Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Reduce equipment maintenance costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

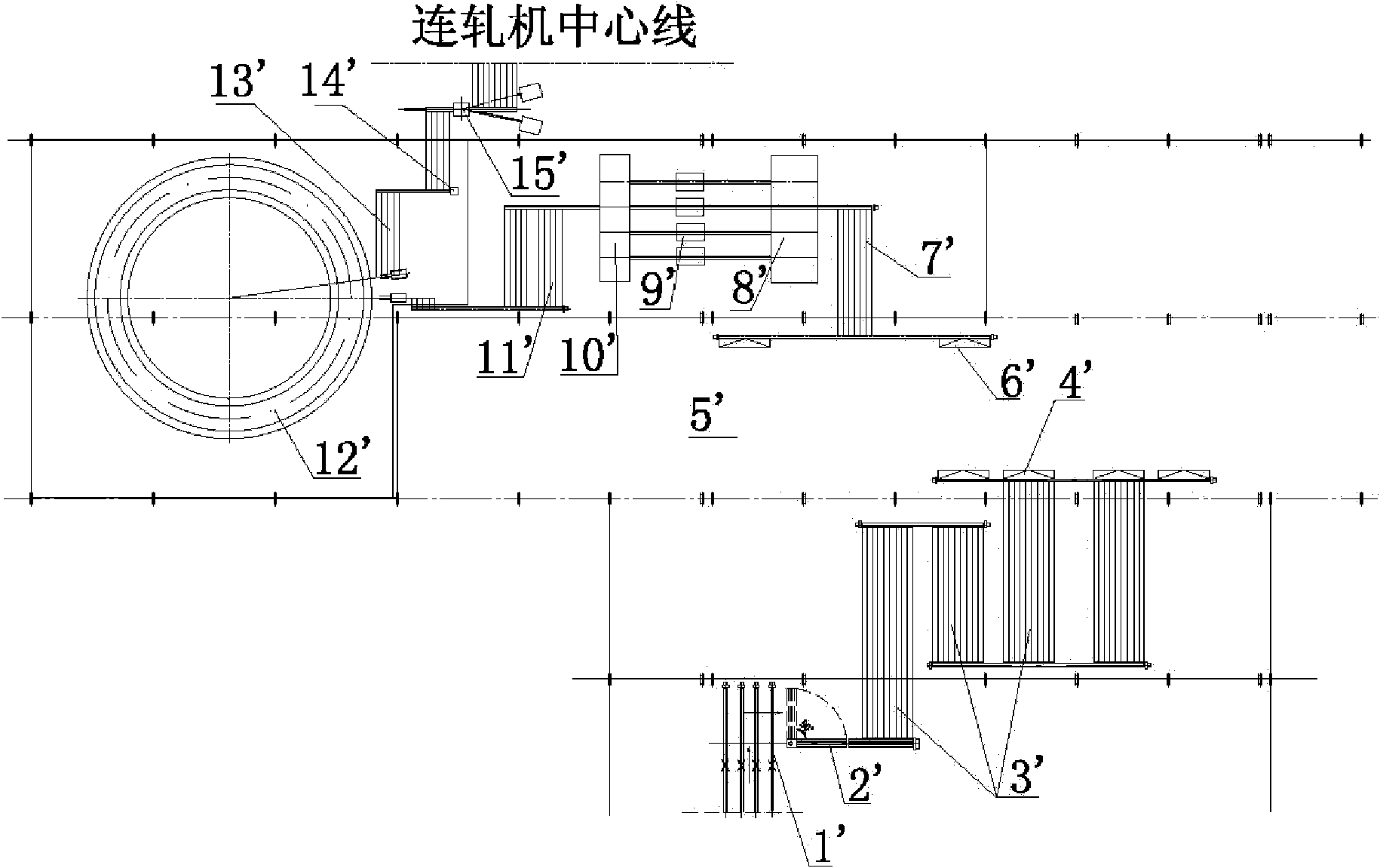

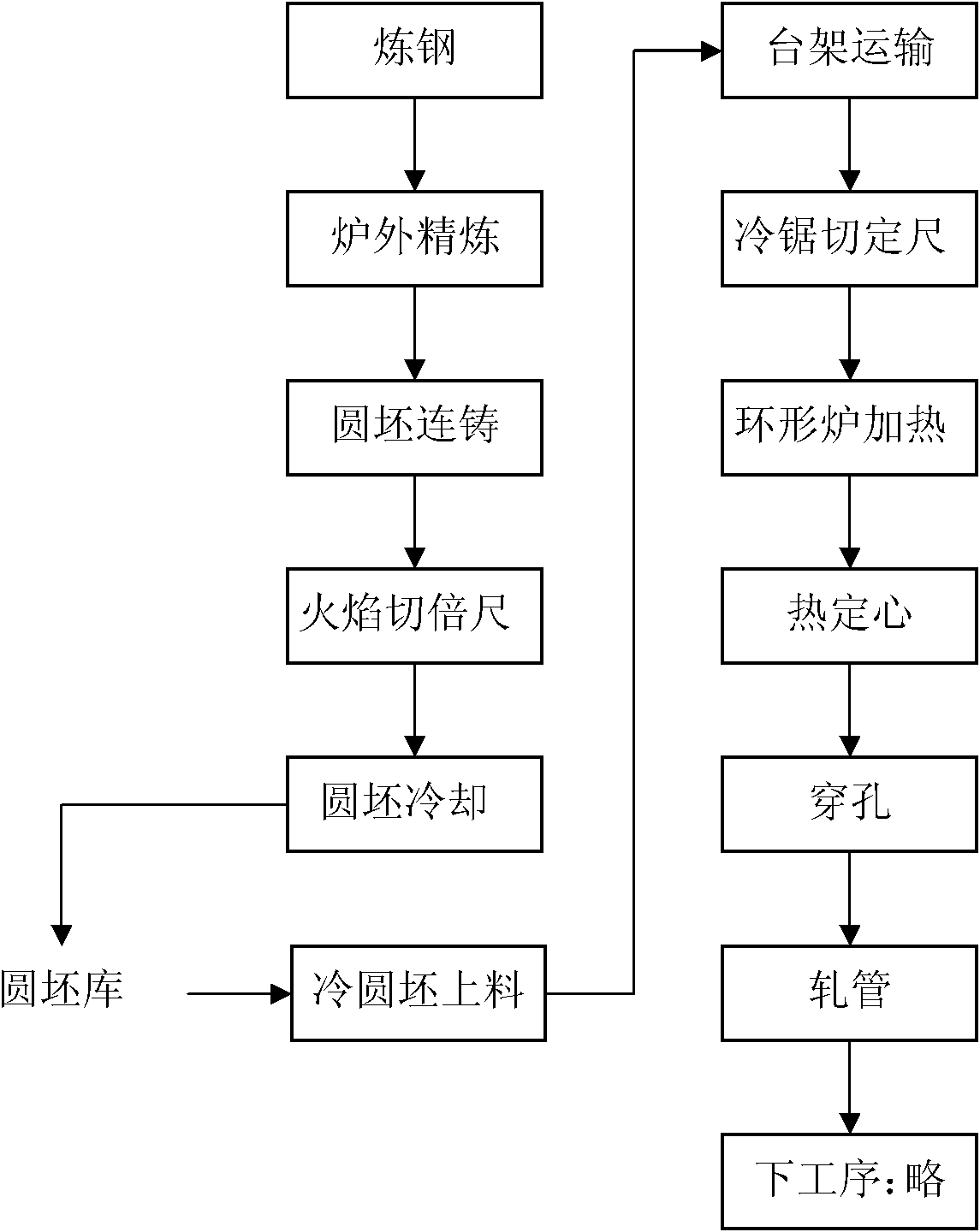

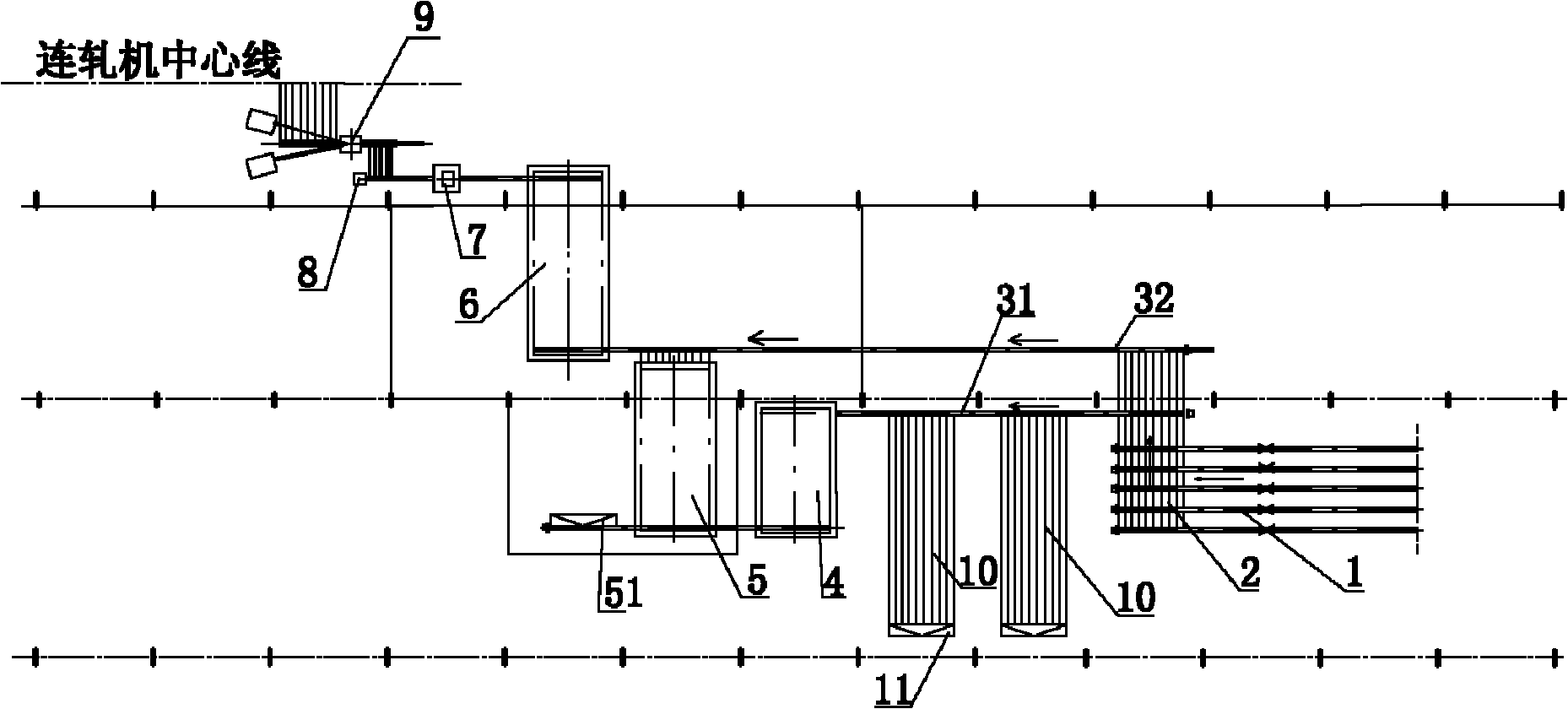

Hot charging method and system for continuous casting round billet of hot rolled steel pipe

ActiveCN101984093ASave fuelLow investment costFurnace typesHeat treatment furnacesProduction lineHeating furnace

The invention discloses a hot charging method and hot charging system for a continuous casting round billet of a hot rolled steel pipe. The method comprises the following steps: casting the refined molten steel into a continuous casting round billet; cutting the continuous casting round billet into multiple length on a continuous casting round billet production line by a flame gun to form a hot continuous casting round billet, wherein the hot continuous casting round billet with a multiple length at least has two flow directions; sending one part of the hot continuous casting round billet into a pre-heating furnace for pre-heating or heat preservation through a first round billet conveying roller way and then into a high-temperature furnace for heating through a second round billet conveying roller way; directly sending the second part of the hot continuous casting round billet into the high-temperature furnace for heating through the second round billet conveying roller way; performing hot sawing on the hot continuous casting round billet sent into the high-temperature furnace for heating into a specified length by hot sawing equipment; and performing hot centering, perforation and tube rolling on the continuous casting round billet which is hot-sawn into the specified length; and performing the next process. The invention can sufficiently use the heat of the hot continuous casting round billet to save a great amount of fuel, while reducing the required equipment and plants, investment on plant construction and cost on equipment maintenance at the same time.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

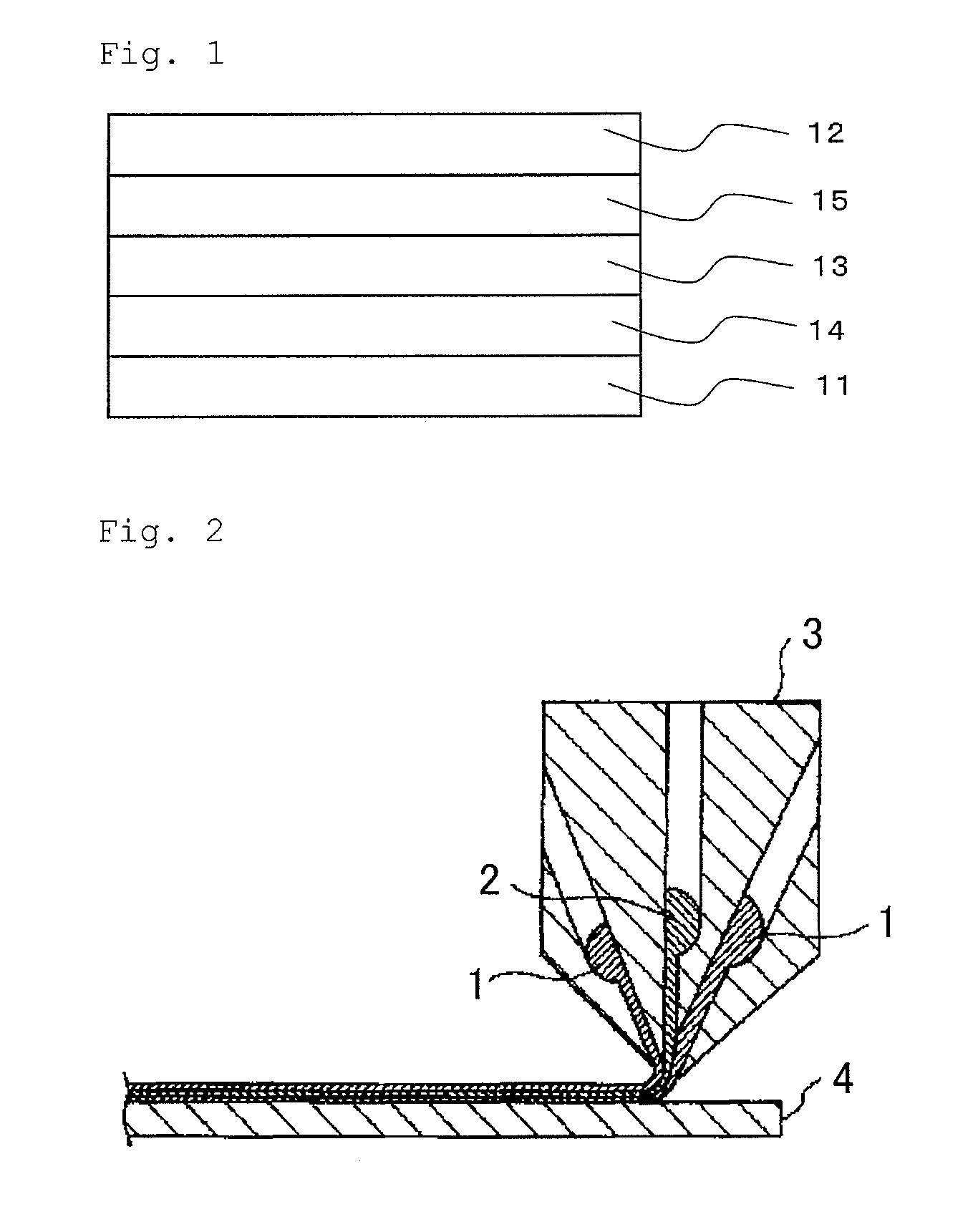

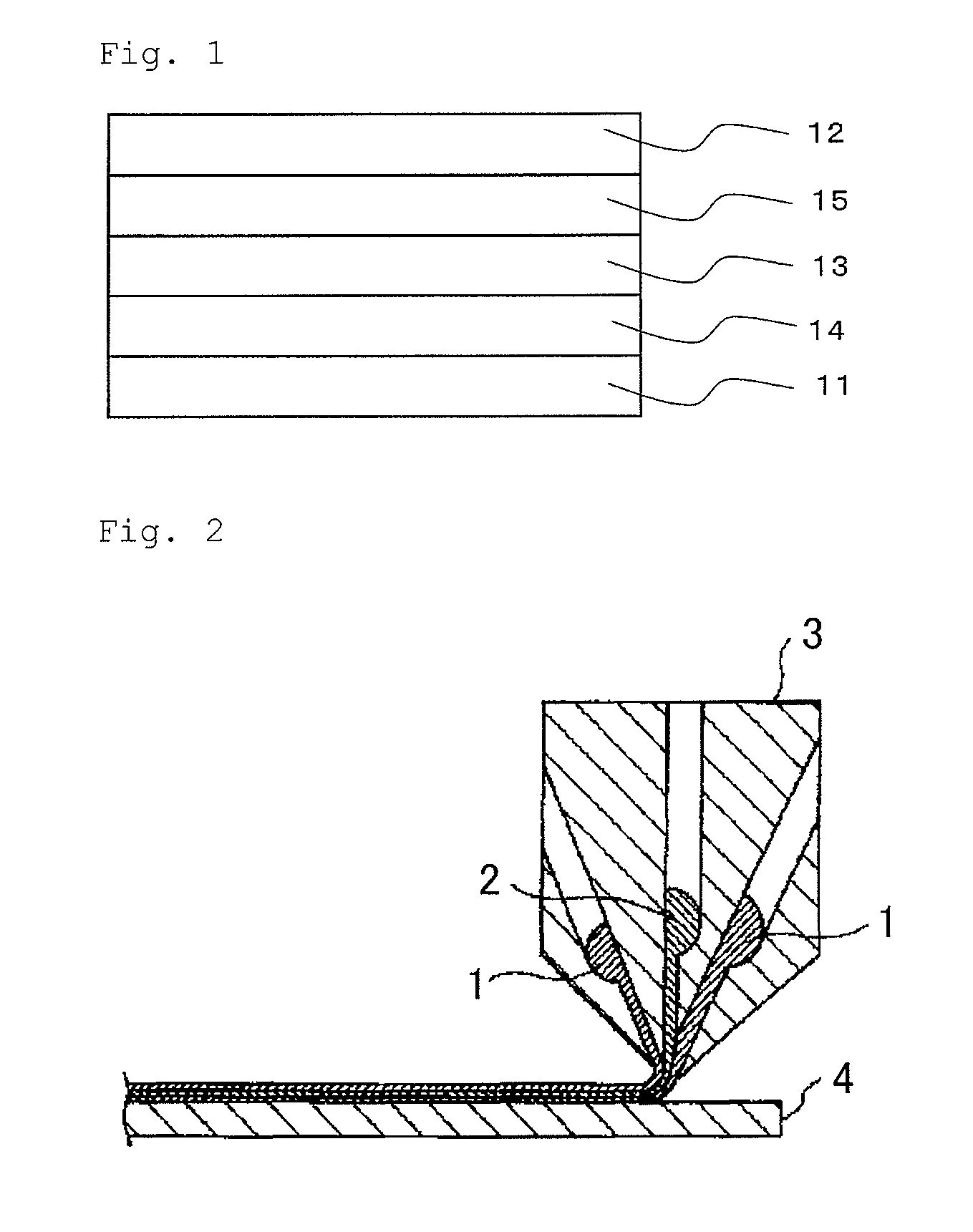

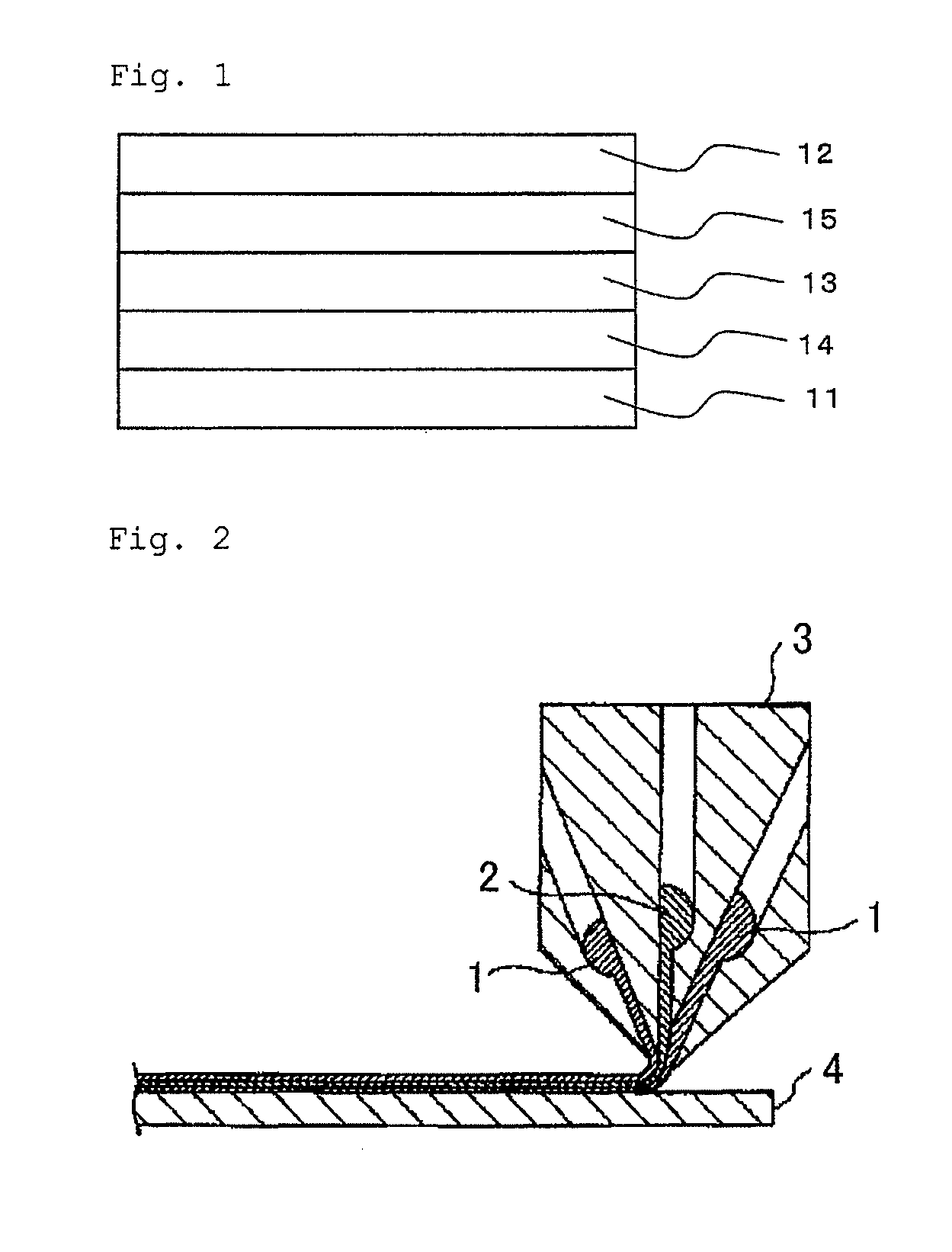

Resin film and method for producing it, polarizer and liquid crystal display device

ActiveUS20110223435A1Increased durabilityHigh product yieldLiquid crystal compositionsSynthetic resin layered productsOrganic acidPolymer science

A resin film including a resin and an organic acid represented by the following formula (1), wherein the ratio of the organic acid to the resin is from 0.1 to 20% by mass:X-L-(R1)n Formula (1)

Owner:FUJIFILM CORP

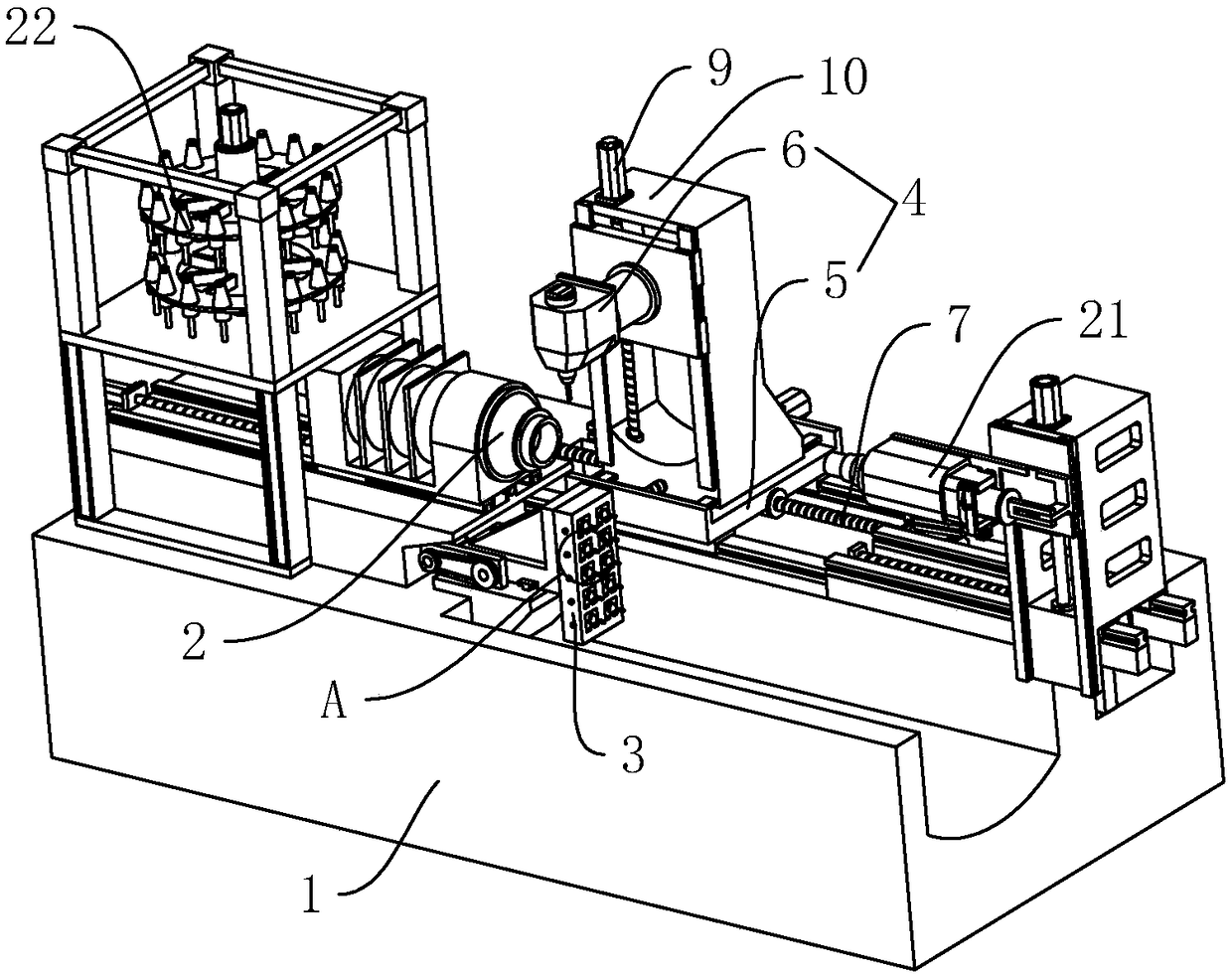

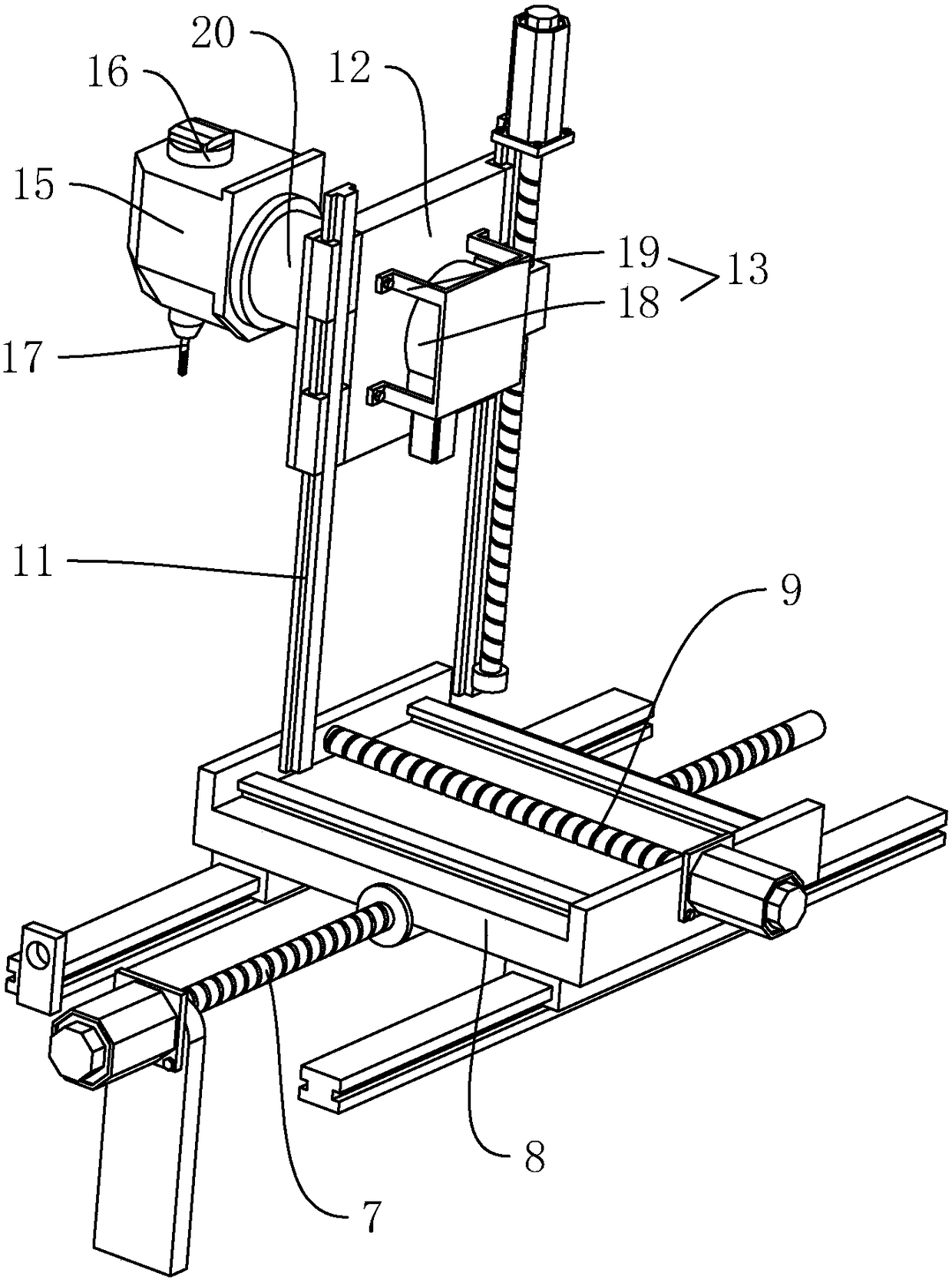

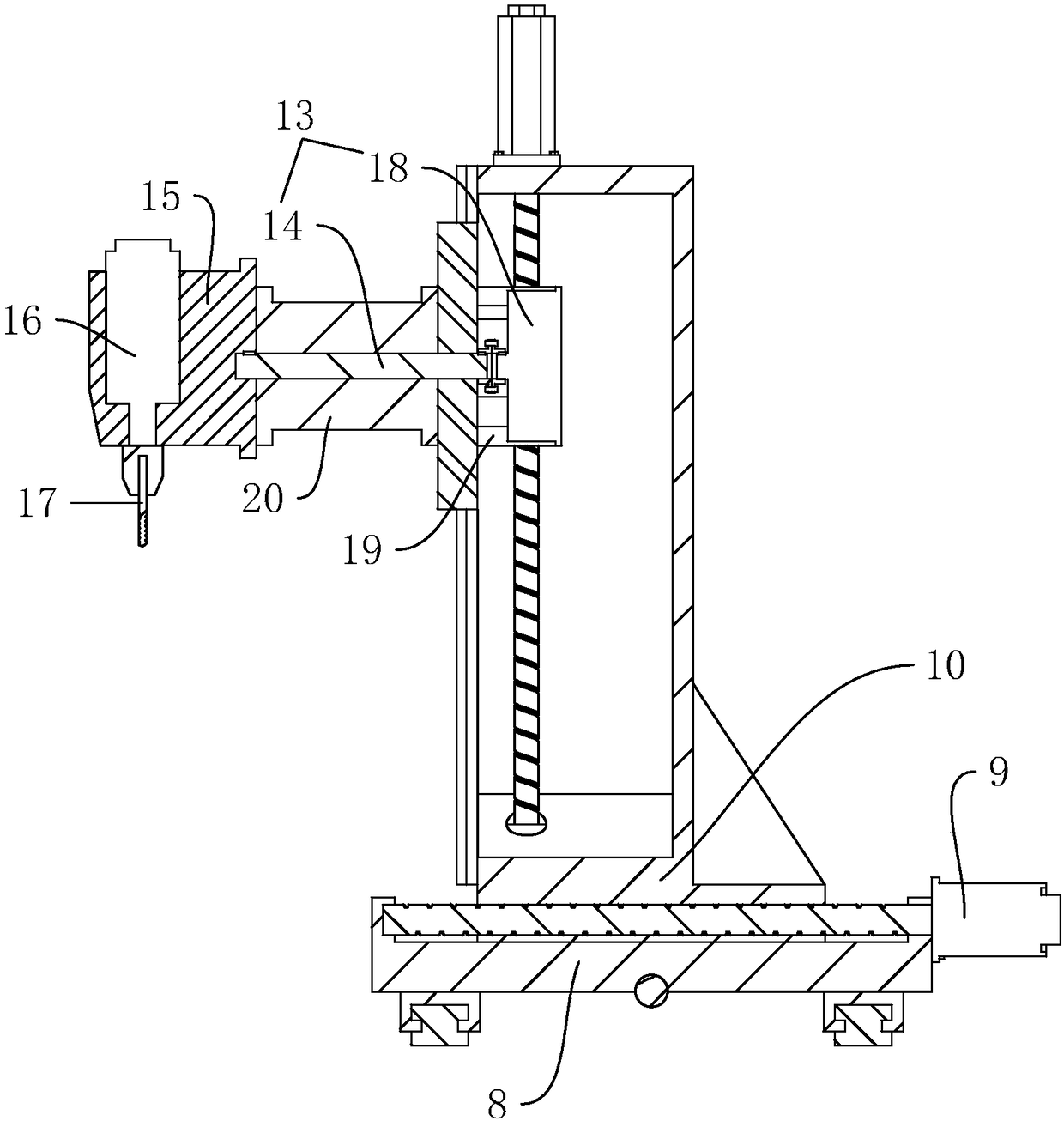

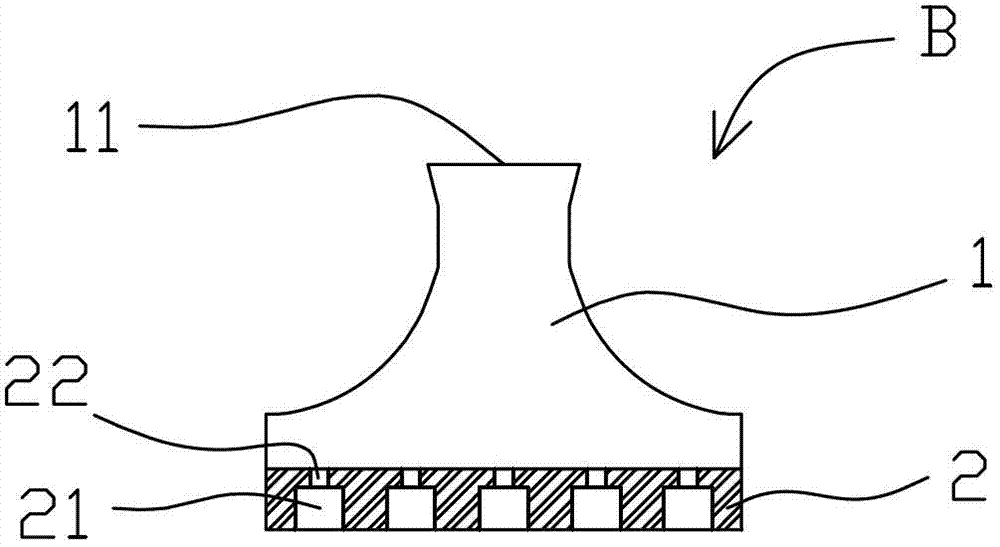

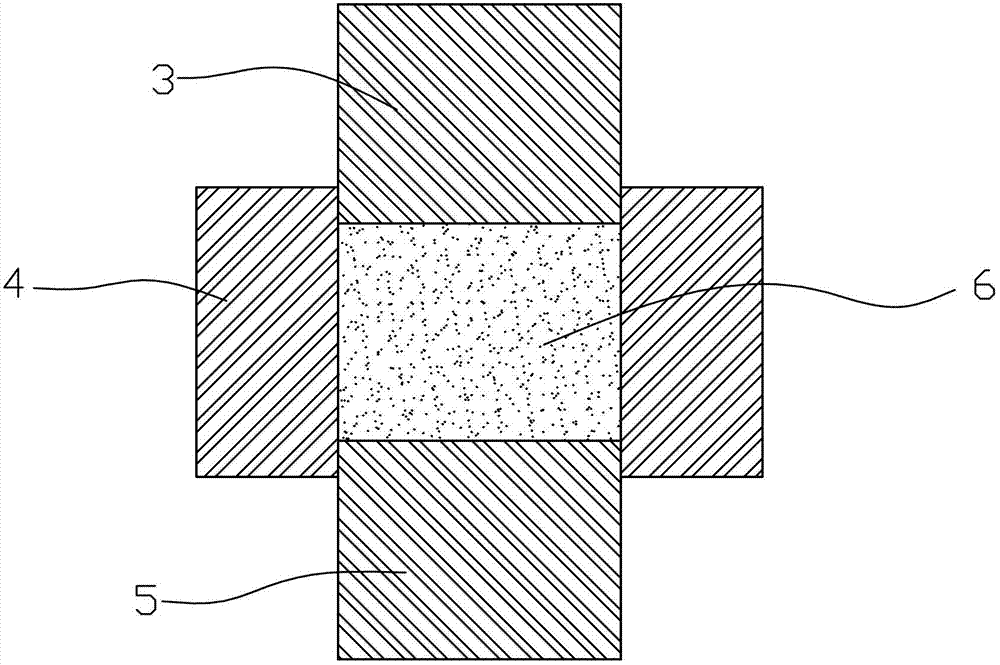

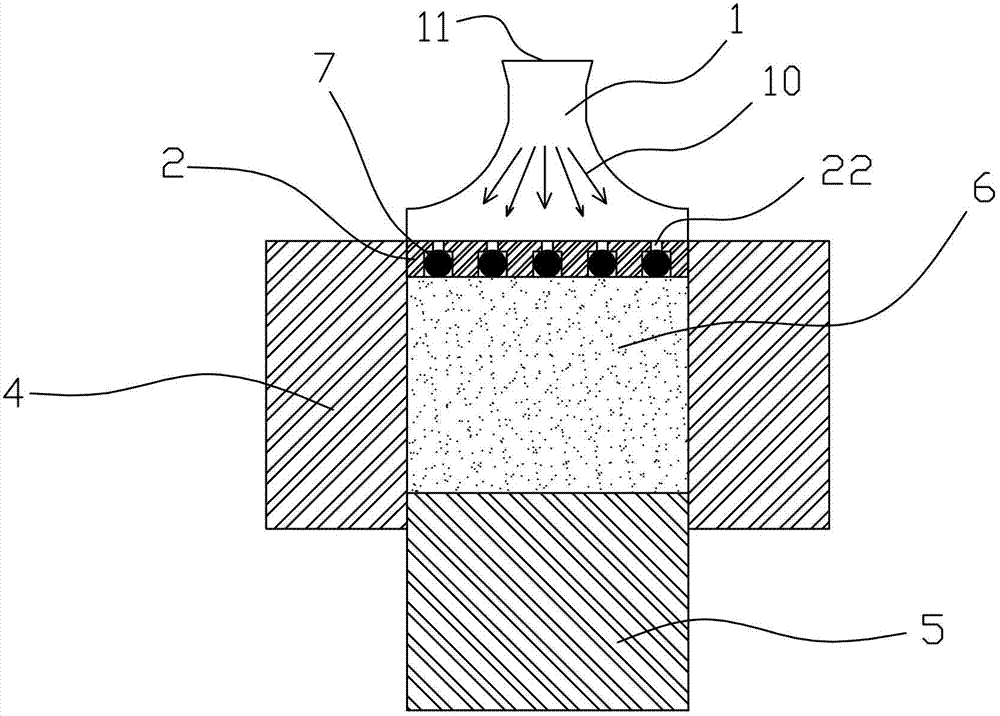

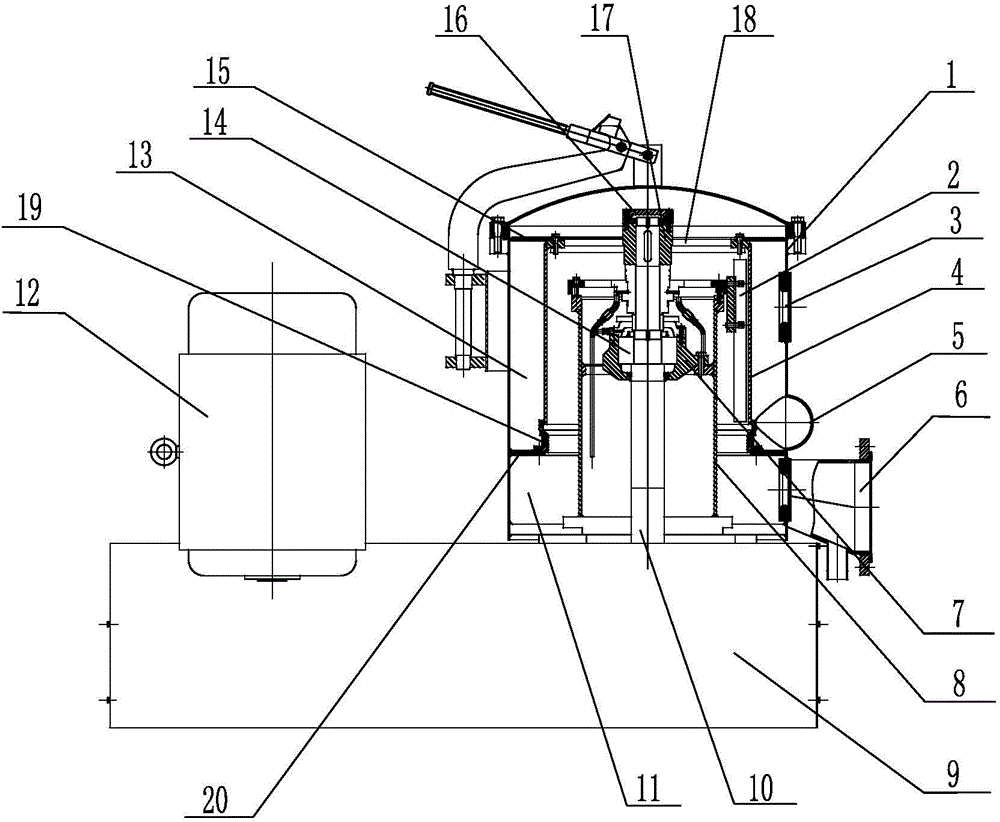

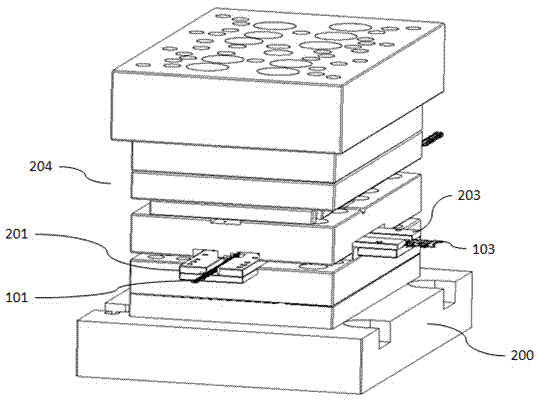

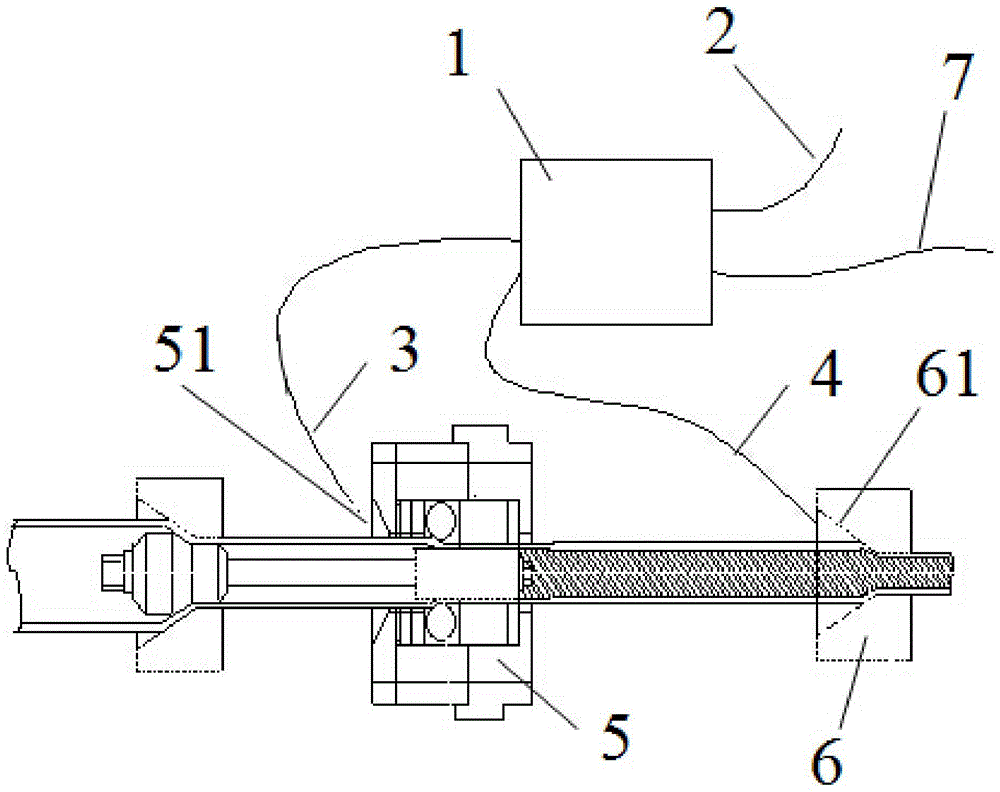

Large-power turning and milling composite machine tool

PendingCN108555602AIncrease productivityReduce production auxiliary timeOther manufacturing equipments/toolsProcessing accuracyMachine tool

The invention discloses a large-power turning and milling composite machine tool, belongs to the technical field of machine tools, and aims to solve a problem in a traditional composite machine tool that a milling device is only used for auxiliary machining. The key point of the technical scheme is that the large-power turning and milling composite machine tool comprises a lathe bed, a main shaftinstalled on the lathe bed, a back face knife table installed at one side of the main shaft, and the milling device installed at the other side of the main shaft. The milling device comprises a driving mechanism and a milling mechanism rotatably installed on the driving mechanism. The large-power turning and milling composite machine tool is capable of, through installing the milling device with aB-axis on the lathe bed, and enabling the milling device to be rotated in multiple degrees, completing the milling and machining of a complicated workpiece by cooperating with the main shaft, effectively shortening a product manufacturing process chain, improving production efficiency, reducing a clamping frequency of the workpiece, and effectively improving machining precision, and further has the advantages of reducing floor area, and reducing production cost.

Owner:津上精密机床(浙江)有限公司

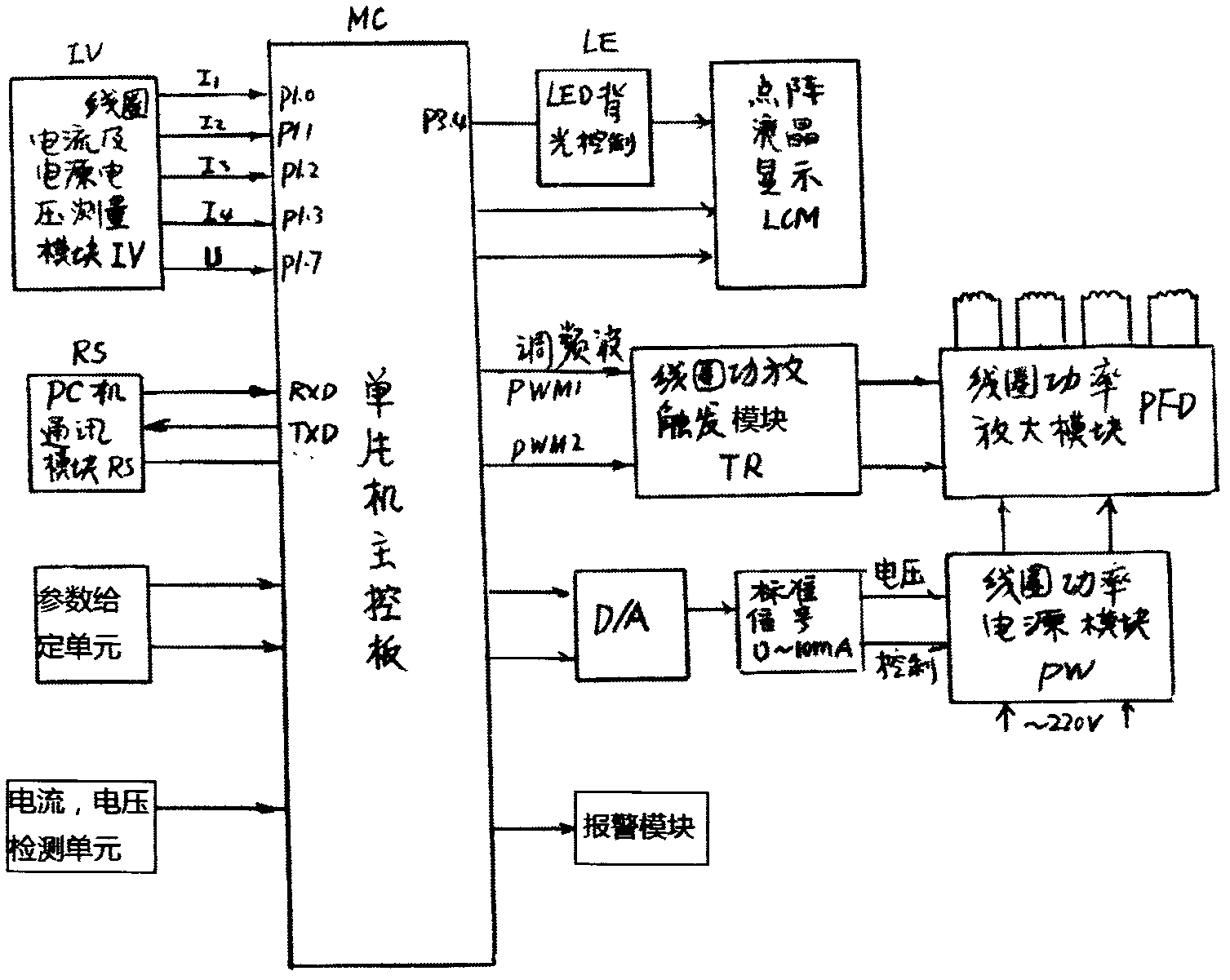

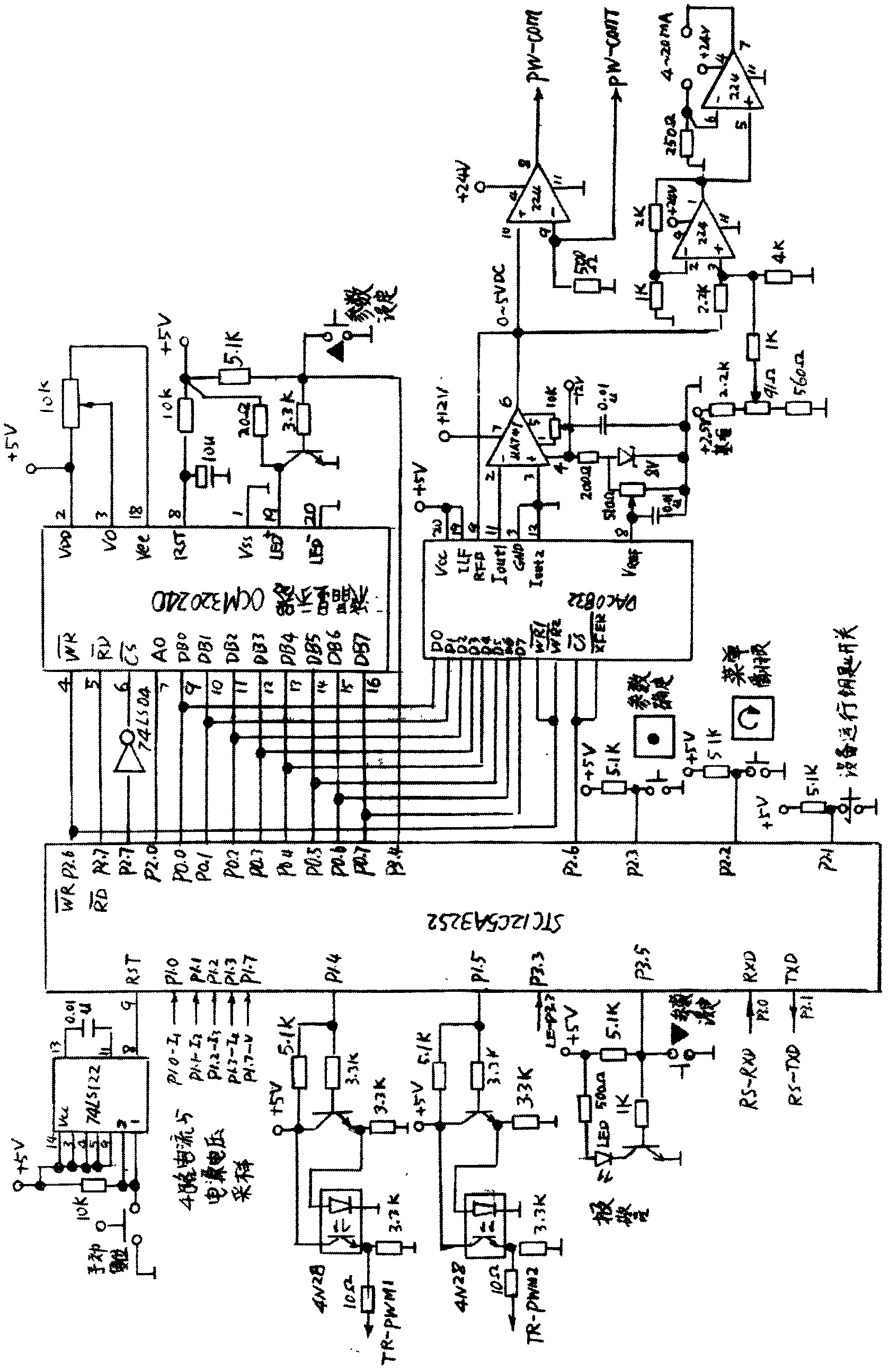

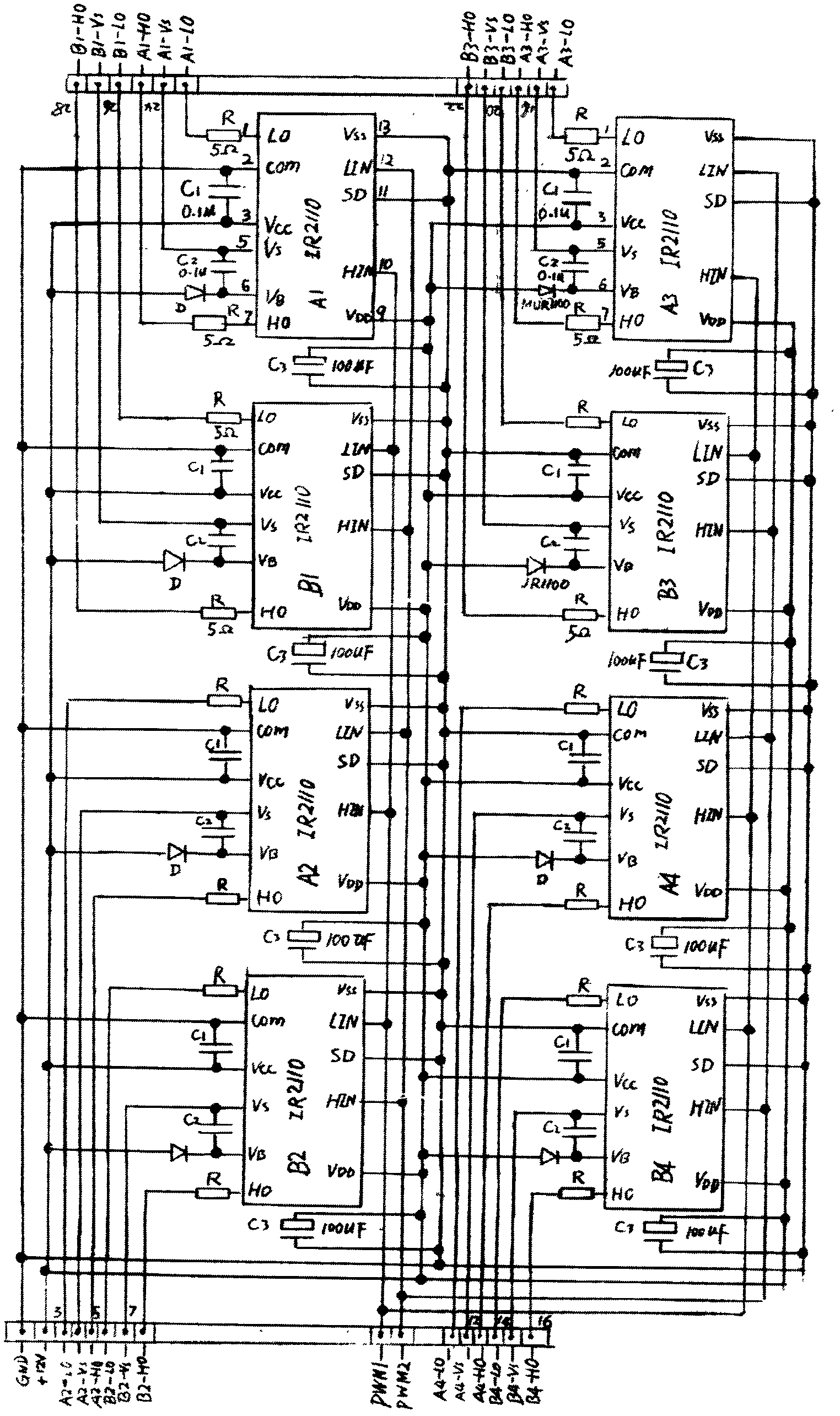

Adjustable-frequency electromagnetic descaling instrument

InactiveCN102627358AAvoid disadvantagesGood descaling effectScale removal and water softeningMicrocontrollerElectricity

The invention discloses an adjustable-frequency electromagnetic descaling instrument, which comprises a singlechip main control board, wherein the singlechip main control board is electrically connected with a coil current and power supply voltage measuring module, an LED (Light-Emitting Diode) backlight control module, a PC (Personal Computer) communication module, an alarm module, a parameter giving unit and a current and voltage detection control unit respectively; the LED backlight control module is further connected with a lattice liquid crystal display; the singlechip main control board is connected with a coil power supply control module through a D / A (Digital to Analog) module; a coil power amplification triggering module is connected with a coil power amplifying module; and the coil power amplifying module is connected with the coil power supply control module. The descaling instrument is suitable for descaling and preventing scale under various field running environments and water quality conditions, is arranged in a field wound form, does not damage field pipelines, has the maximum output power of up to 9KW and maximum adaptation pipe diameter of 3 meters, is suitable for the maximum total water hardness of 4,000 mg / L, is suitable for being applied in medium and large-sized industrial enterprises, and is efficient and environmentally-friendly.

Owner:LIGHT INDAL XIAN MECHANIC DESIGN RES INST

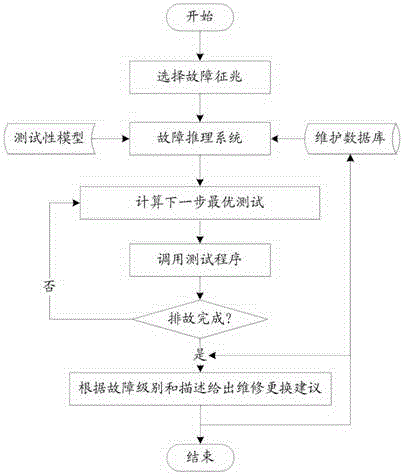

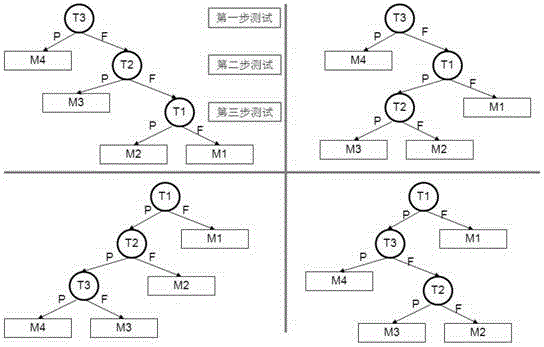

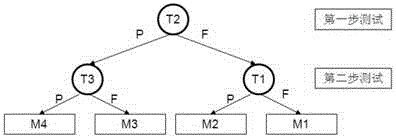

Fault diagnosis method based on electronic equipment testability model

ActiveCN106650942AImprove diagnostic efficiencyReduce diagnostic stepsInference methodsDiagnosis methodsTroubleshooting

The invention relates to a fault diagnosis method based on an electronic equipment testability model, which is applicable to field fault diagnosis of all electronic equipment and belongs to the technical field of measurement and control. The main technical points of the method are as follows: the corresponding relationship of equipment fault mode, signal and test is established based on an electronic equipment testability model; a computer analyses out the test logic contained in the testability model according to the corresponding relationship; automatic reasoning is carried out and corresponding test is performed on a diagnosis node according to the fault phenomenon; and before next test diagnosis, the test process is optimized according to the current test result to realize dynamic fault diagnosis logic. The technical effect is that problems such as difficult and high-cost manual troubleshooting and poor flexibility, versatility and expansibility of binary tree-based troubleshooting are overcome fundamentally, and automatic and intelligent field fault diagnosis of electronic equipment can be realized.

Owner:CSSC SYST ENG RES INST +1

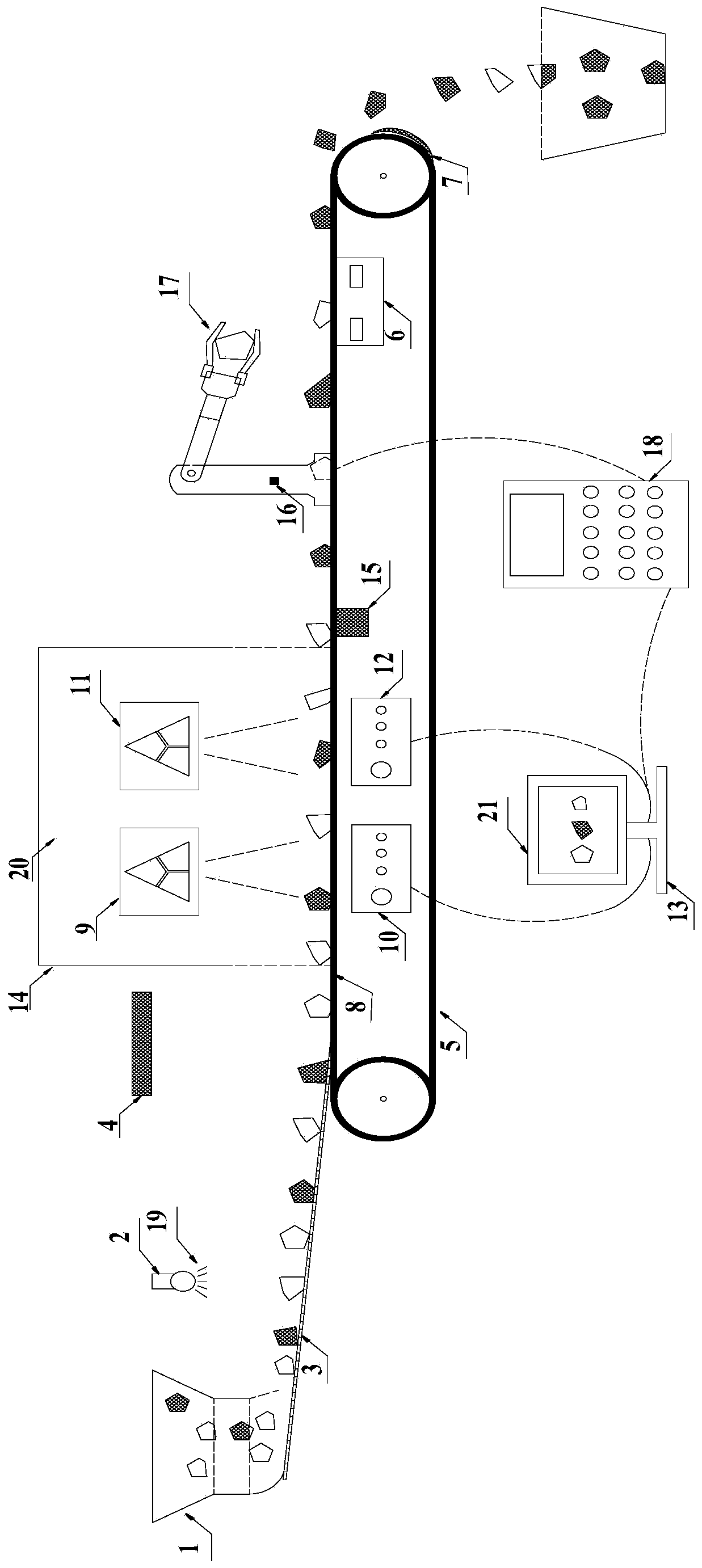

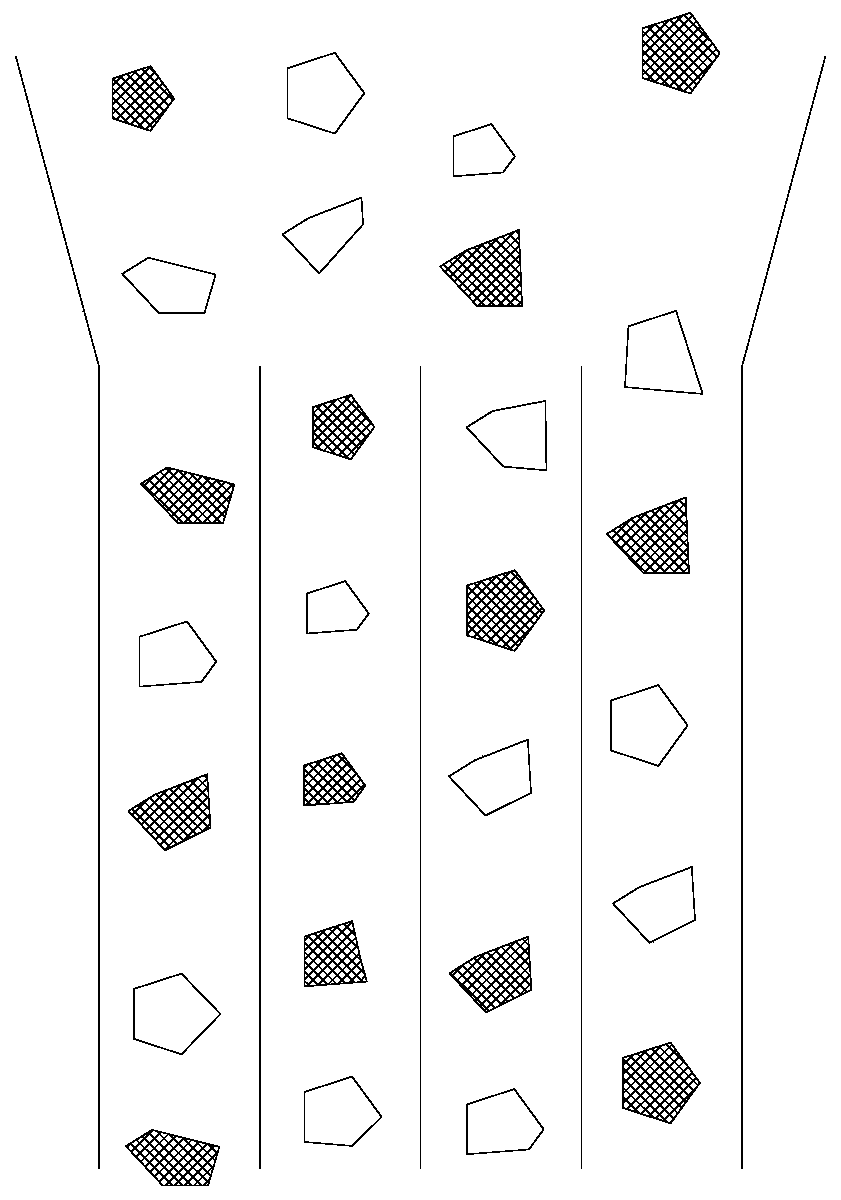

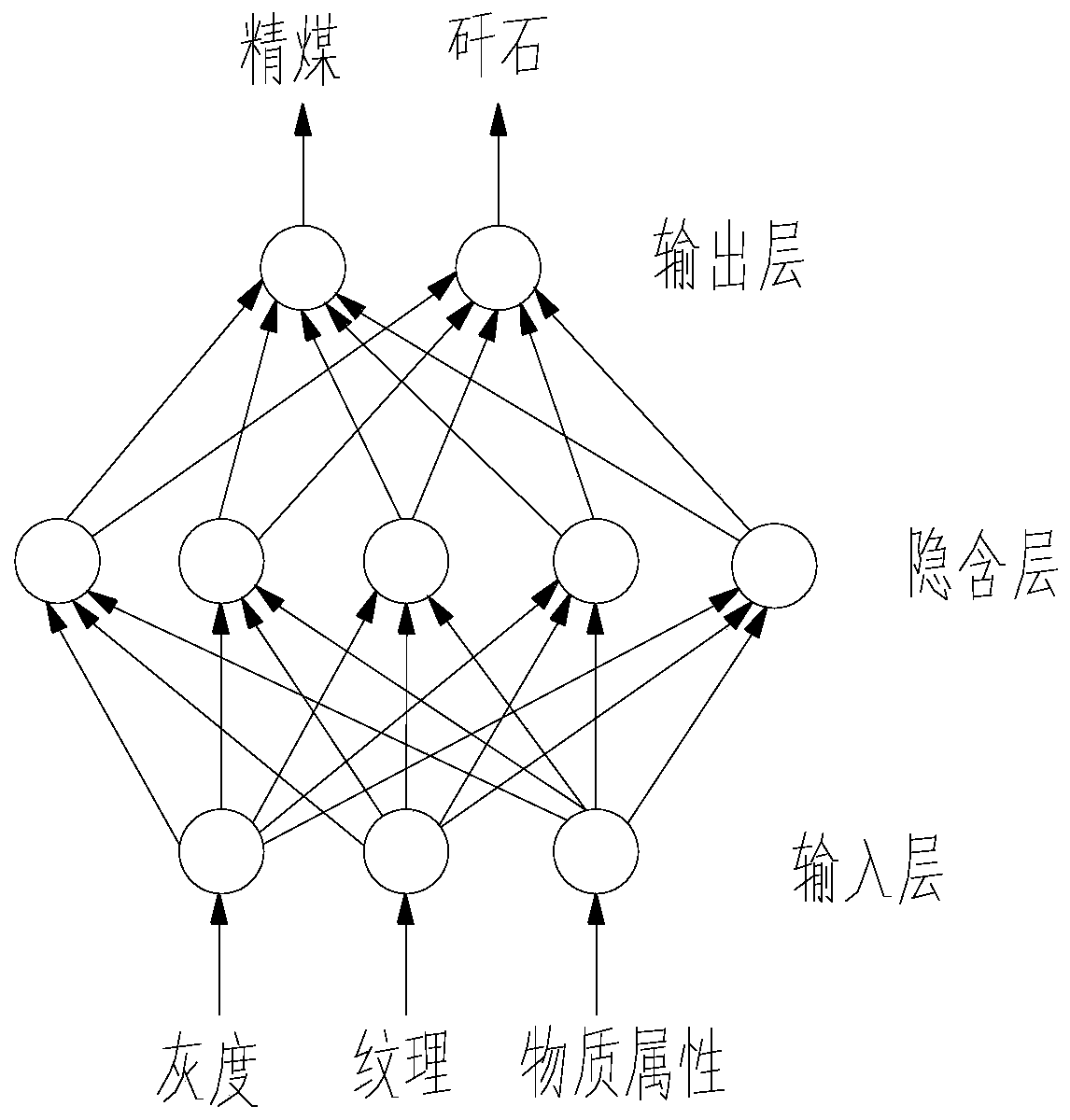

Intelligent dry waste discharge system based on true dual energy X-rays

InactiveCN110773454AStrong adaptabilityReduce manpower inputMagnetic separationSortingProcess engineeringManipulator

The invention relates to the field of coal preparation and waste discharge, in particular to an intelligent dry waste discharge system based on true dual energy X-rays. The intelligent dry waste discharge system includes a feeding mechanism, a conveying mechanism, a recognition mechanism and a sorting mechanism. The feeding mechanism is composed of a feeding funnel and a spray desliming device, the outer part of the feeding funnel is in an inverted cone shape, and the inner part of the feeding funnel is laid with wear-resistant porcelain plates which can reduce the abrasion of funnel wall surfaces; the spray desliming device is composed of spray pipes and a high-frequency sifter; the conveying mechanism is composed of an electronic belt scale which can monitor the feeding quantity in realtime, an electromagnetic iron remover which can reduce the contamination of sundries, a belt cleaner which can clean fine materials, and a lining-up device capable of forming a plurality of regular coal flows; the recognition mechanism is composed of an X-ray generator generating the X-rays with different intensity, a detector receiving the X-rays, an imaging upper computer, a BP neural network, and a lead isolation room; and the sorting mechanism is composed of a positioning device, a manipulator, and a PLC control cabinet. According to the intelligent dry waste discharge system based on thetrue dual energy X-rays, adaptability to coal is strong, intelligent recognition is realized, therecognition accuracy is high, and at the same time, coal-dust pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

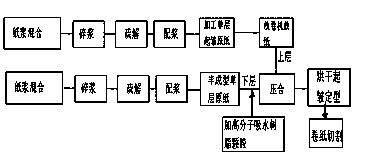

Preparation method for composite processed absorbent paper by using cylinder mould machine

InactiveCN108867149AReduce dosageReduce manufacturing costDryer sectionRaw material divisionFluff pulpSlurry

The invention provides a preparation method for composite processed absorbent paper by using a cylinder mould machine. The method comprises the following steps that 1, wood pulp and fluff pulp are mixed according to a certain proportion; 2, fiber defiberizing is carried out after the mixed pulp liquid is repulped; 3, blending is carried out on the defiberized pulp liquid in a blending pool; 4, thefully mixed blended pulp is sent into the cylinder mould machine to produce single-layer wrinkling base paper; 5, pressing fitting is carried out on the single-layer wrinkling base paper produced instep 4 and single-layer semi-synthetic base paper, wherein the single-layer semi-synthetic base paper is continuously produced, runs synchronously in the same direction with the single-layer wrinklingbase paper, and is loaded with uniformly spread macromolecular water-absorbent resin particles; 6, the pressed and fitted double-layer base paper enters a drying cylinder to be dried, wrinkled and shaped; 7, the shaped product is cut into various sizes according to demands of customers. The prepared absorbent paper is ultrathin, soft, air-permeable and dry and has stable quality.

Owner:卢秀霞

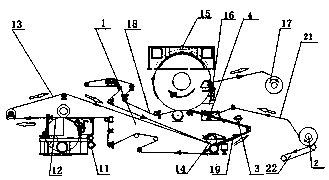

Light-coated kraft production equipment and method

ActiveCN102182098AMeeting the demands of high printing performanceImprove stiffnessSpecial paperPaper/cardboardCardboardSurface layer

The invention discloses light-coated kraft production equipment and a method. The production equipment comprises a triple net forming device, a squeezing device, a front drying device, a film transfer sizing machine, a rear drying device, a hard calendering device, a first scraper coating machine, a first scraper rear drying device, a second scraper coating machine, a second scraper rear drying device, a soft calendering device, a cooling device and a coiling forming device which are sequentially mounted on a rack. In the production of light-coated kraft by adopting the equipment, after the two sides of the original paperboard are sized by the film transfer sizing machine, the ink absorption uniformity of the kraft is improved; and through twice scraper coating, a good coating effect can be obtained at low coating quantity, and the requirement on high printing performance of the kraft can be met; and moreover, the bottom layer, lining layer and surface layer adopt different raw materials as well as proper proportions of raw materials respectively, and the produced light-coated kraft has low ration and high strength.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

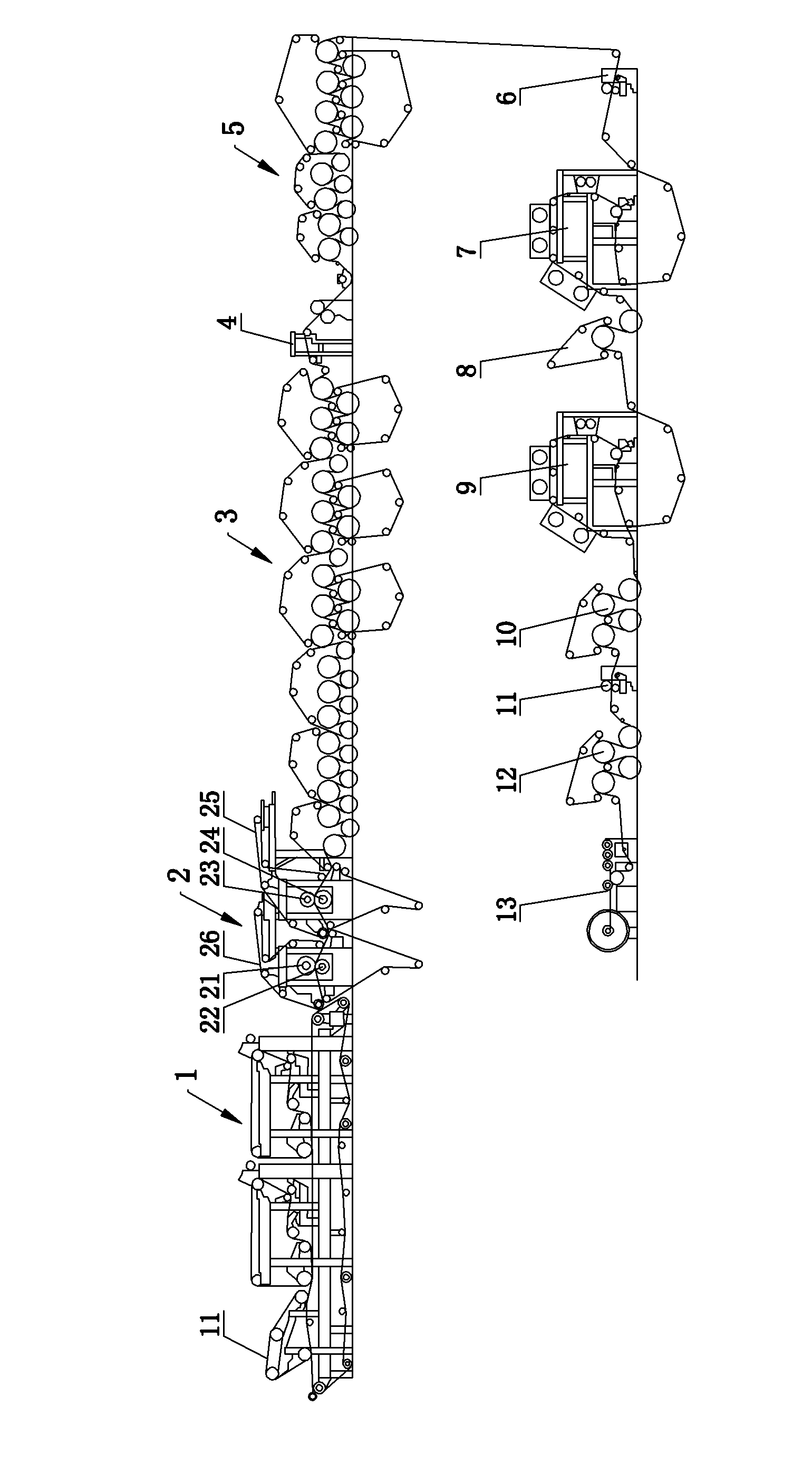

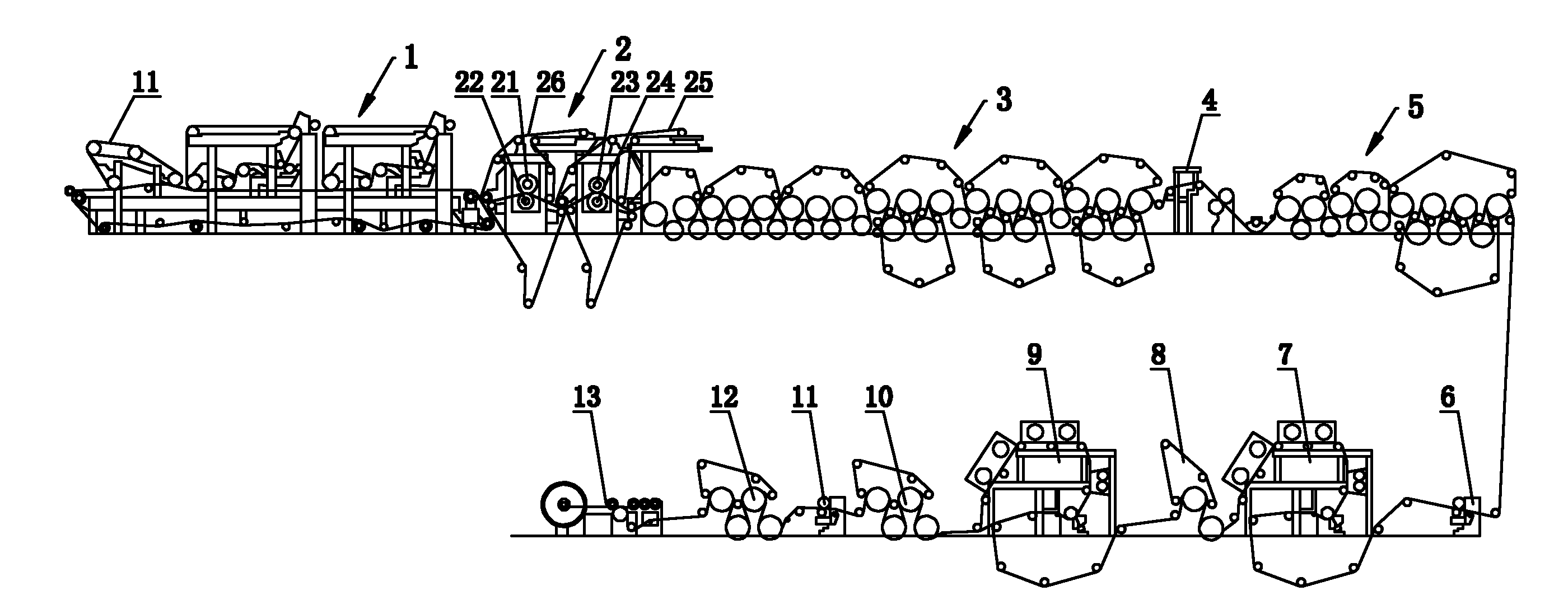

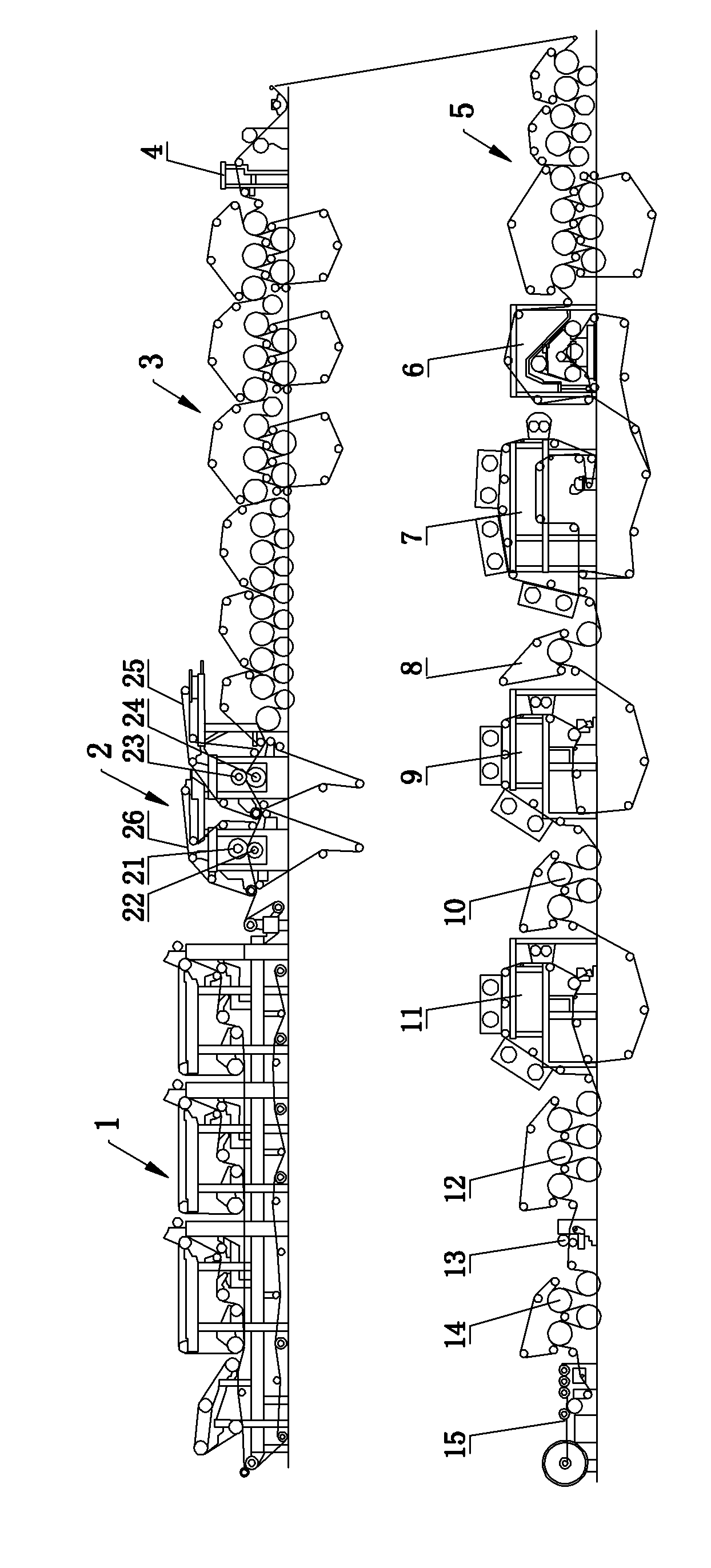

Four-stacked net forming equipment and method for producing coating kraft liner board

InactiveCN102182105AImprove uniformityIncrease coverageSpecial paperPaper coatingSurface layerEngineering

The invention discloses four-stacked net forming equipment and method for producing a coating kraft liner board. The equipment comprises a four-stacked net forming device, a pressing device, a pre-drying device, a surface sizing machine, a post-drying device, a belt calender, a curtain coater, a curtain coating post-drying device, a first blade coater, a first blade coating post-drying device, a second blade coater, a second blade coating post-drying device, a soft calendering device, a cooling device and a coiling forming device which are sequentially arranged on a machine frame. In the invention, When the coating kraft liner board is produced, the sizing is carried out on the surface layer to ensure that the uniformity of absorbing printing ink of the kraft liner board is improved; and during the coating, the respective superiorities of the curtain coating and the blade coating are combined and different raw materials with proper proportions are respectively adopted at the bottom layer, the core layer, the lining and the surface layer to ensure that the produced coating kraft liner board has the advantages of low basis weight, high strength, good bulk and high surface smoothness and can satisfy the requirements for the coating kraft liner board in different printing modes and different fields.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP

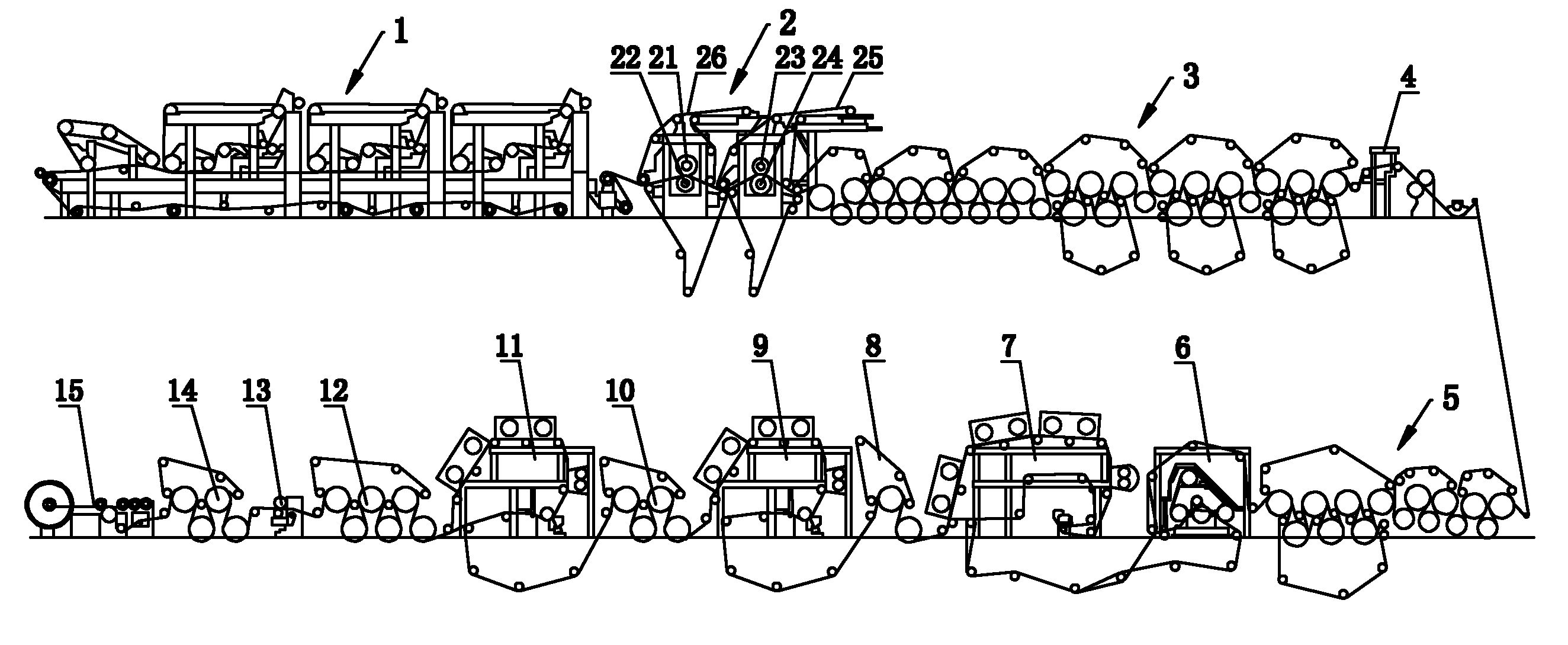

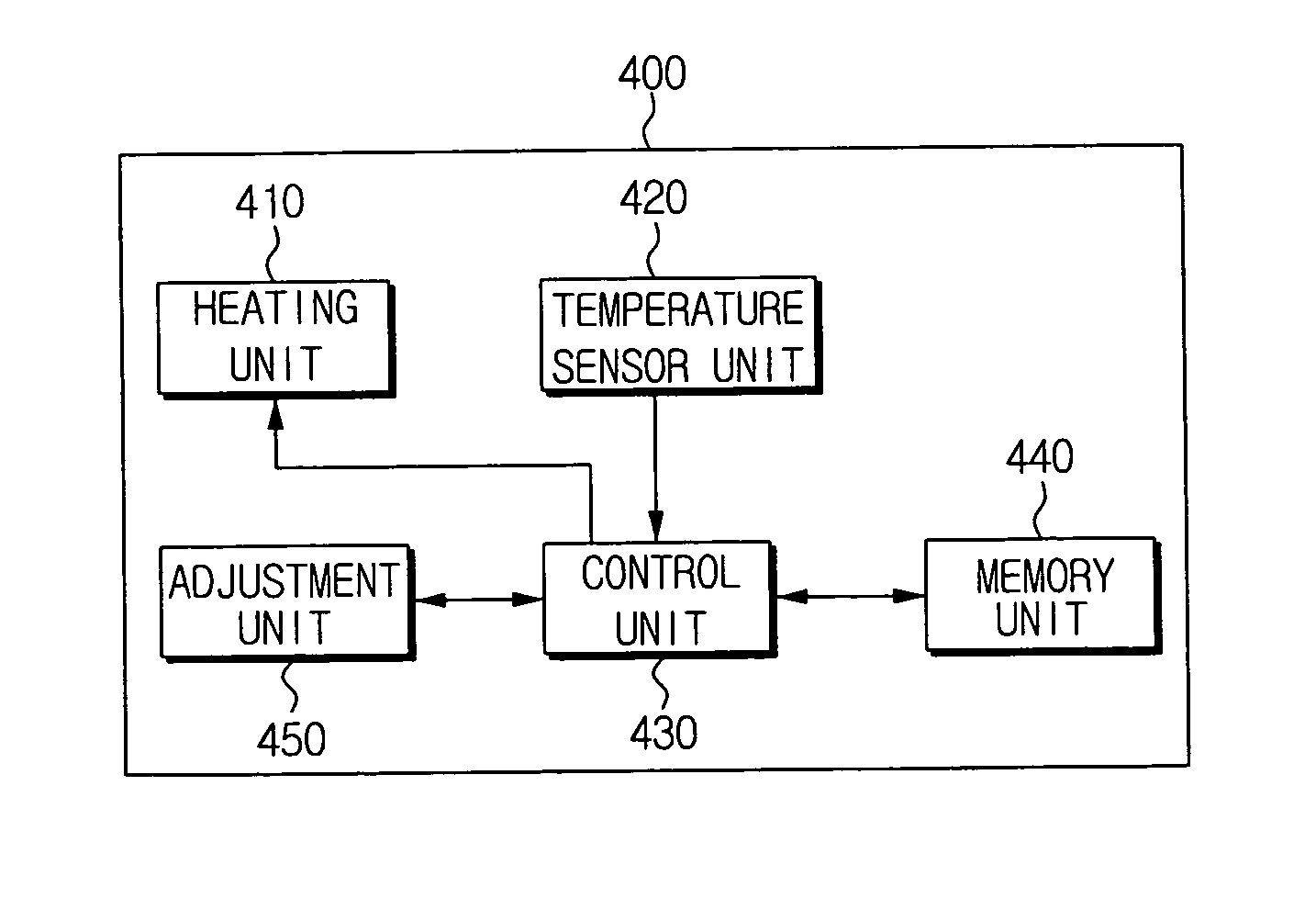

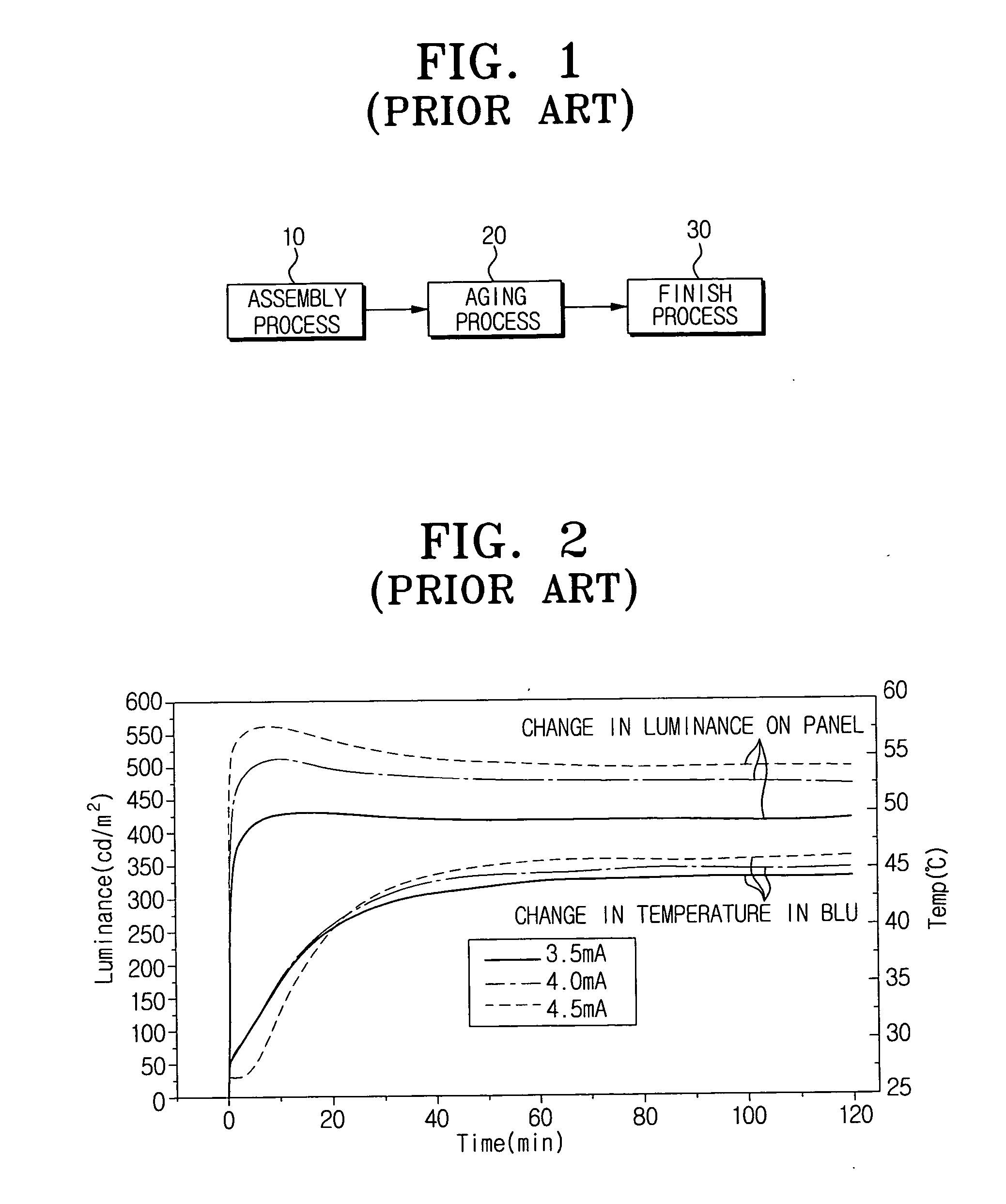

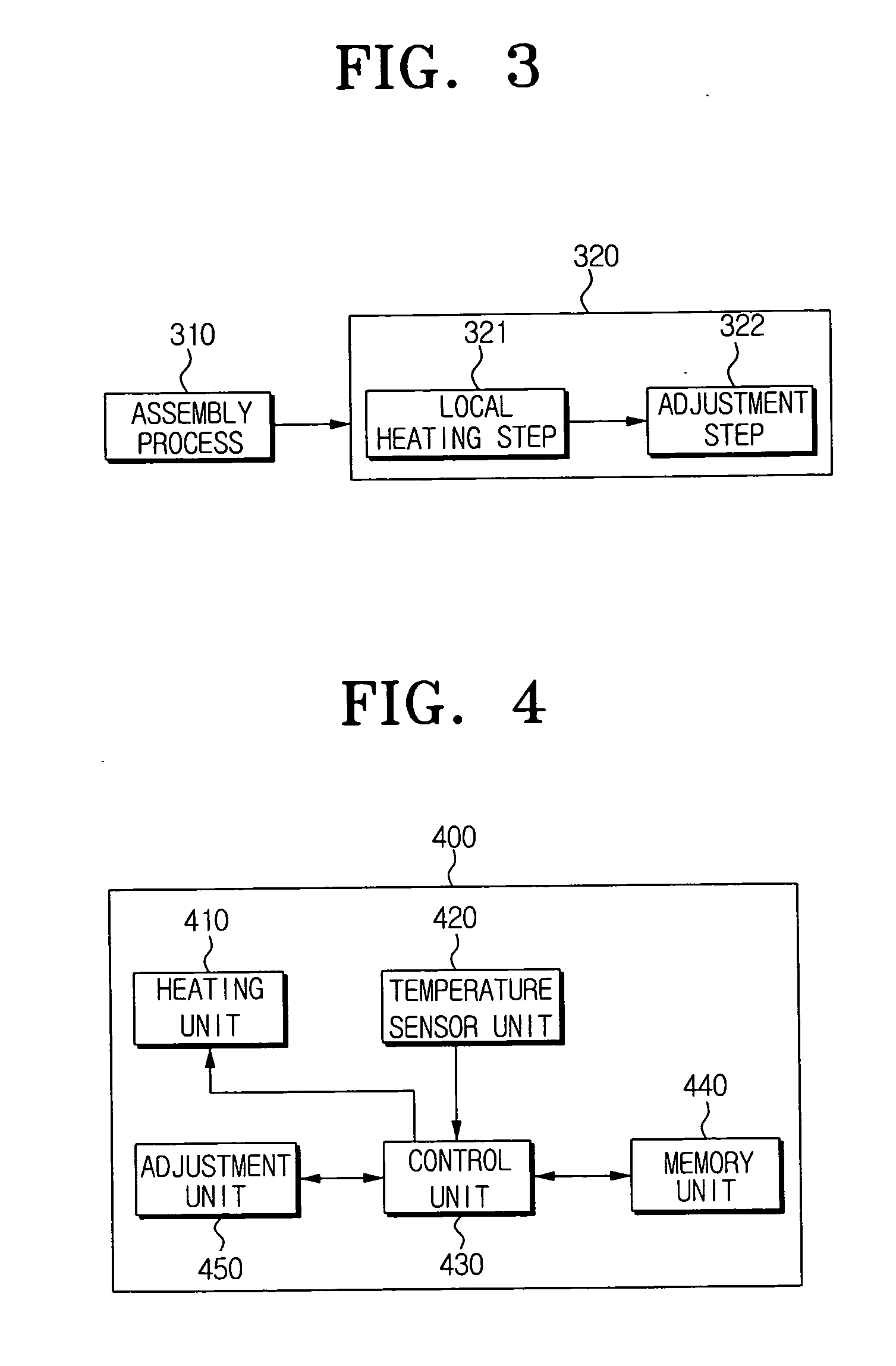

Method of manufacturing liquid crystal display (LCD) without aging process and white balance adjustment apparatus

InactiveUS20070001996A1Reduce equipment maintenance costsLow investment costStatic indicating devicesNon-linear opticsLiquid-crystal displayLiquid crystal

A method of manufacturing a liquid crystal display (LCD) without an aging process. The method of manufacturing the LCD includes: assembling an LCD panel; heating a local area of the assembled LCD panel up to a predetermined target temperature; and adjusting a white balance by setting color coordinate and luminance when the predetermined target temperature is reached. Accordingly, an equipment investment cost and an equipment maintenance cost for the aging process can decrease, and a consumed power can decrease.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for recovering glucosamine hydrochloride from hydrolytic mother liquid of glucosamine hydrochloride

ActiveCN102391322AReduce energy consumptionShort operating timeSugar derivativesSugar derivatives preparationLow temperature depositionRecovery method

The invention relates to a method for recovering a glucosamine hydrochloride from a hydrolytic mother liquid of the glucosamine hydrochloride. According to the method, chitin is added to concentrated hydrochloric acid with the concentration of 30-31% according to a weight ratio of 1:2.5 and is hydrolyzed for 3.5-4.5h at 90-95DEG C, the obtained liquid is cooled, the deposition is crystallized, the mother liquid generated by centrifuge dewatering is added with a special crystal induction agent at 40-50DEG C, is stirred for 25-35min by an anchor stirrer, is cooled to below 10DEG C by refrigerated water, and stands for not less than 4h at the temperature, the supernatant is sucked out by a vacuum tube, and the deposition is centrifuged to dryness to obtain crude crystals. The method allows the energy consumption to be low, the operation time to be short, and the recovery rate to reach 80-85%. Compared with present traditional high-temperature (85-90DEG C) long-time (10h) vacuum concentration recovery methods, the method of the invention allows the recovery rate of the glucosamine hydrochloride to be increased by about 20%, the crude crystal quality to be obviously better because of the low temperature deposition mode, the comprehensive energy consumption to be reduced, the production period to be shortened, the labor cost and the equipment maintenance cost to be reduced, and the production cost to be lower.

Owner:石狮市华宝海洋生物化工有限公司

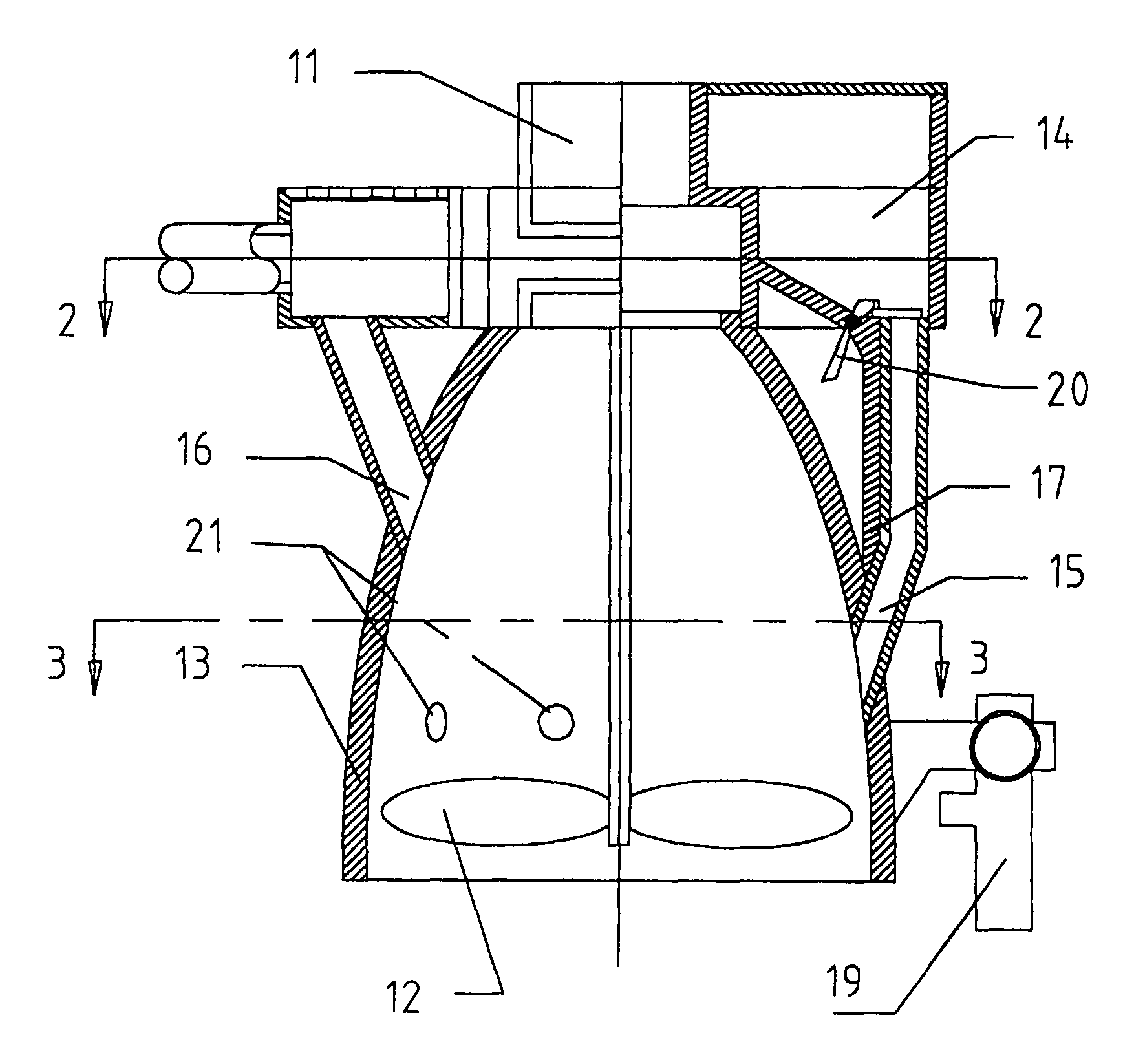

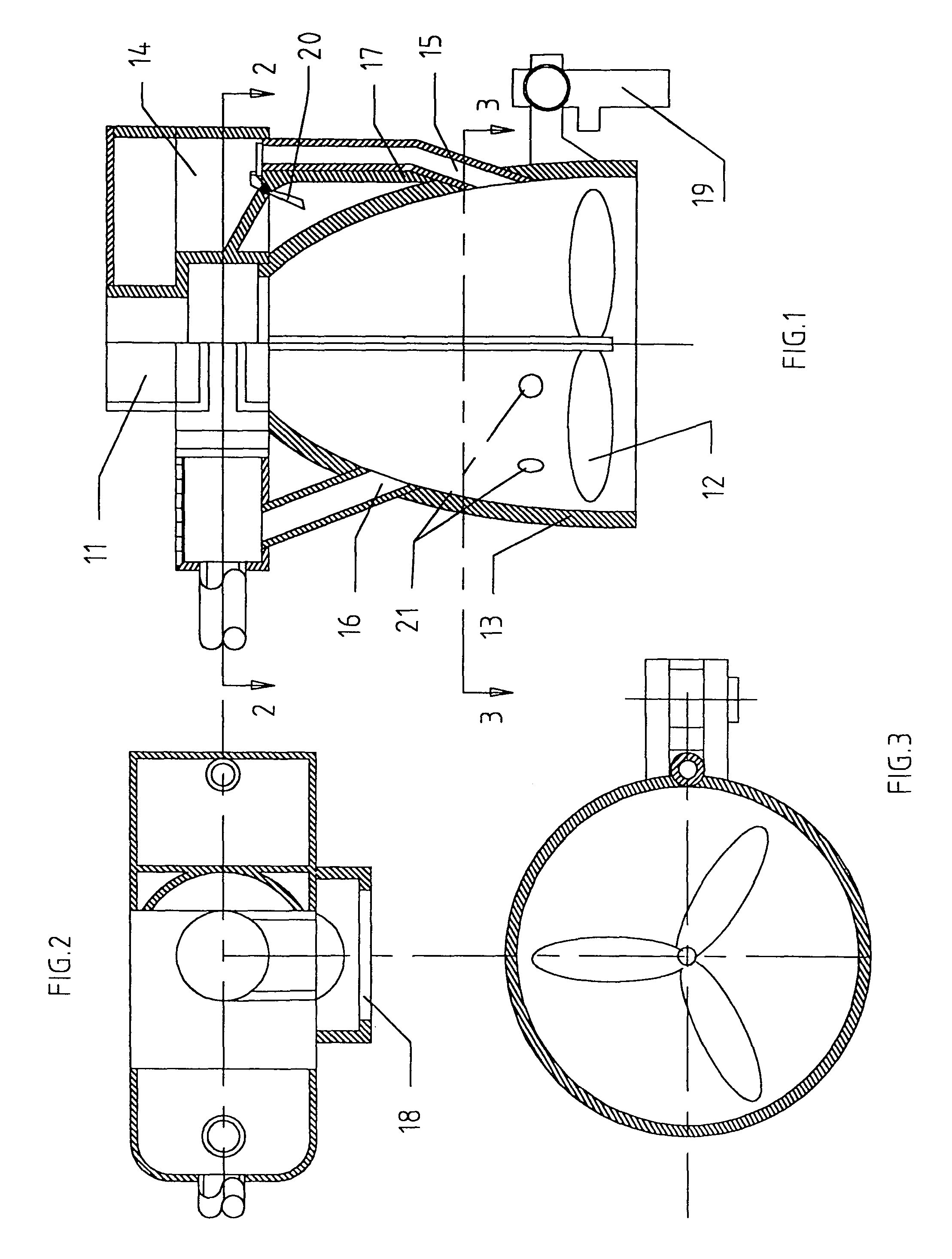

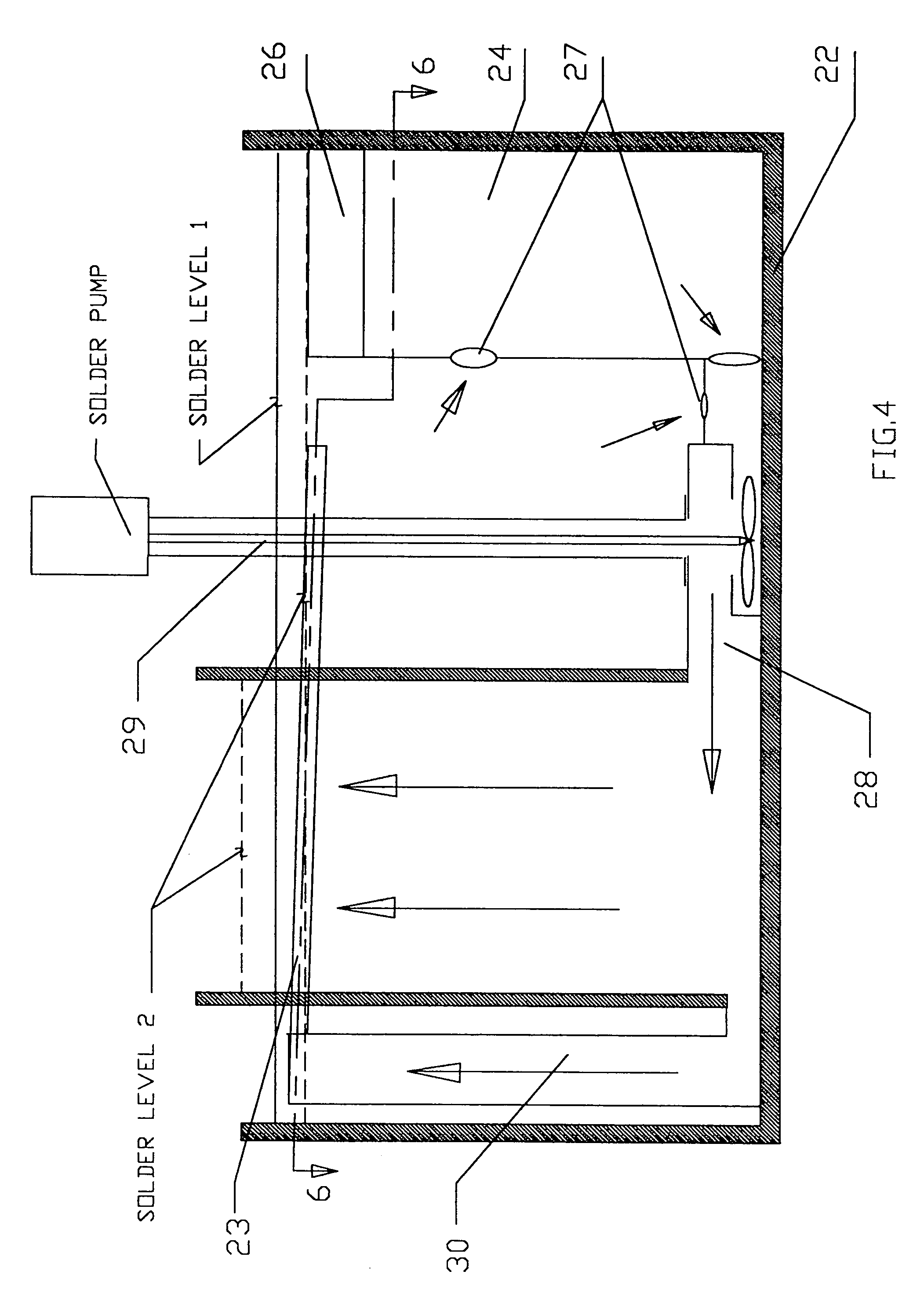

Apparatus and method for recycling of dross in a soldering apparatus

InactiveUS6942791B1Reduce traffic problemsReduce chanceSemi-permeable membranesFatty/oily/floating substances removal devicesImpellerEngineering

An apparatus and method for eliminating dross in a solder pot of a soldering machine by converting the dross into usable solder. The conversion apparatus is comprised of an impeller, a shroud, an electric motor for driving the impeller, a vacuum source operatively connected to the shroud, an arrangement of guides immersed in the solder pot for recirculating liquid solder and a chemical de-oxidizing agent. The impeller and shroud are adjacent to a free surface of the dross which forms at the top portion of the liquid solder. The method includes the steps of adding a measured amount of de-oxidizing agent to the solder pot, agitating and recirculating the liquid solder / de-oxidizer mixture with the impeller to break-up the dross into smaller particles and separate the solder from the dross, and removing a residue of the dross by suction as the recirculating mixture passes beneath the shroud.

Owner:PETROV RADKO G +1

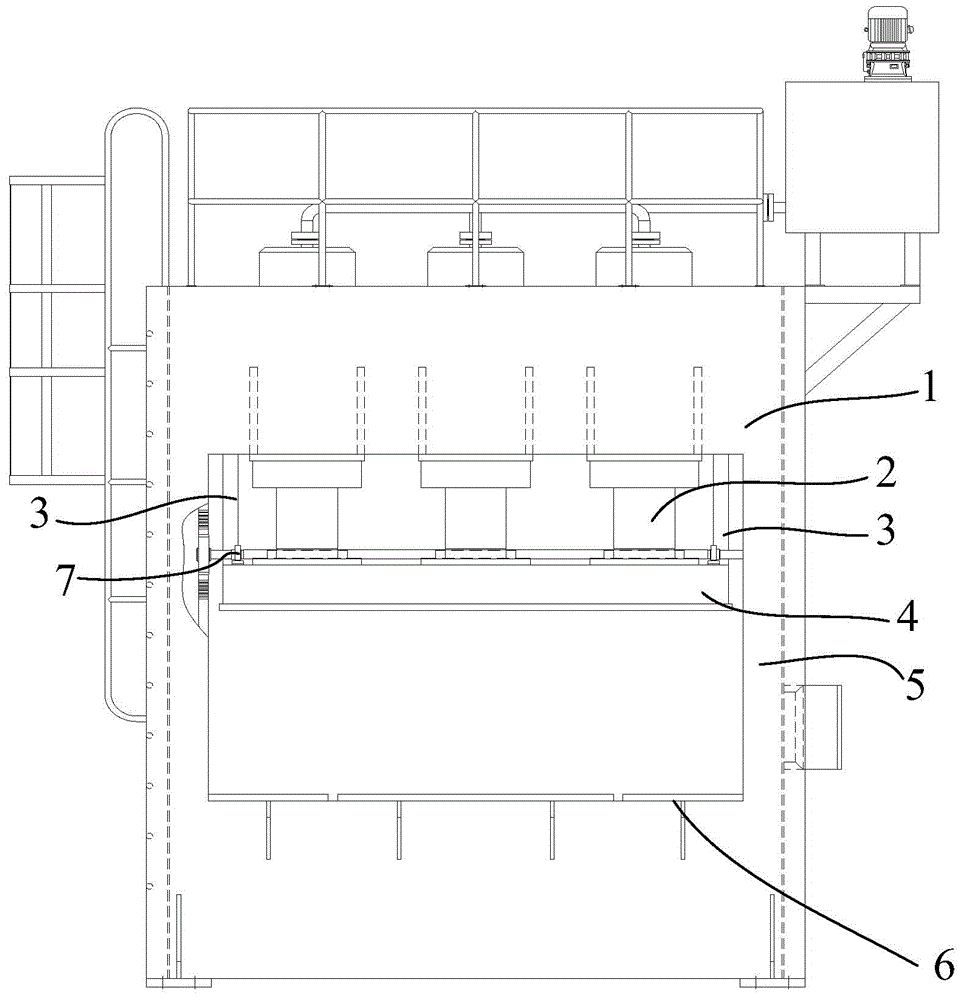

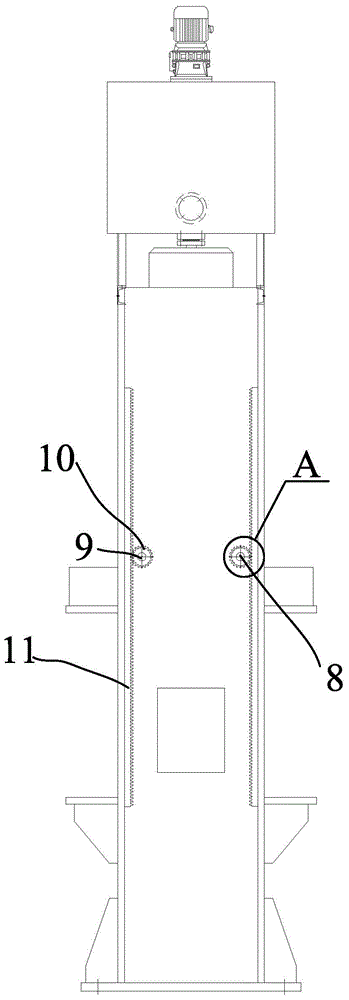

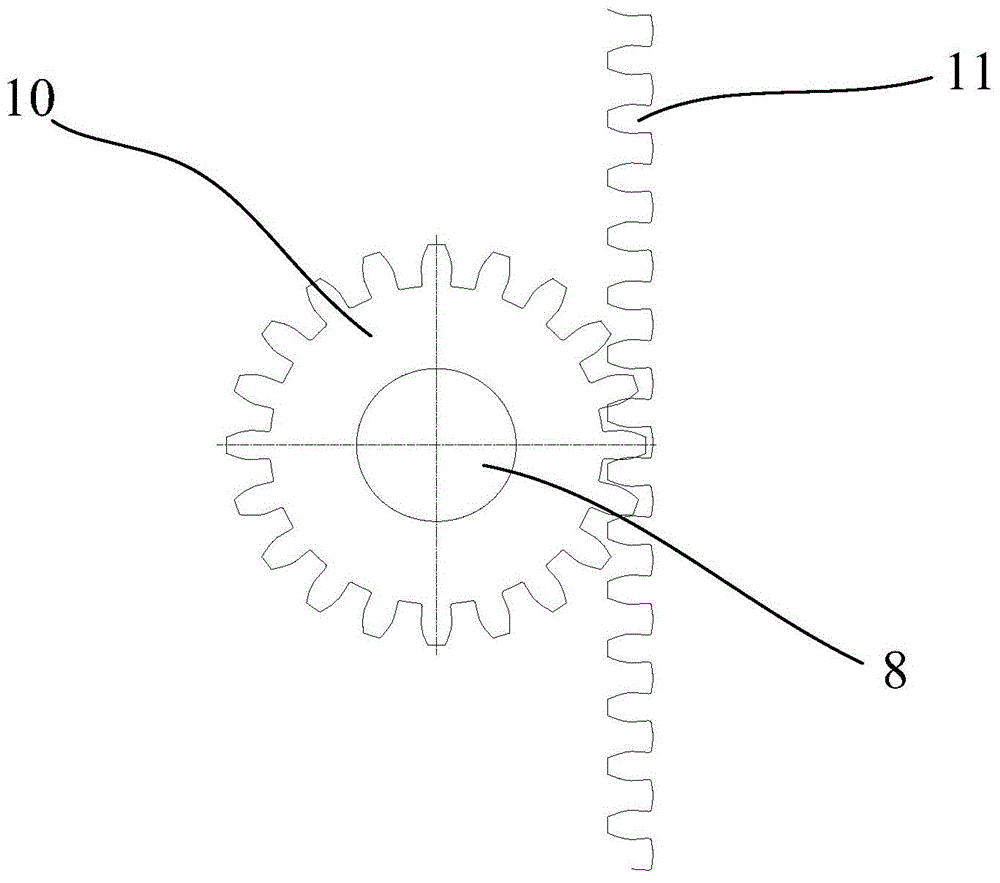

Pre-pressing machine

InactiveCN103552138AReduce equipment maintenance costsSolve the tiltWood veneer joiningEngineeringPlane parallel

The invention discloses a pre-pressing machine. The pre-pressing machine comprises a rack, a moving cross beam, lifting oil cylinders, a plurality of main oil cylinders, synchronizing shafts, gears and racks, wherein the synchronizing shafts are rotationally arranged on the moving cross beam and parallel with a plane of the moving cross beam, and axes of the synchronizing shafts are parallel with a connecting line of the plurality of main oil cylinders; the same gears are arranged at two ends of each synchronizing shaft; and the racks are fixedly arranged on the rack of the pre-pressing machine, correspond to the gears in a one-to-one manner and are meshed with the gears. When the moving cross beam moves up and down, the gears are meshed with the racks and drive the synchronizing shafts to rotate, and rotation angles of two ends of each synchronizing shaft are equal all the time, so that two ends of the moving cross beam move up and down synchronously all the time, the problem that the two ends of the moving cross beam are inclined due to inconsistency of motions of the main oil cylinders is effectively solved, all oil cylinders connected to the moving cross beam are effectively protected, and the equipment maintenance cost is effectively reduced.

Owner:江苏快乐木业集团有限公司

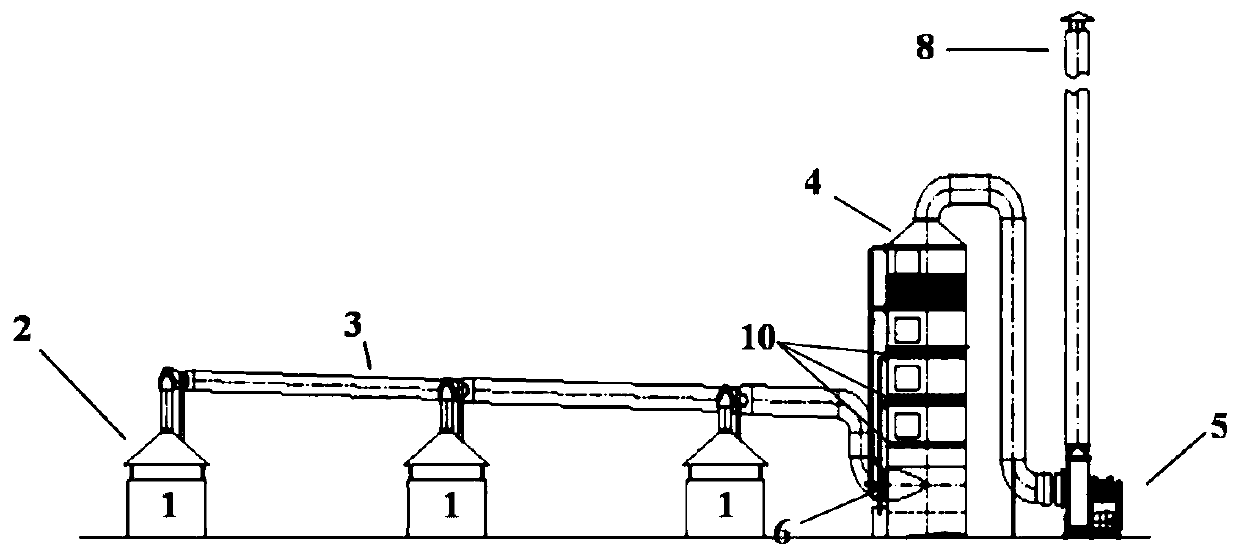

A method for treating distillers' grain waste gas of a Baijiu factory

PendingCN109966867AEfficient removalEasy to handleGas treatmentWater contaminantsEnvironmental resistanceWastewater

A method for treating distillers' grain waste gas of a Baijiu factory is disclosed. The method is characterized in that: a waste gas collecting cover is mounted above a steamer pot and / or waste grainstacking tank to collect waste gas; the waste gas is conveyed into a rotational flow plate-type spraying washing column and subjected to atomized water spraying adsorption treatment; washing wastewater is centralized to a wastewater treatment station for treatment and for cyclic use; and waste gas is then discharged in high altitude. According to the method, distillers' grain gas generated is firstly collected from the source and is treated for removal, and the organic matter removal rate is not less than 90%, thus effectively reducing environment influences caused by distillers' grain waste gas, reducing the risk of environment pollution and facilitating promotion in the Baijiu industry.

Owner:ANHUI XUANJIU GRP

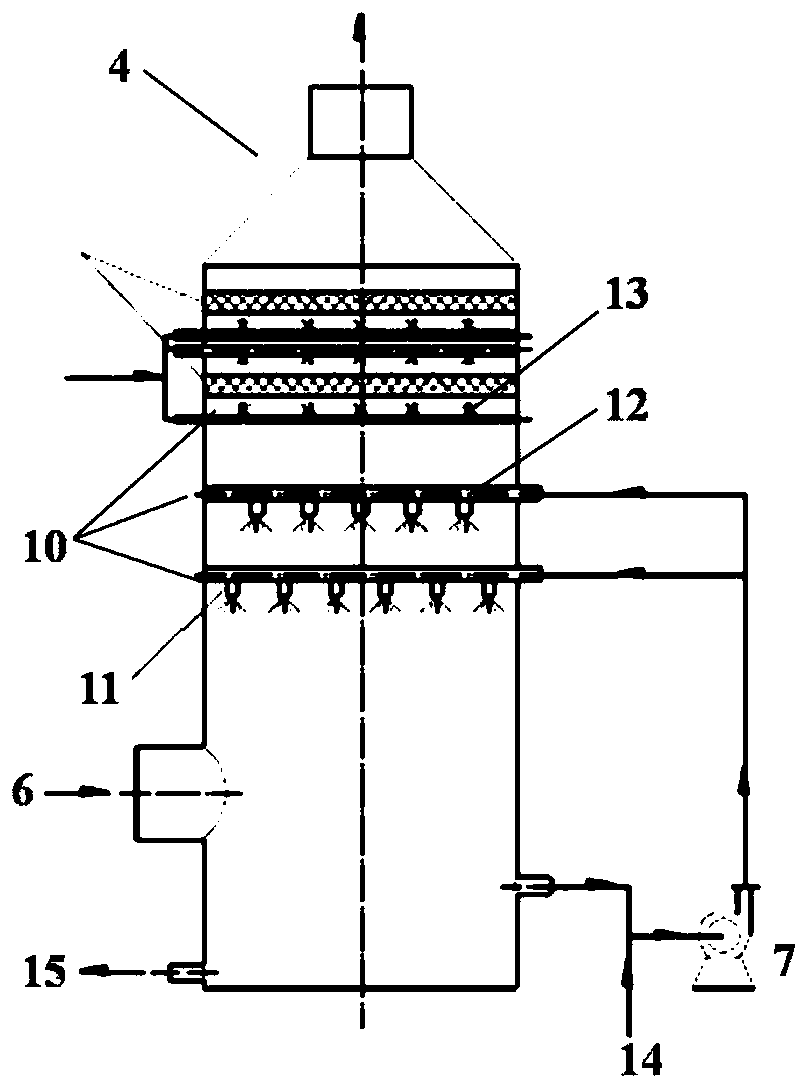

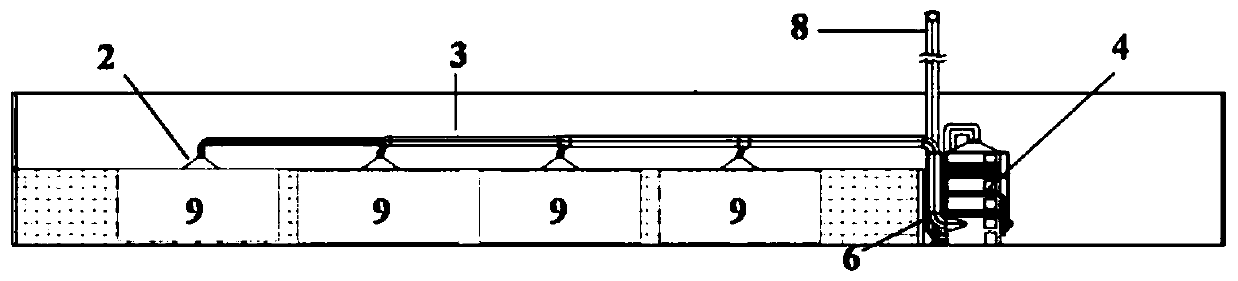

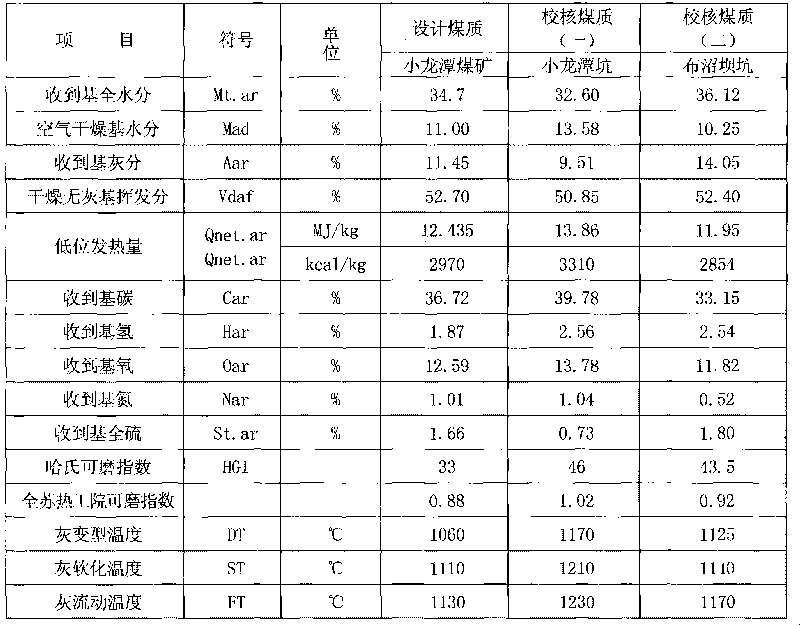

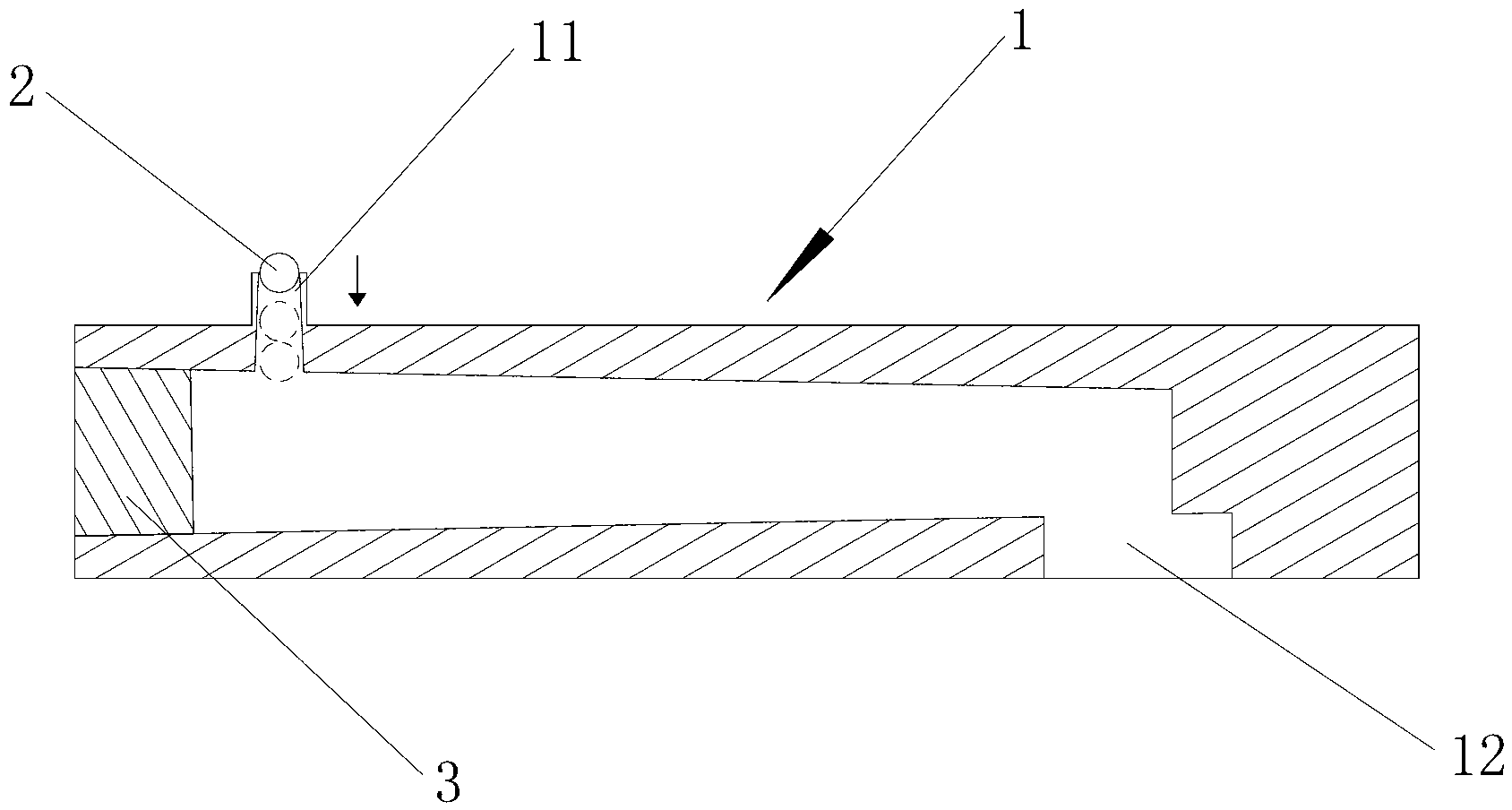

Operation method of circulating fluidized-bed boiler

InactiveCN101709875ALow costReduce equipment maintenance costsFluidized bed combustionApparatus for fluidised bed combustionBrown coalCirculating fluidized bed boiler

The invention belongs to an operation method of a circulating fluidized-bed boiler, in particular to an operation method for keeping the normal bed press of fire coal with strong self-crushing capability. The operation method comprises the steps of: when lignitous coal is used as the fire coal of the circulating fluidized-bed boiler, crushing the grain diameter of the fire coal to 40 mm-50 mm; and keeping the bed press of the lower part of a furnace cavity to achieve 9 KPa to 11 KPa, wherein the residence time of coal grains in the furnace cavity is 10 seconds to 20 seconds. The invention disassembles eight cage type fine crushers of a second-grade coal-transporting crushing system, can save the equipment maintenance cost of the eight cage type fine crushers, also ensure the requirements for the coal transported into a furnace, reasonably increase the residence time of the coal grains in the furnace cavity, enhance the burning efficiency and reduce the workload of bed material increase, thereby achieving the balancing state of the inside and outside circulation of boiler materials.

Owner:云南能投红河发电有限公司

Intelligent valve locator

ActiveCN103216664AGood water resistanceReduce equipment maintenance costsOperating means/releasing devices for valvesPhysicsEngineering

The invention provides an intelligent valve locator comprising a piezoelectric module. The piezoelectric module comprises an air inlet cavity provided with an air inlet and an air outlet, and a sealing ball used for sealing or opening the air inlet of the air inlet cavity. The air inlet is a tapered hole, and the section diameter of the air inlet is gradually increased along the air inlet direction. The sealing ball is supported by a reset spring and can be movably arranged in the air inlet along the axis direction of the air inlet. The diameter of the sealing ball is larger than or equal to the minimum section diameter of the air inlet, and smaller than the maximum section diameter of the air inlet. The sealing ball is made of aluminum alloy materials. The sealing ball made of the aluminum alloy materials is good in oil resistance, water resistance and expansion resistance and long in service life, so damage of the piezoelectric module caused by oil intrusion and water intrusion problems can not occur, maintenance cost is reduced, work efficiency is improved, and application prospects are wide.

Owner:NINE DRAGONS PAPER TAICANG LTD

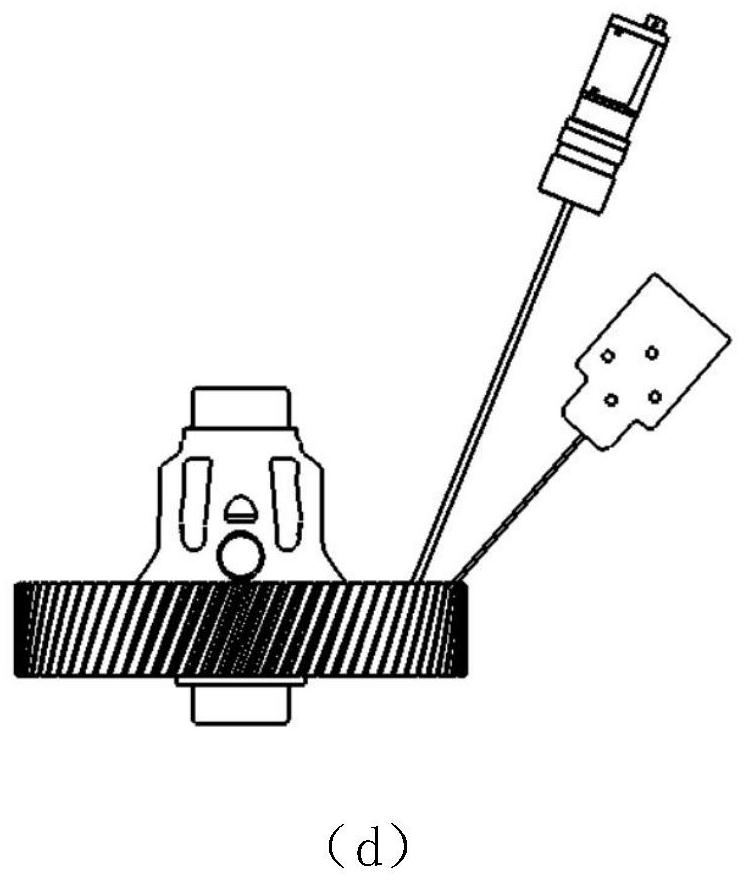

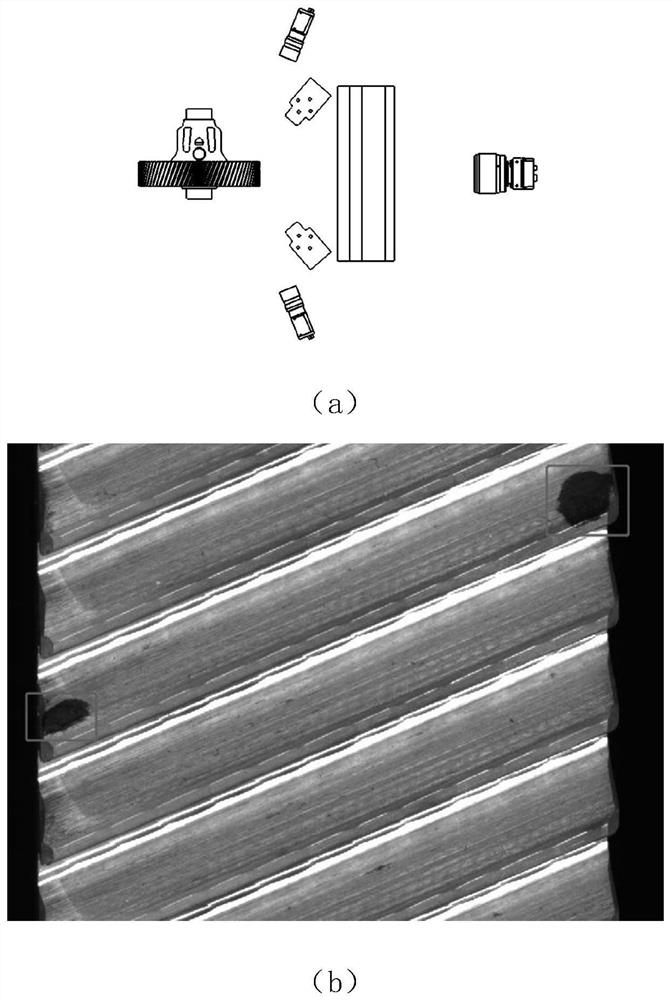

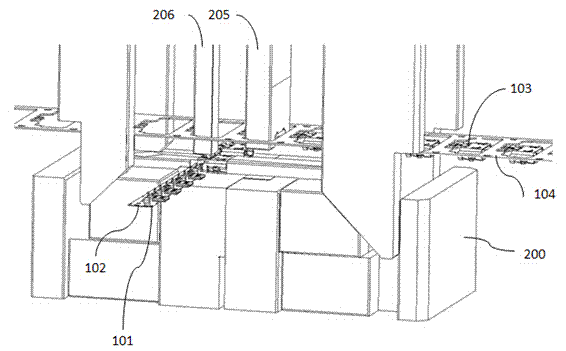

Method for positioning and distributing diamonds in tool bit and distributing device

The invention provides a method for positioning and distributing diamonds in a tool bit and a distributing device. The distributing device comprises a template and a sealing cavity body, wherein the dimension of the lower surface of the template is identical to that of the tool bit, the lower surface of the template is provided with a plurality of counterbores which are distributed according to a cutting mechanism of the tool bit, each counterbore can contain one diamond, and the sealing cavity body is arranged above the upper surface of the template. The bottoms of the counterbores are provided with through holes used for ventilation and extending to the upper surface of the template, the sealing cavity body is communicated with the counterbores through the through holes, and the sealing cavity body is provided with a port for pumping vacuum and inputting airflow. The distributing device can effectively and appropriately distribute the diamonds in three-dimensional space of the diamond tool bit with low cost.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

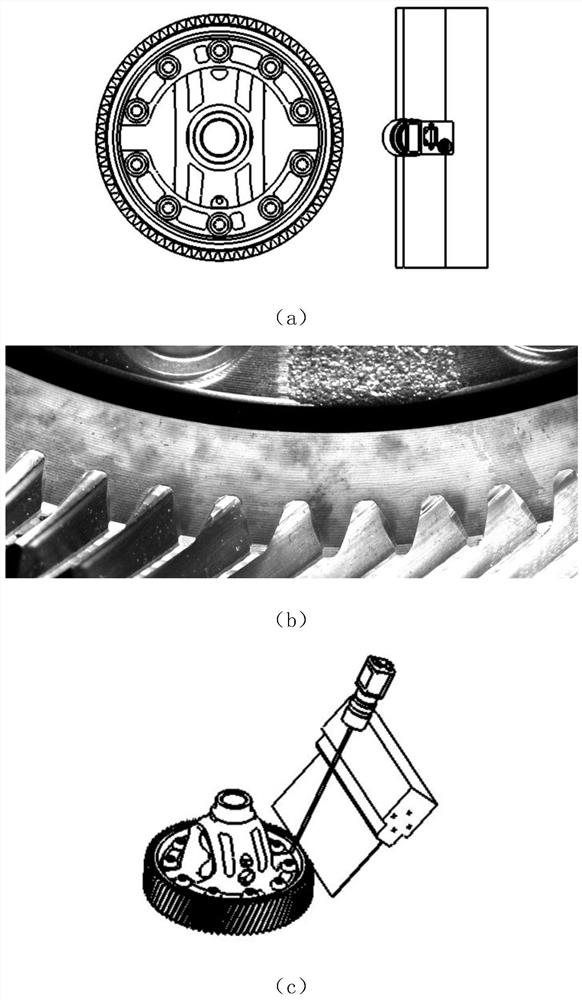

Image acquisition system and method based on gear shaft visual detection, product, equipment and terminal

PendingCN112903693AEfficient collectionIncrease reflectionOptically investigating flaws/contaminationProduction lineGear wheel

The invention discloses an image acquisition system and method based on gear shaft visual detection, a product, equipment and a terminal, and relates to the technical field of gear shaft product defect detection and visual optical design. A shooting station is arranged, the upper and lower end surfaces and the upper and lower tooth surfaces of a gear shaft respectively use a set of independent shooting units which are respectively used for detecting surface defects of the upper and lower end surfaces and the upper and lower tooth surfaces of the gear shaft; end surface shooting units are arranged, the shooting units shooting the upper and lower end surfaces are mirror images of each other along the tooth surfaces, and the upper and lower end surface areas of the gear are shot; tooth surface shooting units are arranged, the shooting units shooting the upper and lower tooth surfaces are mirror images of each other along the axis of the gear, and the upper and lower tooth surface areas are shot. According to the optical design system, the picture information of each surface of the gear shaft is effectively collected, the number of cameras and light sources is reduced, mechanical motion scheme design is facilitated, and potential risks and equipment maintenance cost are reduced. When the optical design system is implemented, an original gear shaft production line does not need to be broken, and shooting can be completed only by stopping on the original production line.

Owner:菲特(天津)检测技术有限公司

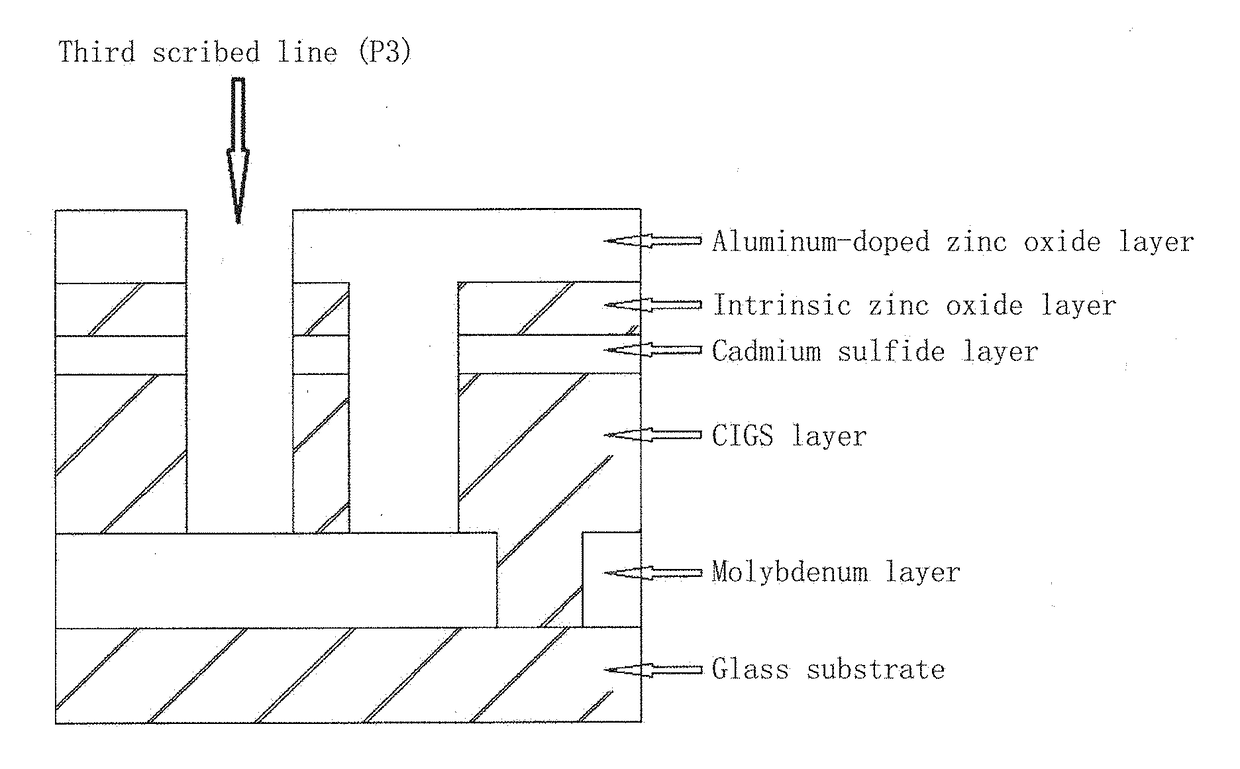

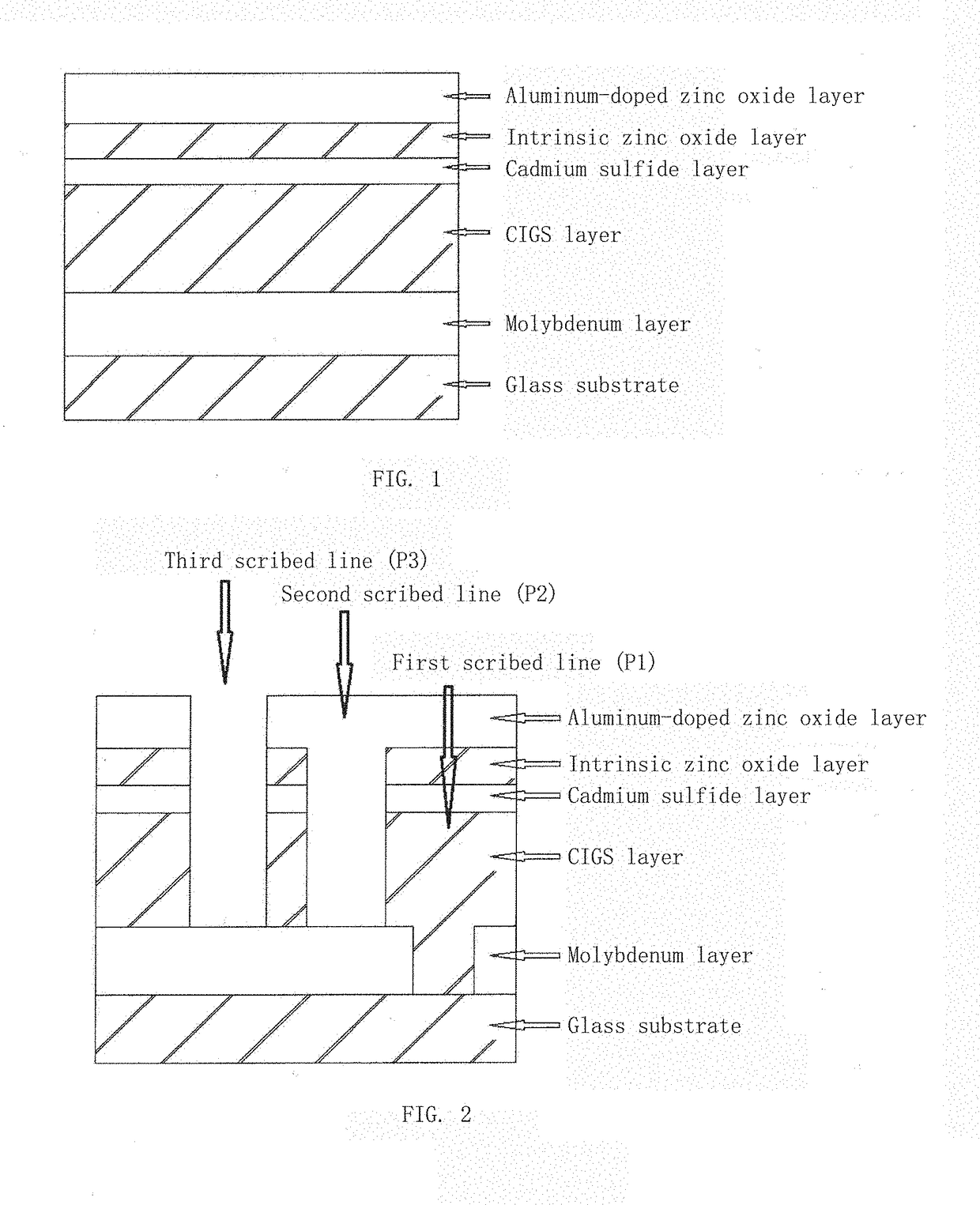

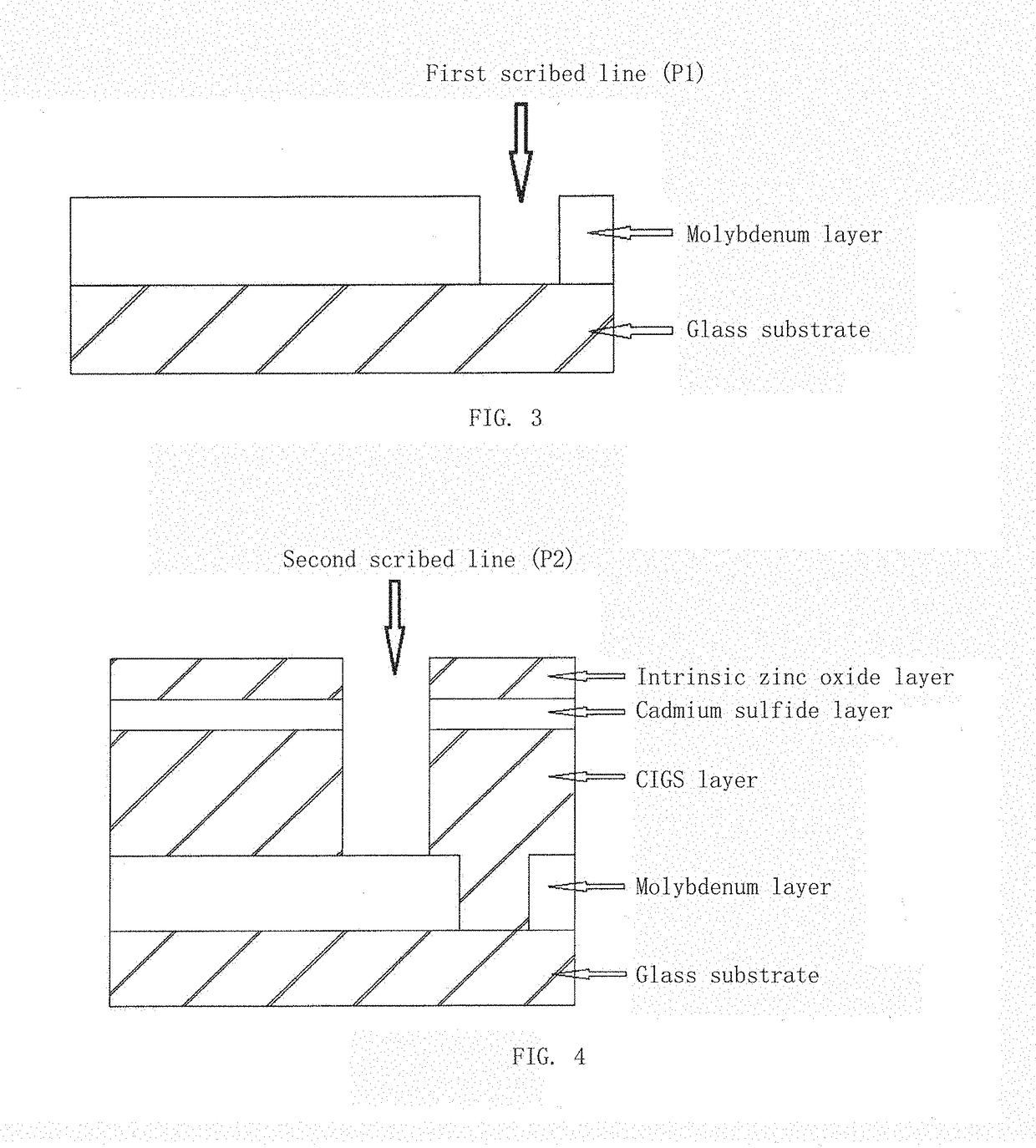

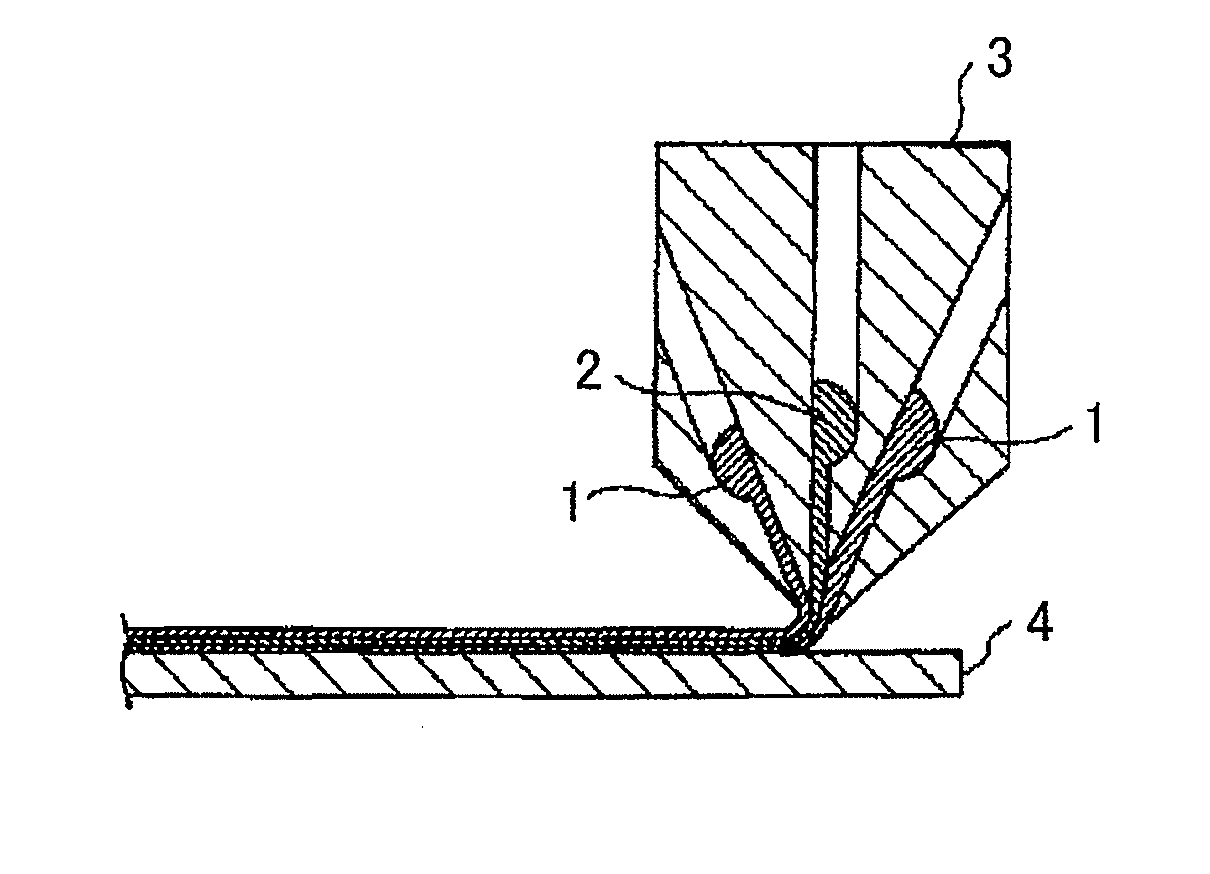

Full-laser scribing method for large-area copper indium gallium selenide thin-film solar cell module

ActiveUS20180114876A1Dead zone area can be reducedIncrease powerFinal product manufactureSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

Disclosed is a full-laser scribing method for a large-area copper indium gallium selenide (CIGS) thin-film solar cell module, including: using a laser I to scribe a molybdenum thin film prepared on soda-lime glass to form a first scribed line (P1); preparing the following film layers in sequence on the molybdenum layer in which P1 has been scribed: a CIGS layer, a cadmium sulfide layer and an intrinsic zinc oxide layer; after finishing preparation of the above film layers, using a laser II for scribing to form a second scribed line (P2), wherein the scribed line P2 is parallel with the scribed line P1; and preparing an aluminum-doped zinc oxide layer on the intrinsic zinc oxide layer in which P2 has been scribed, and using a laser III for scribing to form a third scribed line (P3), wherein the scribed line P3 is parallel with the scribed line P1.

Owner:BEIJING SIFANG CRENERGEY OPTOELECTRONICS TECH CO LTD +1

Resin film and method for producing it, polarizer and liquid crystal display device

ActiveUS8337962B2Increased durabilityHigh product yieldLiquid crystal compositionsSynthetic resin layered productsOrganic acidLiquid-crystal display

A resin film including a resin and an organic acid represented by the following formula (1), wherein the ratio of the organic acid to the resin is from 0.1 to 20% by mass:X-L-(R1)n Formula (1).

Owner:FUJIFILM CORP

Bio-fertilizer and method for producing bio-fertilizer

InactiveCN108069766ALow investment costReduce equipment maintenance costsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersInorganic ChemicalGram

The invention belongs to the field of bio-fertilizer, and relates to biological organic-inorganic composite fertilizer and a production method thereof. The production method comprises the following steps: mixing 65 to 80 percent by weight of fermented bacillus bacteria solution and 20 to 35 percent by weight of silicate bacteria solution to prepare a composite bacteria solution; directly mixing the composite bacteria solution with organic materials as well as inorganic chemical fertilizer and binder, and adsorbing; mixing and stirring, crushing and screening to obtain powder biological organic-inorganic composite fertilizer, or mixing and stirring, crushing, granulating, drying and screening to obtain granular biological organic-inorganic composite fertilizer. By adopting the method provided by the invention, the equipment investment and the equipment maintenance expense can be reduced, the manpower and the labor intensity are reduced, the transportation expense is reduced, and the production cost is decreased; and an effective viable count of each single bacterium of the fertilizer of the invention is one million per gram or more, and the total viable count is 20 million per gramor more.

Owner:QINGDAO KAILIER BIOTECH

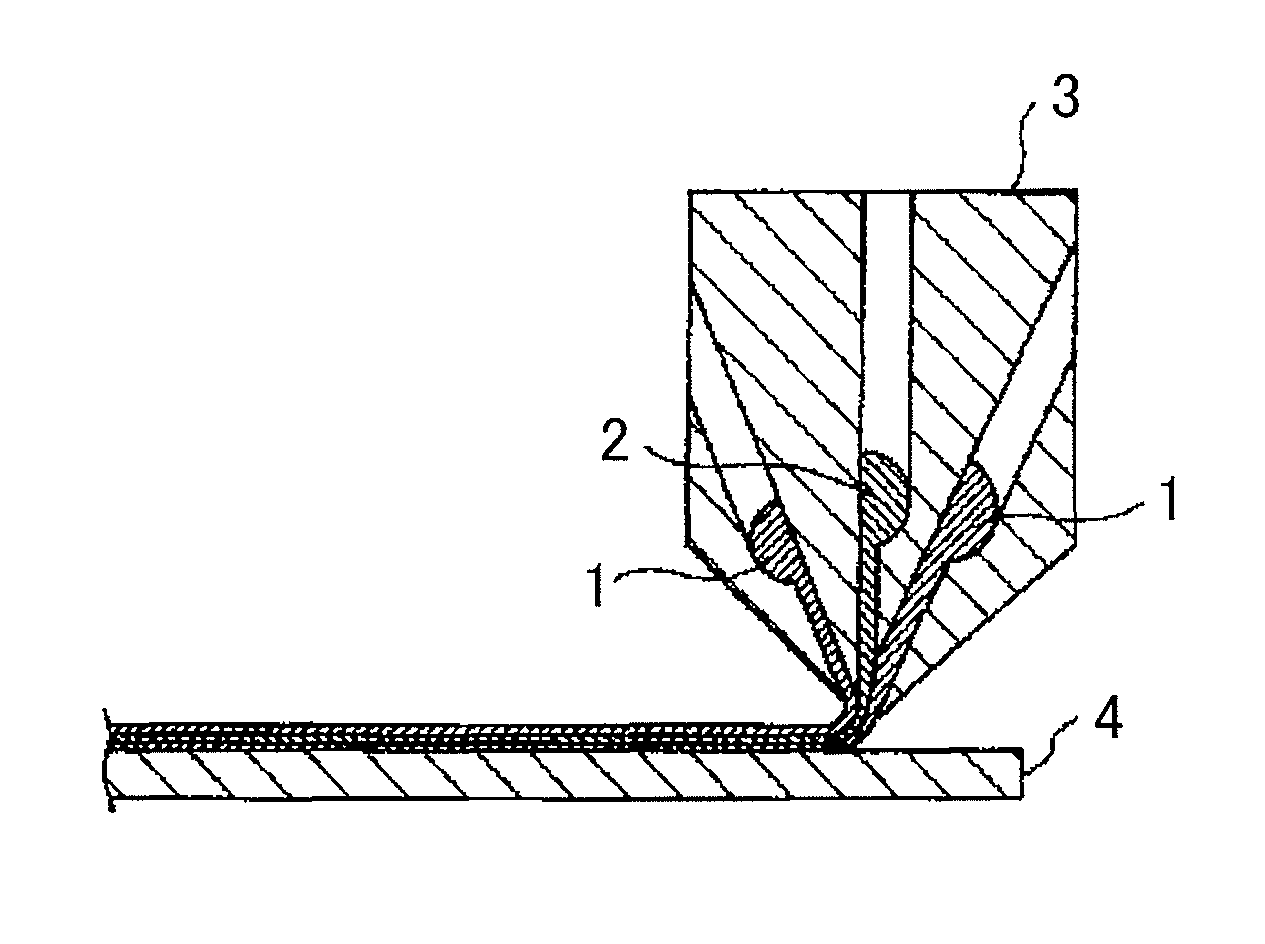

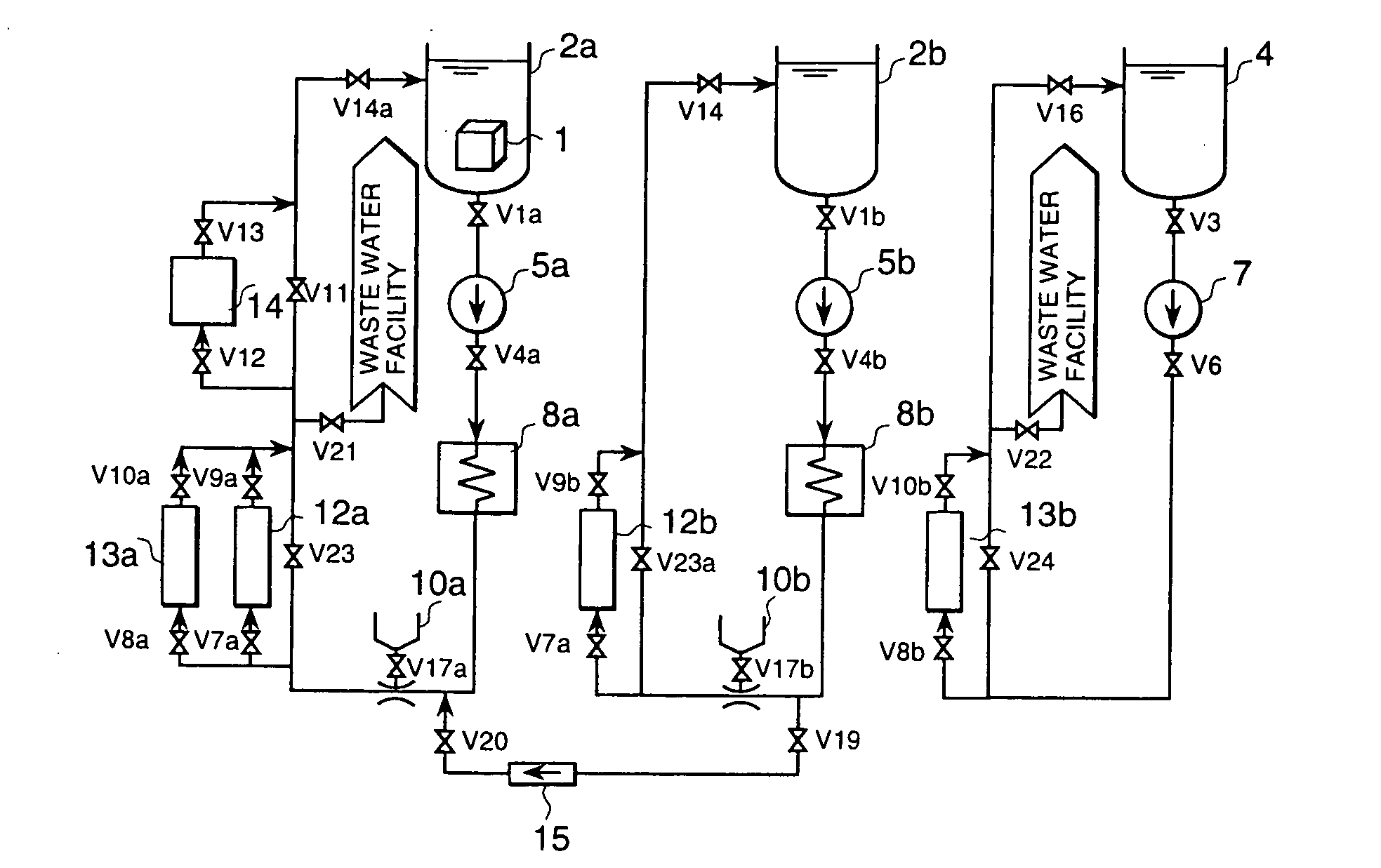

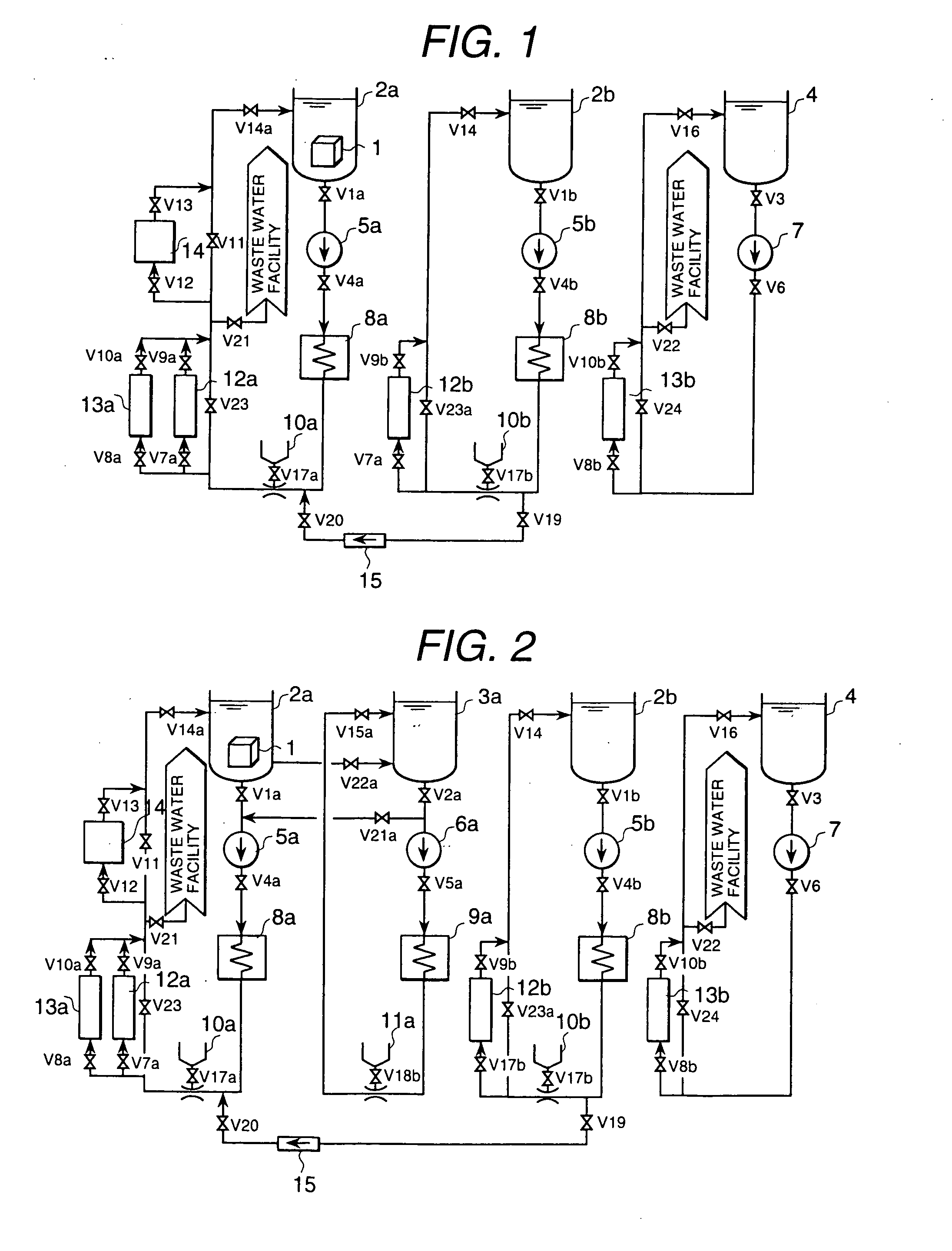

Radioactive substance decontamination method and apparatus

InactiveUS20050014989A1Reduce decontaminationImprove work efficiencyRadioactive decontaminationRadioactive agentEngineering

A radioactive substance decontamination method and apparatus which decontaminates a metal member contaminated by radioactive substance in a short period of time. This apparatus has (1) multiple reducing decontamination tanks having different radiation control values; (2) a carrier for immersing the metal member into the multiple reducing decontamination tanks and a washing tank; (3) a tube for transferring into the second reducing decontamination tank the reducing decontamination agent in the first reducing decontamination tank; (4) a reducing agent decomposer for decomposing a component contained in the reducing decontamination agent of the reducing decontamination tank where the radiation control value is the highest out of the reducing decontamination tanks connected by the tube; and (5) a washing tank for washing the reducing decontamination agent deposited on the decontaminated metal member.

Owner:HITACHI LTD +1

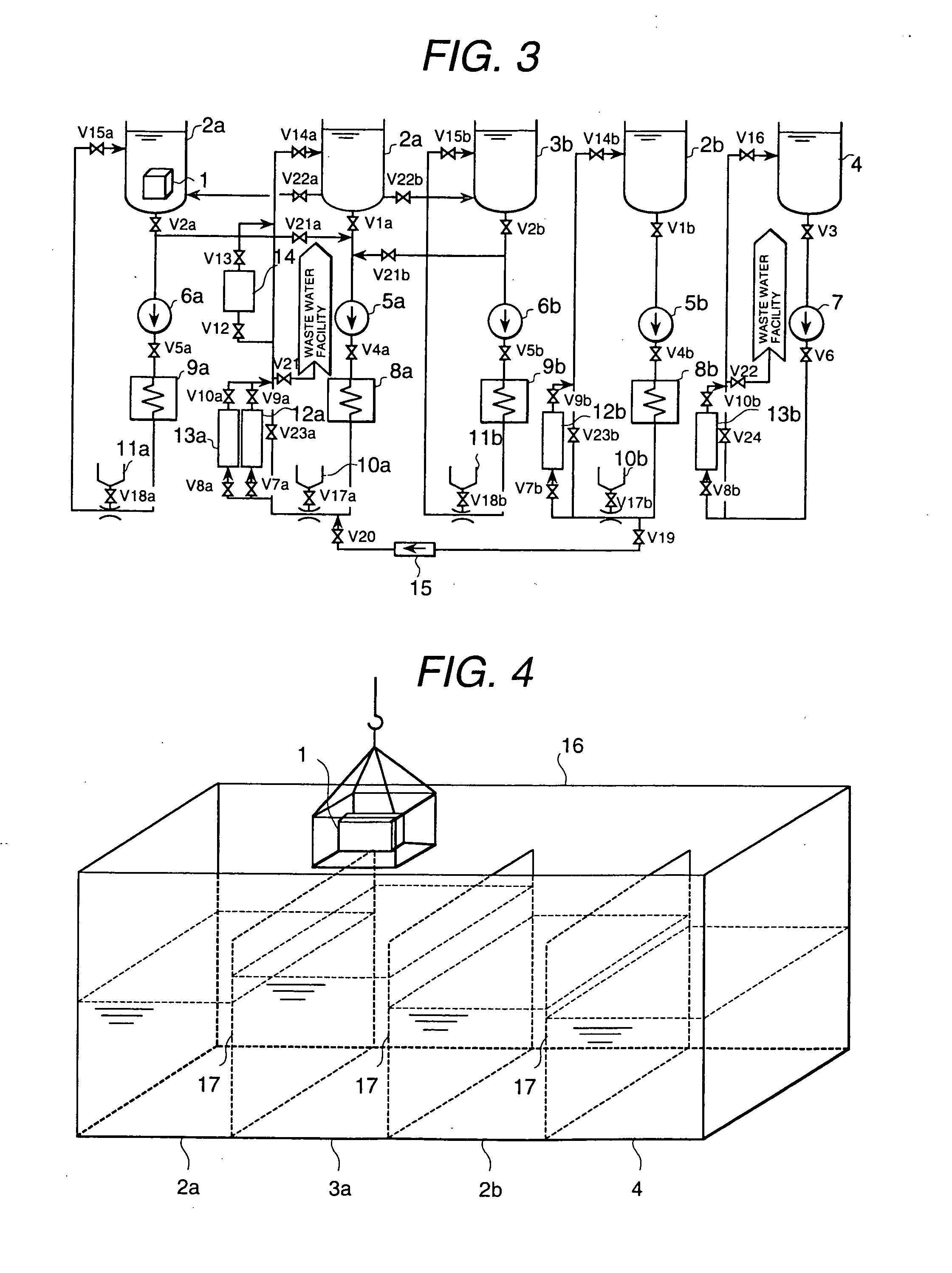

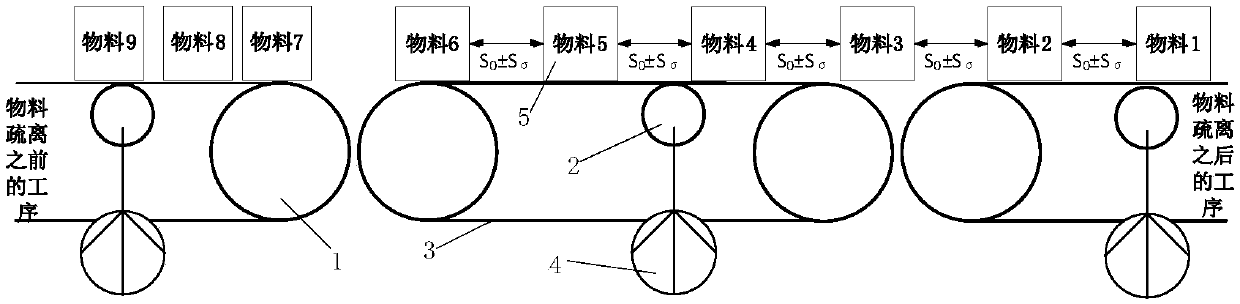

Control method for independent shaped material separation distance on flow production line

InactiveCN109516161AAvoid inaccurate walking distance controlLow input costControl devices for conveyorsProduction lineEngineering

The invention relates to a control method for independent shaped material separation distance on a flow production line. The invention relates to a method of controlling the independent shaped material separation distance on the flow production line. The method comprises the following steps: measuring the diameter of a shaft and the pulse count output by a rotating pulse encoder per revolution through a known conveyor belt; calculating a total pulse count set value of the rotating pulse encoder by deduction; and finally controlling independent shaped materials in an equally spaced manner according to a relationship between the actual set value and the set value of the rotating pulse encoder as a control condition of starting and stopping the conveyor belt. The control method provided by the invention can prevent the condition that the material walking distance is inaccurate to control as a driving roller slips in the material conveying process effectively. The control process is simpleand efficient and low in cost.

Owner:HONGTA TOBACCO GRP

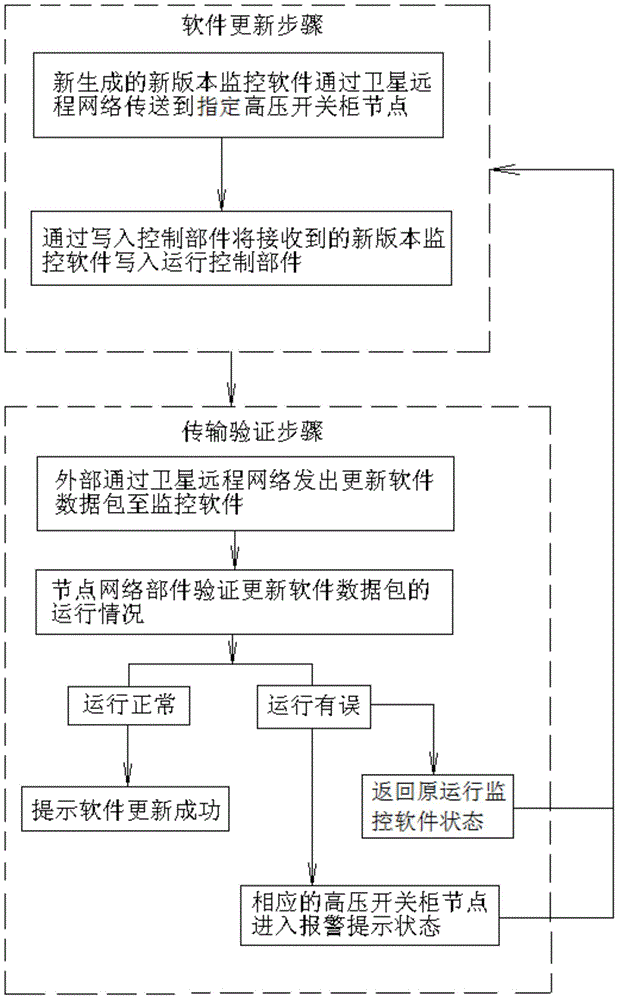

Beidou satellite-based high-voltage switch cabinet remote monitoring method

ActiveCN104102203AImprove work efficiencyReduce equipment maintenance costsData switching networksProgramme total factory controlSatelliteSoftware update

The invention discloses a Beidou satellite-based high-voltage switch cabinet remote monitoring method. The Beidou satellite-based high-voltage switch cabinet remote monitoring method includes a software update step and a transmission verification step; monitoring software operates in each high-voltage switch cabinet node; an operating control component, a write-in control component and a node network component are arranged in the monitoring software; and in the software update step, newly-generated new-version monitoring software is transmitted to a specified high-voltage switch cabinet node through a satellite remote star network, and the newly-generated new-version monitoring software received by the high-voltage switch cabinet node is written into the operation control component through the write-in control component. With the Beidou satellite-based high-voltage switch cabinet remote monitoring method of the invention adopted, monitoring access points can be flexibly updated; a user can upload updated software wherever and whenever in a satellite coverage area through the satellite remote star network; new service items are provided, and the service items can be allocated according to demands; remote fault diagnosis and online debugging can be realized; traditional manual operation is replaced, so that work efficiency can be improved; and equipment maintenance cost and maintenance cost can be reduced.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP +1

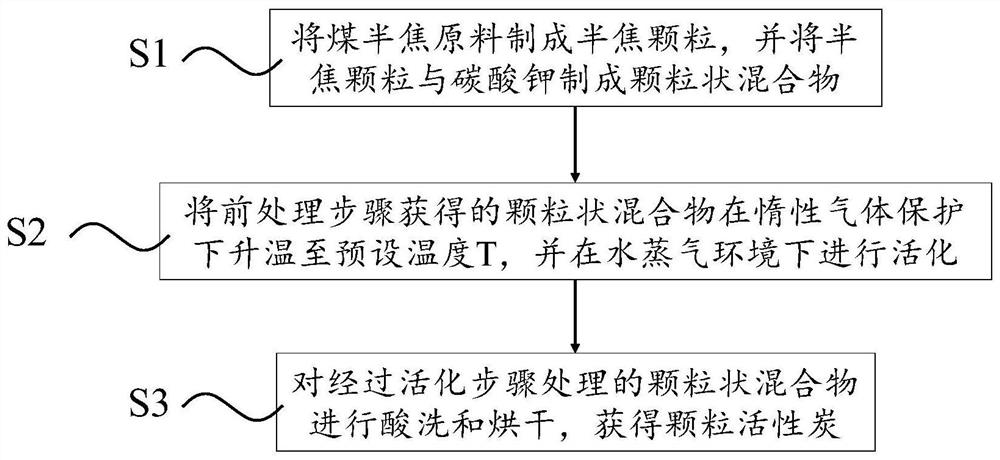

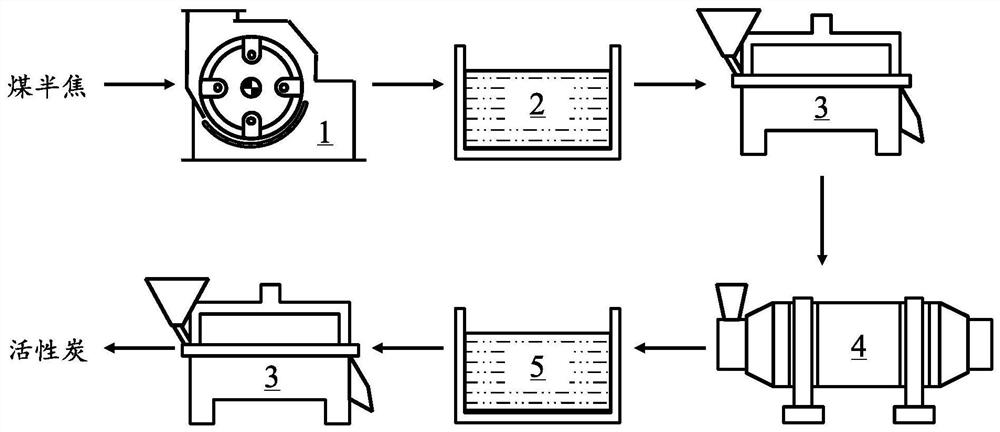

Method for preparing granular activated carbon from coal semicoke

ActiveCN111960415AGuaranteed qualityReduce consumptionCarbon compoundsProcess engineeringPotassium carbonate

The invention relates to a preparation method of activated carbon, which comprises the following steps: a pretreatment step: preparing a coal semicoke raw material into semicoke particles, and preparing the semicoke particles and potassium carbonate into a granular mixture; an activation step: heating the granular mixture obtained in the pretreatment step to a preset temperature T under the protection of inert gas, and activating in a water vapor environment; and a post-treatment step: carrying out acid washing and drying on the granular mixture treated in the activation step to obtain the granular activated carbon. The preparation method of the activated carbon provided by the invention adopts a physical activation and chemical activation combined activation process, so that the energy consumption can be reduced, the consumption of a chemical activator can be greatly reduced, the corrosion to equipment is reduced, the maintenance cost of the equipment is reduced, and the quality of the activated carbon can be ensured.

Owner:ZHEJIANG UNIV

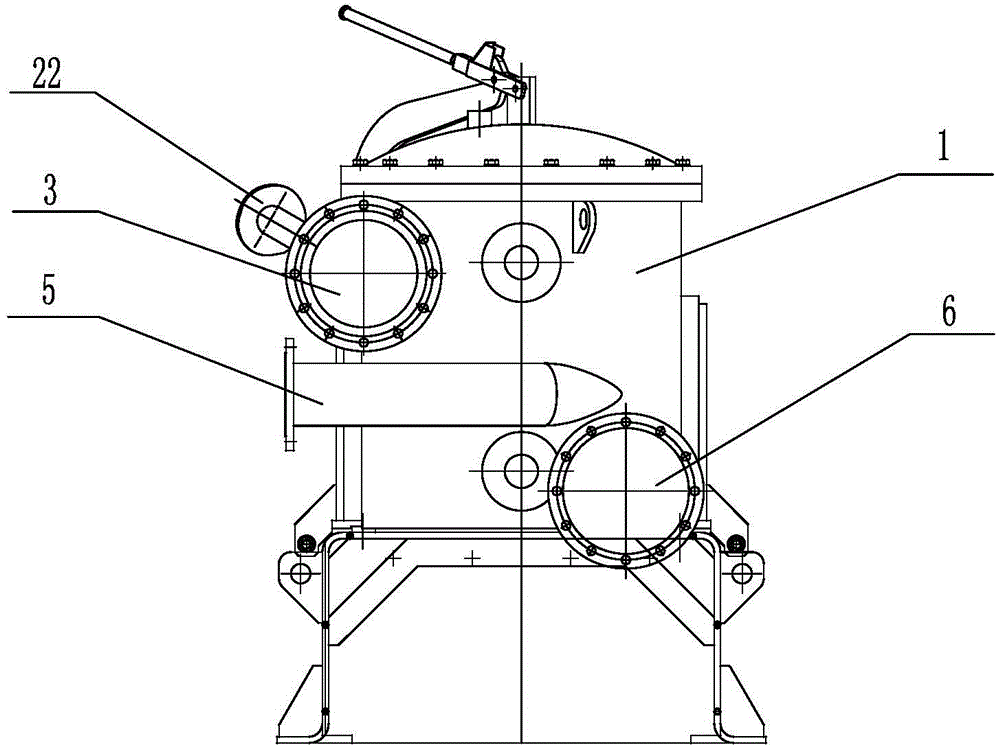

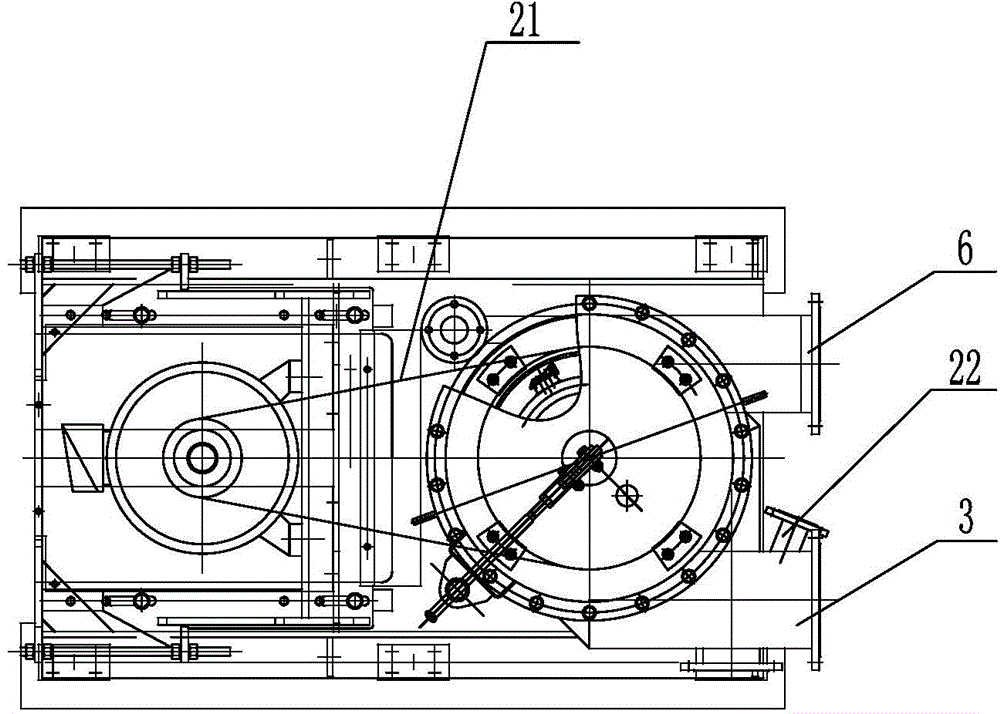

Rotary drum type screening joint machine

The invention relates to a rotary drum type screening joint machine, and belongs to the field of papermaking concentration filtering equipment. The rotary drum type screening joint machine comprises a base, the base is provided with a motor and a cylinder, a rotating shaft is fixedly arranged in the cylinder, the bottom of the rotating shaft is connected with the motor through a belt, the top of the rotating shaft is connected with a rotating plate through a connecting piece, the rotating plate is connected with the top of a screen cylinder, the screen cylinder is arranged on the outer side of a rotating shaft sealing device in a sleeving mode, a fixing rib is arranged on the inner side of the screen cylinder, the fixing rib is fixed to the rotating shaft sealing device through a fastener, a guiding connecting piece is arranged corresponding to the bottom of the screen cylinder and connected with a fixing ring at the lower portion of the cylinder, a lower cavity is formed by the guiding connecting piece, the fixing ring and the lower portion of the cylinder, the lower cavity is communicated with a pulp outlet, an upper cavity is formed by the guiding connecting piece, the fixing ring, the screen cylinder and the upper portion of the cylinder, and the upper cavity is communicated with a pulp inlet and a slag outlet. The rotary drum type screening joint machine is compact in structure, easy to operate, low in energy consumption, thorough in rough slag screening and free of the rough slag winding phenomenon.

Owner:SHANDONG CHENZHONG MACHINERY

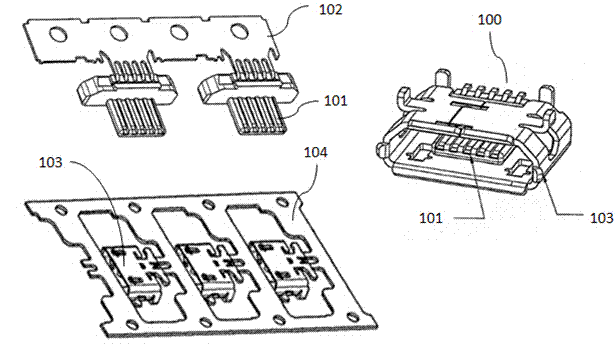

Manufacturing device and method for USB connectors

ActiveCN104733979ASimplify the assembly processImprove yieldContact member assembly/disassemblyUSBComputer engineering

The invention provides a manufacturing device and method for USB connectors. The manufacturing device for the USB connectors comprises a USB connector assembling table, a USB shell guide rail, a USB shell cutting-off device, a USB terminal assembly guide rail and a USB assembling device, wherein the USB shell guide rail, the USB shell cutting-off device and the USB terminal assembly guide rail are installed on the USB connector assembling table, and the USB shell guide rail, the USB terminal assembly guide rail and the USB assembling device are in butt joint. The manufacturing device further comprises a composite stamping die, and the USB assembling device is in butt joint with the composite stamping die and guides assembled USB terminals and assembled USB shells into the composite stamping die. According to the manufacturing device and method for the USB connectors, the cost of manufacturing equipment for the USB connectors can be reduced, the production efficiency of the USB connectors is improved, and the yield of the USB connectors is increased.

Owner:SUZHOU XIANCHUANG PRECISION MOLD

Resin film and method for producing it, polarizer and liquid crystal display device

InactiveUS20120153542A1Increased durabilityHigh product yieldLiquid crystal compositionsDischarging arrangementOrganic acidLiquid-crystal display

A resin film including a resin and an organic acid represented by the following formula (1), wherein the ratio of the organic acid to the resin is from 0.1 to 20% by mass:X-L-(R1)n Formula (1)

Owner:FUJIFILM CORP

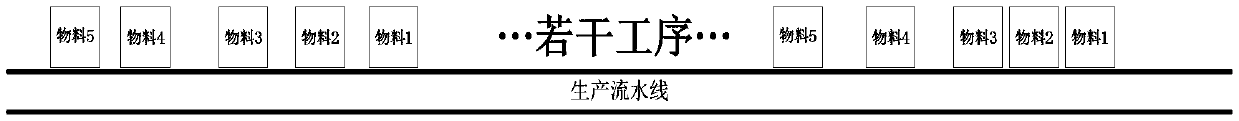

Minimum quantity lubrication cooling system and lubrication cooling method during copper tube drawing

The invention discloses a minimum quantity lubrication cooling system. The system includes: a minimum quantity lubrication cooling controller, wherein the minimum quantity lubrication cooling controller comprises a gas feeding tube for connecting with a high pressure gas to drive, and a first minimum quantity oil gas nozzle and a second minimum quantity oil gas nozzle which are respectively connected with the minimum quantity lubrication cooling controller; a spinning mechanism having a tensile throat with the opening open to one side, wherein the outlet direction of the first minimum quantity oil gas nozzle aligns with the tensile mouth; and a reducing die positioned at one side or both sides of the spinning mechanism, wherein the reducing die has a tapered mouth, the outlet direction of the second minimum quantity oil gas nozzle aligns with the above conical mouth. The invention also provides a lubrication cooling method during copper tube drawing. The method comprises the following steps: providing the minimum quantity lubrication cooling system, and arranging the minimum quantity lubrication cooling system on the table of a stretching device; and connecting a compressed air tube into the minimum quantity lubrication cooling system to provide power.

Owner:广东龙丰精密铜管有限公司

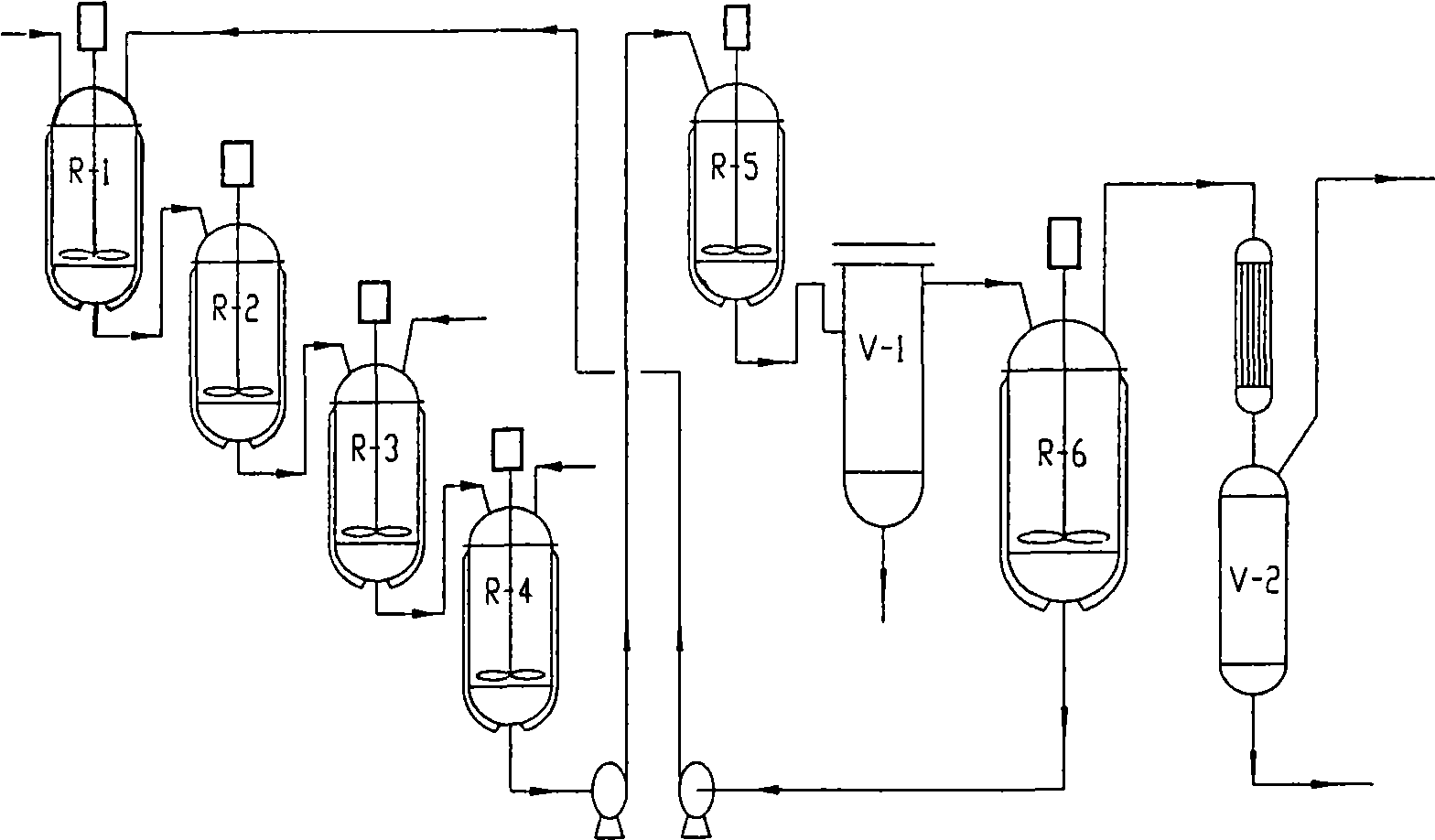

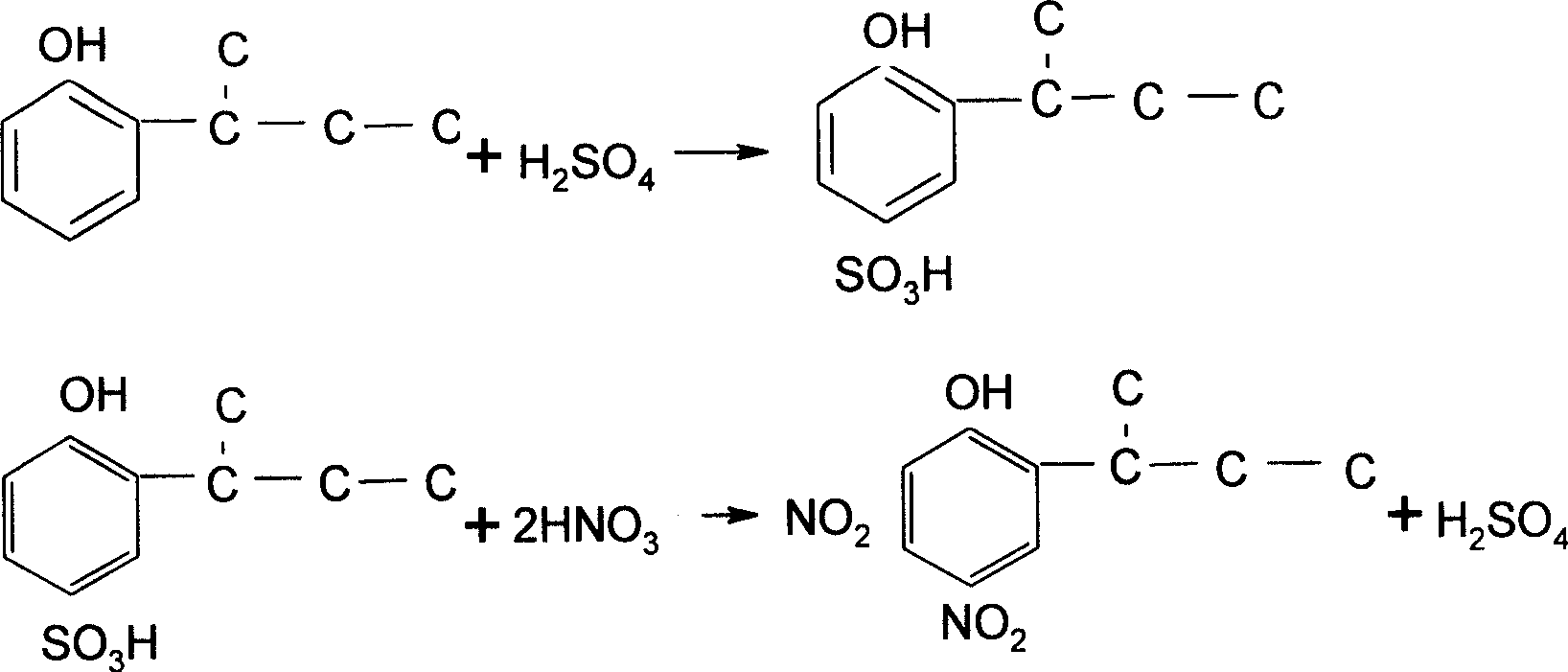

Continuous production method for 4,6-dinitryl o-sec-butylphenol inhibitor

InactiveCN101508648AContinuous productionEasy to controlChemical inhibitorsNitro compound preparationHeat lossesOrtho-sec-butylphenol

The invention provides a method for continuously producing 4, 6-binitro-o-sec-butylphenol polymerization retarder, comprising the following steps: adopting position difference to connect a plurality of reaction kettle devices in series, continuously adding such reaction materials as o-sec-butylphenol, sulphuric acid and nitric acid into the reaction kettle devices in turn through measuring flow according to a molar rate of the sulphuric acid to the o-sec-butylphenol of 1:1.2-1.4 and a molar rate of the nitric acid to the o-sec-butylphenol of 1:2.2-3.2, controlling the temperature through ice brine steam, and obtaining a product through continuous layering devices; and distillating dilute sulphuric acid generated in the reaction by an efficient porcelain enamel kettle in high vacuum to obtain 70 to 90 percent sulphuric acid for recycling, wherein the yield of the product reaches more than 92 percent. The method has the advantages that the production is continuous and production is easy to control and stable. The method has high automation degree and reduces the effects of human factors. The yield already reaches 92 percent; the using amount of the sulphuric acid is reduced by 60 to 70 percent; the method lowers production cost and lightens three-waste governance load. The reaction equipment is shrunk by 7 to 8 times so as to reduce heat loss, equipment maintenance cost, investment and occupied area. The production is safer and cleaner.

Owner:天津瑞泰精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com