Manufacturing method of multi-direction four-anchor-head integral steel anchor beam

A manufacturing method and technology of four anchor heads, which are applied in the directions of bridges, bridge construction, bridge parts, etc., can solve the problems of unsuitable multi-directional four anchor head integral steel anchor beams, etc., to ensure firmness, ensure assembly and welding, reduce The effect of quadratic scribing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] In this embodiment, the manufacturing method of the multi-directional four-anchor head integral steel anchor beam comprises the following steps:

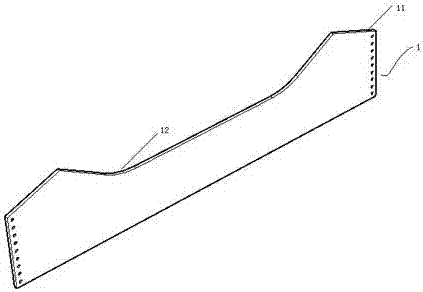

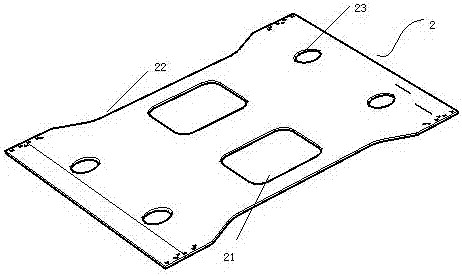

[0030] (1) Fabrication of web unit 1: eg figure 2 As shown, the blanked steel plate is precisely cut by CNC flame, and the two ends of one side of the steel plate are symmetrically formed with inclined planes 11 connected with the two ends of the steel plate, and then leveled with a plate catcher to strictly control the flatness ≤ 0.3mm, and then Bevel processing is performed on the side that is cut with a bevel, and then an arc-shaped groove 12 is formed at the center of the side with the inclination, based on the central axis and the machined edge line of the steel plate with the arc-shaped groove, using The marking needle draws the center line at the central axis of the steel plate, draws the bolt hole position lines on both sides of the steel plate, and draws the anchor head assembly position line on the steel plate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com