Anti-short-circuit porous high-efficiency flushing electrode for arc discharge machining

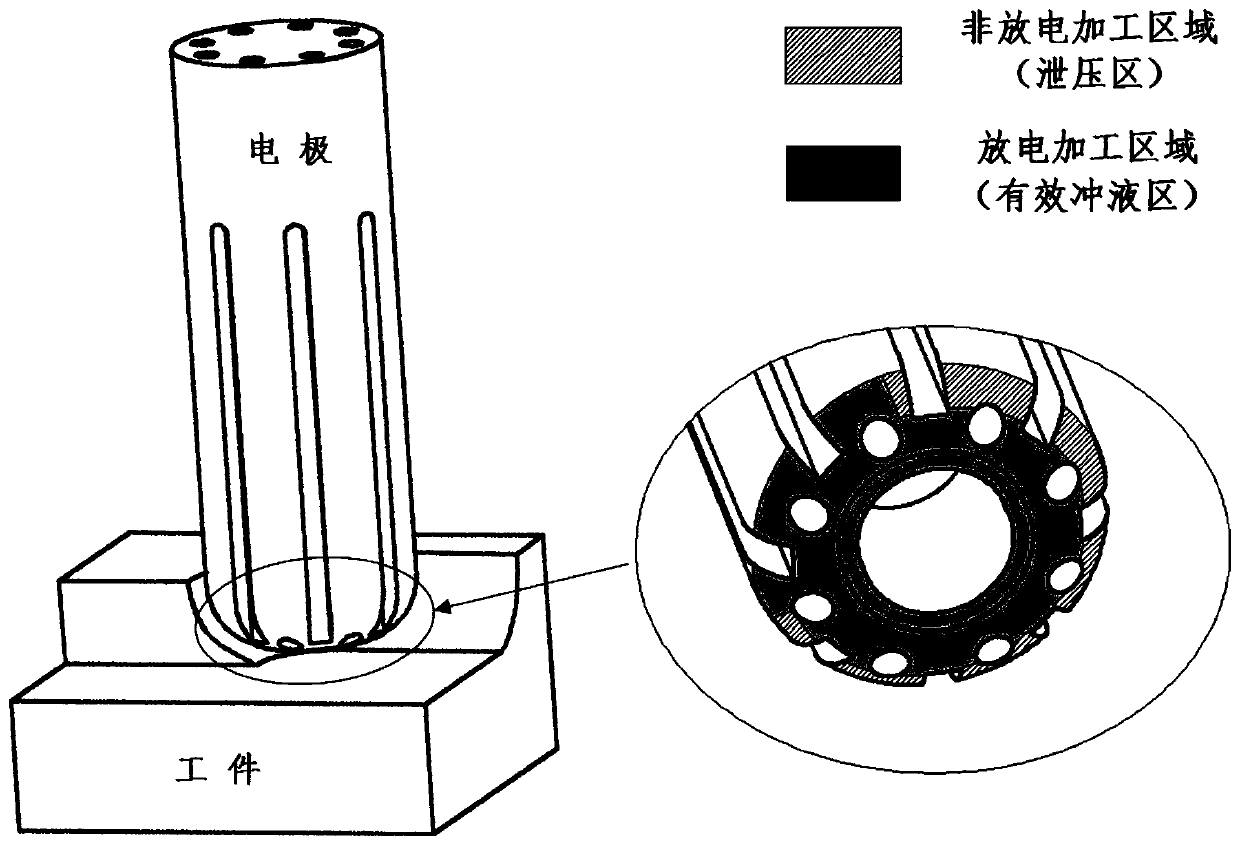

An arc discharge and anti-short circuit technology, which is applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of unstable arc discharge processing state, low EDM efficiency, and low effective flushing ratio, etc. Machining surface quality, good high-speed arc discharge machining state, and the effect of avoiding machining short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

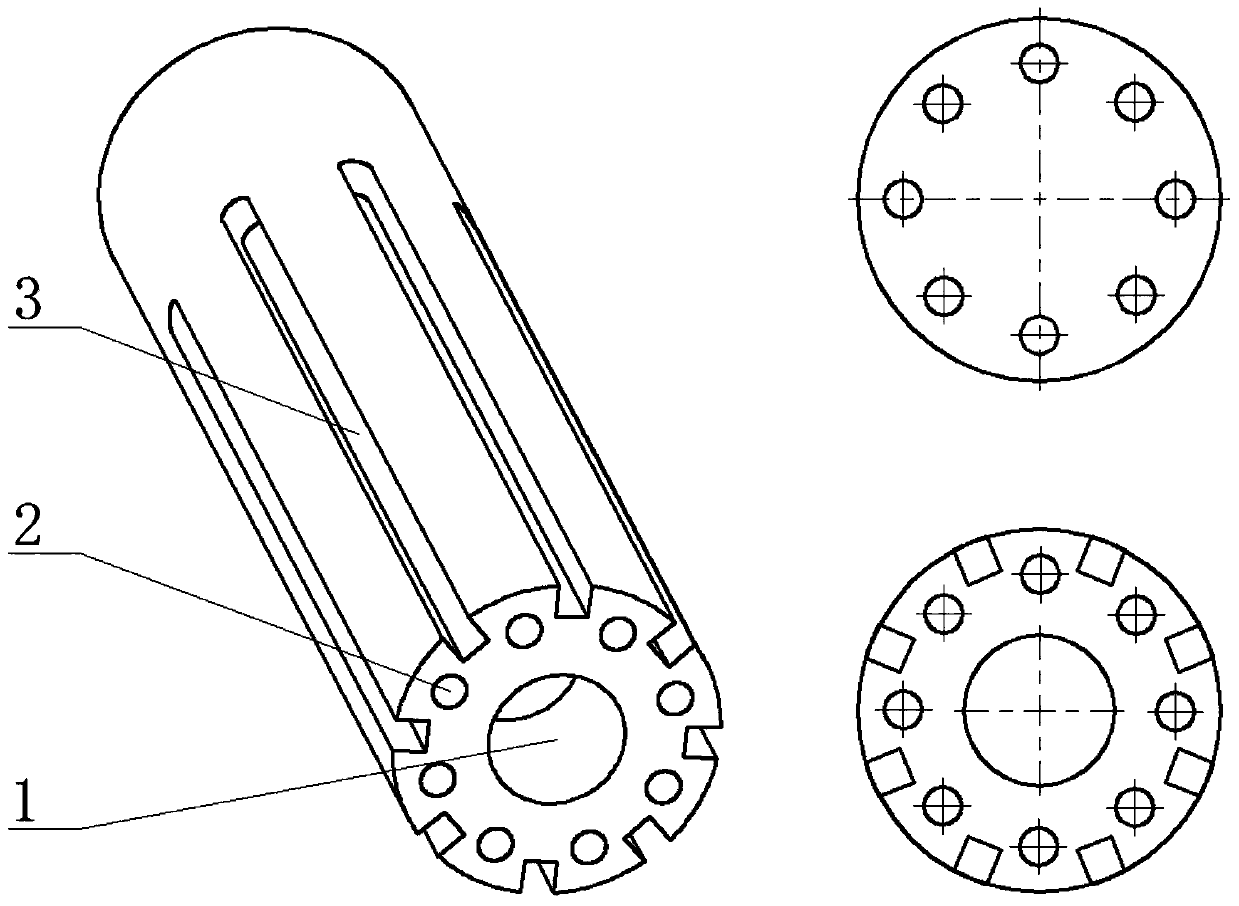

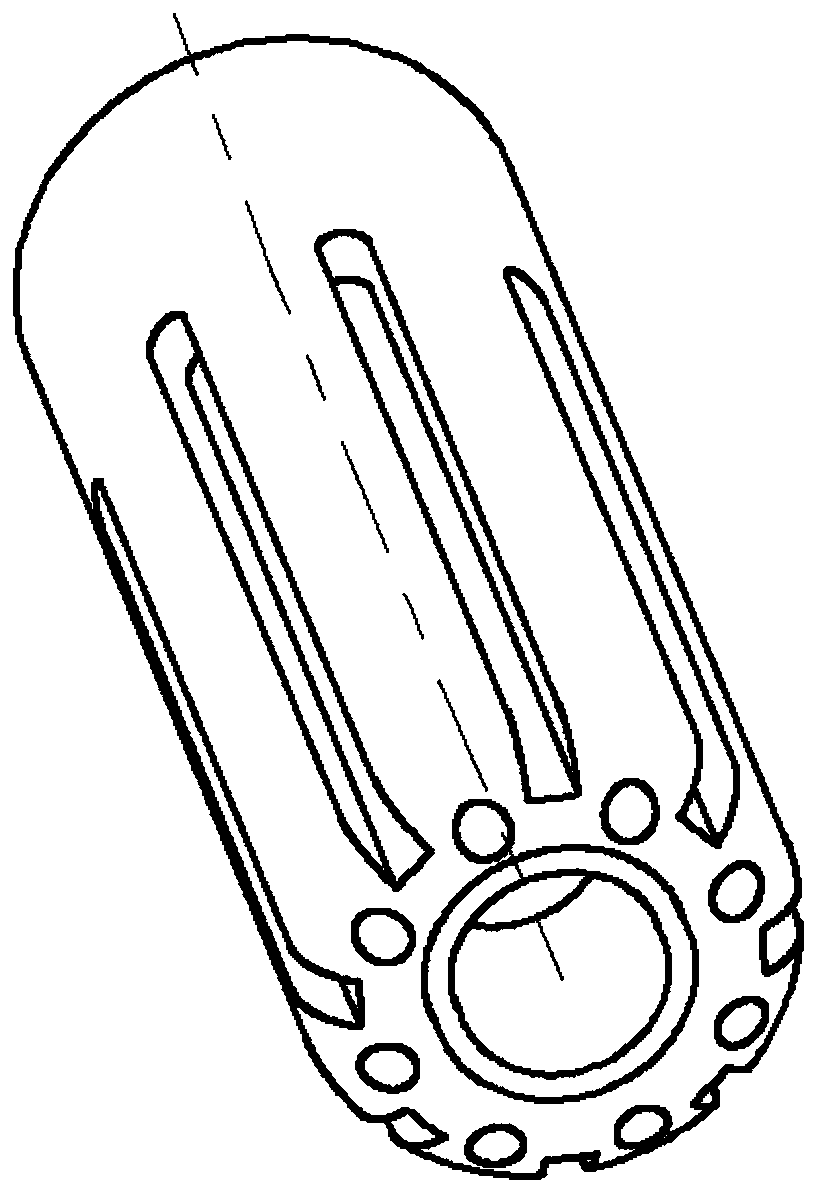

[0027] The electrode material is graphite, the electrode diameter is 20mm, the length is 120mm, the diameter of the central blind hole 1 is 7mm, the depth is 90mm, the diameter of the inner flushing through hole 2 is 3mm, and the number is 8, and the flushing chip removal groove 3 is 2.5mm wide and 1.5mm deep. mm, length 90mm, quantity 8, before performing high-speed arc discharge machining complex shape workpiece with three-dimensional features, install the electrode on the rotating spindle of the machine tool, connect the electrode to the negative pole or positive pole of the discharge power supply, the workpiece and the discharge The positive or negative pole of the power supply is connected, and the discharge gap required for processing is formed between the electrode and the workpiece through the servo movement of the machine tool. The current loop is composed of the discharge power supply, the electrode, the discharge gap and the workpiece, and the discharge power supply p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com