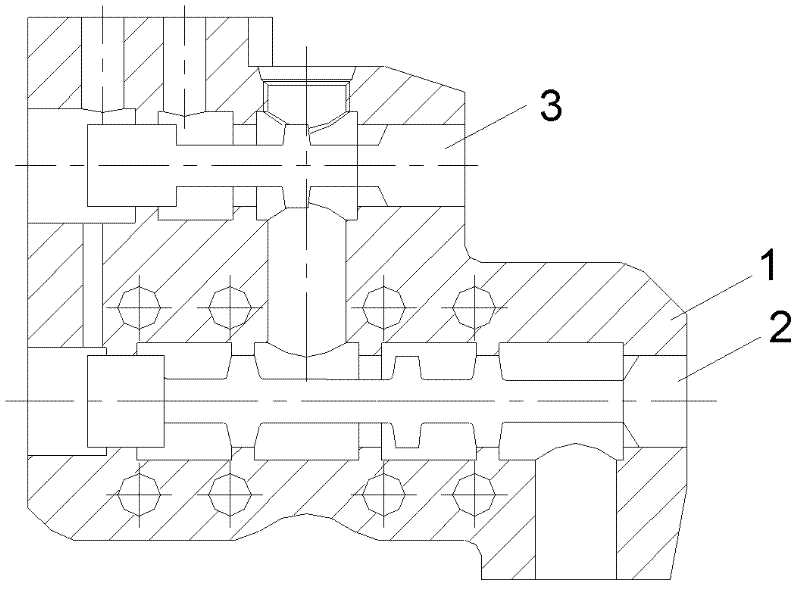

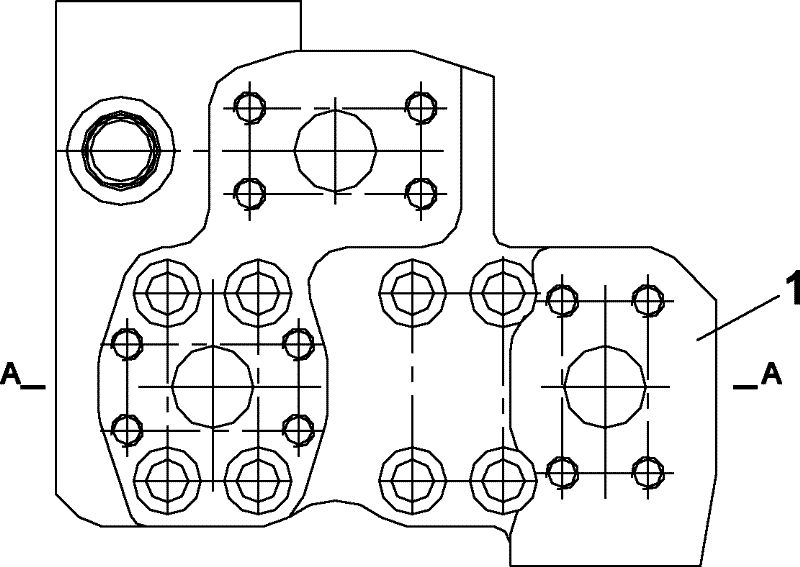

[0020] Example. The hydraulic switching valve is made of aluminum alloy material. The switching valve is used to realize the automatic switching between high speed and low speed of the excavator. Such as figure 1 , 2 As shown, a valve body 1 is included, and a large valve stem 2 and a small valve stem 3 are housed in the valve body 1. The valve body 1 is made of aluminum alloy material, the aluminum alloy material is calculated by weight percentage, and its composition is Cu 2.0-6.0%, Mn 0.05%, Ti 0.01-0.5%, Cr 0.01-0.2%, Cd 0.01% ~0.4%, Zr 0.01~0.25%, B 0.005~0.04%, rare earth element Pr 0.05~0.3%, and the rest are Al and trace impurity elements. The preparation method of the aluminum alloy comprises the following steps: (1) adding an appropriate amount of aluminum ingot or molten aluminum liquid into the melting furnace, heating to melt it completely and keeping it warm at 660-850°C; Add Ti, Cr, Cd, Zr, B, Pr trace elements after Cu, Mn alloy elements stir evenly; Chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com