Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256results about How to "Reduce molding difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

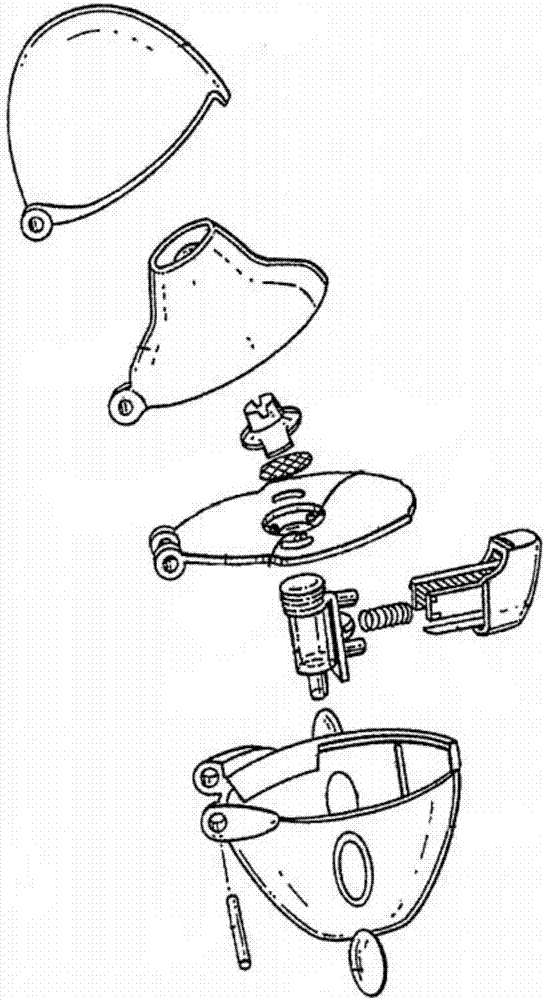

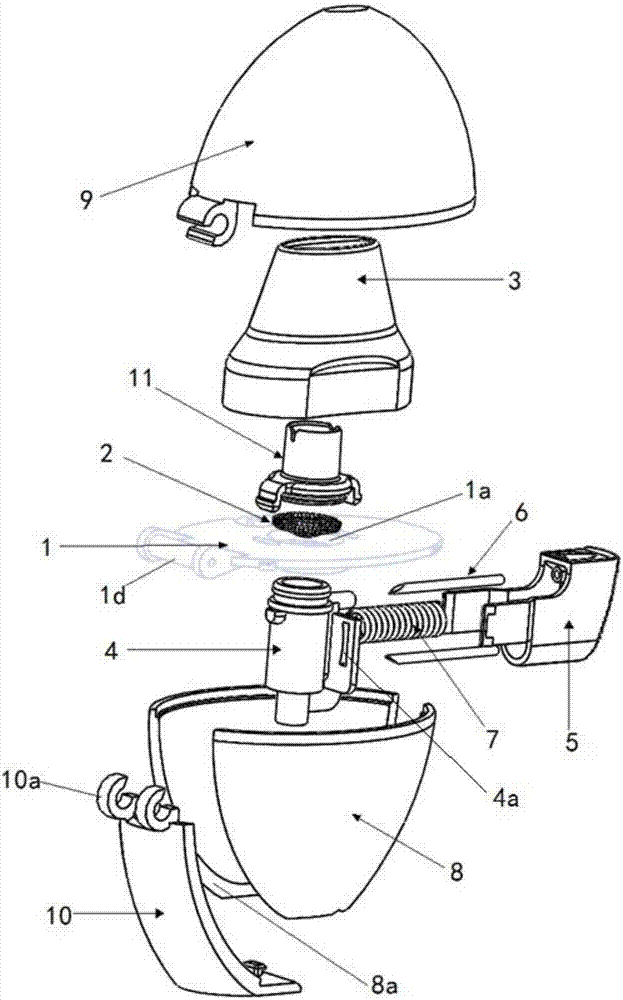

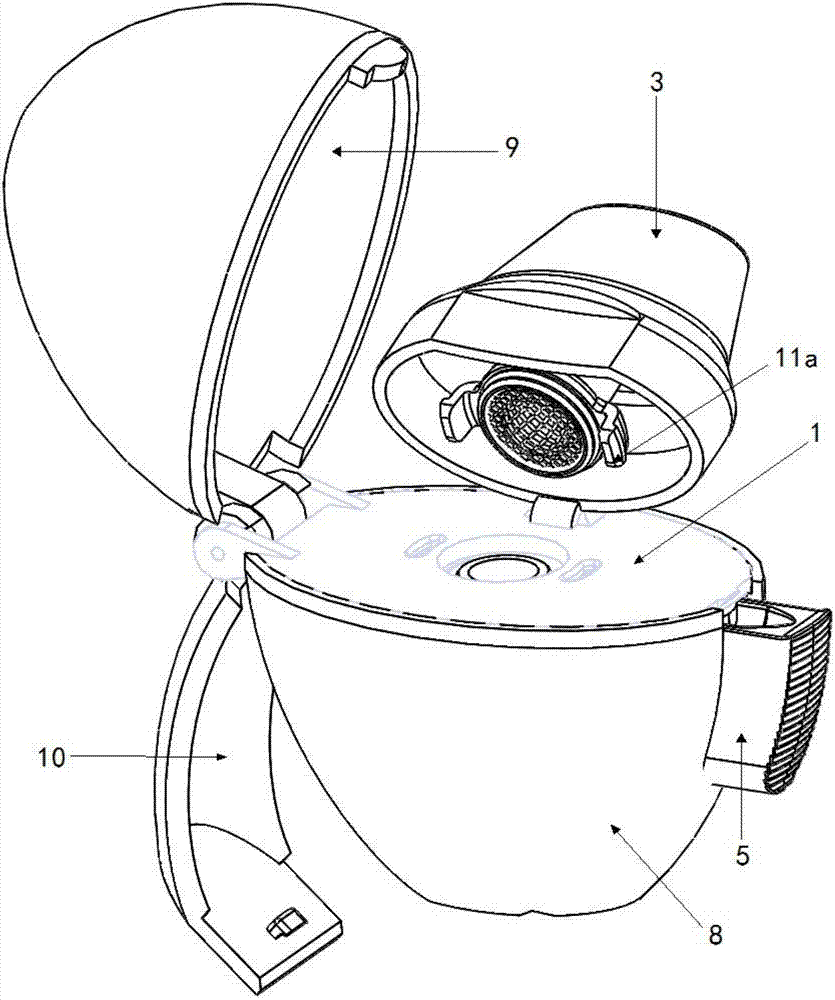

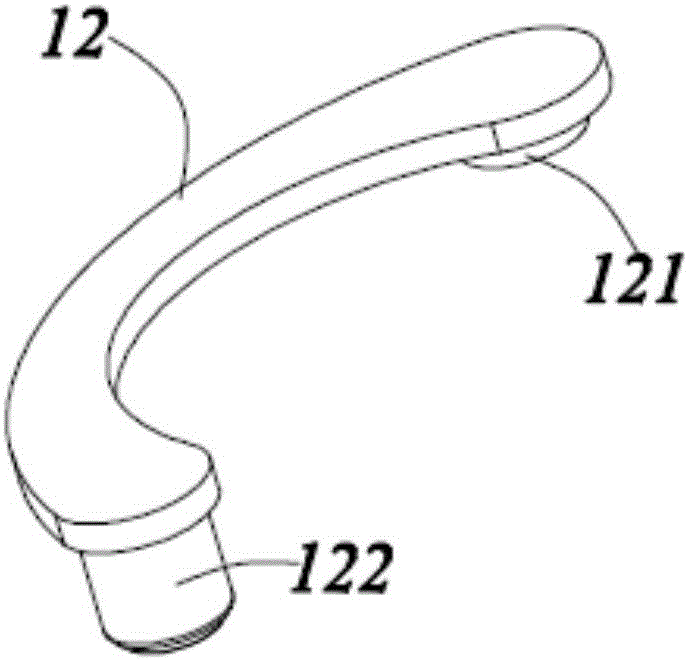

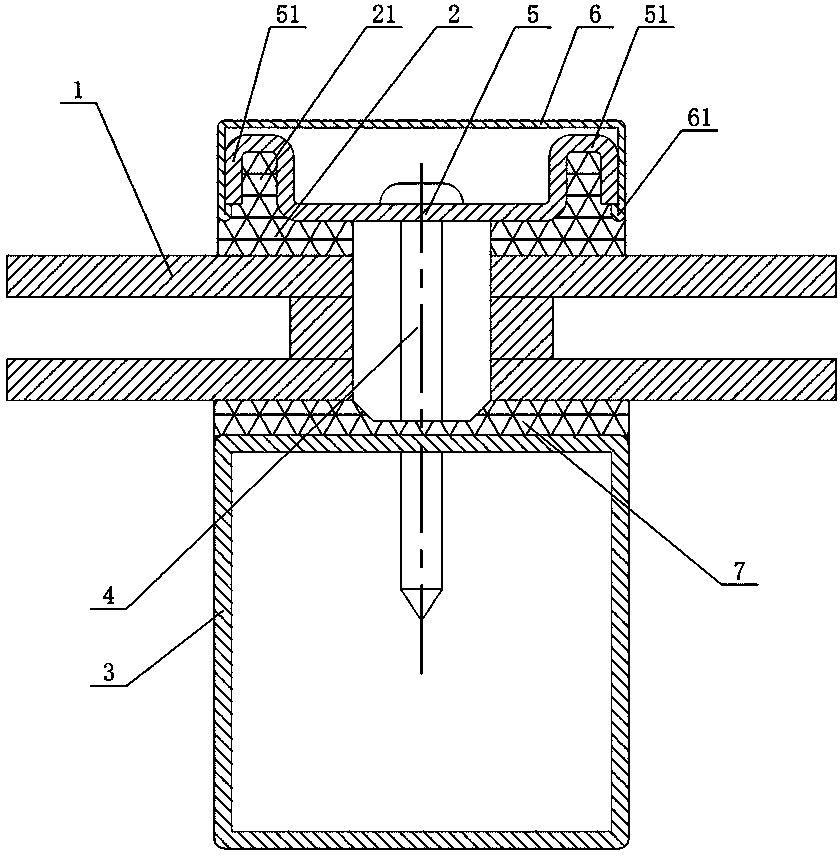

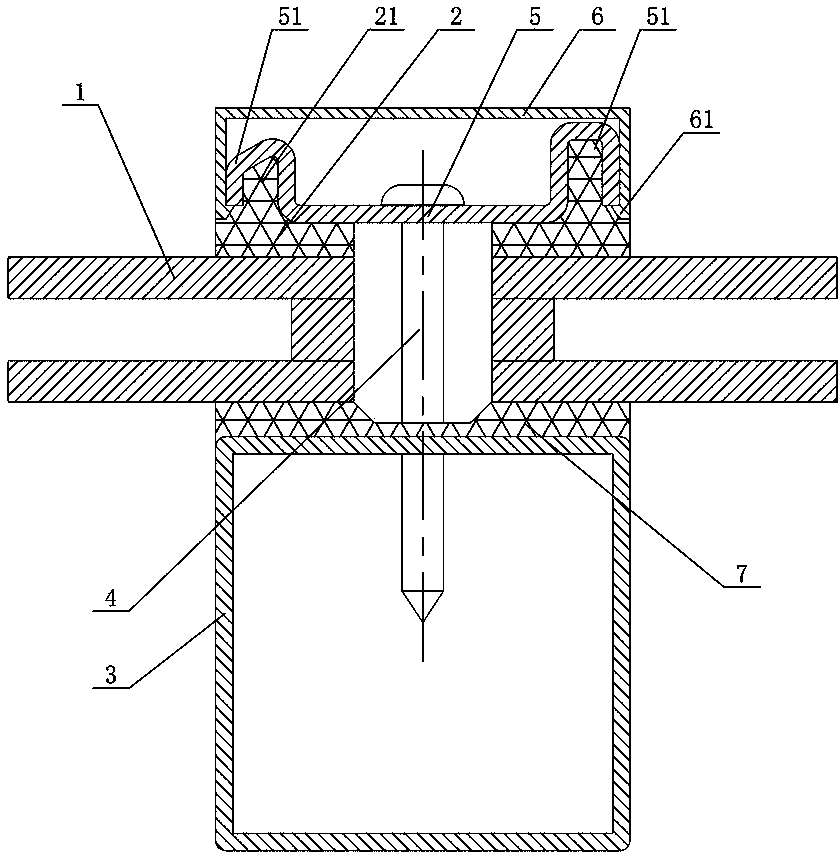

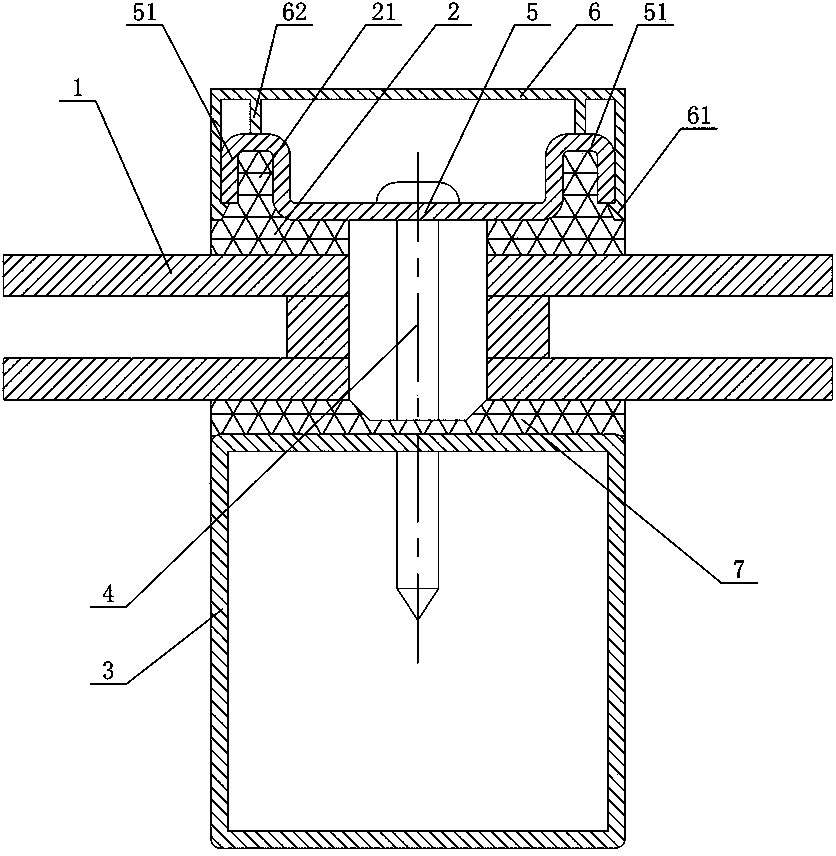

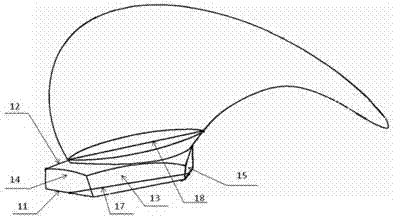

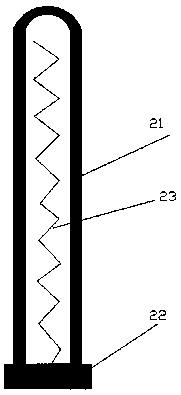

Dry powder inhaler

PendingCN106924845AEasy to assembleReduce manufacturing costMedical devicesInhalatorsBiomedical engineeringDry-powder inhaler

The invention discloses a dry powder inhaler, which comprises a bearing plate, a suction nozzle, a capsule chamber, a button, a spring and a lower shell, wherein through holes are formed in the bearing plate in a going-through mode; the suction nozzle is connected to the upper side of the bearing plate and is arranged on the through holes; the capsule chamber is connected to the lower side of the bearing plate and is located on the through holes; tip pins, which are made from metal, are connected to the button, and the tip pins, through a pressing action of the button, can extend into the capsule chamber; the spring is clamped between the button and the capsule chamber, and by virtue of the spring, elasticity away from the direction of the capsule chamber is exerted; the upper side of the lower shell is of an opening structure; the bearing plate is connected to an opening of the upper side of the lower shell, and meanwhile, the capsule chamber is accommodated within the lower shell; the tip pins are fixedly connected to the button by virtue of a plastic tip pin seat; the tip pins and the tip pin seat are fixed in an injection-molding mode; and the tip pin seat and the button are fixed in a clamping mode. According to the dry powder inhaler, the tip pins, when used, are prevented from getting fallen or displaced easily; and moreover, the capsule chamber can be cleaned by a user more conveniently.

Owner:SUZHOU SINGMED MEDICAL DEVICE SCI & TECH LTD

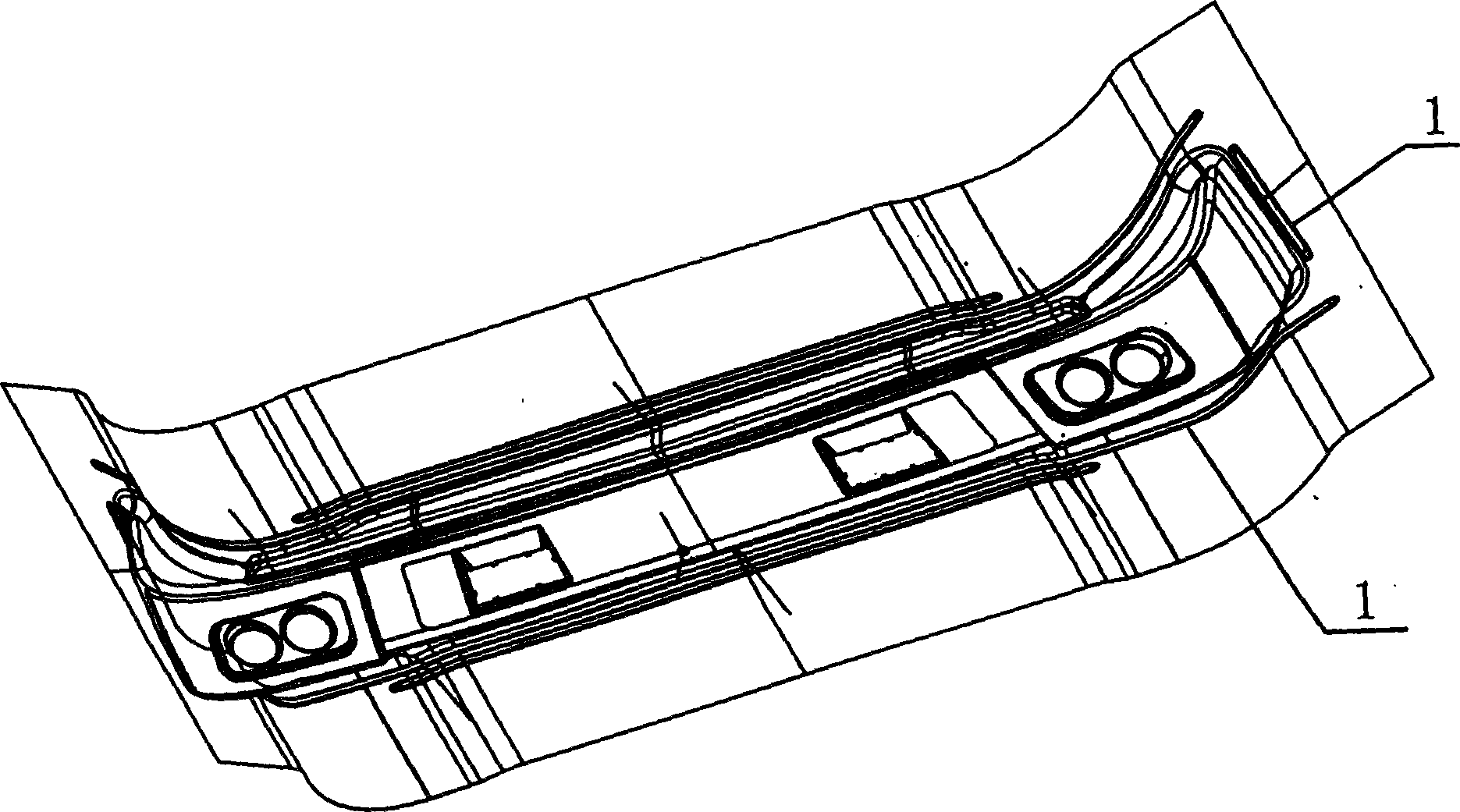

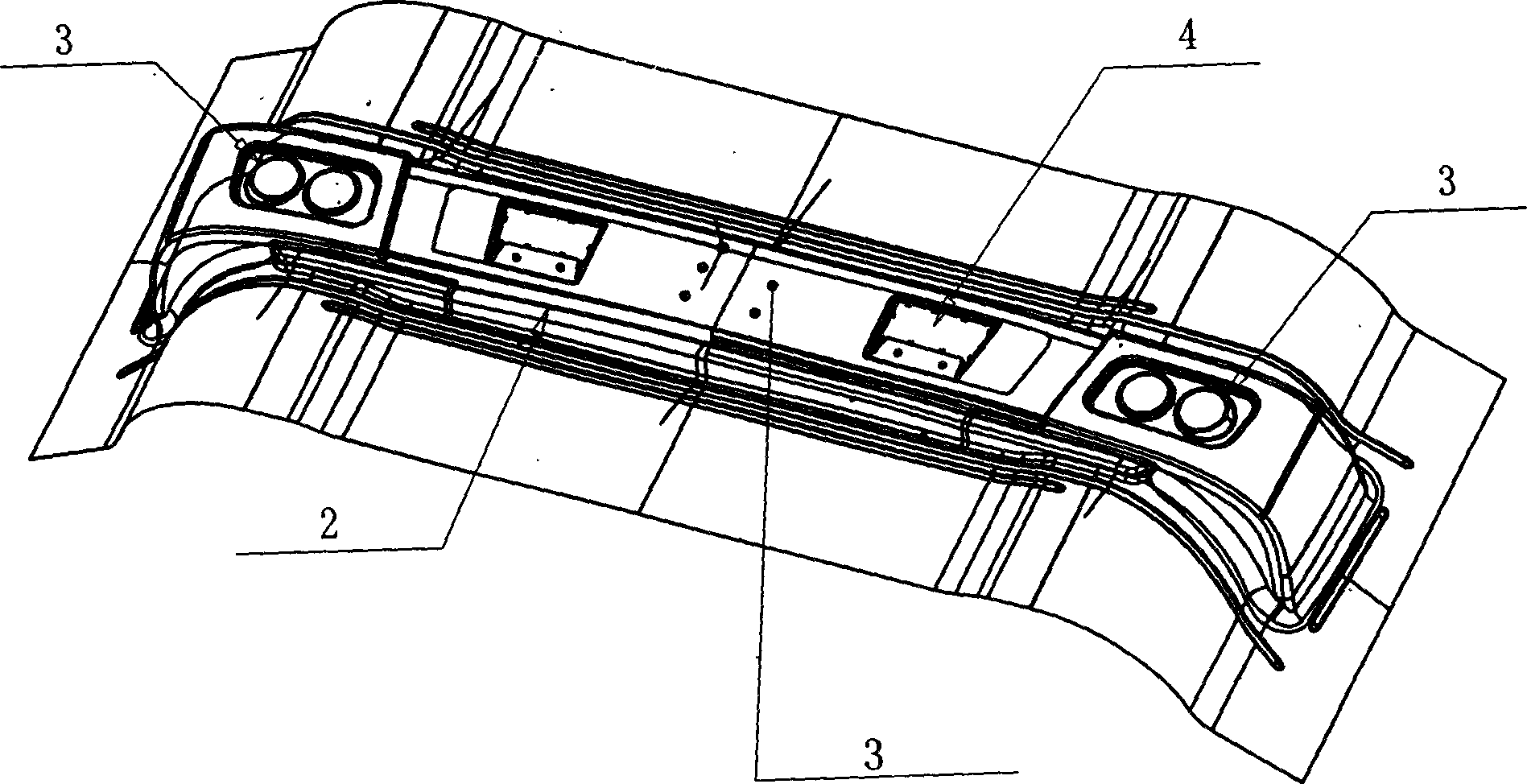

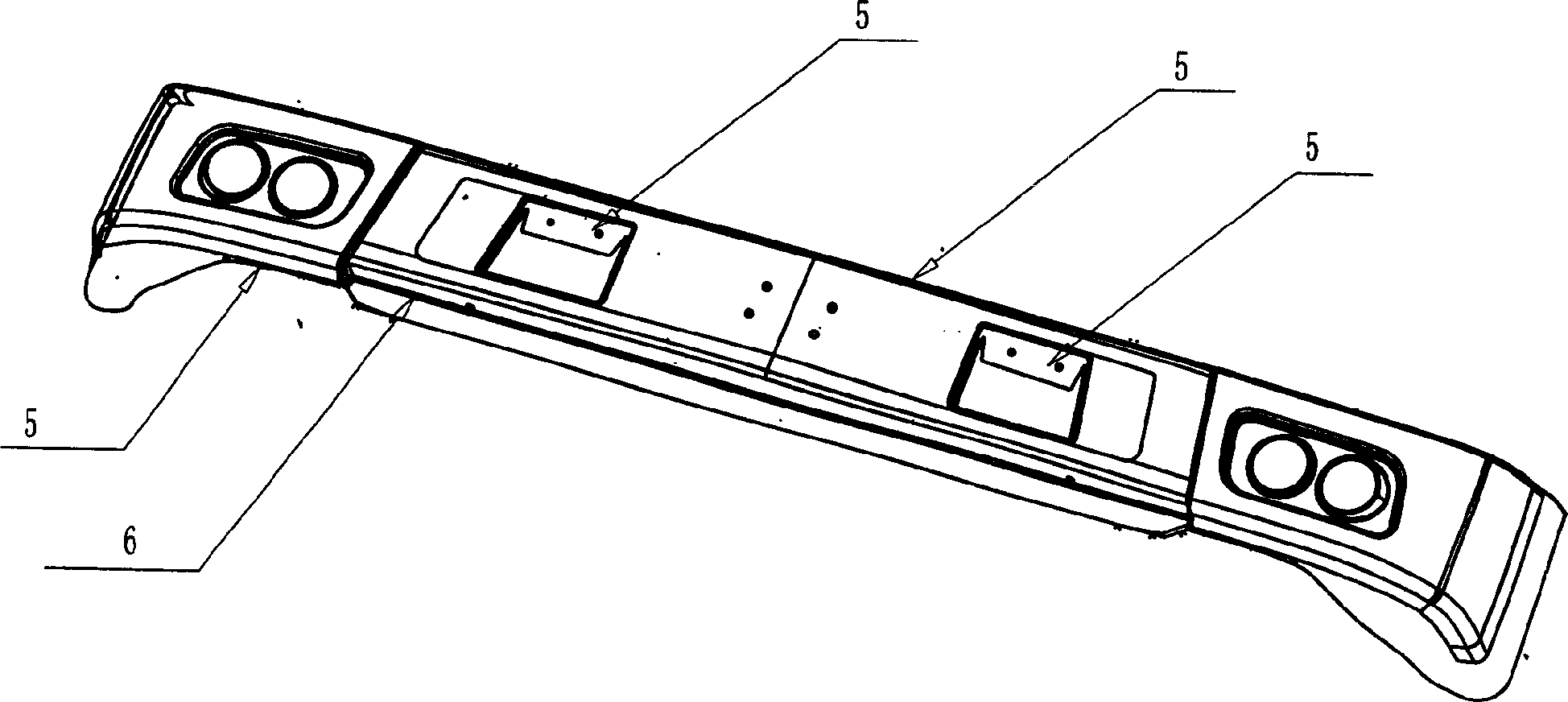

Punch process of integral automobile metal bumper

The present invention discloses the punch process of integral automobile metal bumper with the advantages of low cost for mold, short production period, high product surface quality, etc. The punch process includes the steps of once drawing to form drawn ribs on two ends of bumper; trimming edge and punching hole; shaping and flanging; punching hole, trimming bevel edge and cutting tongue; re-punching hole, trimming bevel edge and punching side hole.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

Polymer matrix composite used for liquid-oxygen containers and preparation method and using method of polymer matrix composite

A polymer matrix composite used for liquid-oxygen containers and a preparation method and a using method of the polymer matrix composite relate to polymer matrix composite and a preparation method thereof. Aiming to solve the problems that existing liquid-oxygen containers made of resin matrix composite are poor in liquid oxygen compatibility or liquid-oxygen containers made of perfluor polymer are difficult in forming. The polymer matrix composite used for the liquid-oxygen containers is made of epoxy resin, benzoxazine resin, prussic acid fat, solvent and auxiliaries. The preparation method includes: firstly, weighing; secondly, preparing prussic acid fat prepolymer; thirdly, fusing and mixing to obtain epoxy / benzoxazine rubber solution; and fourthly, preparing the rubber solution. The using method includes: firstly, subjecting to impregnation, forming by combining a winding forming method, a vacuum bag hot-pressing tank forming method and a hang-pasting forming method, curing by a gradient-heating curing method, and finally performing thermal treatment, and obtaining a liquid-oxygen container. The polymer matrix composite is mainly used for preparing liquid-oxygen containers.

Owner:HARBIN INST OF TECH

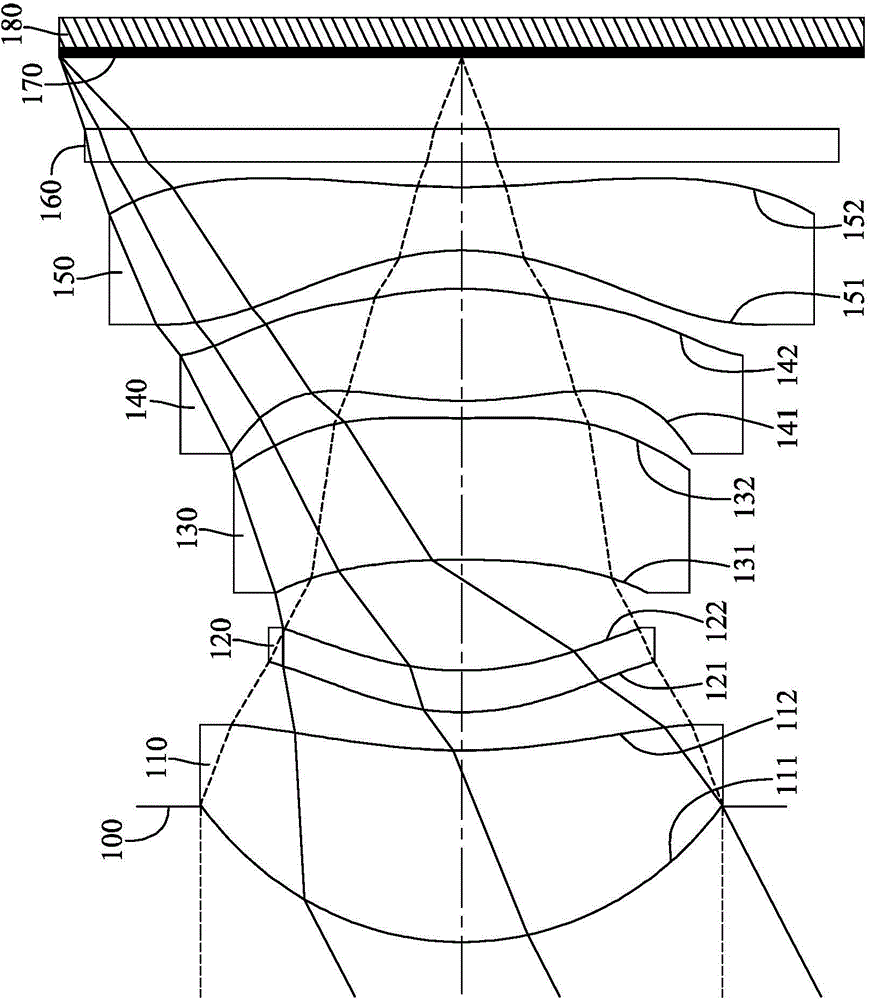

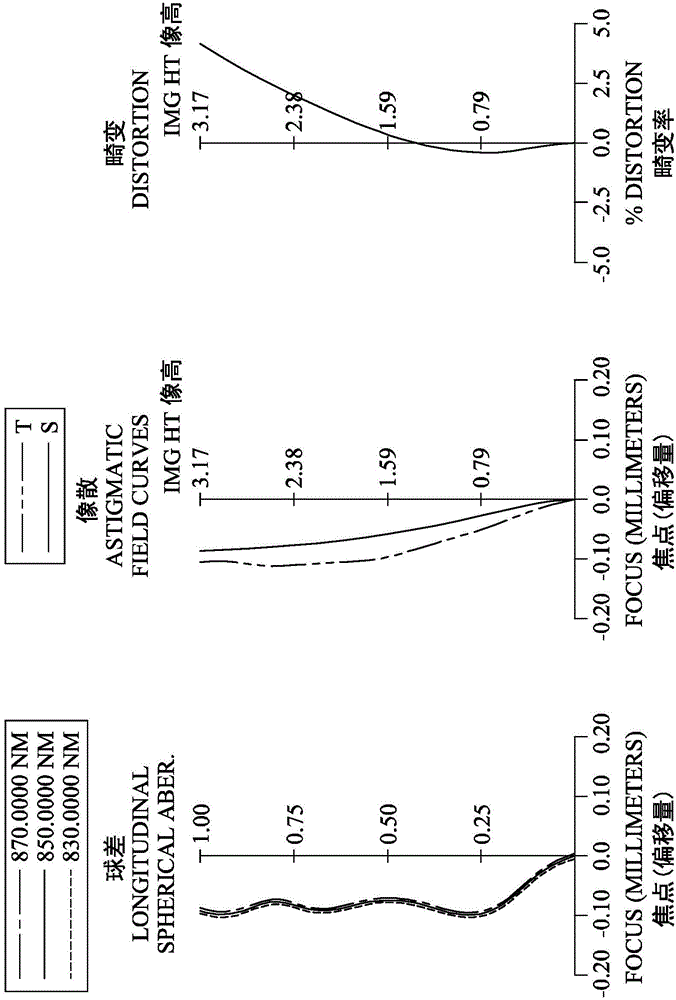

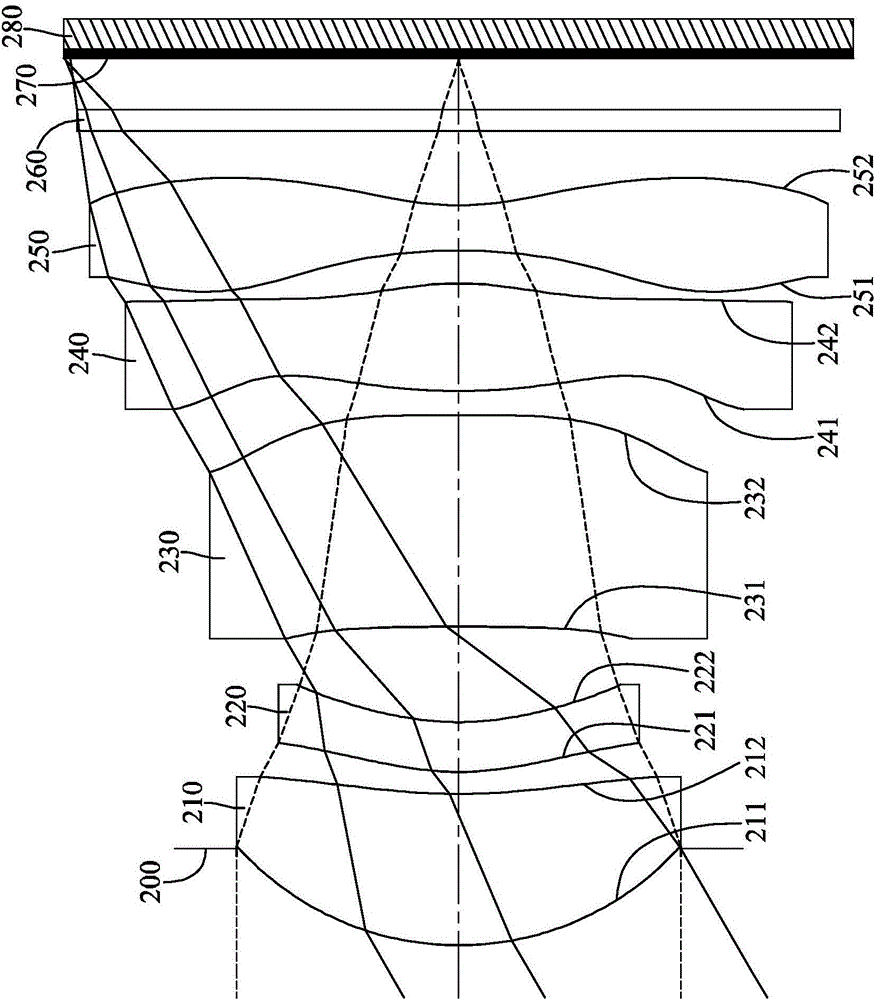

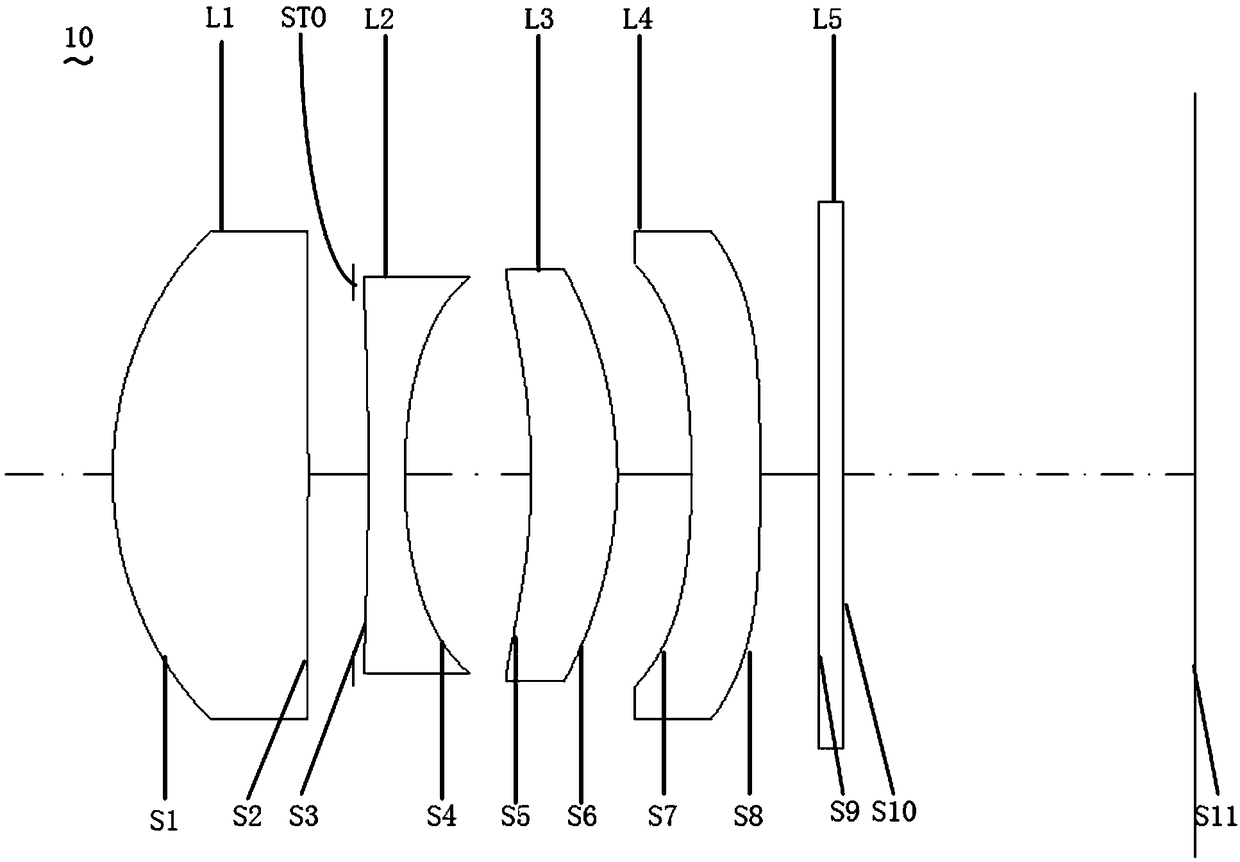

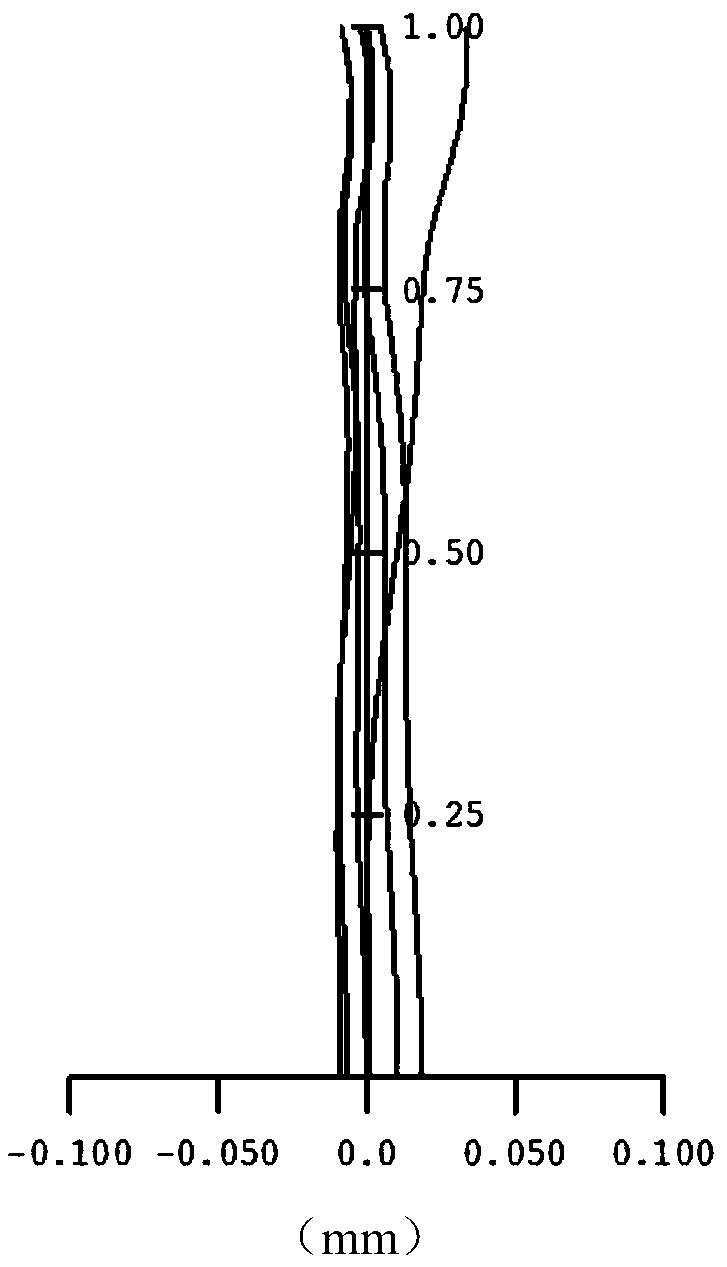

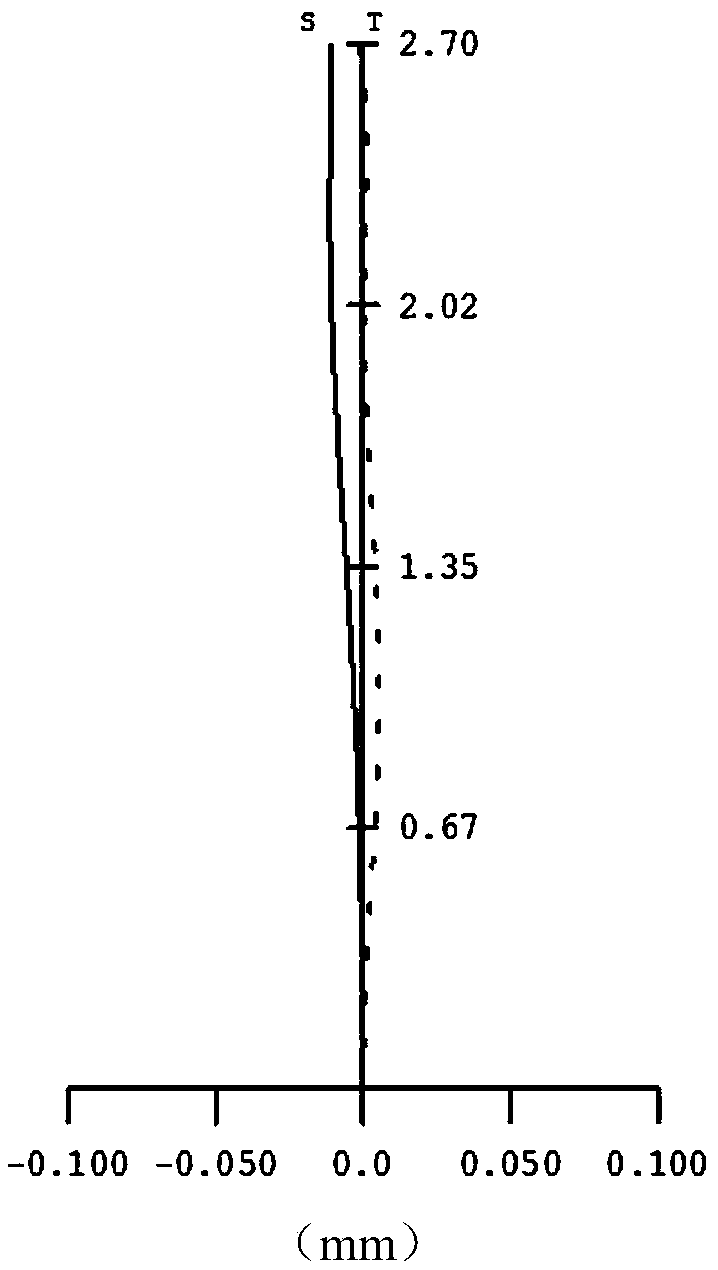

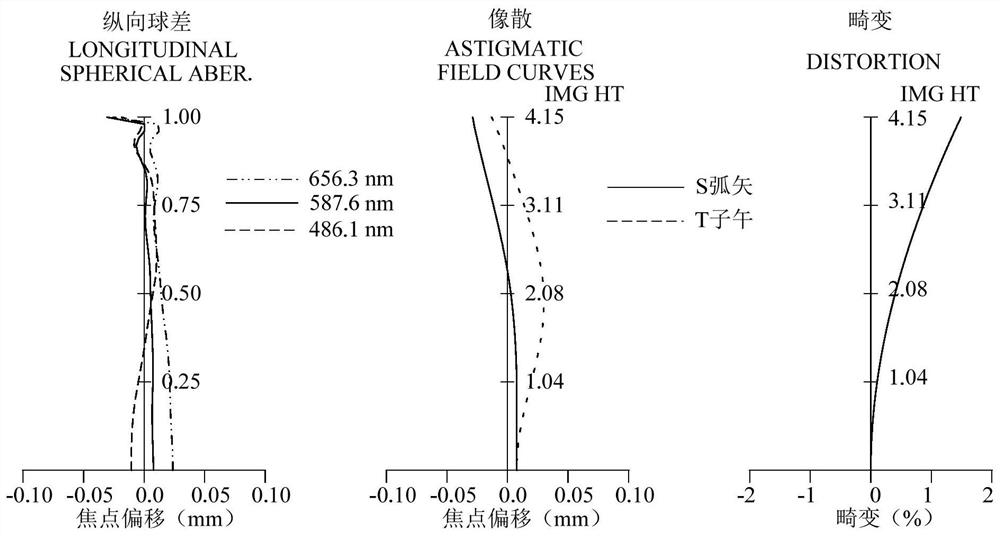

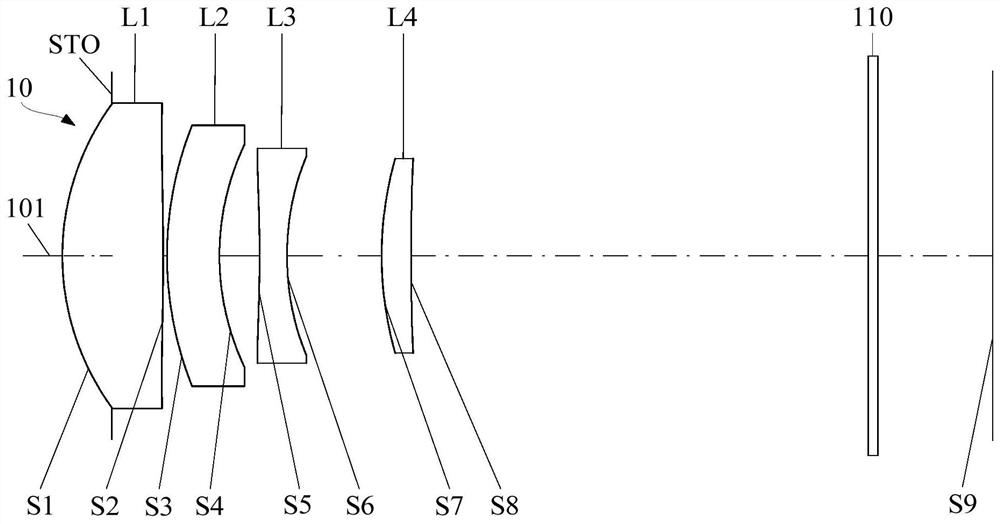

Optical imaging lens group, image capturing device and electronic device

ActiveCN105739060ALittle change in shapeAvoid Surface Reflection IssuesOptical elementsImage captureNegative refraction

The invention discloses an optical imaging lens group, an image capturing device and an electronic device. The optical imaging lens group comprises, from the object side to the image side, a first lens, a second lens, a third lens, a fourth lens and a fifth lens which have refraction power. The first lens has positive refraction power and an object side surface, close to an optical axis, of the first lens is a convex surface. The second lens has positive refraction power and an object side surface, close to an optical axis, of the second lens is a convex surface. The third lens has refraction power. The fourth lens has positive refraction power; an object side surface, close to an optical axis, of the fourth lens is a convex surface; an image side surface close to the optical axis is a convex surface; and the object side surface and image side surface are both aspheric surfaces. The fifth lens has negative refraction power; an object side surface, close to an optical axis, of the fifth lens is a concave surface; an image side surface close to the optical axis is a concave surface; the image side surface, away from the axis, is provided with a convex surface; the object side surface and the image side surface are both aspheric surfaces. Any two of the above adjacent lenses are spaced by air. The invention also discloses an image capturing device provided with the optical imaging lens group and an electronic device provided with the image capturing device.

Owner:LARGAN PRECISION

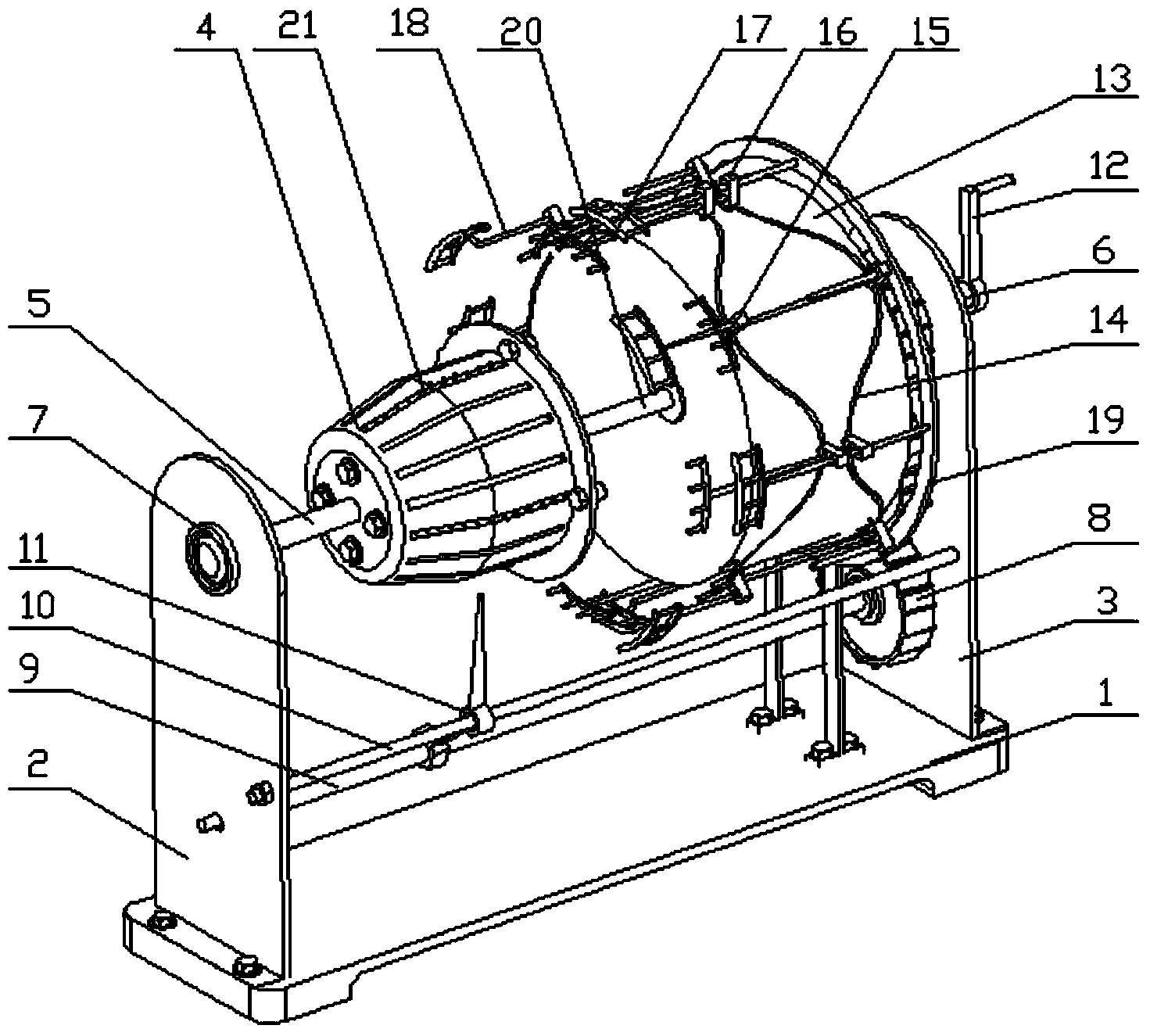

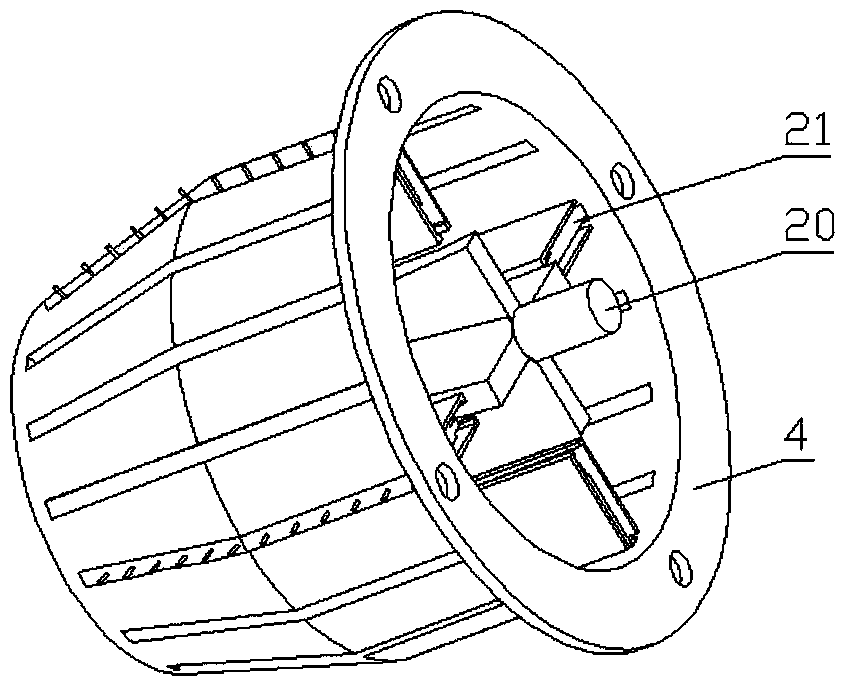

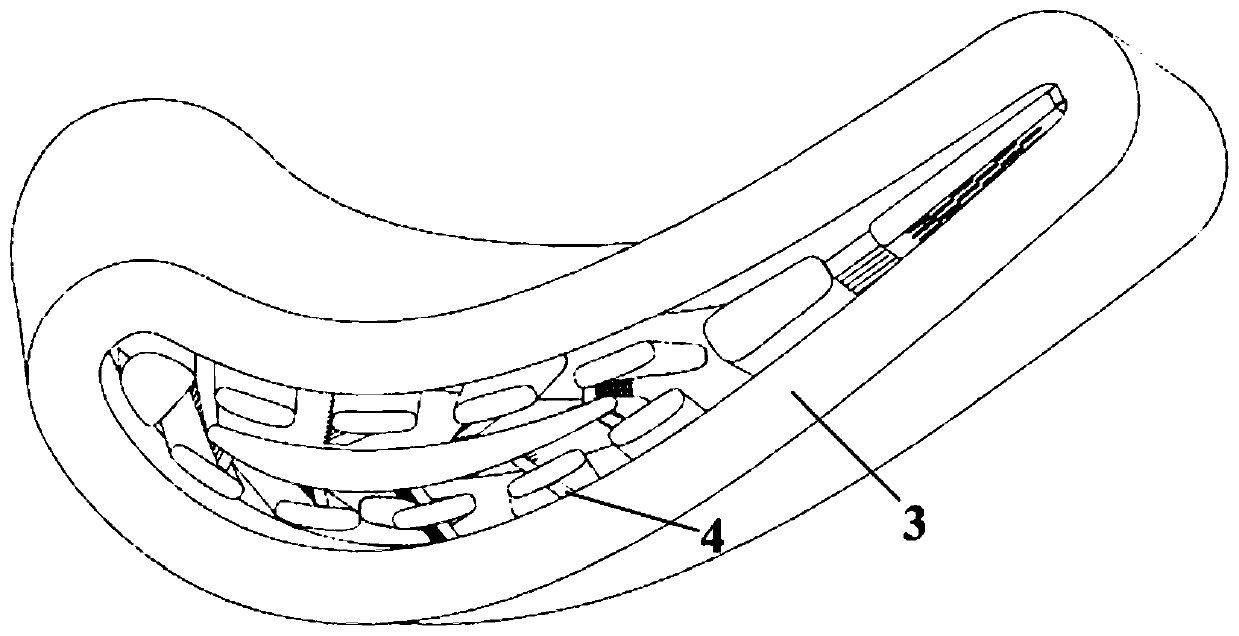

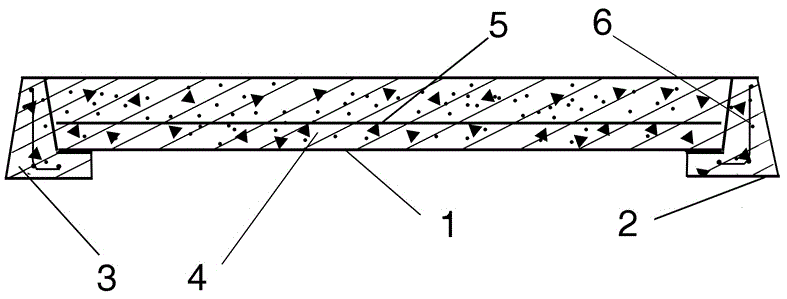

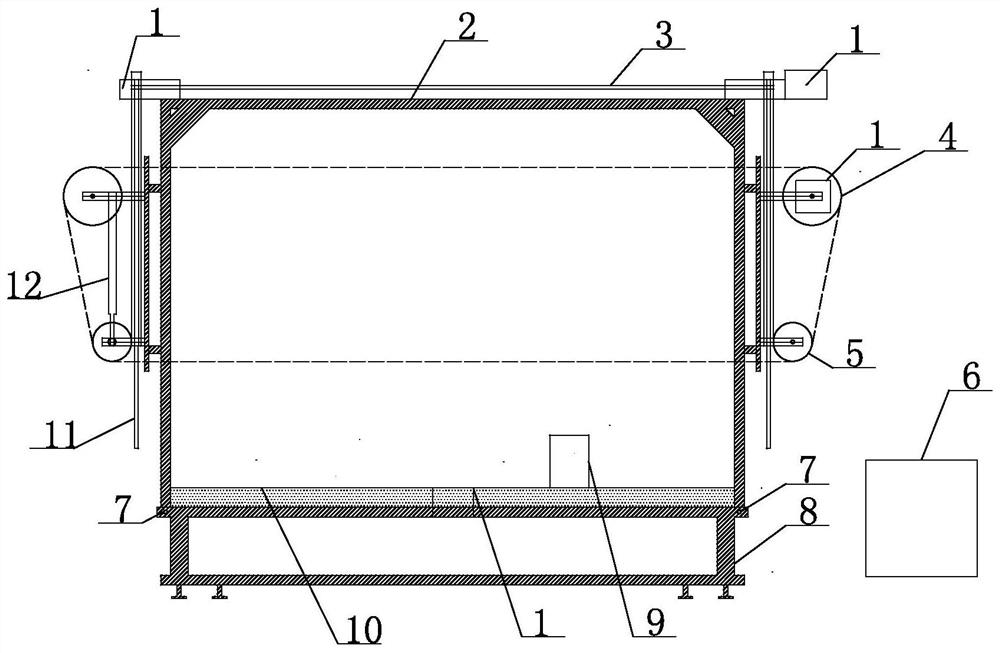

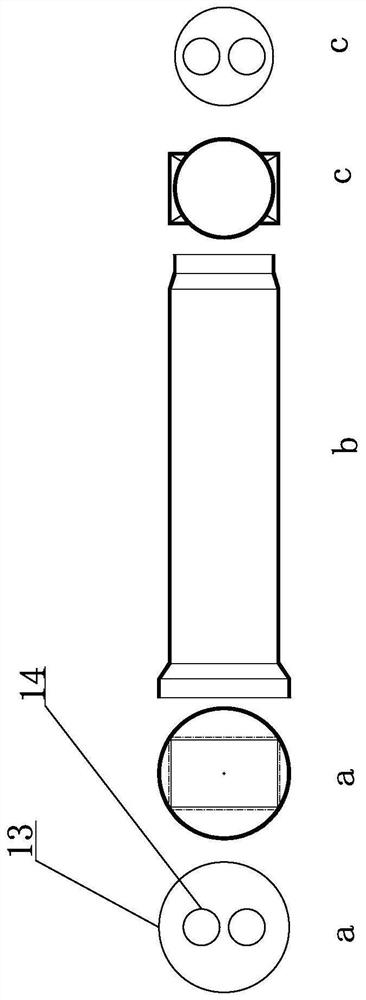

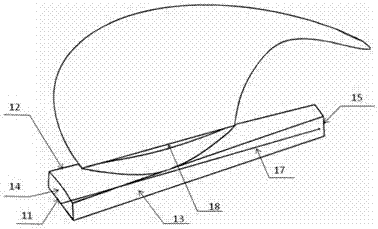

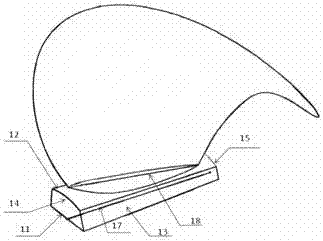

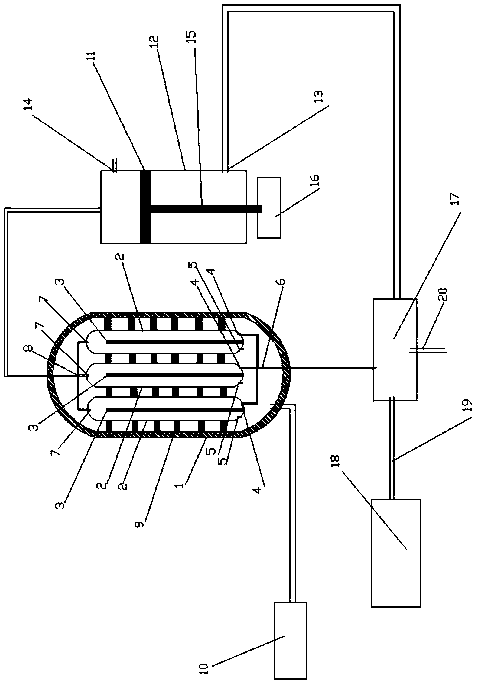

Device and method for forming variable cross-section thin-wall conical carbon fiber perform

ActiveCN103707521ATo achieve reinforcementReduce molding difficultyFiberCarbon fiber reinforced composite

The invention discloses a device and a method for forming variable cross-section thin-wall conical carbon fiber perform and aims at solving the technical problem of a complex method for forming a variable cross-section thin-wall conical carbon fiber perform by using a current carbon fiber perform forming device. Due to the design of a winding die and design philosophies of paving along with the die, winding and shaping, locating a core die, sewing locally, weaving and reinforcing, the forming device is capable of low-cost continuous preparation of a carbon fiber reinforced composite conical variable cross-section thin-wall part perform body; the method is simple; according to the forming method, four processes of paving, winding, sewing and weaving the fiber are continuously performed on the same device, so that the forming difficulty of the variable cross-section thin-wall conical carbon fiber perform is prominently reduced; in the preparation process, process parameters with influence on reinforced body forming quality and the wall thickness of the perform can be controlled in real time. Compared with the background art, no special expensive equipment is needed in the method; the method is capable of forming freely according to the shape of the needed perform.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

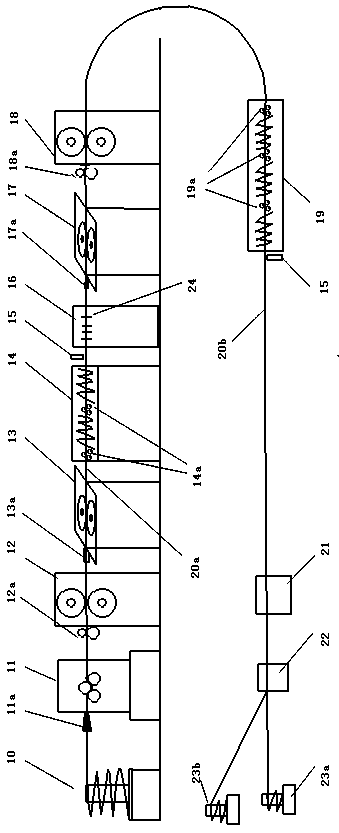

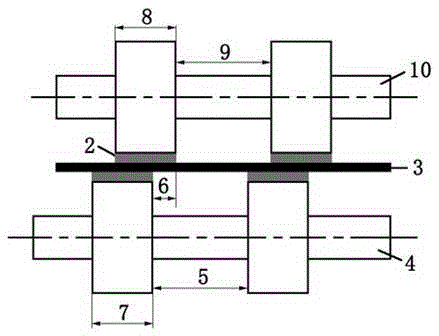

Production system and method for high-ductility ribbed steel bar

InactiveCN109877154AReduce hardnessEase quenching strengthMetal rolling arrangementsRebarManufacturing line

The invention discloses a production system and method for a high-ductility ribbed steel bar, and belongs to the field of steel bar cold rolling. The production system at least comprises two kinds ofrolling equipment and two kinds of heat treatment devices. The two kinds of rolling equipment comprise a rolling reducing mill and a rolling rib pressing machine. The two kinds of heat treatment devices comprise a primary heat treatment device and a secondary heat treatment device. The two kinds of the heat treatment devices are arranged at the front position and the rear position of the rolling rib pressing machine correspondingly. Temperature detectors are arranged behind the two kinds of the heat treatment devices. The primary heat treatment device, the secondary heat treatment device and the temperature detectors are also connected with a production line controller. The last steel bar rolling rib pressing processing is conducted after primary heat treatment, the hardness of the steel bar during cold rolling can be lowered, and therefore cold rolling power required in cold rolling can be reduced, energy is saved, and tensile strength and rate elongation are further improved throughsecondary heat treatment.

Owner:河南省鼎鼎实业有限公司

Turbine blade air film hole precision forming method

InactiveCN110732637AComplete structureGood precisionPolycrystalline material growthFoundry mouldsDirectional solidificationTurbine blade

The invention discloses a turbine blade air film hole precision forming method, and belongs to the field of rapid casting based on a photocuring forming technology. The turbine blade air film hole precision forming method comprises the following steps: 1) manufacturing a turbine blade resin mold by using the photocuring rapid forming technology; 2) pouring ceramic slurry into a resin mold prototype of a turbine blade through a gel casting method to obtain a casting mold blank body, so that forming of an air film hole ceramic core is realized; 3) further strengthening the air film hole ceramiccore through vacuum freeze drying and high-temperature sintering, so that forming of different ceramic-based air film hole ceramic cores is realized; and 4) for the air film hole ceramic cores with different types of ceramic bases, combining a directional solidification technology to realize air film hole casting forming of various high-temperature alloys, and finally removing the ceramic cores remained in a metal blade and an air film hole through a core removing process, so that high-quality forming of the cast air film hole is realized. The turbine blade air film hole precision forming method is reasonable in design and simple and convenient to operate, and can realize forming of the high-quality cast air film hole.

Owner:XI AN JIAOTONG UNIV

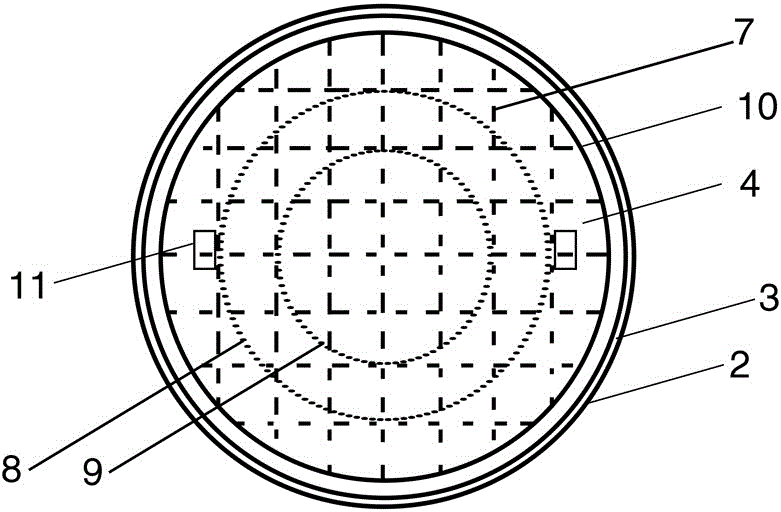

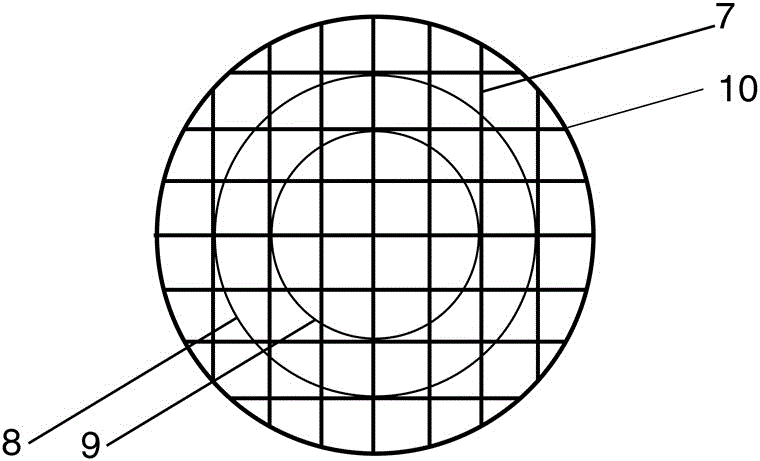

Reactive powder concrete material manhole cover and manufacturing method thereof

ActiveCN106337442ASimple designReduce molding difficultyArtificial islandsCeramic shaping apparatusFire controlRebar

The invention discloses a reactive powder concrete material manhole cover which comprises a manhole cover body and a manhole base. The reactive powder concrete material manhole cover is characterized in that the manhole base is composed of a first reactive powder concrete body and reinforcing steel bars arranged in the first reactive powder concrete body; the manhole cover body is composed of a second reactive powder concrete body in a shape of an inverse circular truncated cone and a reinforcing steel bar supporting body arranged in the second reactive powder concrete body; and the reinforcing steel bar supporting body is formed by a ring-shaped steel hoop, #-shaped reinforcing steel bars, inner annular reinforcing steel bars and outer annular reinforcing steel bars, wherein the two ends of the #-shaped reinforcing steel bars are fixedly connected with the ring-shaped steel hoop or connected with the ring-shaped steel hoop into a whole, the inner annular reinforcing steel bars are fixedly connected with the #-shaped reinforcing steel bars or connected with the #-shaped reinforcing steel bars into a whole, and the outer annular reinforcing steel bars are fixedly connected with the #-shaped reinforcing steel bars or connected with the #-shaped reinforcing steel bars into a whole. A manufacturing method of the manhole cover includes the steps of reinforcement cage manufacturing, reactive powder concrete mixture manufacturing, and manhole cover body and manhole base manufacturing. By means of the reactive powder concrete material manhole cover and the manufacturing method, the manhole cover is excellent in performance, durable in use and capable of being used as municipal engineering public services such as tap water, telecom, electric power, gas, heating power, fire control and environmental sanitation.

Owner:福建诚兴新材料科技有限公司

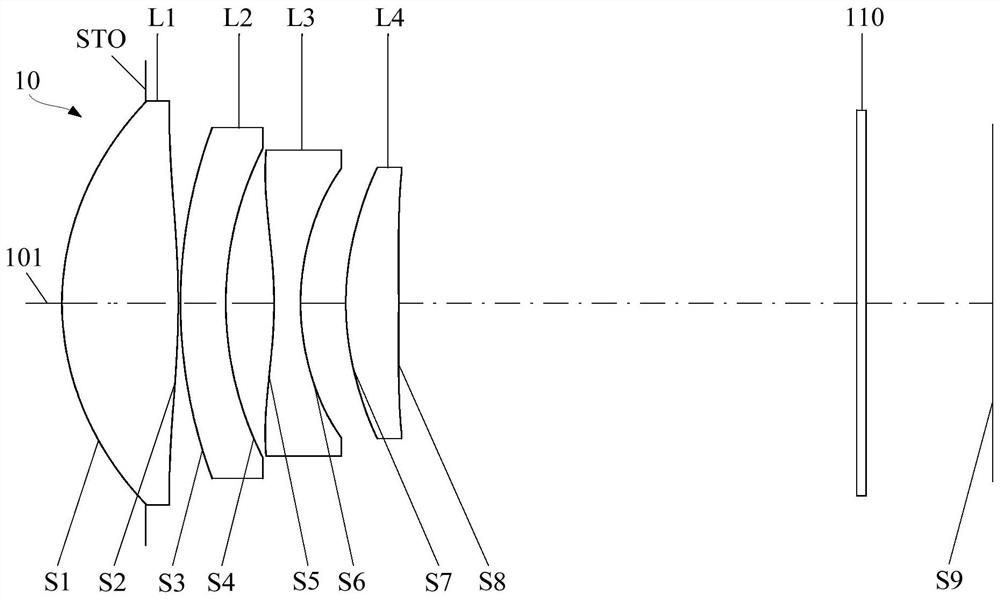

Telephoto lens, telephoto camera module group, and electronic device

The invention discloses a telephoto lens, a telephoto camera module group and an electronic device. According to the embodiment of the invention, the telephoto lens sequentially comprises a first lenshaving a positive refractive power, a second lens having a negative refractive power, a third lens having a refractive power and a fourth lens having a refractive power from the object side to the image side. The object side surface of the first lens is a convex surface. The object side surface and the image side surface of the second lens are both concave surfaces. The object side surface of thethird lens is a concave surface. The telephoto lens satisfies the following relationship: TTL / f<0.96, wherein TTL is the distance from the object side of the first lens to the imaging plane of the telephoto lens on the optical axis, and f is the effective focal length of the telephoto lens. The telephoto lens has a short TTL through a reasonable TTL configuration, thereby shortening the cone length of the telephoto lens.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

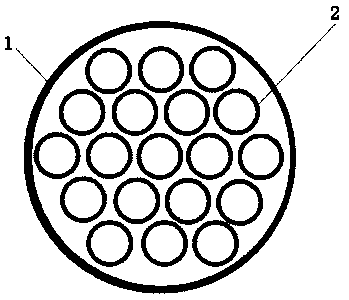

Flexible cable used for new energy automobile

ActiveCN107039117AImprove eliminationMeet special use requirementsRubber insulatorsInsulated cablesInsulation layerElectrical conductor

The invention discloses a flexible cable used for a new energy automobile. The cable comprises a conductor and an insulation layer used for wrapping the conductor. The outer part of the insulation layer is provided with a cooling layer in a wrapped manner, and at least one cooling medium channel extended along the length direction of the insulation layer is disposed in the cooling layer, and is used to introduce the cooling medium for the cooling and the heat dissipation of the insulation layer. Heat energy radiated by the insulation layer outwardly is effectively, reliably, quickly, and greatly eliminated by the cooling medium, and then the heat energy radiated on the outer part of the cooling layer is reasonable, controllable, and safe, and then the special use requirement of the new energy automobile is satisfied. The flexible cable is in service and operated reliably, safely, and stably in various severe environments, and has advantages of simple structure, convenient forming, small forming difficulty, low forming costs, compact structure, good flexibility, excellent heat dissipation effect, high flame resistant performance, high reliability, good safety performance, and strong practicability.

Owner:TBEA DEYANG CABLE CO LTD

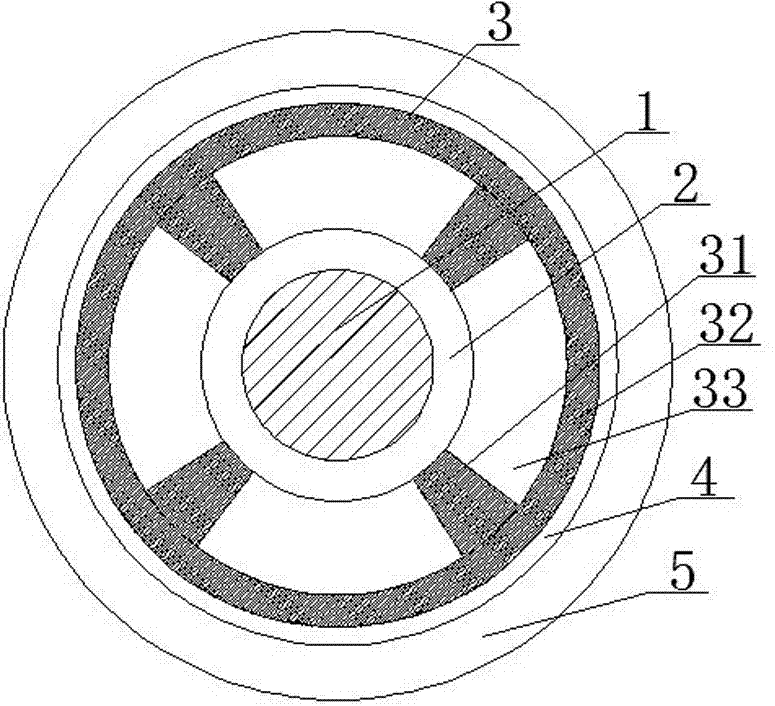

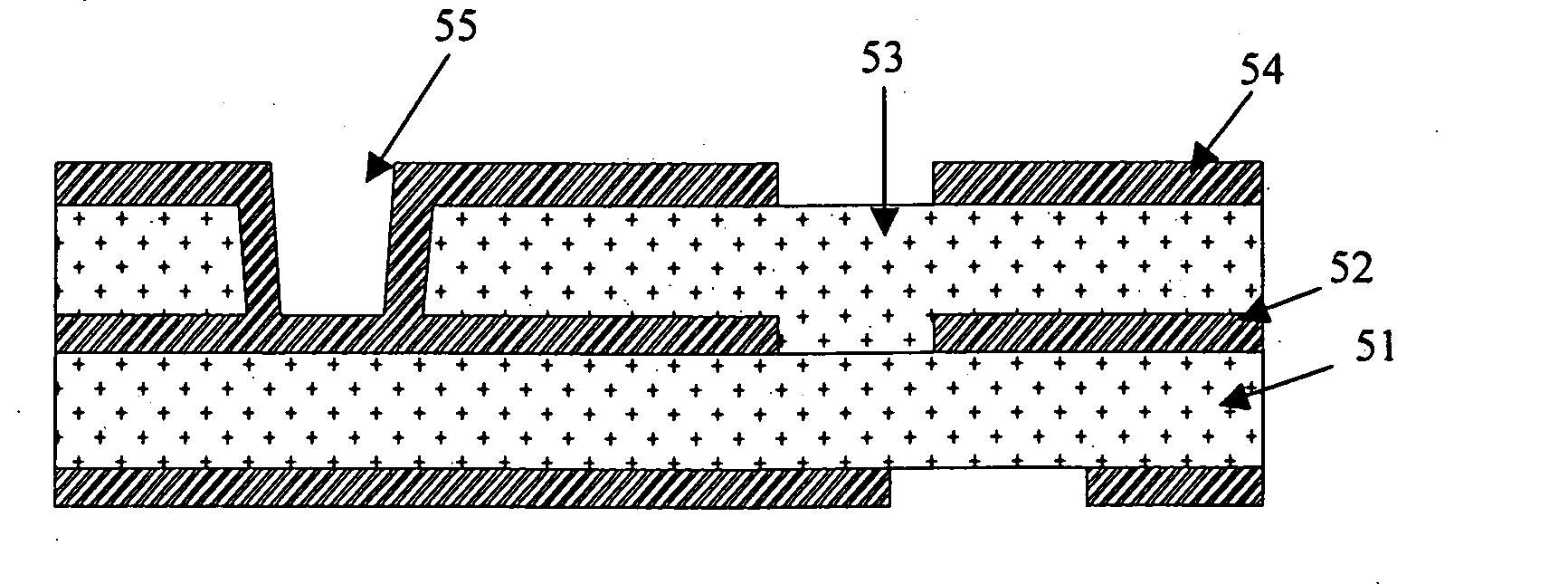

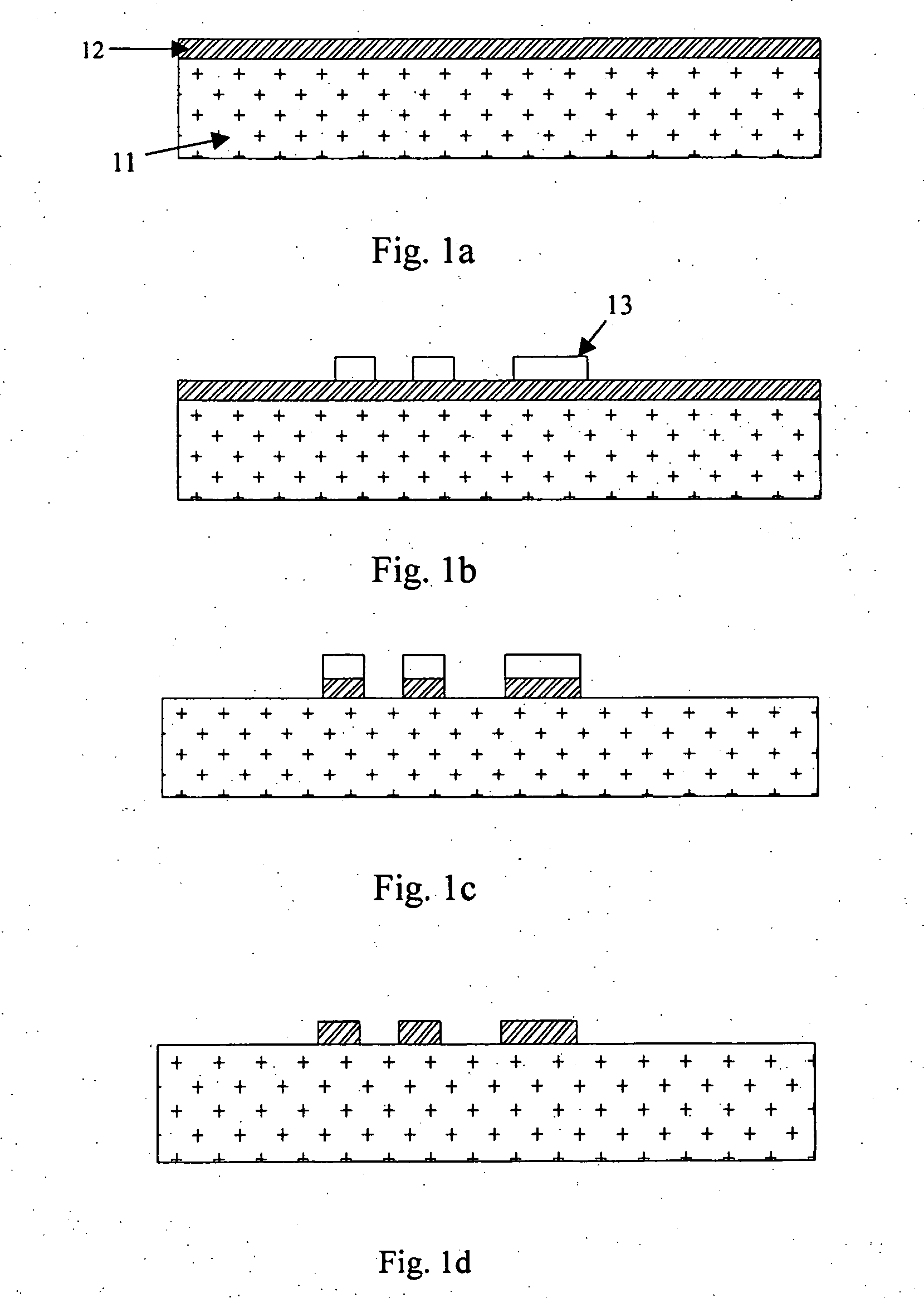

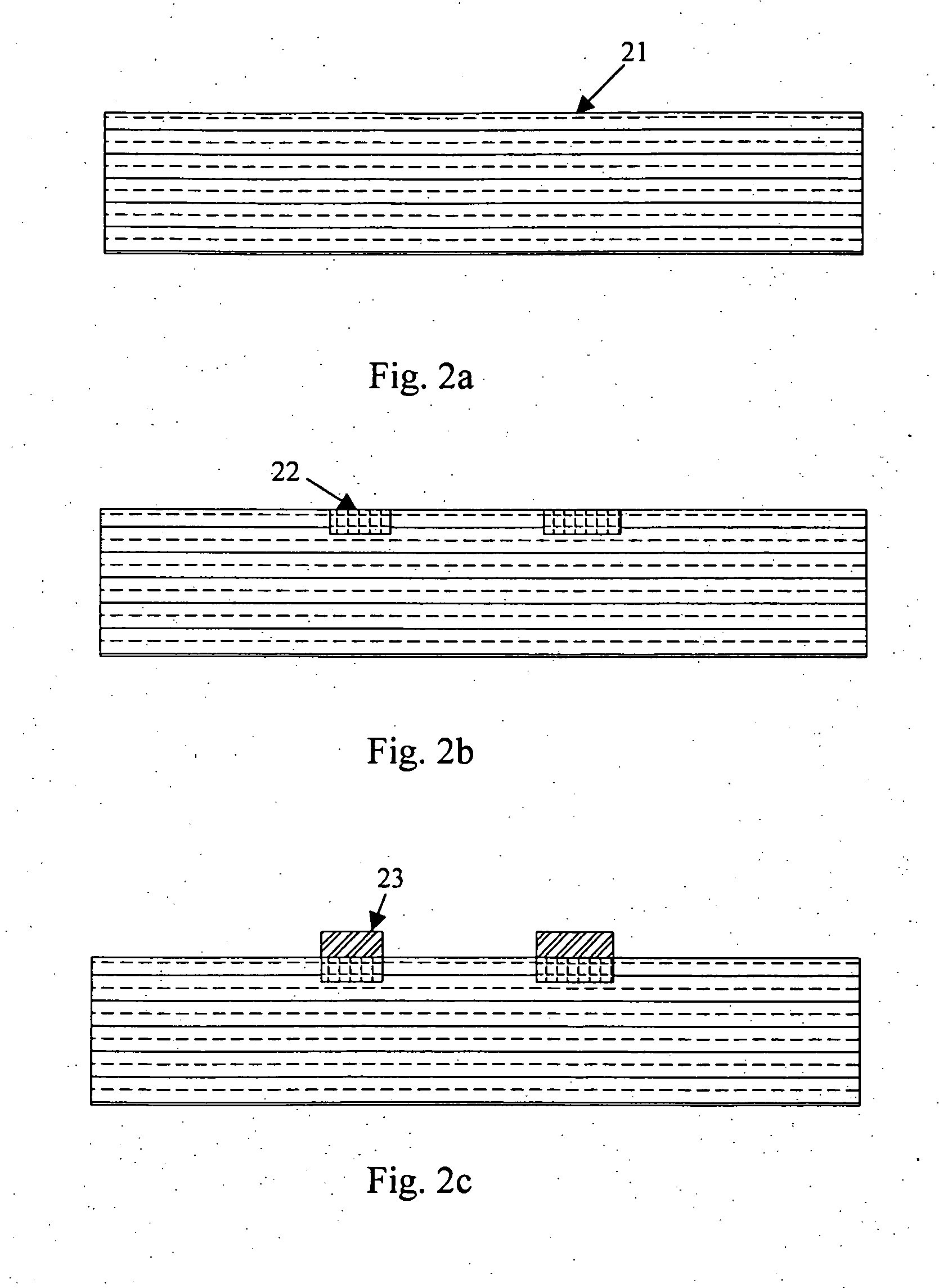

Methods of preparing printed circuit boards and packaging substrates of integrated circuit

ActiveUS20080251495A1High densityReduce spacingDecorative surface effectsVacuum evaporation coatingImage transferEngineering

A method of forming printed circuit boards and packaging substrates for integrated circuits based on filling-vias plating and a semi-additive process, comprising the following steps: (1) providing a dielectric layer on a substrate; (2) providing blind vias on said dielectric layer; (3) providing a first seed layer after providing blind vias; (4) providing solid conductive vias by a filling-vias plating process after providing a first seed layer, and also providing a copper layer covering the first seed layer during the filling-vias plating process; (5) removing said first seed layer as well as the copper layer formed thereon, and retaining solid copper pillars in the conductive vias; (6) providing a second seed layer which is used to form wires by a semi-additive process; (7) providing a photo-sensitive thin film, and providing a plating resistant layer by image-transfer to expose a wire pattern; (8) thickening wires; (9) removing the photo-sensitive thin film; (10) removing the exposed second seed layer and retaining the thickened wires, thus form a desired conductive pattern; (11) repeating steps (1)-(10) to form an upper layer of wires, thereby completing the fabrication of the fine wires in the subsequent layers of wires and effecting inter-layer interconnections of the solid conductive vias.

Owner:SHANGHAI MEADVILLE SCI & TECH

Preparation method of aluminum oxide ceramic guide rail

The invention relates to a preparation method of an aluminum oxide ceramic guide rail and belongs to the technical field of ceramic guide rail preparation. The preparation method comprises the following steps of: (1) mixing aluminum oxide and a sintering aid, mixing the mixture, water, a dispersing agent and a binder, and carrying out ball milling to obtain required slurry; (2) spray-drying the slurry to obtain granulation powder for later use; (3) performing a cold isostatic pressing process on the granulation powder to obtain a biscuit; (4) performing inner hole cutting on the biscuit by using fretsaw equipment to obtain a square hole ceramic guide rail biscuit; (5) sintering the green body to obtain a blank, milling the blank, and carrying out sintering to obtain a crude product; and (6) carrying out accurate grinding and polishing on the crude product to obtain the aluminum oxide ceramic guide rail. The preparation method is scientific and reasonable in design, and the prepared ceramic guide rail has the advantages of low volume density, high hardness, large elastic modulus, low thermal expansion coefficient, high hardness and high wear resistance.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

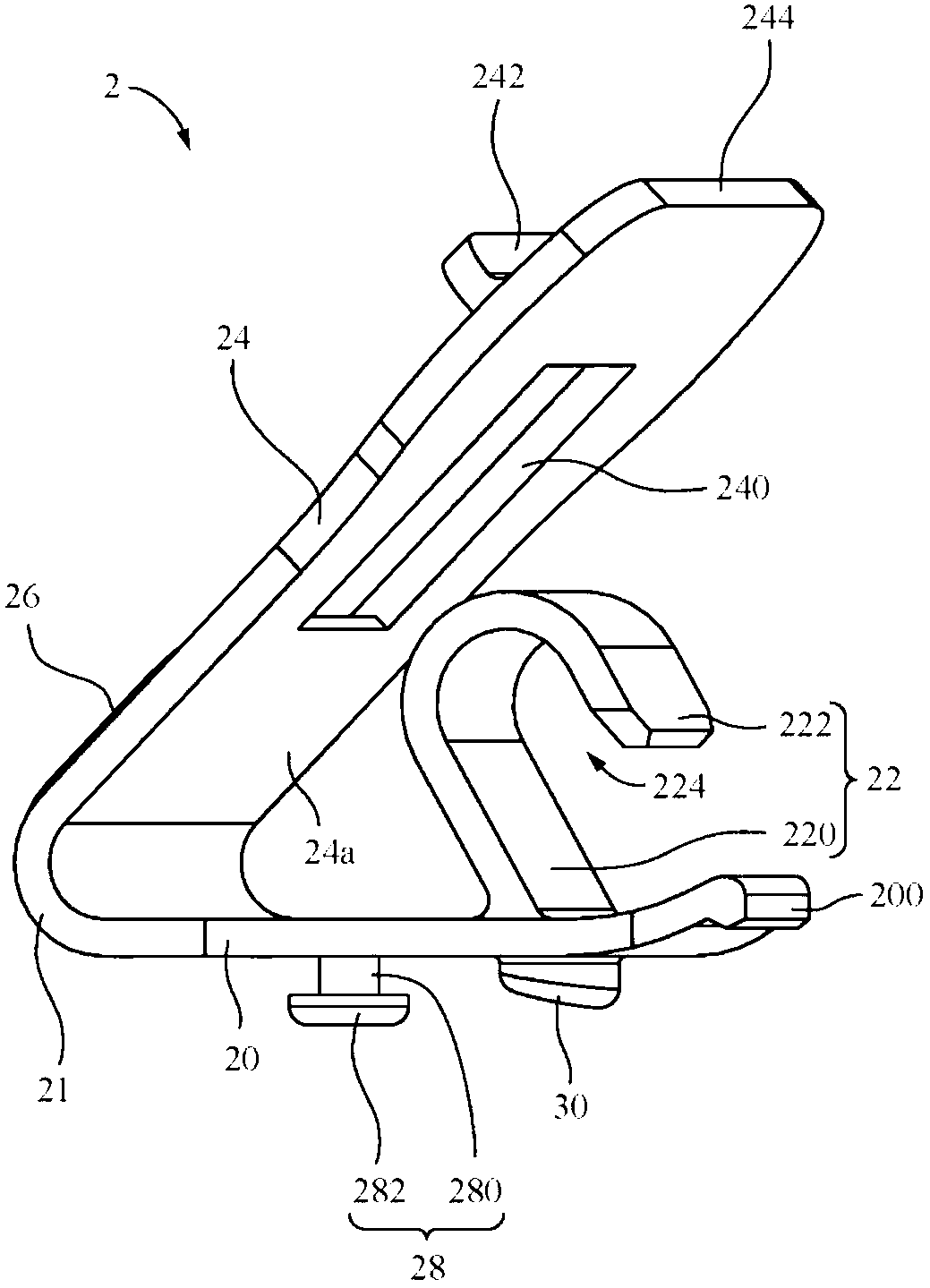

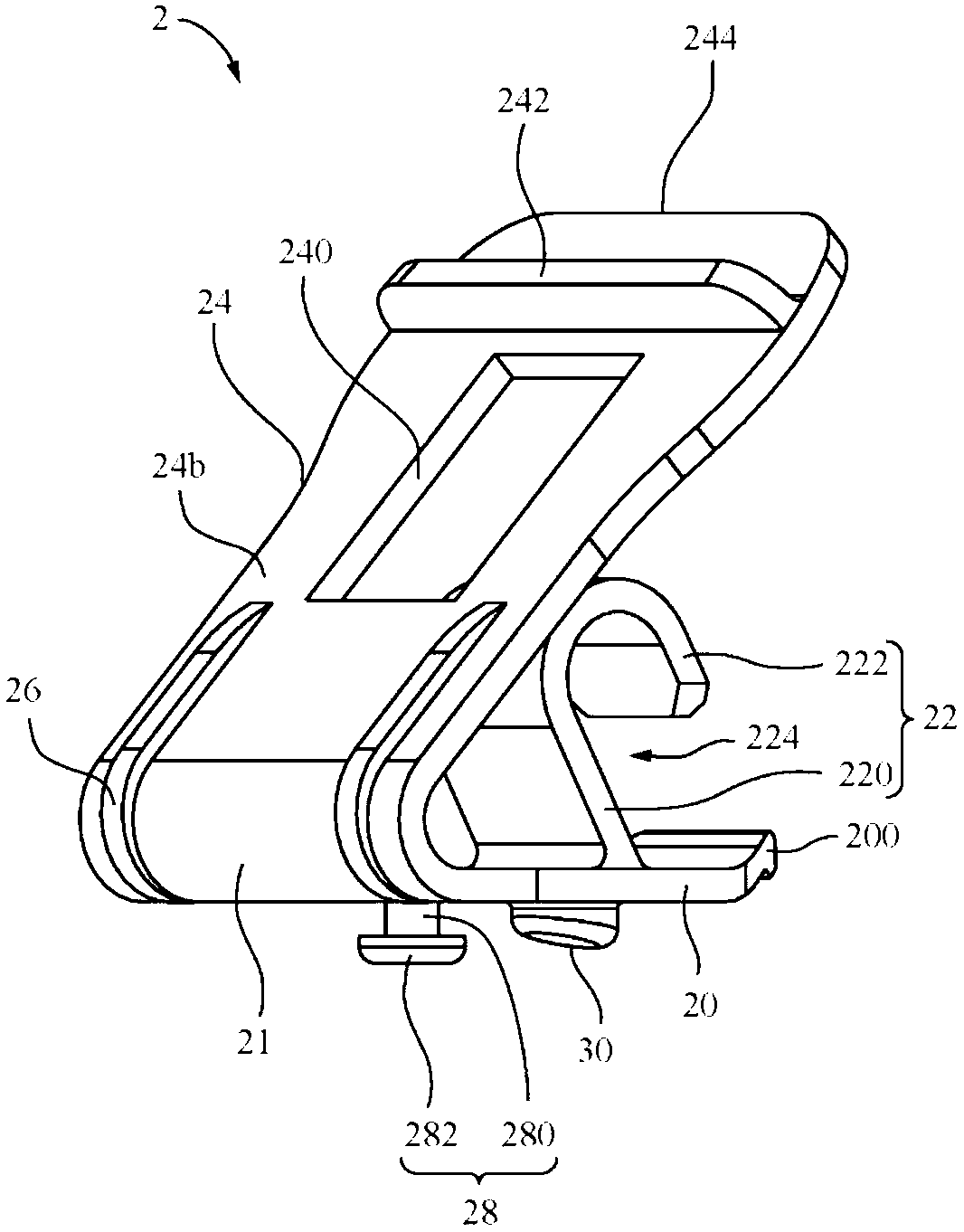

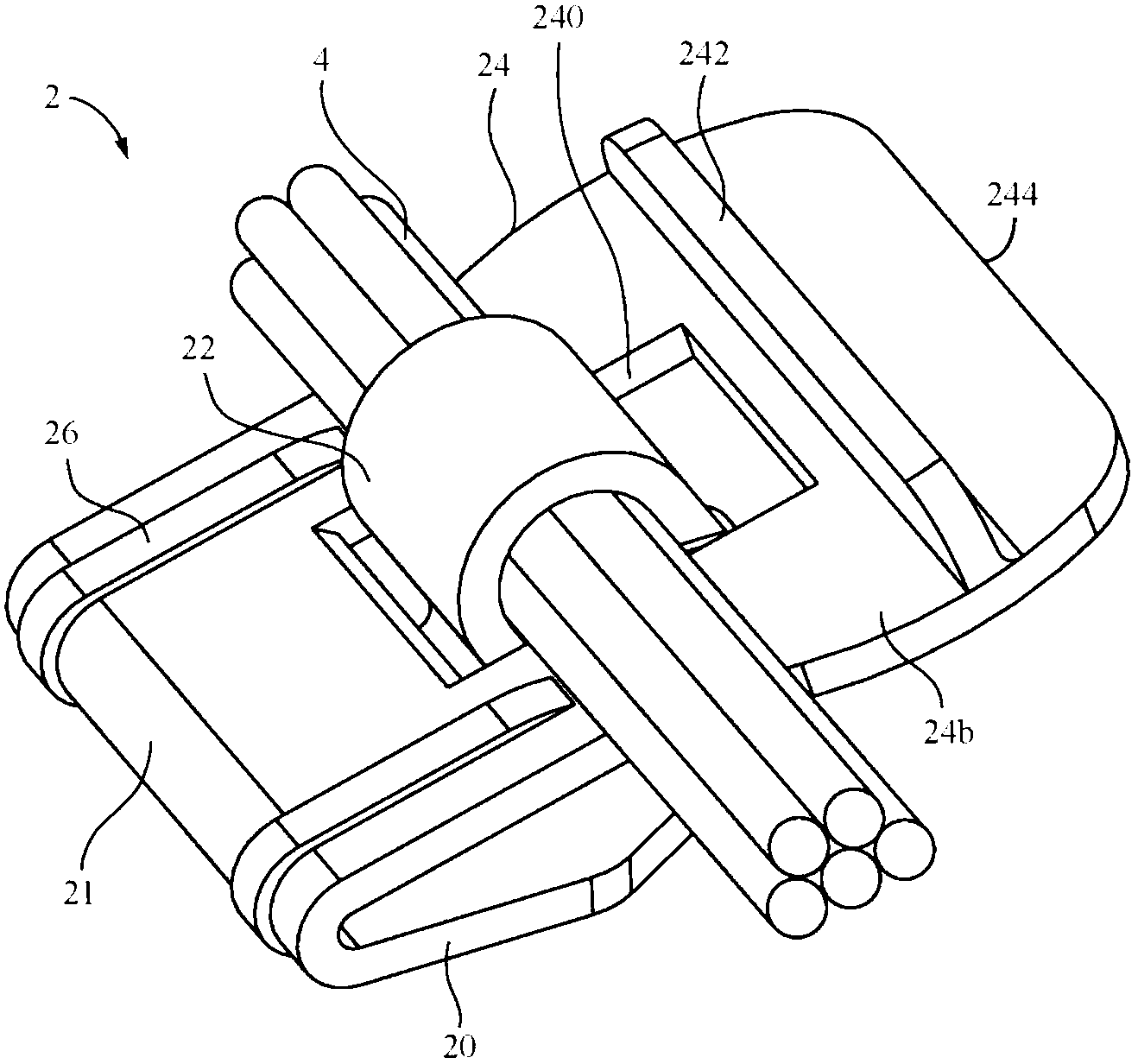

Wire clamp and electronic device using same

InactiveCN102705587ASimple structureLow structural requirementsPipe supportsCircuit arrangements on support structuresMechanical engineeringElectron

The invention provides a wire clamp and an electronic device using the wire clamp. The wire clamp is used for holding a wire. The wire clamp comprises a main body, a wire hook structure and an elastic sheet part, wherein the wire hook structure is connected with the main body, the elastic sheet part is connected with the main body and has a through-hole, and the elastic sheet part can be bended relative to the main body to move towards the main body, so as to allow the wire hook structure to partially pass through the through-hole. The wire is clamped between the elastic sheet part and the wire hook structure which partially passes through the through-hole. The wire clamp is mainly applied to the common wire arrangement as well as wire layout in electronic devices. The wire clamp has simple structure and low requirements for structure and material, therefore, the forming difficulty is low, the fabrication is facilitated and the occurrenceof structural function failures can be avoided mostly. The wire clamp provided by the invention can be used as a standard part.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

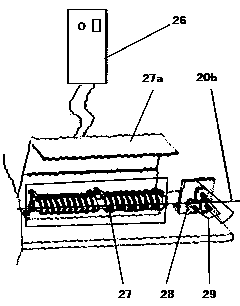

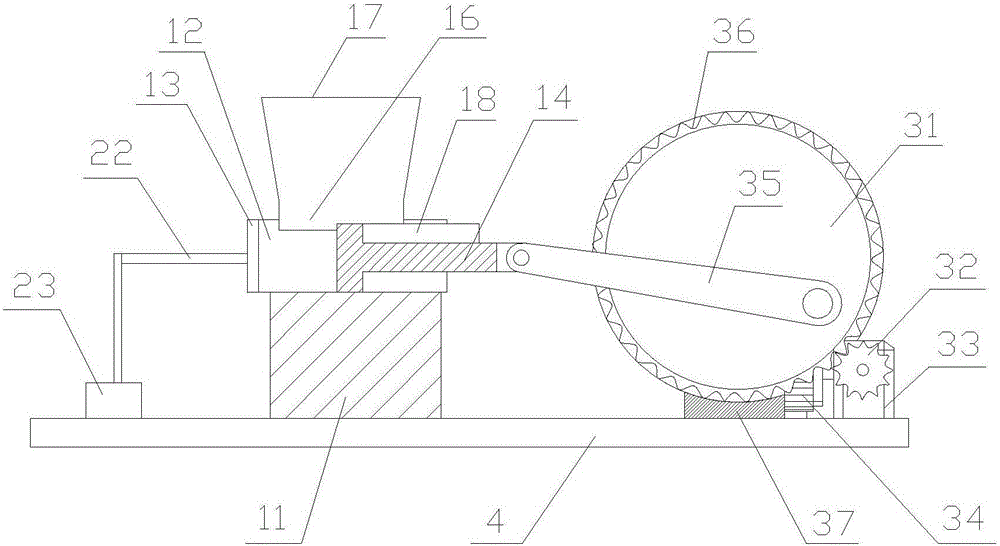

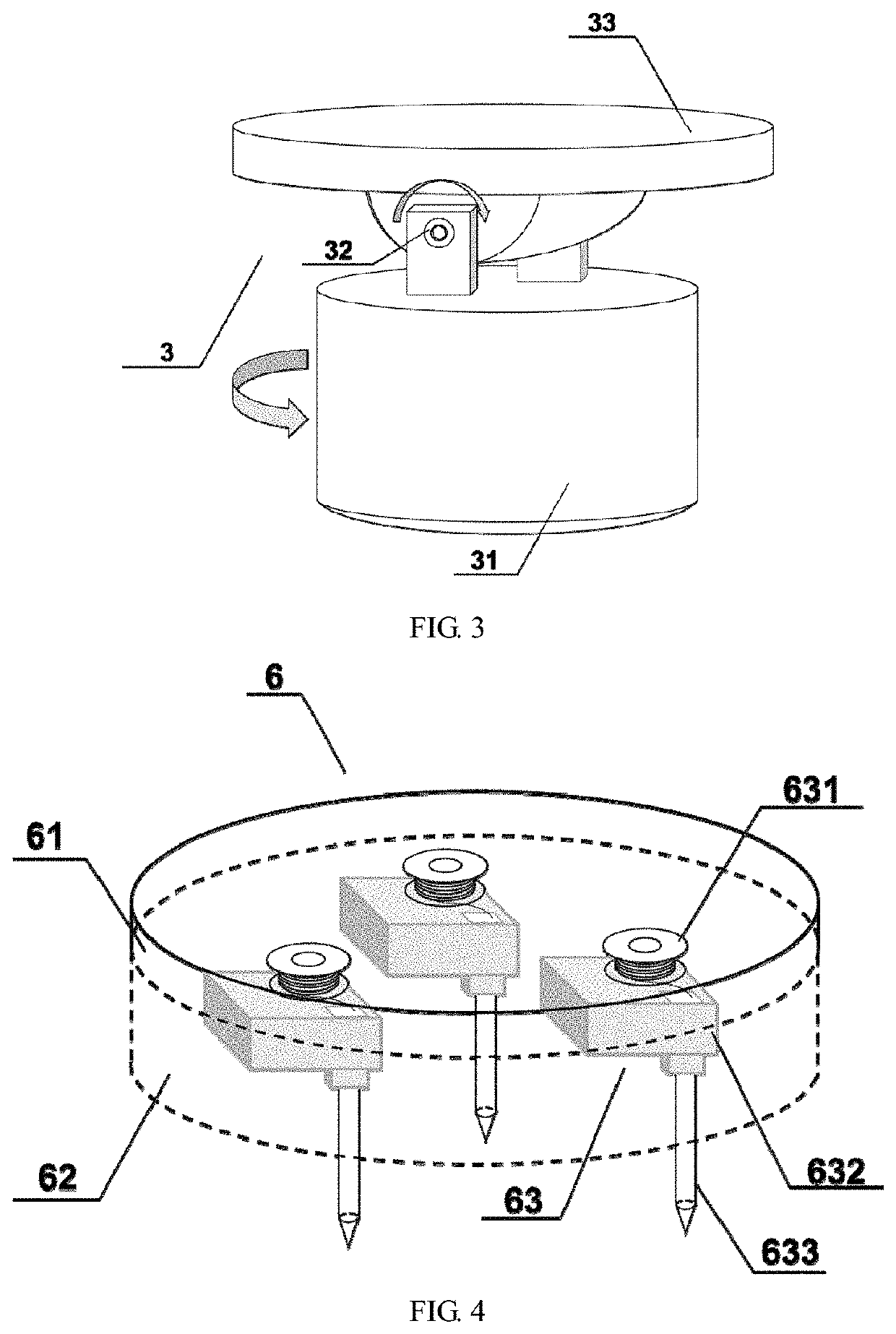

Granulator

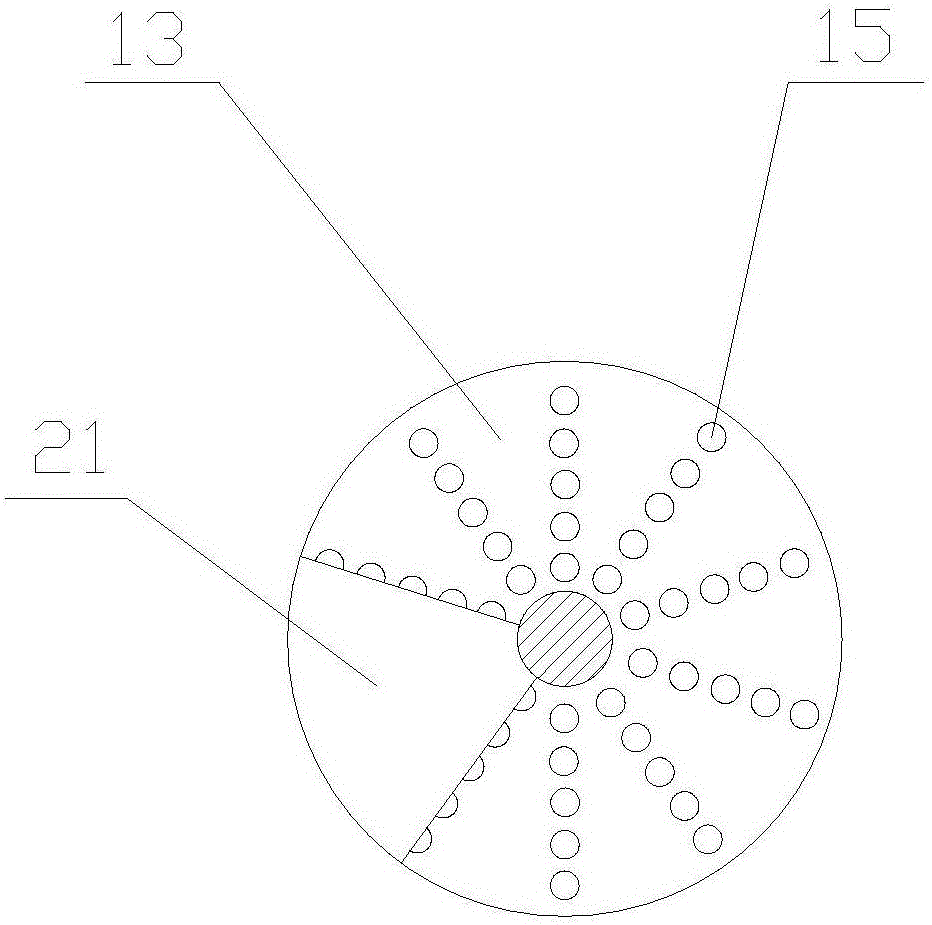

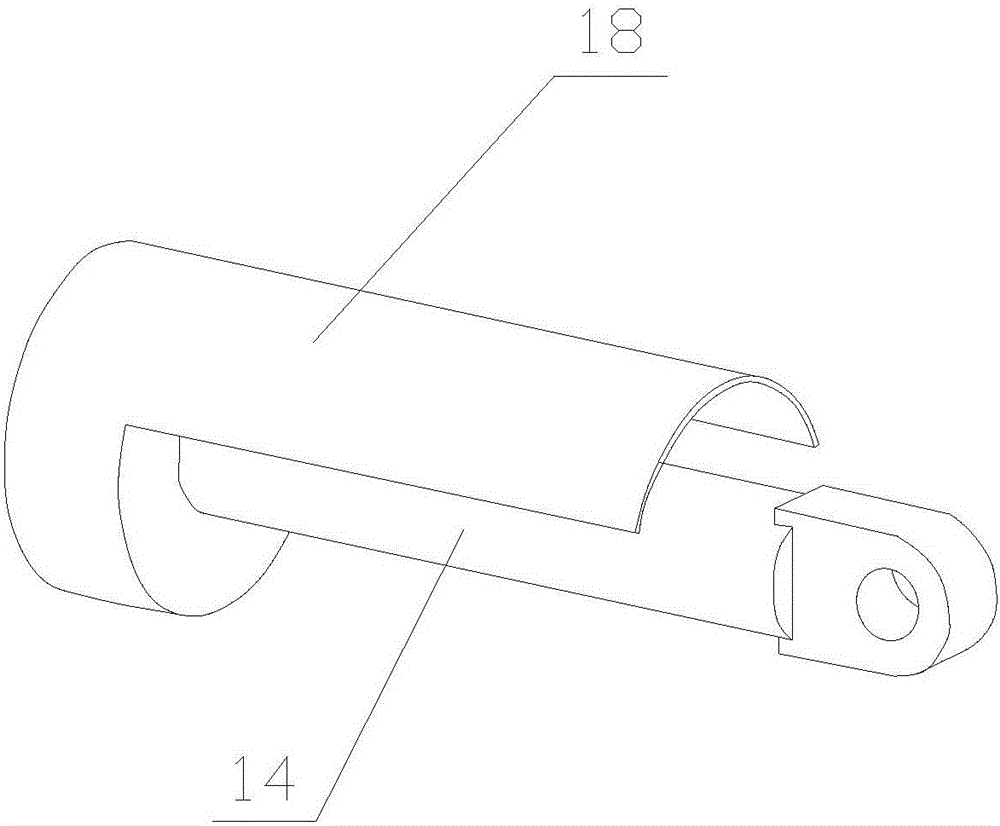

InactiveCN105709660AUniform sizeGuaranteed uptimeGranulation by material expressionReciprocating motionEngineering

The invention provides a granulator. The granulator comprises a material extruding device, a cutter device and a driving device, wherein the material extruding device comprises a first support, a material extruding barrel, a sieve plate and a piston, the material extruding barrel is arranged on the first support, the sieve plate is arranged on the front end surface of the material extruding barrel, a plurality of through holes are uniformly distributed on the sieve plate, a feeding hole is formed at the upward side of the material extruding barrel, a feed hopper is arranged above the feeding hole, the piston is located in the material extruding barrel, the tail part of the piston is connected with the driving device for driving the piston to do reciprocating motion in the material extruding barrel, a circular arc shaped baffle plate is arranged on the piston, the length of the circular arc shaped baffle plate is more than that of the feeding hole, the cutter device comprises a fan-shaped cutter, a cutter rotating shaft and an electromotor, the fan-shaped cutter is arranged on the surface of the sieve plate, positioned outside the material extruding barrel, the circular center of the fan-shaped cutter is articulated with the center of the sieve plate, and the circular center of the fan-shaped cutter is connected with the electromotor by the cutter rotating shaft. The granulator has a simple structure, has no get-stuck phenomenon and can process uniform granules.

Owner:HAIAN JULI MAGNETIC MATERIAL CO LTD

Silicon-based ceramic core slurry and application thereof

ActiveCN112500143AHigh thermal shock resistancePromote absorptionAdditive manufacturing apparatusFoundry mouldsSilicon oxidePhoto curing

The invention discloses a preparation method and application of a silicon-based ceramic core. Mixed slurry obtained according to the mixing ratio is formed by using a photocuring method to obtain a mold core biscuit, the mold core biscuit is degreased and then impregnated with a ceramic slurry, the impregnated mold core biscuit is dried, and the dried mold core biscuit is sintered in an air atmosphere by using a buried powder sintering method to obtain the silicon-based ceramic core. By means of the method, forming of a high-surface-precision silicon-based ceramic core blank can be achieved, the forming precision of the silicon-based ceramic core is improved, the production process of the ceramic core is accelerated, and the forming difficulty of the silicon-based ceramic core of a complexstructure is lowered. Degreasing and sintering treatment are carried out on the mold core biscuit obtained through the photocuring method, dipping lifting treatment is carried out on the mold core biscuit through the silicon oxide inorganic slurry, and the surface precision of the silicon-based ceramic mold core blank can be effectively improved. The method is simple, and the forming difficulty of the silicon-based ceramic mold core with a complex structure is reduced.

Owner:西安国宏天易智能科技有限公司

Polymer multi-material high-flexibility laser additive manufacturing system and method thereof

ActiveUS20200031057A1Reduce difficultyExtended service lifeManufacturing platforms/substratesManufacturing driving meansDetentErbium lasers

The invention belongs to the field of filament additive manufacturing, and discloses a polymer multi-material high-flexibility laser additive manufacturing system and a method thereof. The system comprises a first robot arm, a second robot arm, a positioner, a rotational extrusion nozzle in which a plurality of extrusion modules are disposed and a laser, each extrusion module is used for extruding one kind of filament, and the rotational extrusion nozzle is connected with the first robot which drives the rotational extrusion nozzle to move according to a preset trajectory; the laser is connected with the second robot, and is used for emitting a laser to fuse the filament extruded from the rotational extrusion nozzle, and through the cooperative motion of the first robot and the second robot, the extrusion and fusion of the filament are performed synchronously; the positioner serves as a forming mesa, and the rotation of the positioner cooperates with the motions of the two robots. With the present invention, problems such as easy blocking and short service life of the extrusion nozzle in the FDM forming are solved, thereby ensuring high flexibility of the manufacturing system and achieving the extrusion forming of the multi-material filaments.

Owner:HUAZHONG UNIV OF SCI & TECH

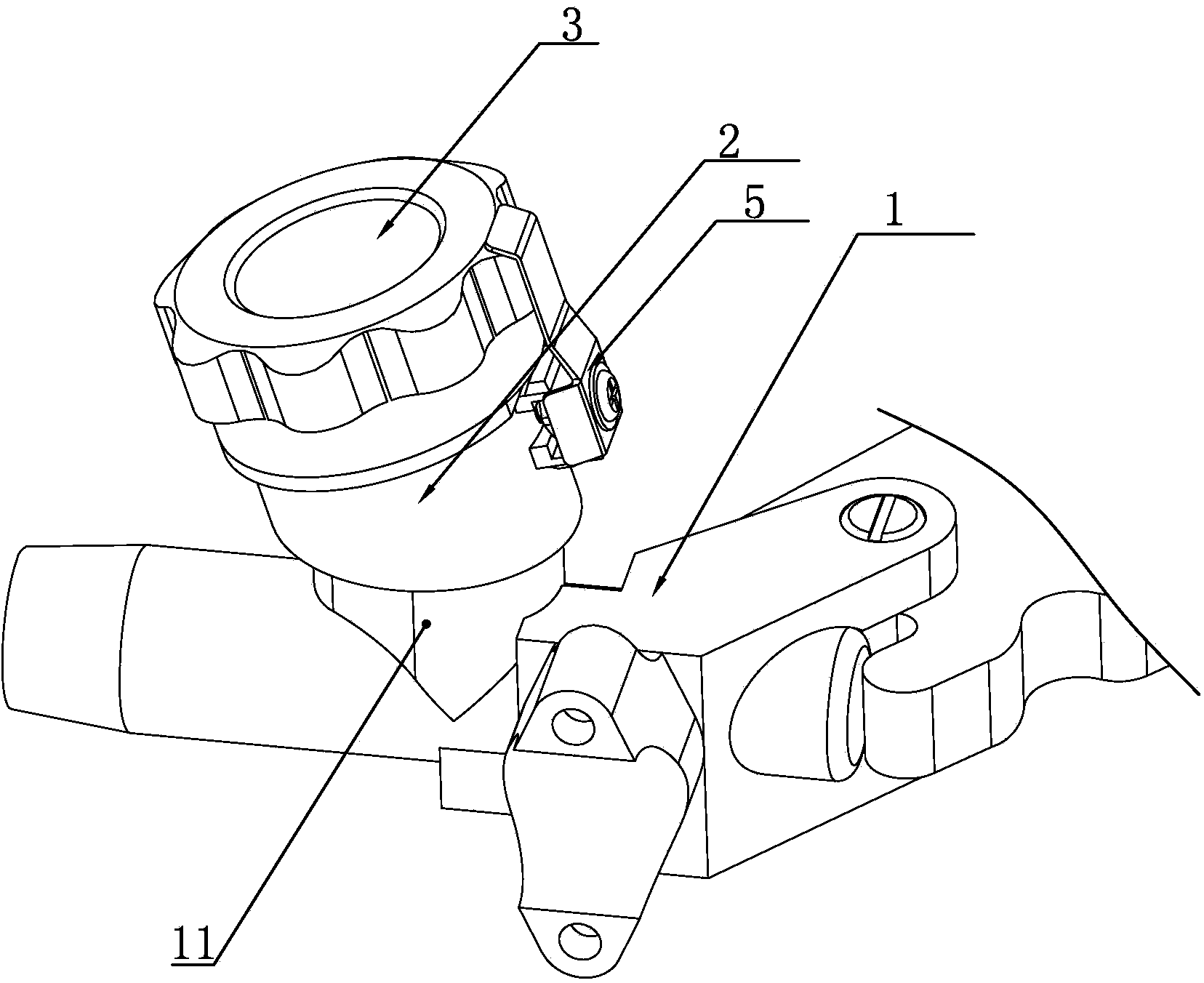

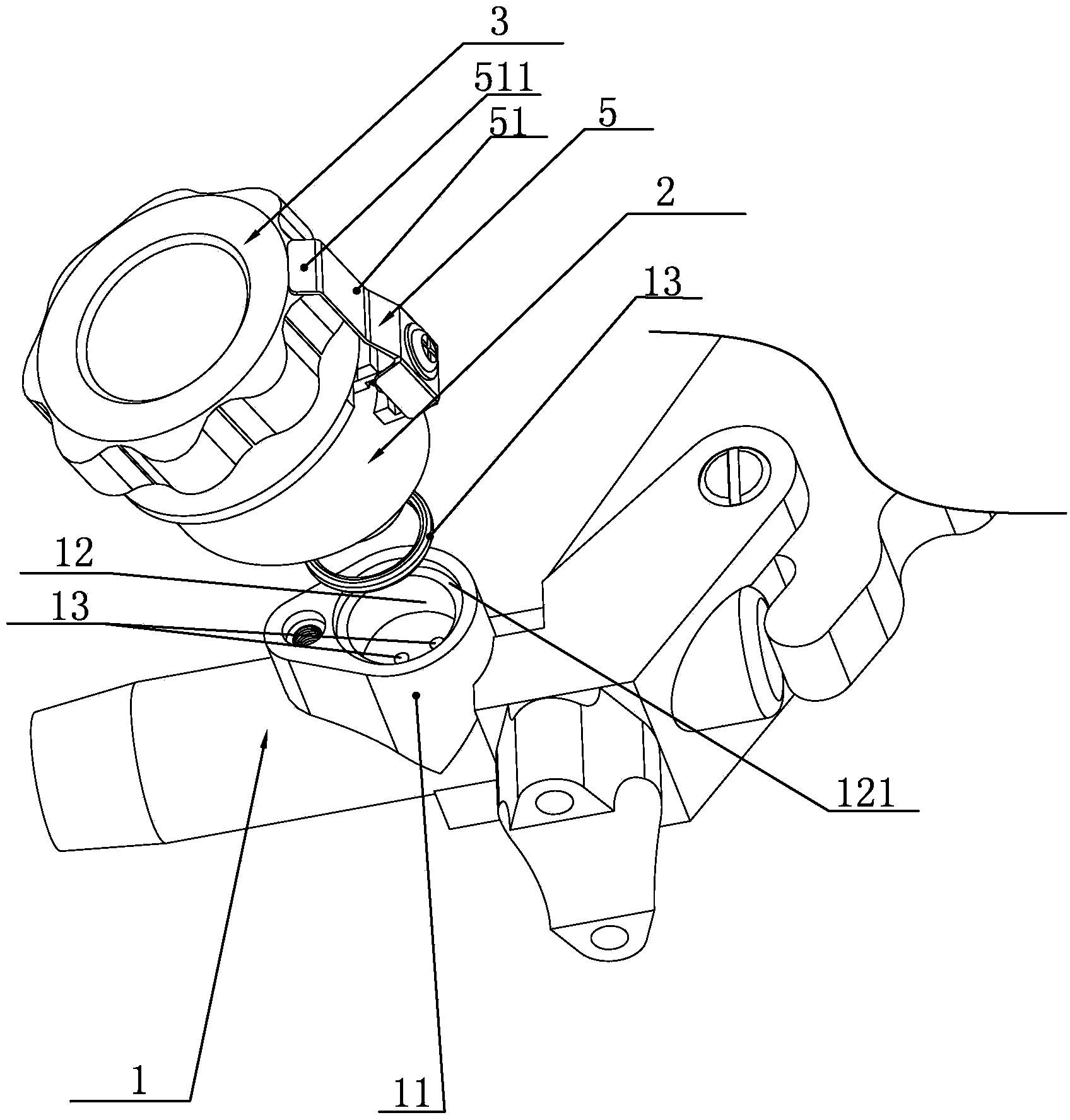

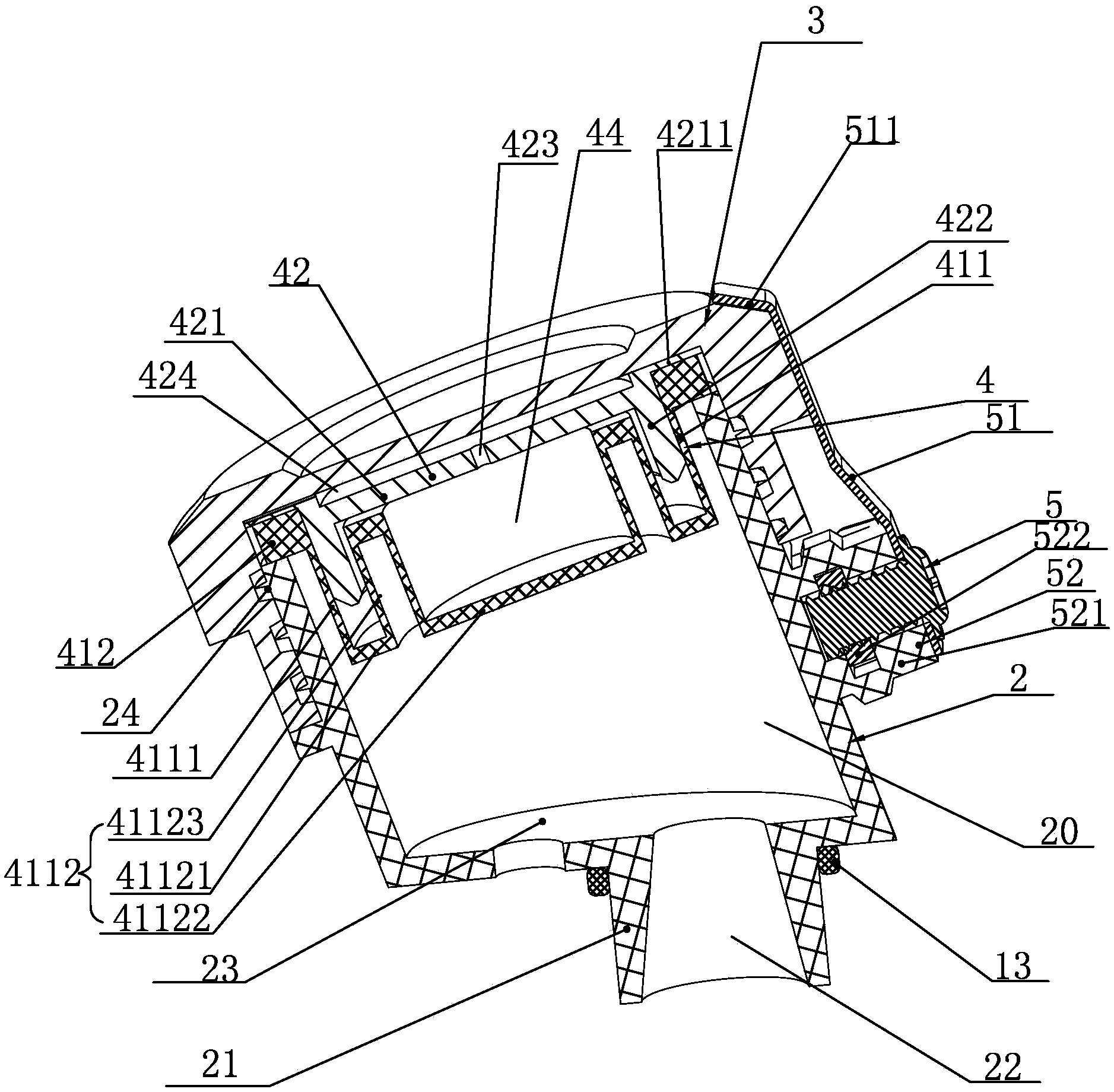

Plastic oil cup device for hydraulic braking device

ActiveCN104071138AReduce replacement costsEasy to assembleFluid braking transmissionReservoir arrangementsInjection mouldingPlunger

The invention relates to a plastic oil cup device for a hydraulic braking device. The plastic oil cup device comprises a main braking pump body, an oil cup main body with an oil storing cavity, and an oil cup cap which covers the opening of the oil storing cavity in the oil cup main body, wherein an oil cup washer is arranged between the oil cup cap and the opening of the oil storing cavity in the oil cup main body; the oil cup main body is a plastic part which is injected with plastic, and the bottom of the oil cup main body extends downwards to form a positioning column; an oil communicating channel communicated with the oil storing cavity is formed in the positioning column; an oil cup substrate on which the oil cup main body is mounted is arranged on the main braking pump body, and a positioning seat hole is formed in the oil cup substrate; an oil inlet and an oil outlet which are communicated with a plunger valve component are formed in the bottom of the positioning seat hole; the positioning column at the bottom of the oil cup main body is inserted into the positioning seat hole in the oil cup substrate in a sealing manner, and the bottom of the oil cup main body is supported on the oil cup substrate; and the oil cup main body is removably mounted on the oil cup substrate. Compared with the prior art, the plastic oil cup device has the advantages of convenient processing, low cost, convenient maintenance and replacement, convenient assembling and good sealing performance.

Owner:RUIAN JINJI VEHICLE PARTS COMPONENTS

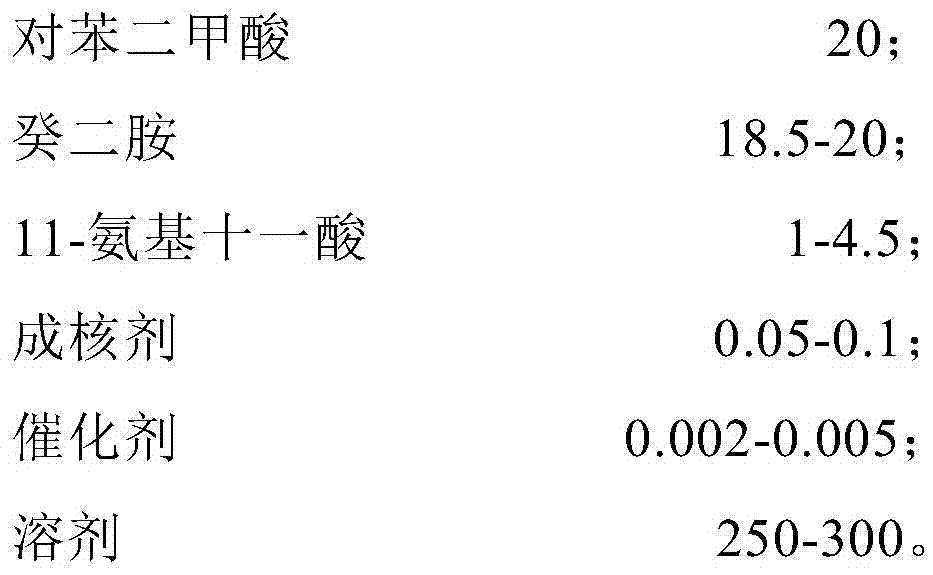

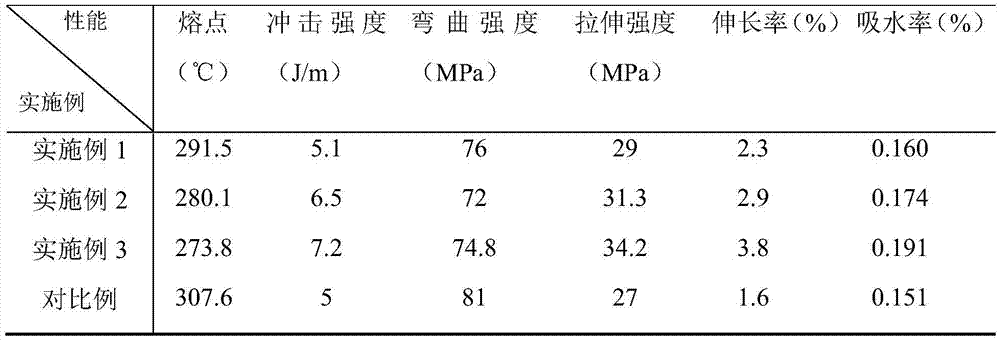

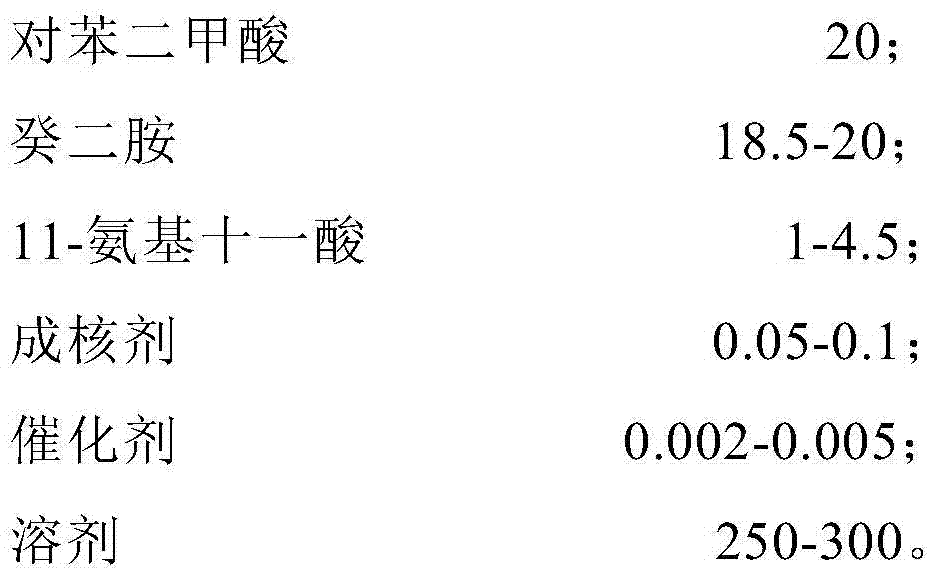

Environmental-protection bio-based semi-aromatic PA10T/11 copolymerization material and preparation method thereof

The present invention relates to an environmental-protection bio-based semi-aromatic PA10T / 11 copolymerization material and a preparation method thereof, wherein the environmental-protection bio-based semi-aromatic PA10T / 11 copolymerization material is prepared from the following components by mole: 20 parts of terephthalic acid, 18.5-20 parts of diaminodecane, 1-4.5 parts of 11-aminoundecanoic acid, 0.05-0.1 part of a nucleating agent, 0.002-0.005 part of a catalyst, and 250-300 parts of a solvent. Compared to the material in the prior art, the material of the present invention has the following characteristics that the monomer 11-aminoundecanoic acid in the PA10T / 11 provides the flexible chain segment to the main chain molecule, such that the flexibility of the main chain molecule is increased, the toughness is improved, the obtained product has the wide processing window, and the molding processing difficulty is lower than the molding processing difficulty of PA10T; and the synthesis material has characteristics of low water absorption and good material stability. According to the present invention, the PA10T / 11 is prepared by using the one-step melt condensation polymerization method so as to continuously perform the whole polymerization process, wherein the one-step melt condensation polymerization method has advantages of less process step, short polymerization period, high production efficiency, low production cost and the like, and creates the conditions for the future continuous industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

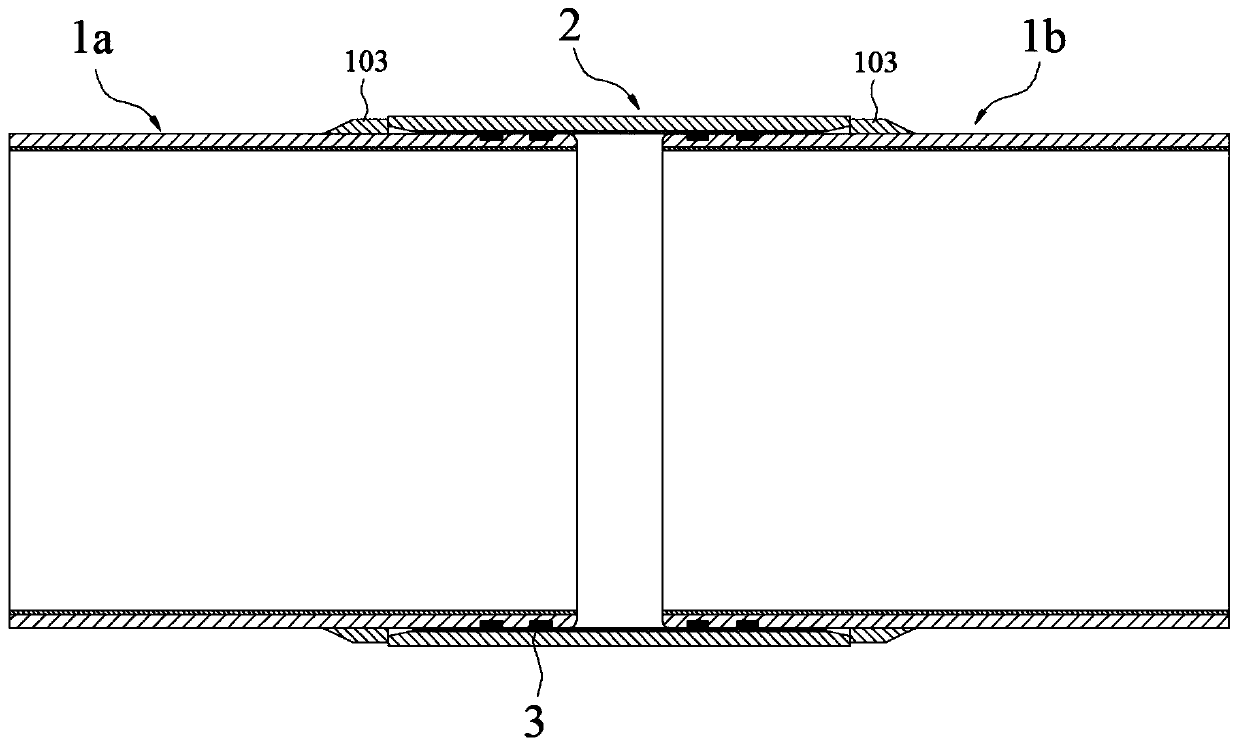

Bamboo composite pipe connecting structure and preparation method thereof

PendingCN110375134AImprove quality and efficiencyImprove forming efficiencyCouplingsRigid pipesWaste productEngineering

The invention discloses a bamboo composite pipe connecting structure and a preparation method thereof and belongs to the technical field of bamboo composite pipe connection. One end of each bamboo composite pipe is set as a pipeline socket with a blocking platform and a sealing groove, and the pipeline sockets on the two corresponding to-be-connected bamboo composite pipes are set as cylindrical bundle sections, so that the pipeline sockets of the two bamboo composite pipes are inserted at the two ends of the bundle sections and corresponding connection of the two bamboo composite pipes is realized. The bamboo composite pipe connecting structure provided by the invention is simple in structure and convenient and rapid in preparation process; the process defect in the existing bamboo composite pipe connecting structure forming process can be effectively overcome; waste products of forming parts are reduced; waste of materials are reduced; the preparation cost and the application cost ofthe bamboo composite connecting structure can be saved; and good application prospect and promotion value are achieved.

Owner:中林鑫宙竹缠绕发展有限公司

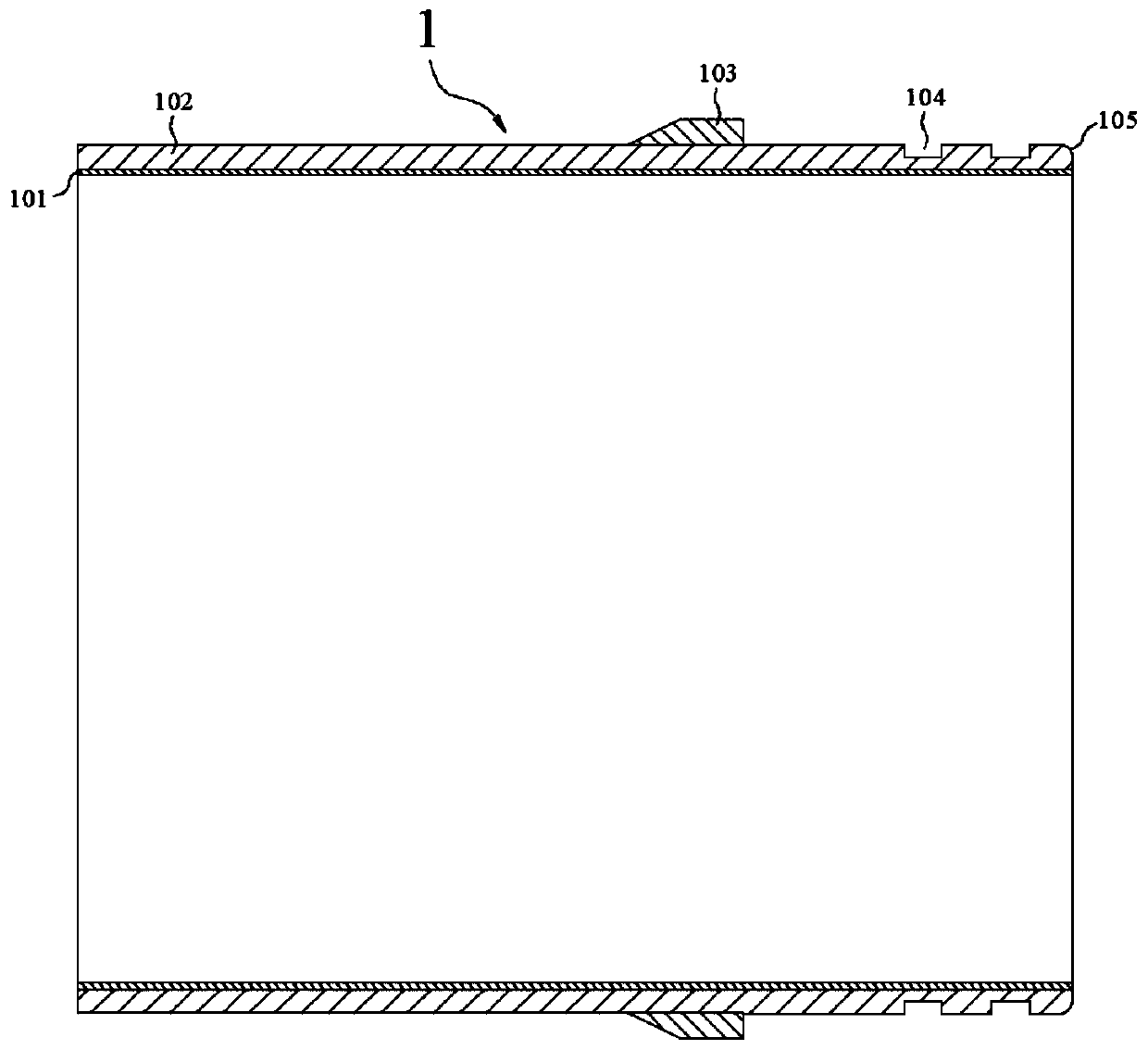

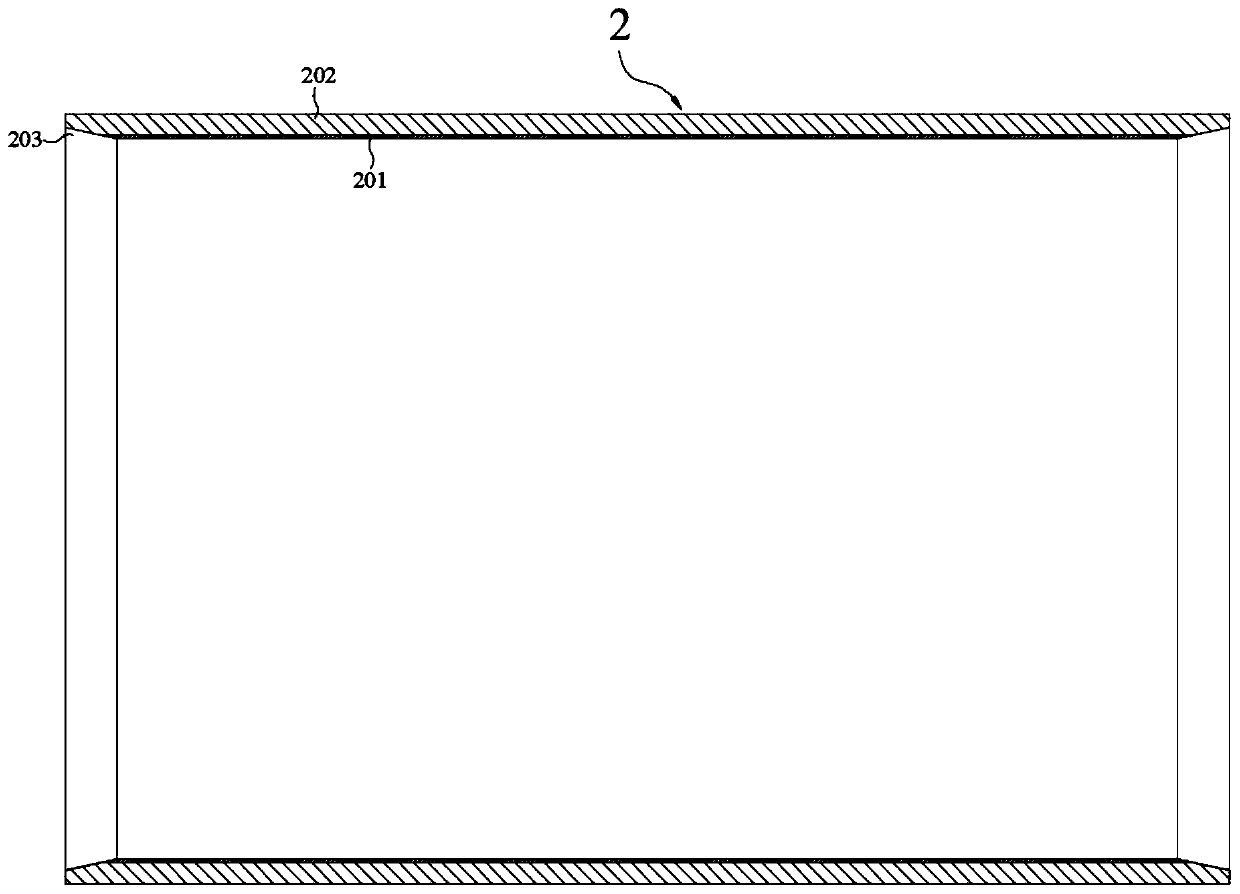

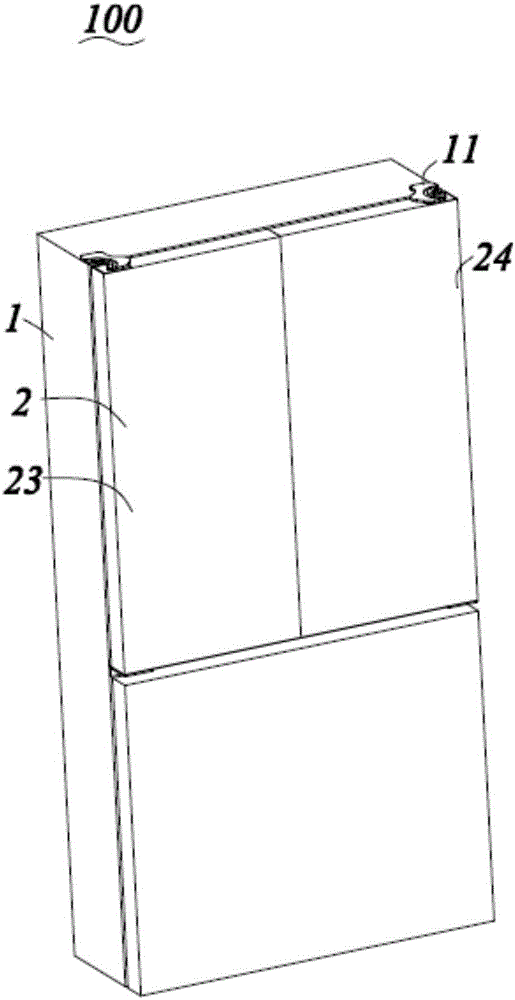

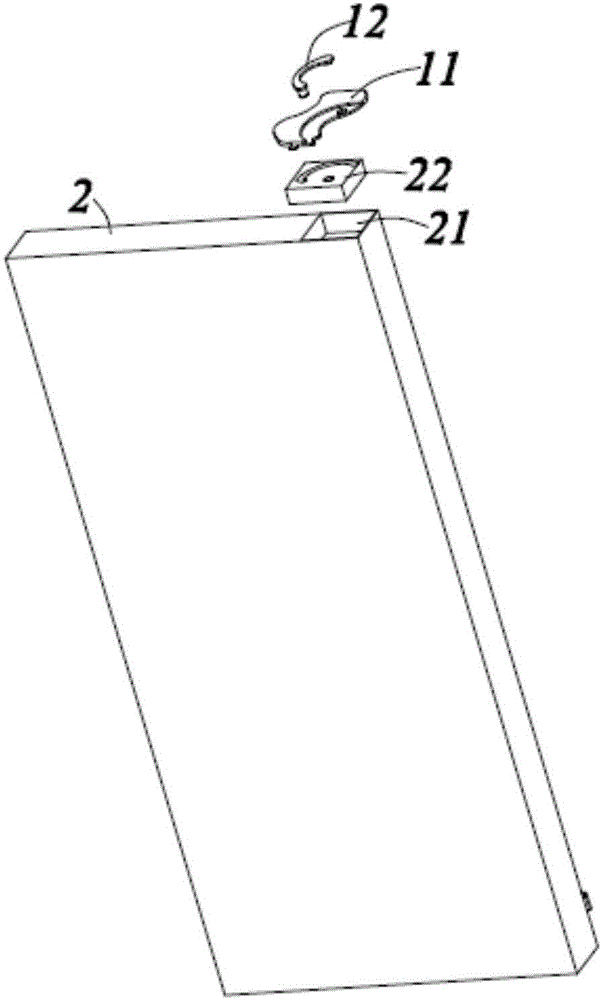

Refrigerator

ActiveCN106839613AImprove sealingReduce molding difficultyLighting and heating apparatusPin hingesEngineeringRefrigerated temperature

The invention provides a refrigerator. The refrigerator comprises a refrigerator body and a door body used for opening and closing the refrigerator body. The refrigerator body comprises a fixed hinge and a movable hinge. One end of the fixed hinge is fixed to the refrigerator body, and the other end of the fixed hinge protrudes out of the refrigerator body and is provided with a guide shaft towards the door body in a protruding mode. The door body is provided with a guide groove used for being matched with the guide shaft. The guide groove comprises a first groove body. The first groove body is provided with a first position and a second position. The first groove body obliquely extends inwards in the width and thickness direction of the refrigerator from the first position to the second position. One end of the movable hinge and the refrigerator body are in pivoted connection through a first rotating shaft and a first rotating groove, and the other end of the movable hinge protrudes out of the refrigerator body and is in pivoted connection with the door body through a second rotating shaft and a second rotating groove. The refrigerator disclosed by the invention is good in sealing effect, sealing elements cannot be abraded easily, forming difficulty of the door body is low and cost is also low.

Owner:HAIER SMART HOME CO LTD

Fireproof curtain wall system

ActiveCN104358335ANot easy to come outReduce the difficulty of fasteningWallsFire proofingKeelEngineering

The invention discloses a fireproof curtain wall system. The fireproof curtain wall system comprises a fireproof panel, a keel, a fastening bolt, a steel pressing plate and a decorative cover, wherein the fastening bolt penetrates through the steel pressing plate and is connected with the keel; the fireproof panel is pressed against the keel through the steel pressing plate; the decorative cover is buckled on the steel pressing plate; bending parts of which openings face the fireproof panel are arranged on two sides of the steel pressing plate; fastening parts which extend inwards are arranged on the two sides of the decorative cover and are buckled at the bottom ends of the outer side walls of the bending parts; the outer side walls of the bending parts are attached to the inner side wall of the decorative cover. The fireproof curtain wall system has the advantages of simple structure, simple formation, low cost and high buckling strength.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

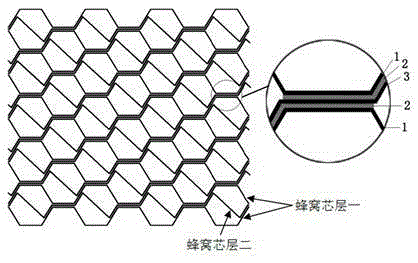

Honeycomb paper core innovation structure and core paper gluing technique

InactiveCN105415762AQuantitative lowHigh compressive strengthLaminationLamination apparatusHoneycombPulp and paper industry

The present invention relates to a honeycomb paper core innovation structure and a core paper gluing technique. The structure is characterized by consisting of honeycomb core layers I and honeycomb core layers II which are made of different materials; the honeycomb core layers II are staggered; and the shape of the honeycomb core layers II in honeycomb cells is determined by the adhesion size. The honeycomb core paper adhesion technique can be implemented in two ways. According to the adhesion technique in the first way, front and reverse surfaces of the two rolls of honeycomb core paper II are glued in a staggered manner, and the two rolls of honeycomb core paper I are respectively glued and compounded with the two rolls of honeycomb core paper II through an octagonal drum to obtain core paper. According to the adhesion technique in the second way, the first layer of the honeycomb core paper I is not glued, after being glued respectively in a staggered manner, the following three honeycomb core layers are respectively adhered to the previous honeycomb core layers, and then the last layer is glued in a staggered manner, and is glued to the previous cutting unit after being cut off by a cutter so as to form continuous core paper. Compared with the original process, the honeycomb paper core gluing technique provided by the present invention is seldom changed, and has the advantages of convenience in design, reasonable structure, high strength, easiness in material selection, simplicity, low cost and the like.

Owner:TIANJIN VOCATIONAL INST

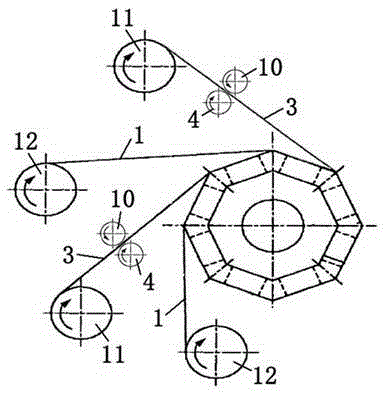

Propeller with combined continuous fiber reinforced composite blades for ship

The invention belongs to the technical field of propellers and relates to a propeller with combined continuous fiber reinforced composite blades, in particular to a propeller with combined continuous fiber reinforced composite blades for a ship. The propeller with the combined continuous fiber reinforced composite blades for the ship is characterized in that the assembly surfaces of dovetail grooves in a propeller hub and blade roots are planes, and thus the assembly positioning precision of the dovetail grooves and the blade roots is high; the blades are inserted from large ends of the dovetail grooves in the propeller hub, then an end cap is fixed to the propeller hub to exert fastening force so as to mount the blades in position, thus mounting is convenient, and the composite blades are not damaged; the space between the dovetail grooves and the blades is filled with resin adhesive, the end cap and the propeller hub are fixed, the blades are not loosened, dropped or damaged under a working condition after testing, and thus the propeller has high reliability; and the structure, performance and manufacturing features of the composite blades are fully taken into account in the aspect of designing of the dovetail grooves in the propeller hub, and thus the blades are suitable for various immersion propellers and water surface propellers.

Owner:AVIC BASIC TECH RES INST

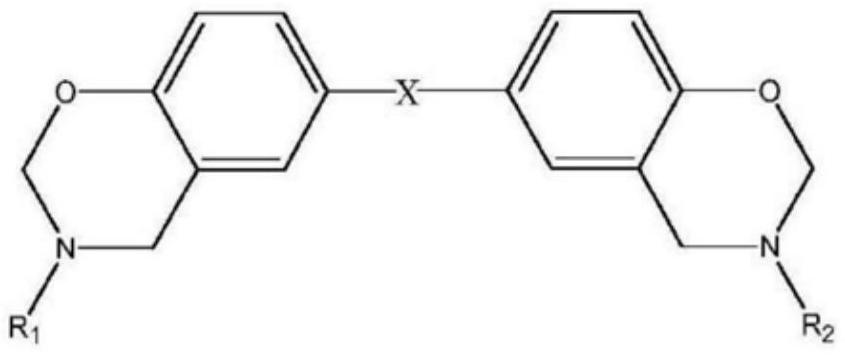

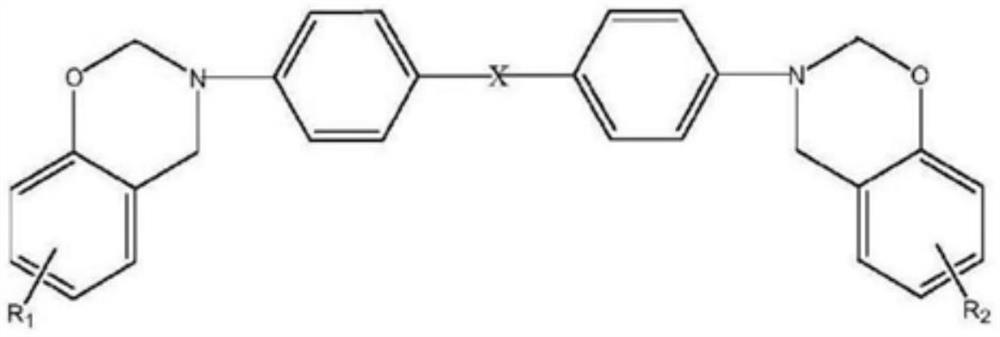

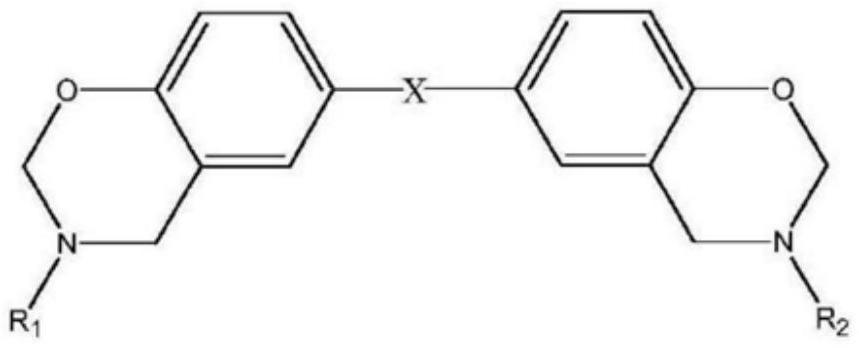

Benzoxazine-containing curable resin composition and preparation method thereof

The invention provides a benzoxazine-containing curable resin composition and a preparation method thereof. The resin system comprises a benzoxazine monomer, an epoxy resin and a toughening agent, wherein the benzoxazine monomer is a bifunctional benzoxazine compound comprising at least one of dihydric phenol type benzoxazine and diamine type benzoxazine. The resin system comprises the componentsin parts by mass: 50-80 parts of the benzoxazine monomer, 10-40 parts of the epoxy resin, and 10-40 parts of the toughening agent. The resin system disclosed by the invention has the advantages of good manufacturability, high toughness and excellent comprehensive mechanical properties, and the prepared composite material has good compression and shearing properties when the benzoxazine resin composition disclosed by the invention is used as matrix resin of the composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

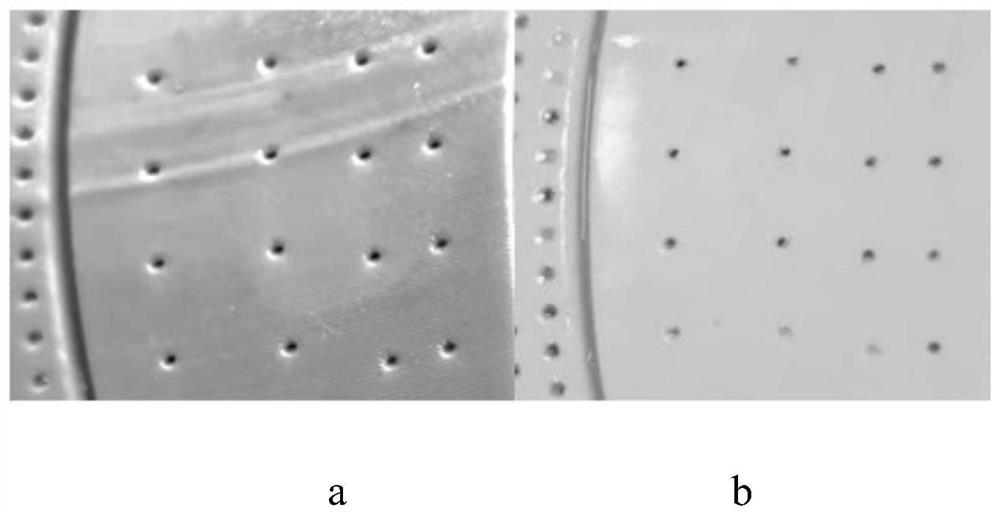

Method and device of reducing wall thickness of going-to-the-sun surface of ceramic solar panel

InactiveCN101586882AImprove heat collection efficiencyReduce molding difficultySolar heating energySolar heat devicesAbsorption rateExtrusion

The thickness of the outer wall of the prior ceramic solar panel formed by vacuum extrusion is determined by a mold, the thinner the ceramic solar panel the more difficult forming and the lower forming rate of the ceramic solar panel, even the ceramic solar panel can not be formed, the test proves that the thinner the sun suction surface (going-to-the-sun surface) of the ceramic solar panel, the higher efficiency of the ceramic solar panel heat collector. The invention grinds or mills the going-to-the-sun surface of the ceramic solar panel biscuit by hands and a portable grinder and special equipment, and decreases the thickness of the going-to-the-sun surface, thereby leading the ceramic solar panel to have higher production yield and have higher solar energy absorption rate.

Owner:曹树梁

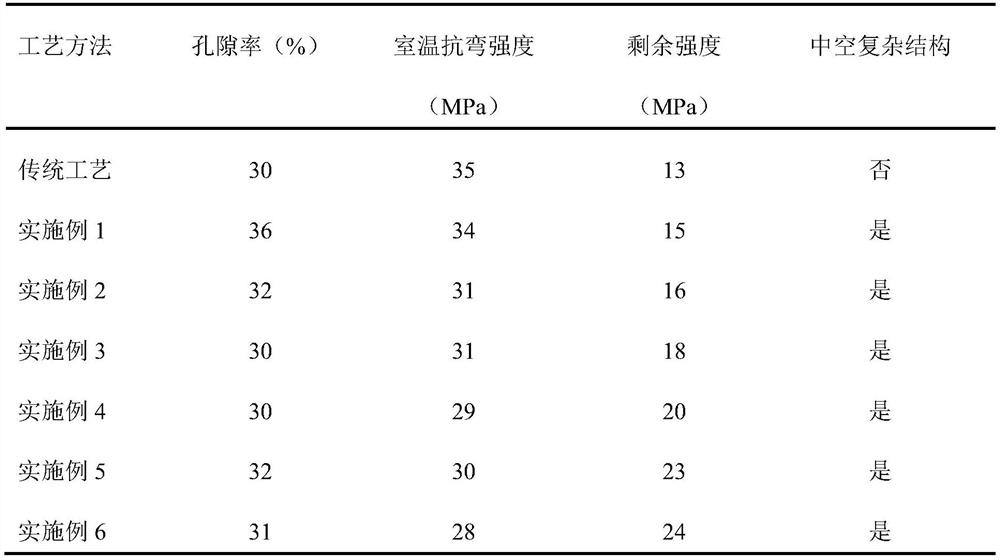

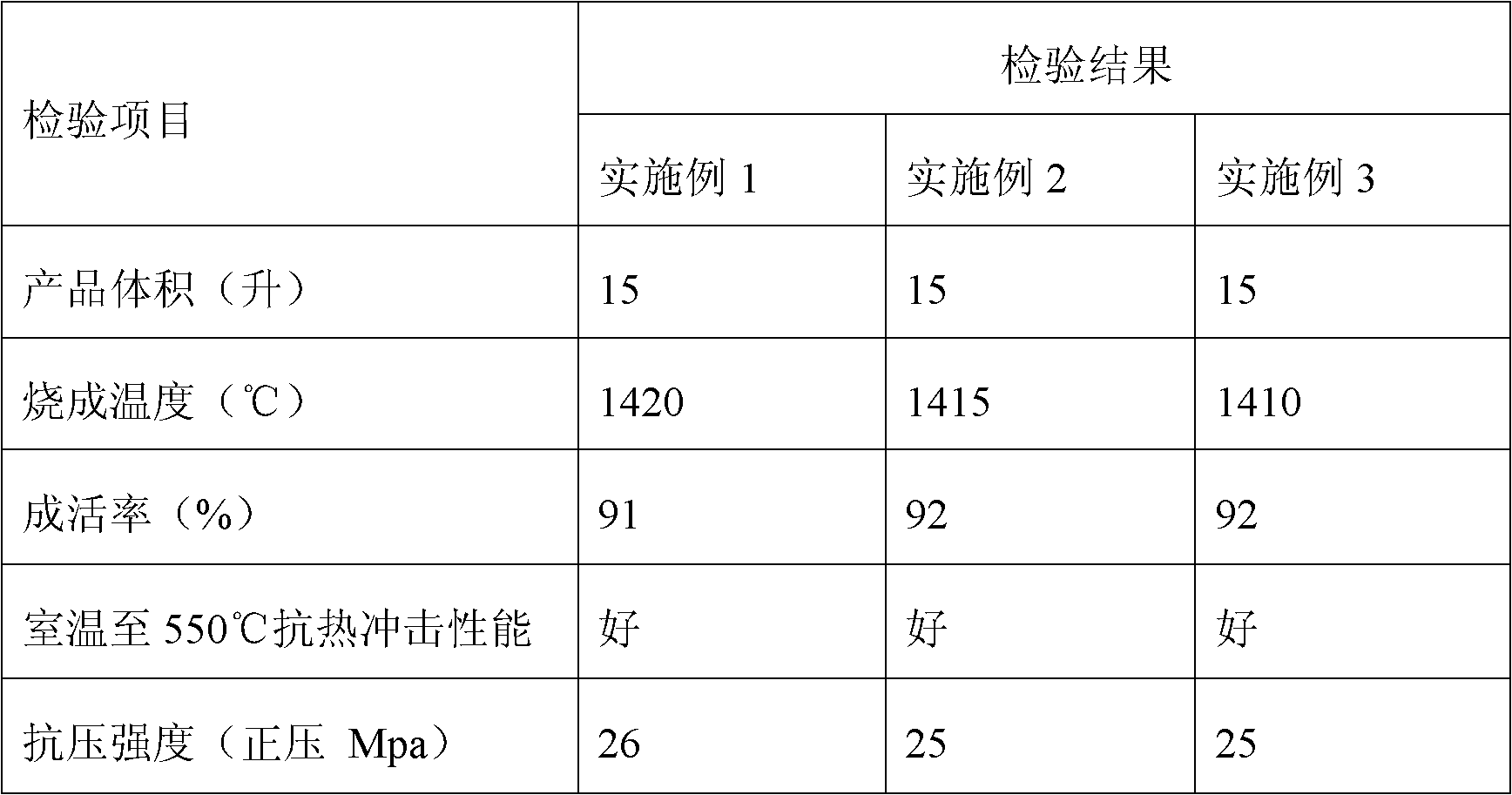

A kind of preparation method of honeycomb ceramic

The invention discloses a method for preparing honeycomb ceramics, in which hydroxypropyl methylcellulose is used as a binder, which enhances the plasticity during molding and reduces the difficulty of molding; uses clay to increase the strength of the product and improve the quality of the finished product. Rate. Quartz powder is used in the raw materials, which increases the firing reaction temperature and improves the thermal shock resistance of the product. Stearic acid is used in the raw materials, which relieves the resistance during extrusion molding, increases the lubricity during extrusion, makes the molding process of large-volume blanks easier, and can increase the yield of finished products.

Owner:YIXING PRINCE CERAMICS

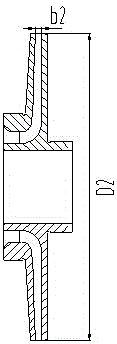

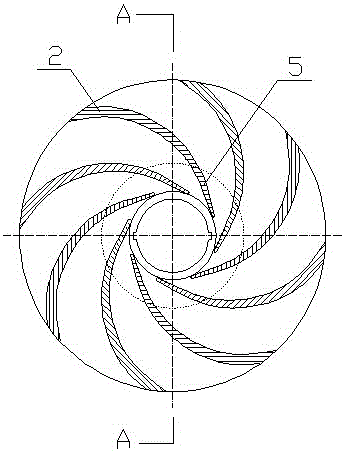

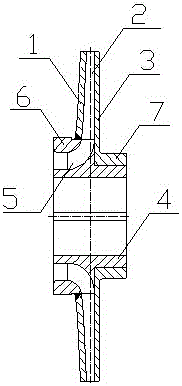

Low-specific-speed impeller structure and machining method thereof

The invention discloses a low-specific-speed impeller structure and a machining method thereof. The structure comprises an impeller body part and an impeller root part; the impeller body part includes a front cover plate, a blade body part and a back cover plate; the impeller root part includes a hub, a blade root part and a sealing ring part; the middle part of the back cover plate is downwards projected to form a sleeve; the back cover plate coats the back part of the hub through the sleeve; the front cover plate coats the sealing ring part; an annular welding line is formed between the front cover plate and the sealing ring part; and the front cover plate and the sealing ring part are tightly welded through the annular welding line. The machining method comprises the following steps: 1) the impeller body part and the impeller root part are respectively cast; 2) the impeller body part coats the impeller root part from the back end of the impeller root part; and the front cover plate coats the sealing ring part; and 3) the annular welding line between the front cover plate and the sealing ring part is tightly welded. The structure is low in machining difficulty, high in machining precision and better in total quality, improves the machining yield, is high in impeller stability, and can effectively improve the guide efficiency.

Owner:重庆水泵厂有限责任公司

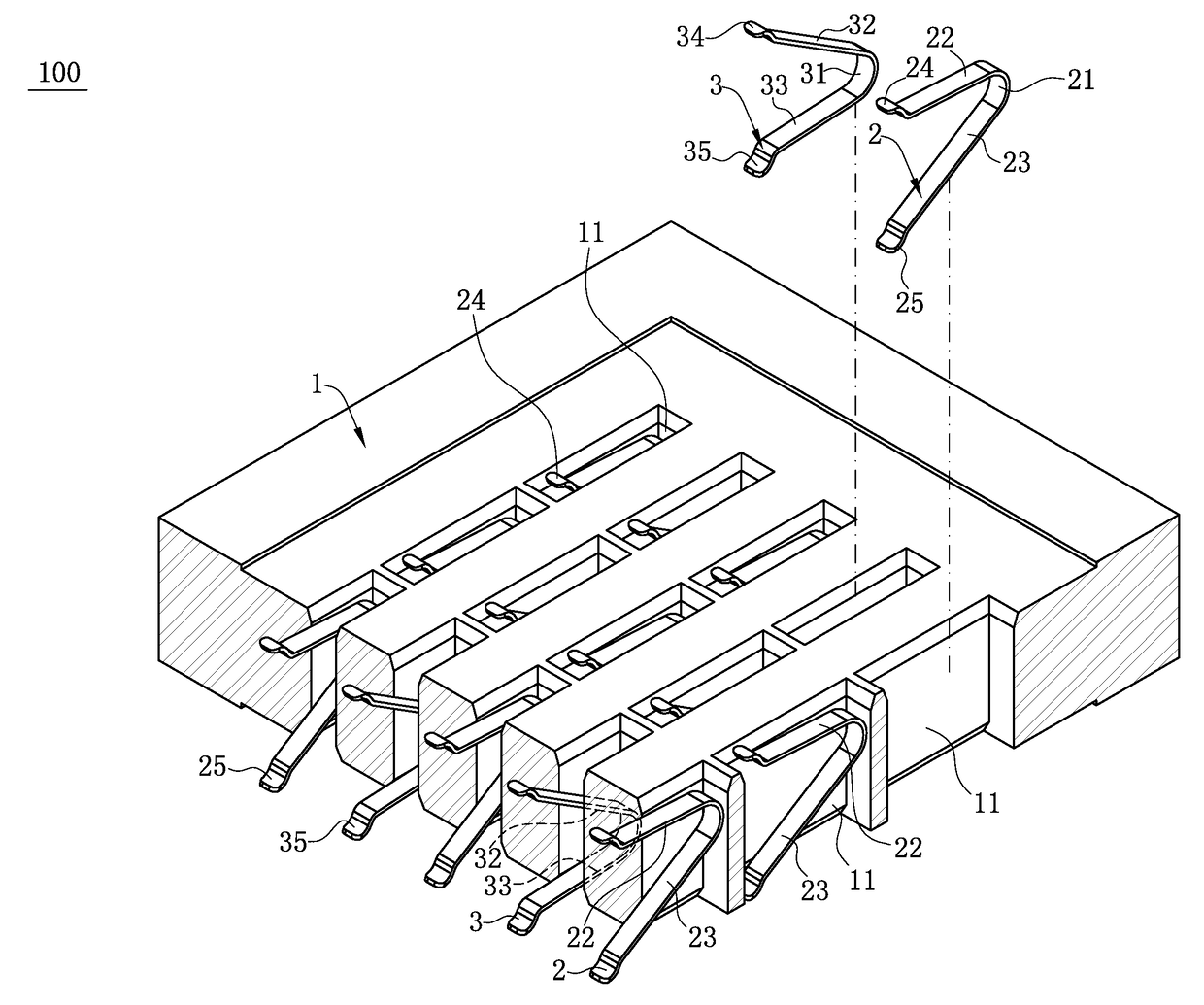

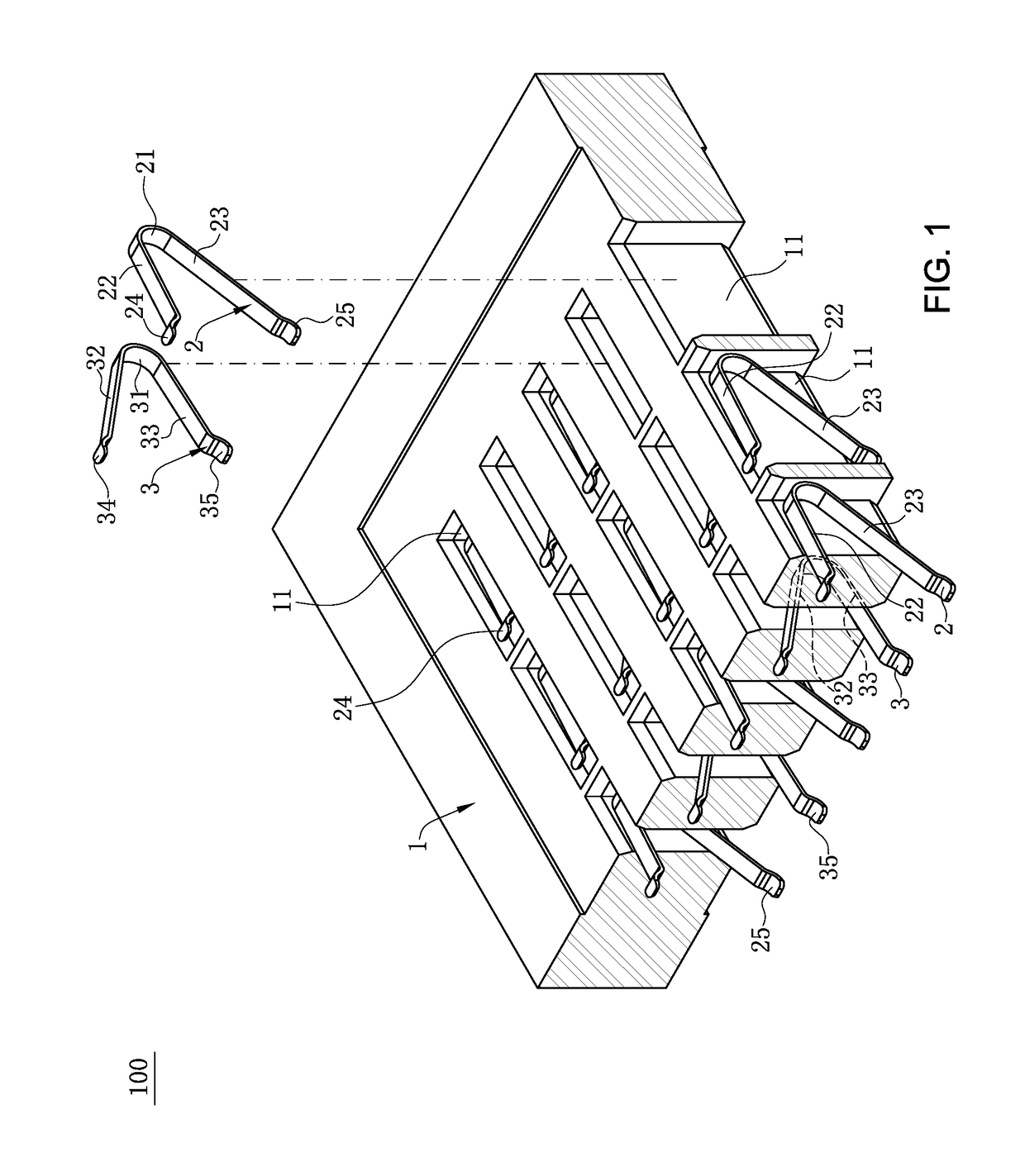

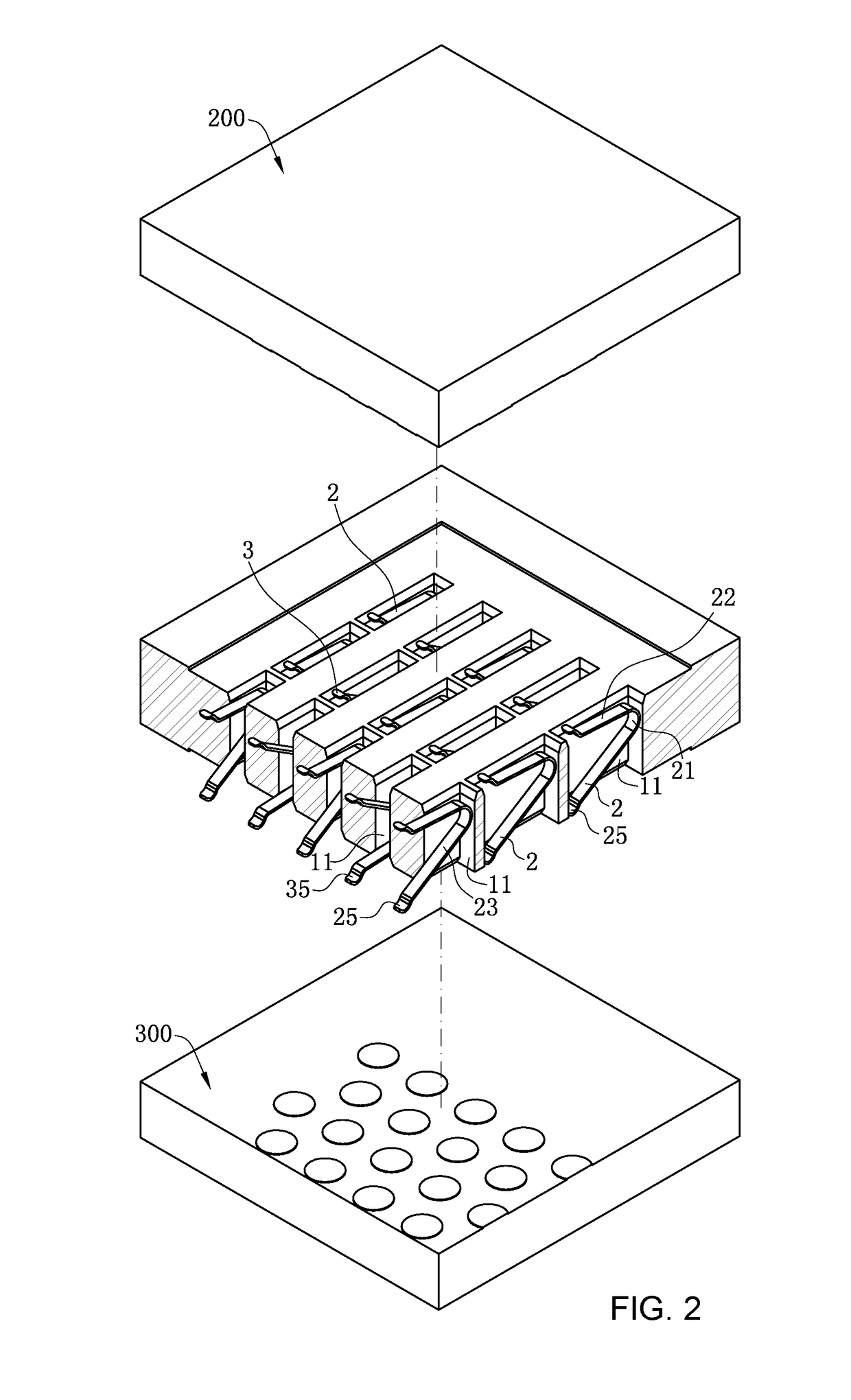

Electrical connector

ActiveUS10103470B2Directly facing areaReduce decreaseContact member manufacturingElectrical measurement instrument detailsElectrical connectionElectrical connector

An electrical connector includes an insulating body having multiple receiving slots, and multiple first terminals and multiple second terminals respectively received in the receiving slots. Each first terminal has a first connecting portion, a first elastic arm bending and upward extending from the first connecting portion, and a first conducting arm bending and extending from the first connecting portion. Each second terminal has a second connecting portion, a second elastic arm bending and extending upward from the second connecting portion, and a second conducting arm bending and extending from the second connecting portion. A bent position between each of the first connecting portions and a corresponding one of the first elastic arms is higher than a bent position between each of the second connecting portions and a corresponding one of the second elastic arms.

Owner:LOTES

Supercritical reaction device

ActiveCN107892345ARealize high temperature and high pressure washing functionPrevent burstWater treatment parameter controlWater treatment compoundsControl systemMetallic materials

The invention relates to a supercritical reaction device. The device includes a pressure container, at least one reactor arranged in the pressure container, a pressure and temperature sensor and a pressure control system; the pressure control system controls the pressure in the pressure container and the reactors to maintain equal according to pressure signal data collected by the pressure and temperature sensor. According to the device, by adopting the in-built reactors and an external pressure protection device, the pressure bearing characteristic of the inner reactors are greatly improved,the adoption of non-metal materials as in-built reactors can be possible, the corrosion problem in existing supercritical reaction devices is solved, and the cost of equipment is remarkably reduced.

Owner:吴丹丹

Optical system, camera module and electronic equipment

ActiveCN112764201AReduce molding difficultyReduce processing costsOptical elementsOptical axisEngineering

The invention relates to an optical system, a camera module and electronic equipment. The optical system comprises, in order from an object side to an image side along an optical axis: a first lens element with positive refractive power; a second lens element with negative refractive power having an object-side surface being convex in a paraxial region thereof; a third lens element with negative refractive power having a concave image-side surface in a paraxial region thereof; a fourth lens element with positive refractive power having an object-side surface being convex in a paraxial region thereof; the optical system satisfies the following conditions: 0.5 < SD42 / ImgH < 0.85, ImgH>4.0mm, SD42 is the maximum effective radius of the image side surface of the fourth lens, and ImgH is half of the image height corresponding to the maximum field angle of the optical system. By means of the design, on one hand, the system has the long-focus characteristic, on the other hand, aberration can be well restrained, the emergent angle of main light rays of an edge view field is restrained when the main light rays emerge from the fourth lens, and therefore the main light ray angle of an inner view field can be better matched with an image sensor.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com