Tool for pressed assembling of rear oil seal of carnkshaft of engine

A technology for press-fitting tools and engines, which is applied in the manufacture of tools, hand-held tools, etc., can solve problems such as difficult to ensure the tightness of oil seals, difficult to ensure oil seals, and easily damaged oil seals, so as to ensure quality and performance, ensure assembly accuracy, and ensure The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

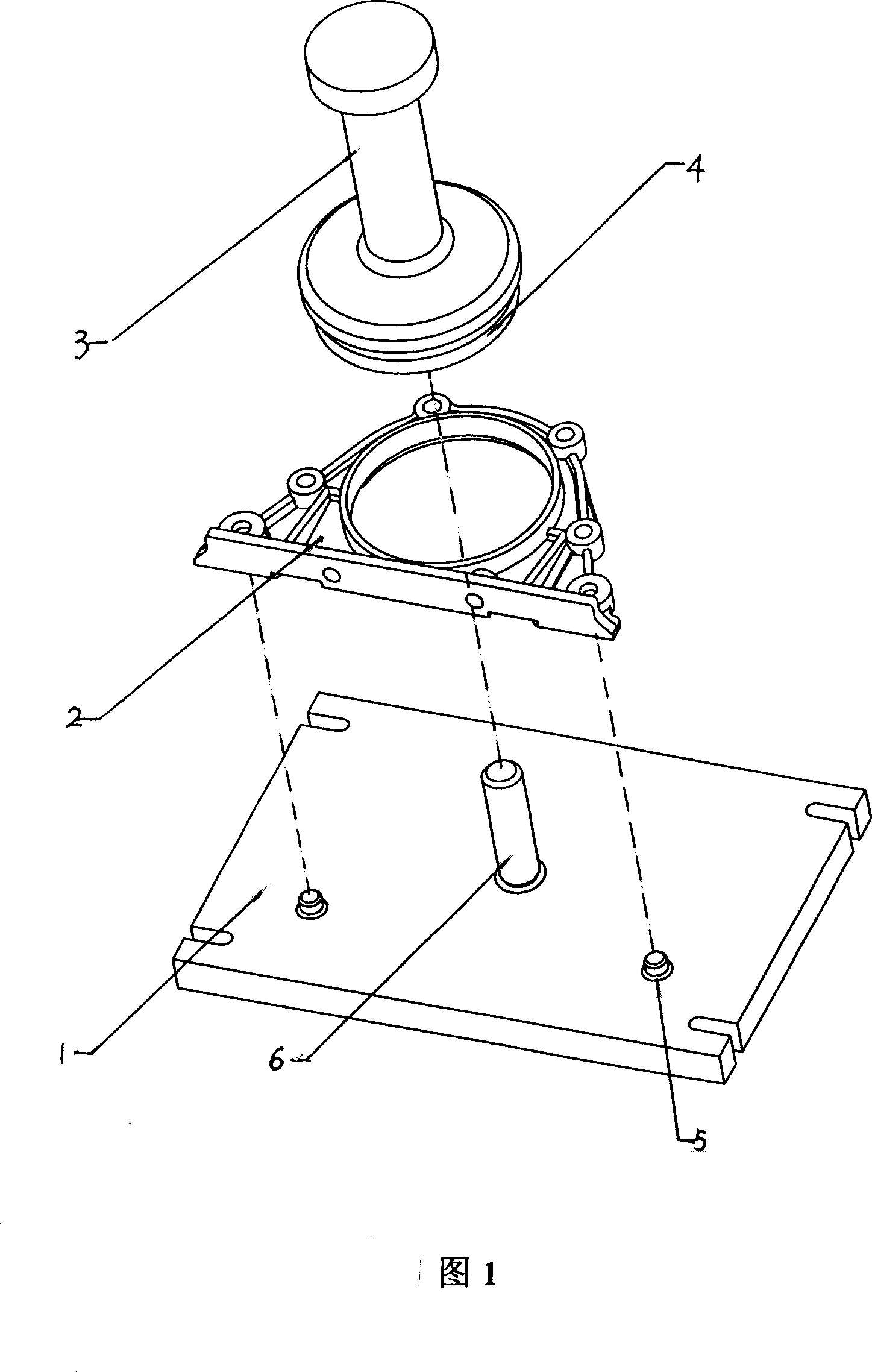

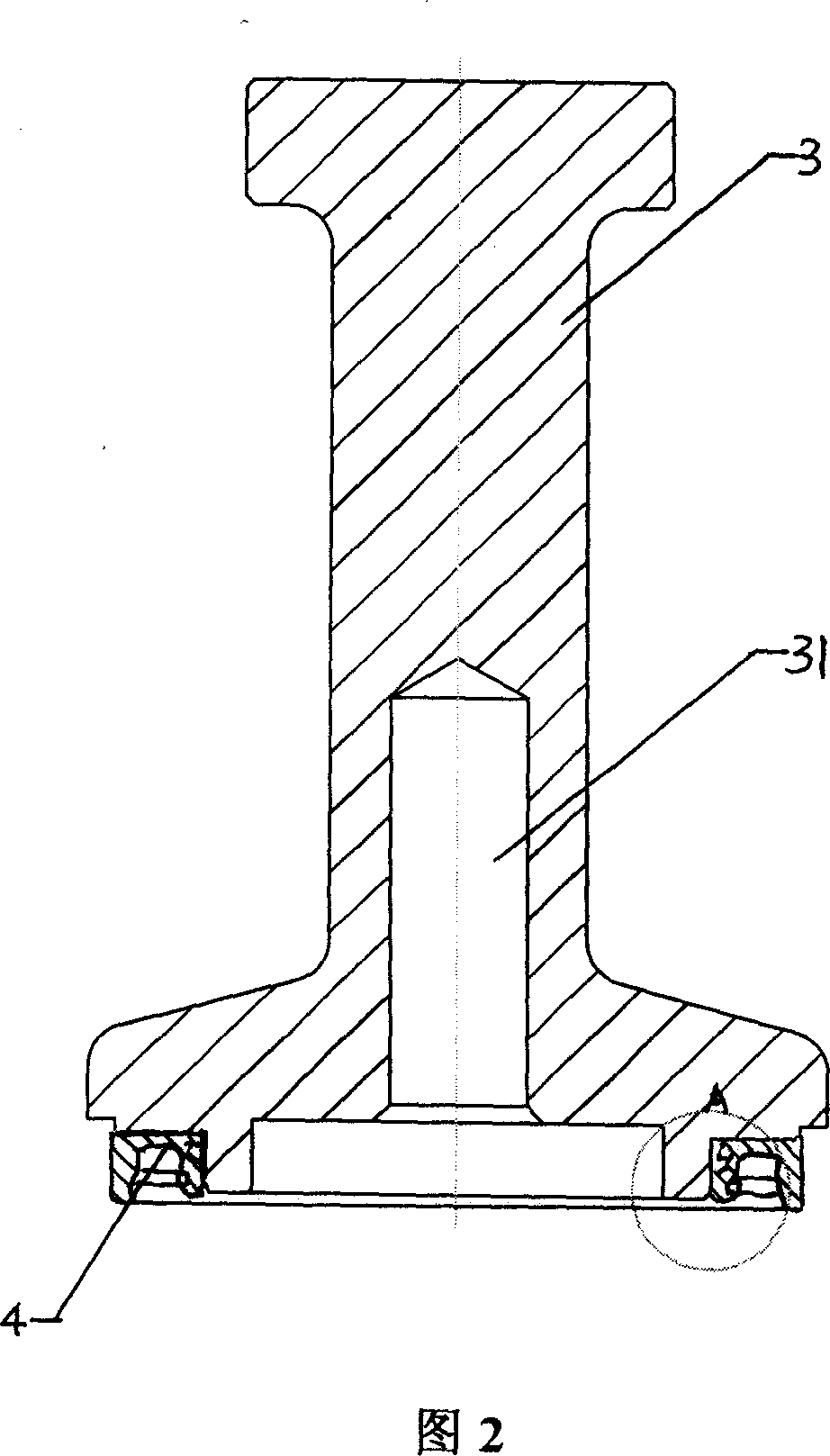

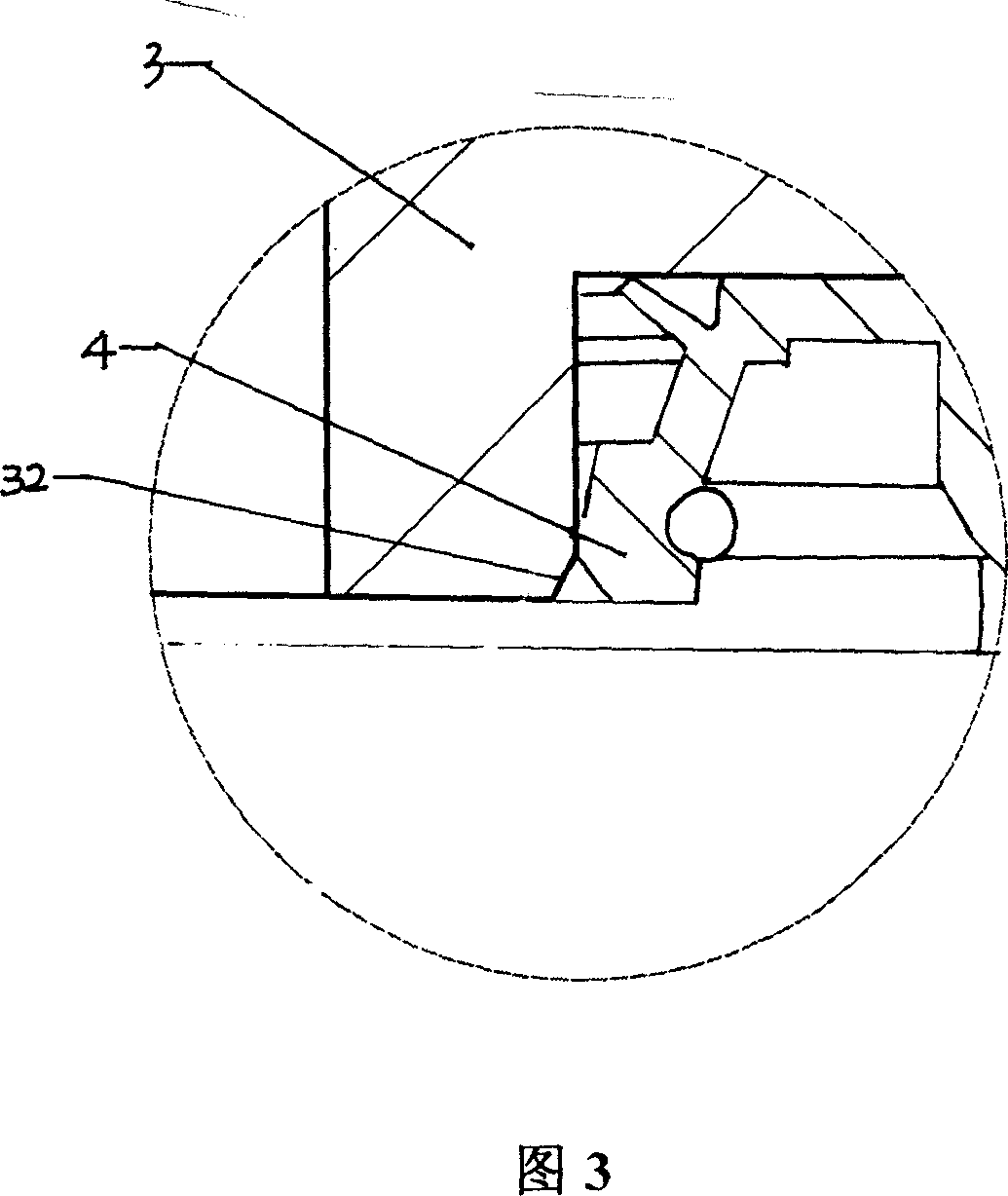

[0011] Referring to FIG. 1 , the press-fit tool is composed of a support base 1 , a press-fit sleeve 3 , a positioning pin 5 and a guide rod 6 . A positioning pin 5 is knocked into the support seat 1 through interference fit, and a guide rod 6 is arranged on the support seat 1 corresponding to the center position of the rear end cover 2 of the crankshaft. The guide rod 6 and the center hole 31 of the shank of the press fitting sleeve Clearance fit, referring to Fig. 2 and Fig. 3, the bottom end of the press-fit sleeve 1 is in interference fit with the crankshaft rear oil seal 4, and a positioning slope 32 is provided at the bottom end.

[0012] See Figure 1 for the oil seal after press-fitting the crankshaft. First, fix the support base 1 with positioning pins and guide rods on the workbench with four M6 bolts, then place the crankshaft rear end cover 2 on the support base 1, and pass the support base The positioning pin 5 on 1 is positioned with the clearance of the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com