Split bin type fireproof heat preservation plate production technology

A fire-proof insulation board and production process technology, applied in the direction of heat preservation, fire prevention, layered products, etc., can solve the problems of poor product uniformity, high processing waste rate, large space occupation, etc., achieve high production efficiency, low processing waste rate, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

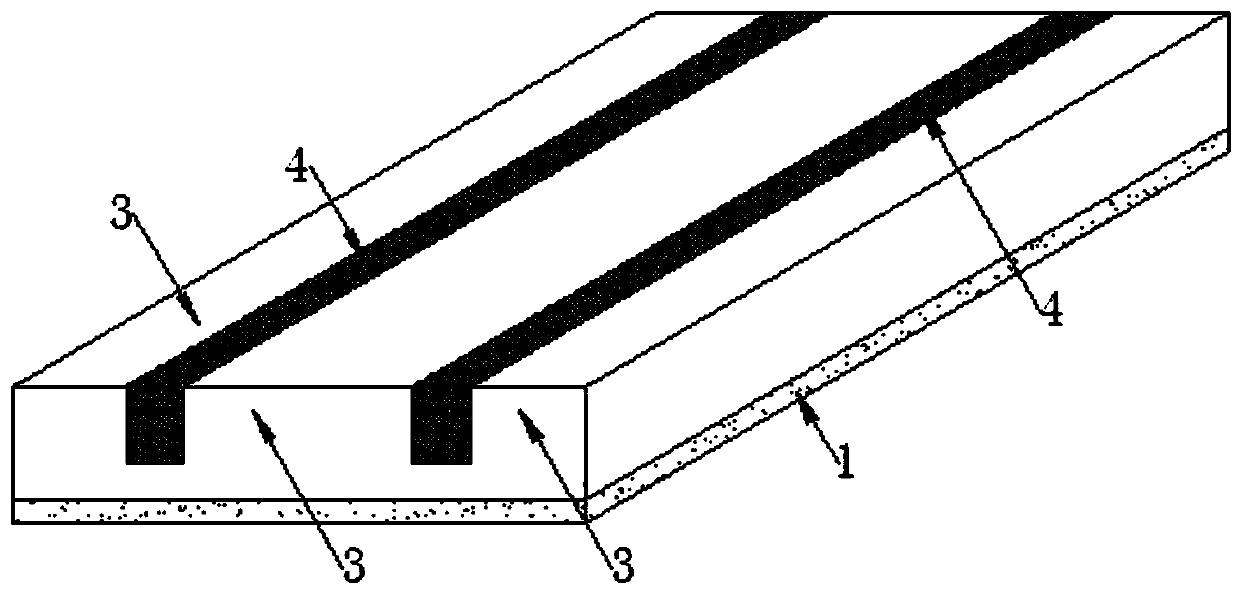

[0035] A production process of split-warehouse type fireproof insulation board includes the following steps:

[0036] S1: Lay or bond the reinforcement layer 1 on the lower surface of the insulation board;

[0037] S2: Machining grooves on the insulation board body, the grooves divide the insulation board body into several bins 3, and the depth of the grooves is not less than two-thirds of the thickness of the insulation board body;

[0038] S3: Fill the groove with Class A material to form a fire barrier 4;

[0039] S4: Lay or bond the reinforcing layer 1 on the upper surface of the insulation board.

Embodiment 2

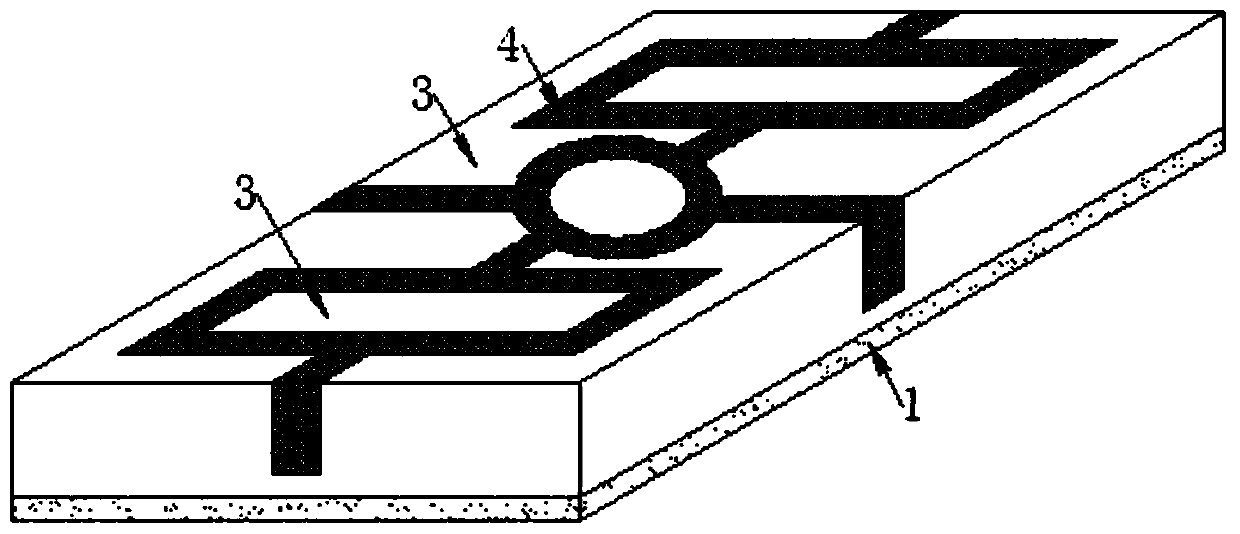

[0041] A production process of split-warehouse type fireproof insulation board includes the following steps:

[0042] S1: Lay reinforcement layer 1 and reinforcement material 2 on the lower surface of the insulation board in sequence, where reinforcement layer 1 is a mortar layer, and reinforcement material 2 is polypropylene fiber;

[0043] S2: Machining grooves on the insulation board body, the grooves divide the insulation board body into several bins 3, the ends of the grooves are located on the side of the insulation board body, and the groove depth is five times the thickness of the insulation board body. Four quarters

[0044] S3: Fill the groove with lightweight aggregate concrete to form a fire barrier 4;

[0045] S4: Lay reinforcement layer 1 on the upper surface of the insulation board, and reinforcement layer 1 is a mortar layer.

Embodiment 3

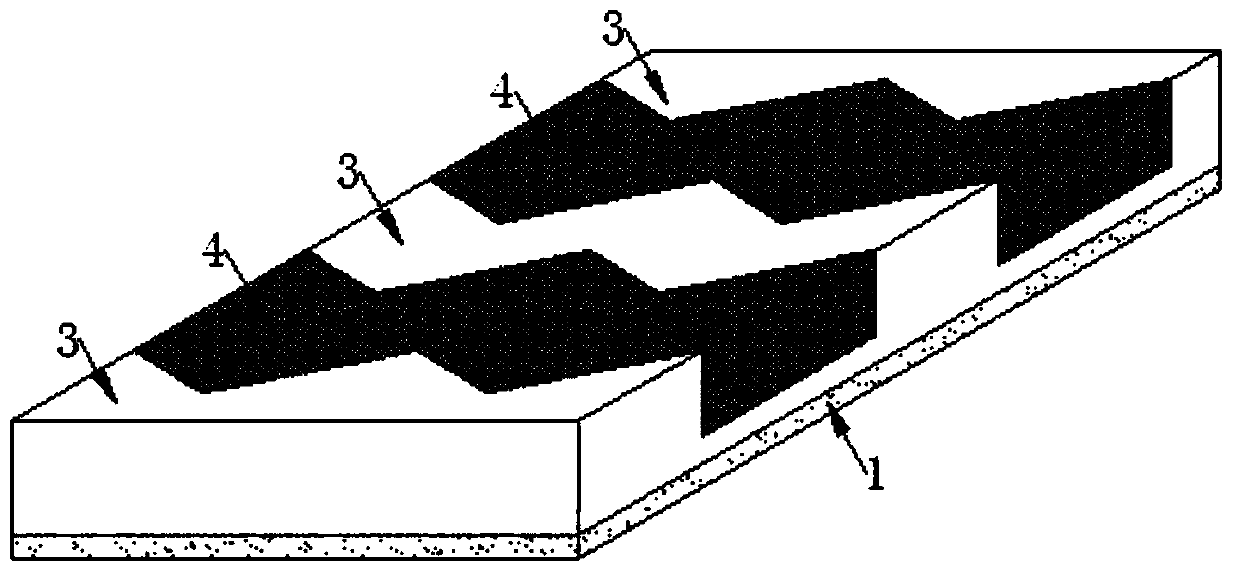

[0047] A production process of split-warehouse type fireproof insulation board includes the following steps:

[0048] S1: Lay reinforcement layer 1 and reinforcement material 2 in sequence on the lower surface of the insulation board body, where reinforcement layer 1 is a mortar layer and reinforcement material 2 is a steel wire mesh;

[0049] S2: Machining two transverse fold-line grooves on the insulation board body, the grooves divide the insulation board body into several bins 3, the depth of the groove is three-quarters of the thickness of the insulation board body;

[0050] S3: Fill the groove with rock wool to form a fire barrier 4;

[0051] S4: Lay reinforcement layer 1 and reinforcement material 2 on the upper surface of the insulation board body, reinforcement layer 1 is a mortar layer, and reinforcement material 2 is glass fiber yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com