A kind of preparation method of honeycomb ceramic

A honeycomb ceramic, particle size technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of large temperature difference between the inside and outside of the green body, large diesel engine volume, and reduced survival rate, etc. The effect of easy and reduced molding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention discloses a preparation method of honeycomb ceramics, which comprises the following steps:

[0013] (1) Prepare talcum powder of 35-45 parts by weight, alumina of 20-25 parts by weight, clay of 25-30 parts by weight, quartz powder of 5-10 parts by weight, hydroxypropyl methyl of 5-10 parts by weight Cellulose, 2-3 parts by weight of stearic acid and 20-30 parts by weight of deionized water.

[0014] (2) Mix the above materials first.

[0015] (3) The above-mentioned mixed material is formed into a green body by extrusion, and the green body is dried.

[0016] (4) The above-mentioned green body is fired at 1400°C-1430°C and kept for 10 hours to obtain the finished product. Wherein, during firing, the temperature rises by 50°C per hour until 1400°C-1430°C.

[0017] In this method:

[0018] The particle size characteristics of the talcum powder are D10: 1um-2um, D50: 9um-11um, D90: 18um-20um;

[0019] The particle size characteristics of alumina are D10:...

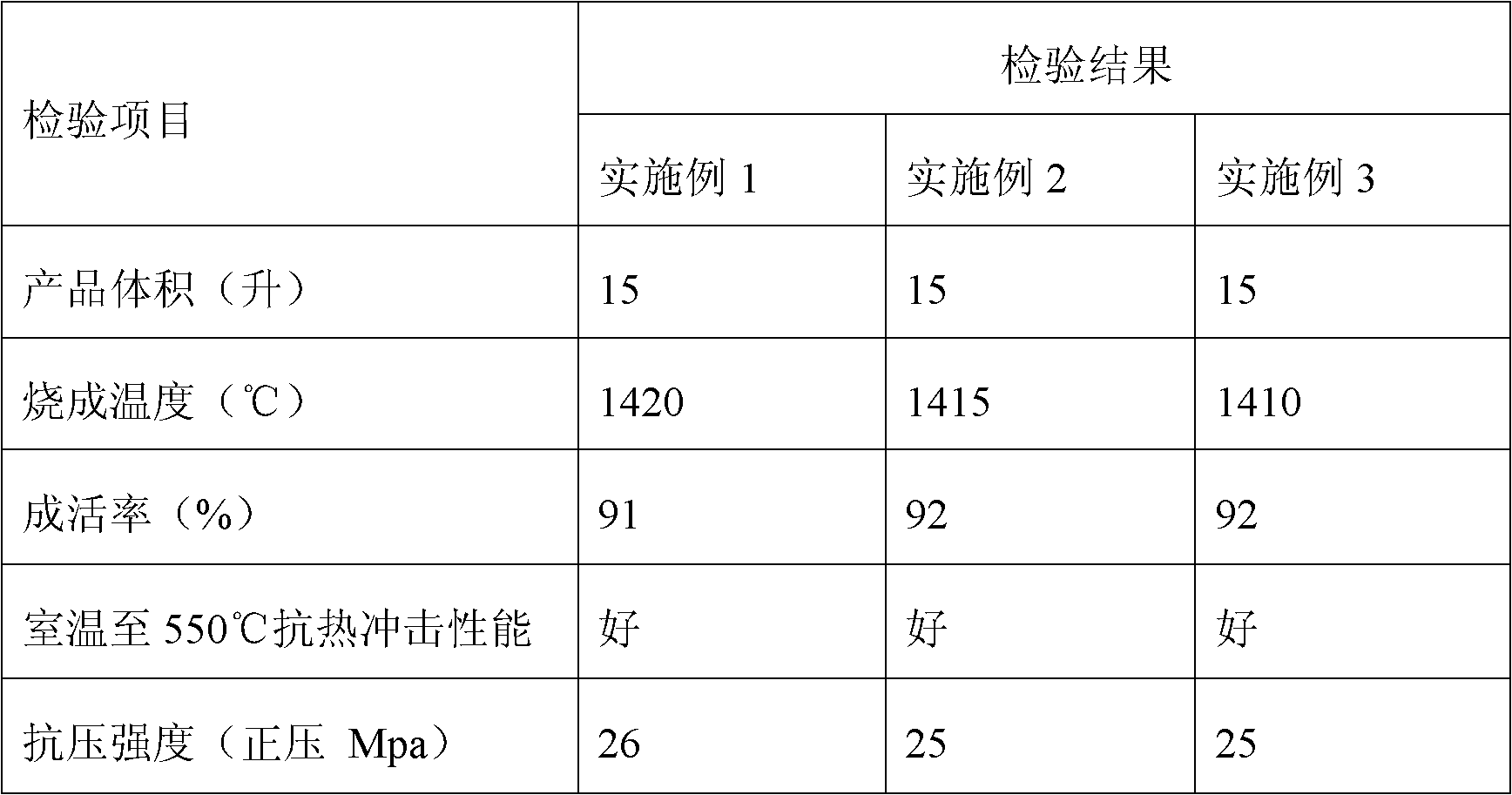

Embodiment 1

[0023] Provide the talcum powder of 35 parts by weight, the aluminum oxide of 25 parts by weight, the clay of 30 parts by weight, the quartz powder of 10 parts by weight, the hydroxypropyl methylcellulose of 6 parts by weight, the stearic acid of 2 parts by weight and 28 parts by weight Parts of deionized water, the honeycomb ceramics were prepared by the above preparation method, and the highest firing temperature was 1420°C.

Embodiment 2

[0025] Provide the talcum powder of 40 parts by weight, the alumina of 24 parts by weight, the clay of 28 parts by weight, the quartz powder of 8 parts by weight, the hydroxypropyl methylcellulose of 6 parts by weight, the stearic acid of 2 parts by weight and 27 parts by weight Parts of deionized water are used to prepare honeycomb ceramics through the above preparation method, and the highest firing temperature is 1415°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com