Machining method for forming holes in peripheral surface of housing of timing gear and special combination drilling machine for machining method

A combined drilling machine and gear chamber technology, applied in the field of mechanical parts processing, can solve the problems of difficulty in ensuring accuracy, different positioning references, and low processing efficiency, so as to avoid errors, ensure position accuracy, and improve processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

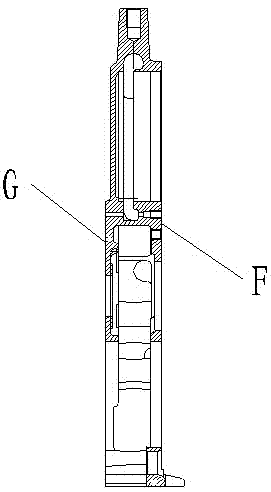

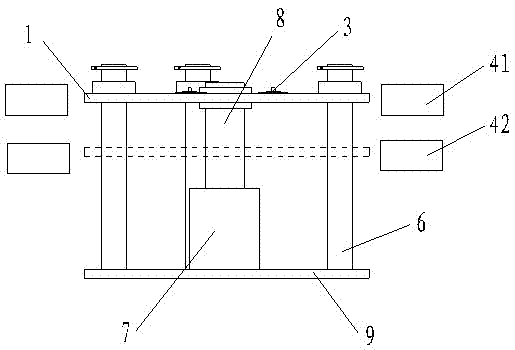

[0022] Embodiment 1: with reference to attached figure 2 , 3 , with processing attached figure 1 Take the timing gear chamber shown in as an example. A special combination drilling machine for processing the peripheral surface of a timing gear chamber, comprising a workpiece clamping table 1 installed in the drilling machine; An oil cylinder 7 is arranged between them; the bottom of the oil cylinder 7 is fixed on the machine tool base plate 9, and the end of the ejector rod 8 of the oil cylinder 7 is fixed on the center of the workpiece clamping table 1; the outer circumference of the workpiece clamping table 1 is provided with four Lugs 2; four guide posts 6 are arranged between the workpiece clamping table 1 and the machine tool base plate 9; the bottom ends of the guide posts 6 are fixed on the machine tool base plate 9, and the top ends of the guide posts 6 pass through the lugs 2 And the workpiece clamping platform 1 can lift and slide on the guide column 6; the top o...

Embodiment 2

[0023] Embodiment 2: On the basis of Embodiment 1, a special combination drilling machine for processing the peripheral surface of the timing gear chamber, wherein at each processing station, a drill bit is installed in the upper multi-axis device 41, and a tap is installed in the lower multi-axis device 42 The drill bits and taps of the multi-axis device 4 are all horizontal, and the number and position of the drill bits and taps are respectively opposite to the holes on the outer peripheral surface of the timing gear chamber to be processed; the workpiece clamping platform 1 is under the action of the oil cylinder 7 When rising to the upper multiaxial device 41, the drilling operation is completed under the action of the upper multiaxial device 41; when the workpiece clamping table 1 descends to the lower multiaxial device 42 under the action of the oil cylinder 7, 42 to complete the tapping operation.

Embodiment 3

[0024] Embodiment 3: a kind of processing method of the peripheral surface of the timing gear chamber, which utilizes the special combined drilling machine for processing the peripheral surface of the timing gear chamber described in embodiment 1, comprising the following steps:

[0025]① Place the timing gear chamber on the workpiece clamping table 1, and the positioning pin 3 passes through the process positioning pin hole of the timing gear chamber;

[0026] ②Start the hydraulic chuck 5, the pressure block 52 above the hydraulic cylinder 51 descends, and press the timing gear chamber on the workpiece clamping table 1;

[0027] ③Start the oil cylinder 7 above the bottom plate 9 of the machine tool, and lift the workpiece clamping table 1 to the position of the multi-axis device 4 equipped with the drill bit;

[0028] ④ Start the motor to drive the drill bit in the multi-axis device 4 to complete the processing of the through holes on the five outer peripheral surfaces A, B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com