Control method for independent shaped material separation distance on flow production line

A control method and production line technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., and can solve the problems of intermittent or instantaneous slipping of the conveyor belt on the shaft of the moving roller, the running speed of the conveyor belt, the material waiting, and the process of blocking the material, etc. , to avoid inaccurate control of material walking distance, simple and efficient control process, and reduce equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

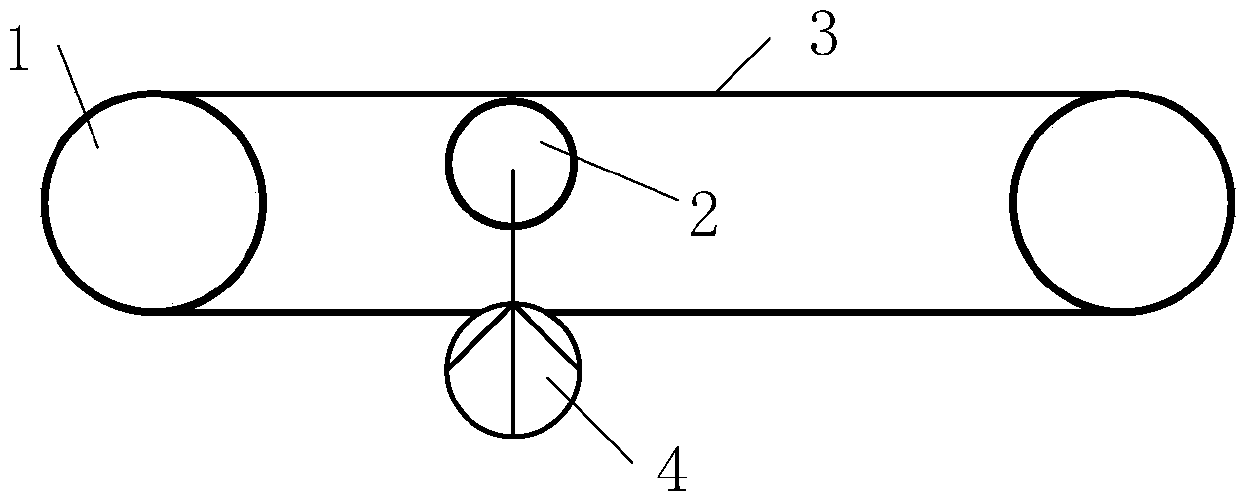

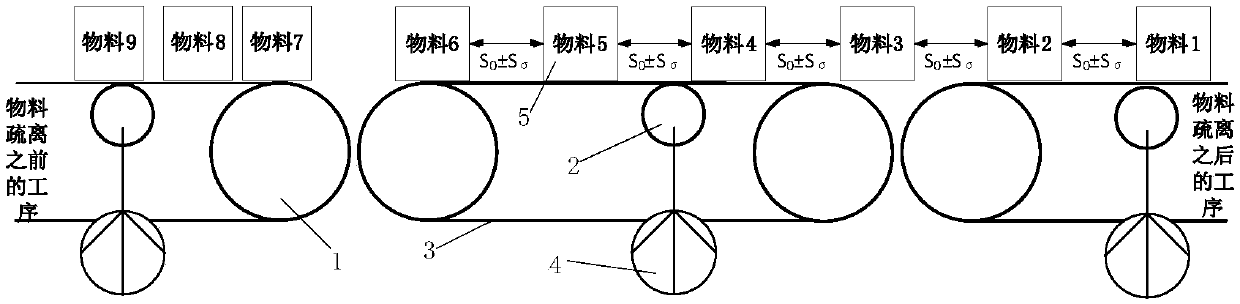

[0022] For the belt conveyor that conveys materials, choose the idler near the middle of the belt conveyor as the measuring shaft roller, that is, install the rotary pulse encoder on the shaft end of the idler to monitor the belt operation, such as figure 2 Shown. Because the belt conveyor idler supports the belt and materials, it rotates with the belt by friction under the gravity of the belt and materials. When the belt slips and stops, although the driving roller continues to rotate, it is used as a measurement The roller of the shaft will also stop rotating with the belt. Determine the distance traveled by the belt (material) by the total number of pulses counted by the rotary pulse encoder installed on the measuring shaft, and start and stop the belt conveyor according to the relationship between the actual pulse value of the rotary pulse encoder and the set value Under the control conditions, the equidistant control between independent tangible materials is finally reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com