Plastic oil cup device for hydraulic braking device

A technology of hydraulic brakes and brakes, which is applied to the field of oil cup devices on hydraulic brakes and plastic oil cup devices, which can solve the problems of scrapped brakes, difficult forming and processing, and high production costs of oil cups, so as to reduce difficulty and reduce materials. cost, avoiding irreparable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

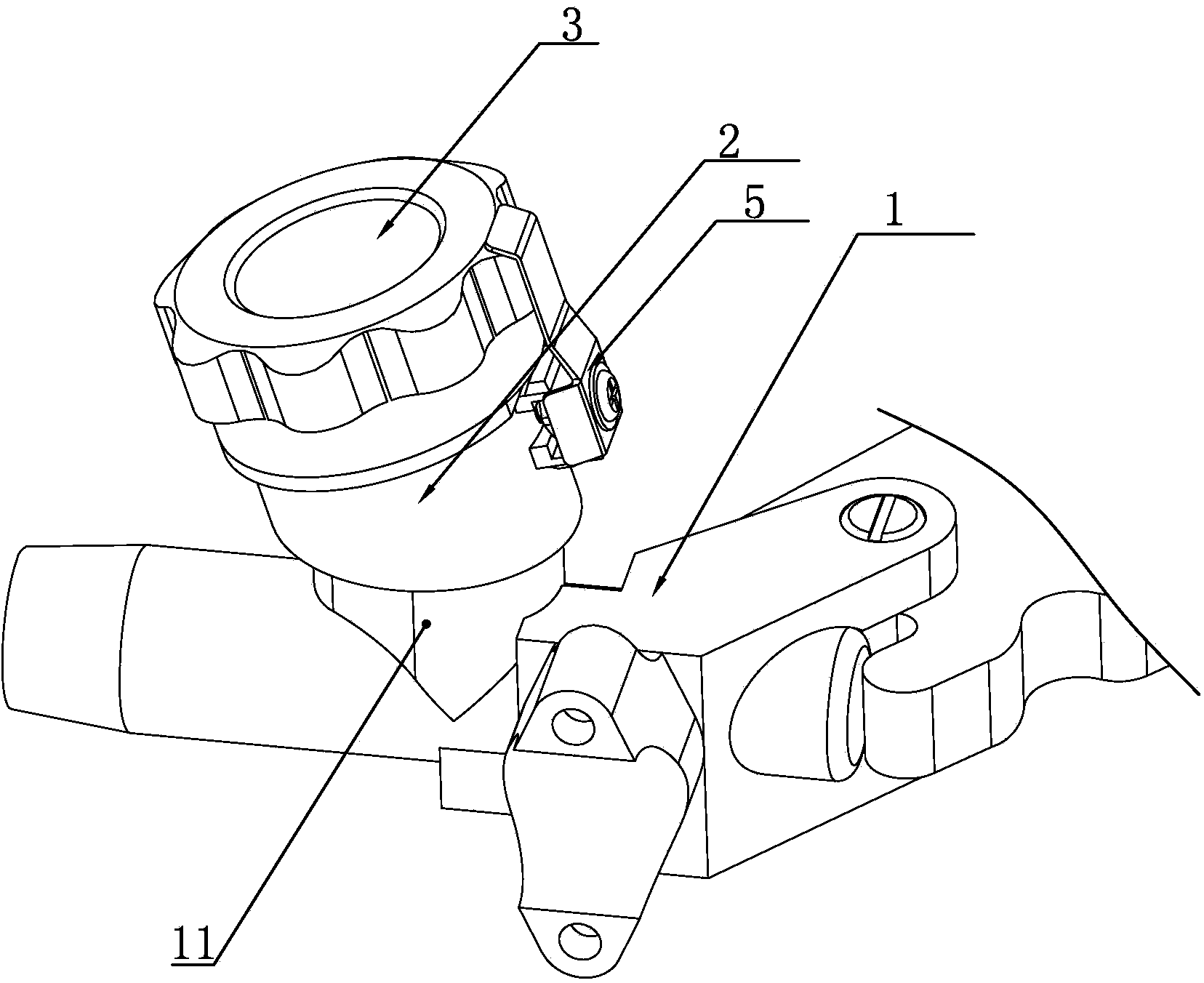

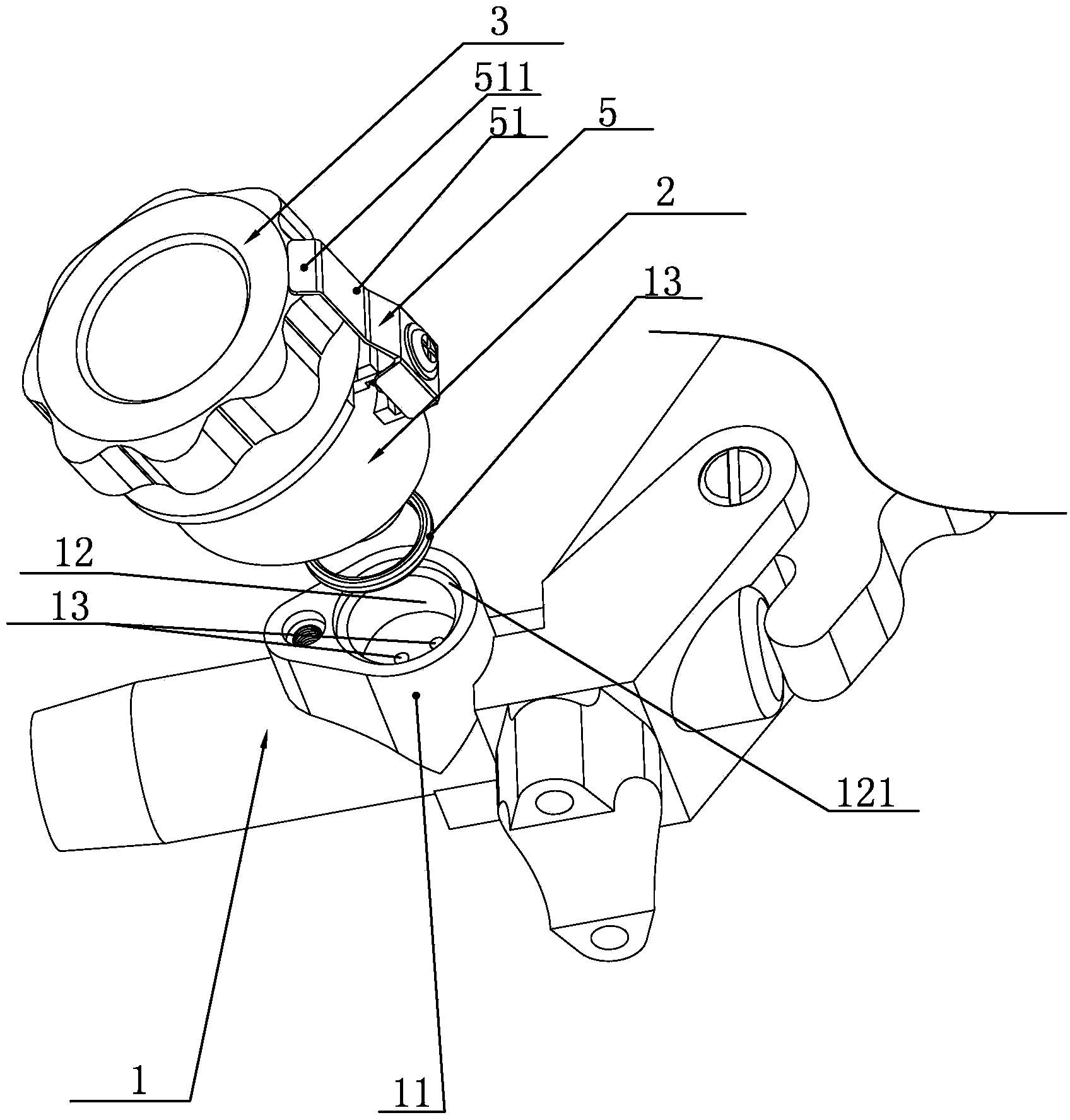

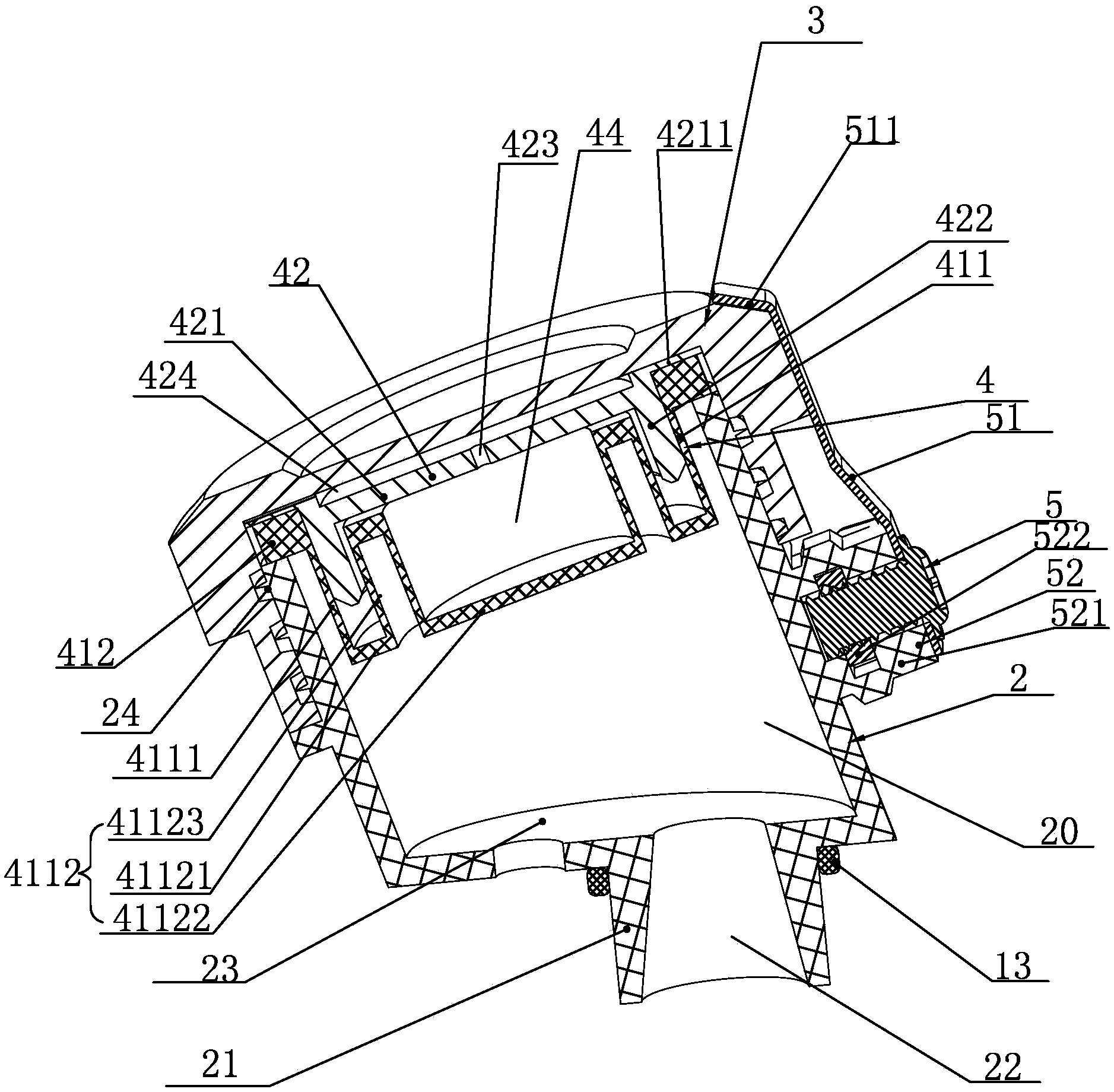

[0029] See attached figure 1 to attach Figure 5 , a plastic oil cup device for a hydraulic brake disclosed in the present invention includes a brake main pump body 1, an oil cup main body 2 with an oil storage chamber 20, and an oil storage chamber 20 covered on the oil cup main body 2 An oil cup cover 3 at the mouth, an oil cup pad 4 is arranged between the oil cup cover 3 and the mouth of the oil storage chamber 20 on the oil cup main body 2 . The main body 2 of the oil cup is a plastic part formed by plastic injection molding. The bottom of the main body 2 of the oil cup extends downward with a positioning post 21, and the positioning post 21 is provided with an oil passage 22 communicating with the oil storage chamber 20; The main pump body 1 is provided with an oil cup base 11 installed on the main body 2 of the oil supply cup. The oil cup base 11 is provided with a positioning seat hole 12, and the bottom of the positioning seat hole is provided with an oil inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com