Production system and method for high-ductility ribbed steel bar

A ribbed steel bar and production system technology, applied in the field of steel bar cold rolling, can solve problems such as lifting, crystal phase structure damage, and hard-to-restore grain structure of steel bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

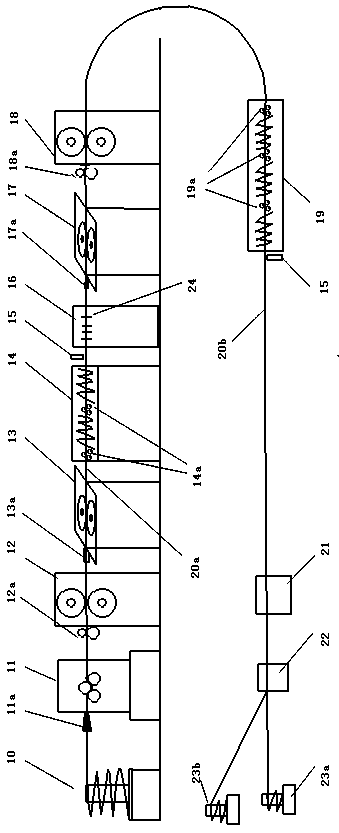

[0042] The specific technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and embodiments. In the following description, the front and rear directions refer to the flow direction of steel bars, the left and right directions refer to the two sides in the forward direction of the steel bar production line, and the up and down directions refer to the up and down directions in the vertical direction.

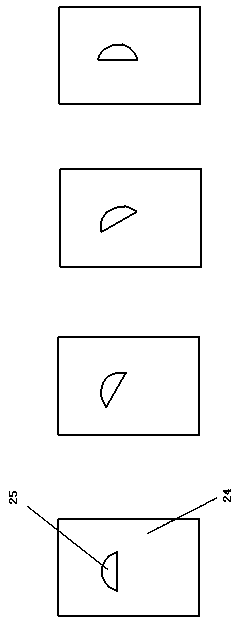

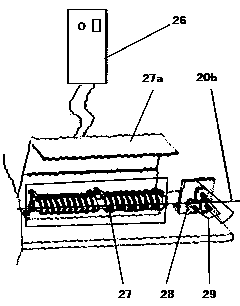

[0043] The labels in the attached drawings respectively represent: 10-pay-off machine, 11a-directional sleeve 1, 11-descaler, 12a-directional roller 1, 12-rolling reducer in the up and down direction, 13a-directional sleeve 2 , 13-Rolling and reducing machine in the left and right direction, 14a-Stable roller in the direction of steel bar 1, 14 Primary heat treatment device, 15-Temperature detector, 16-Steering device, 17a-Orientation sleeve 3, 17-Rolling in the left and right direction Ribbing machine, 18a-directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com