Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce data collection time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

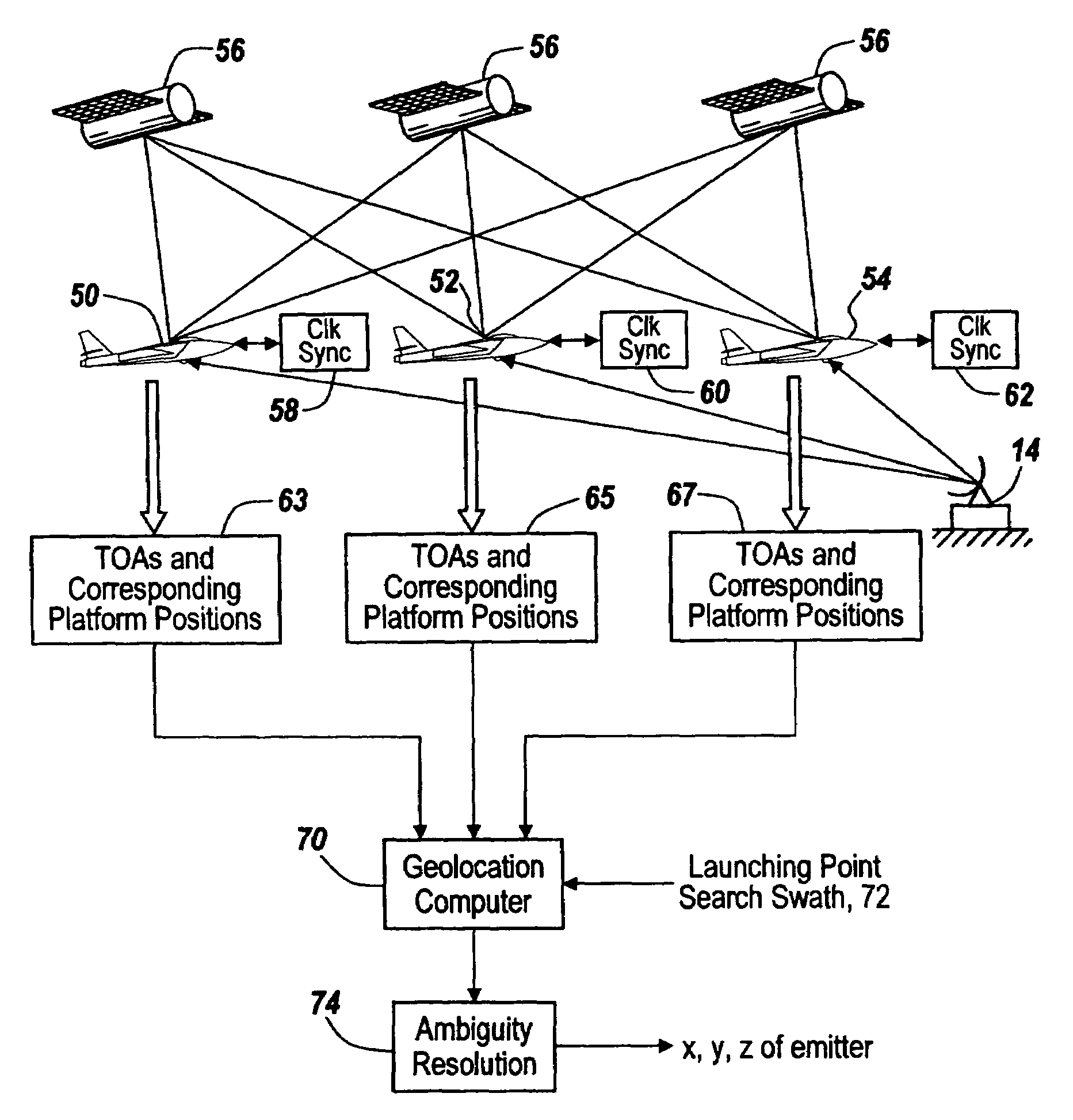

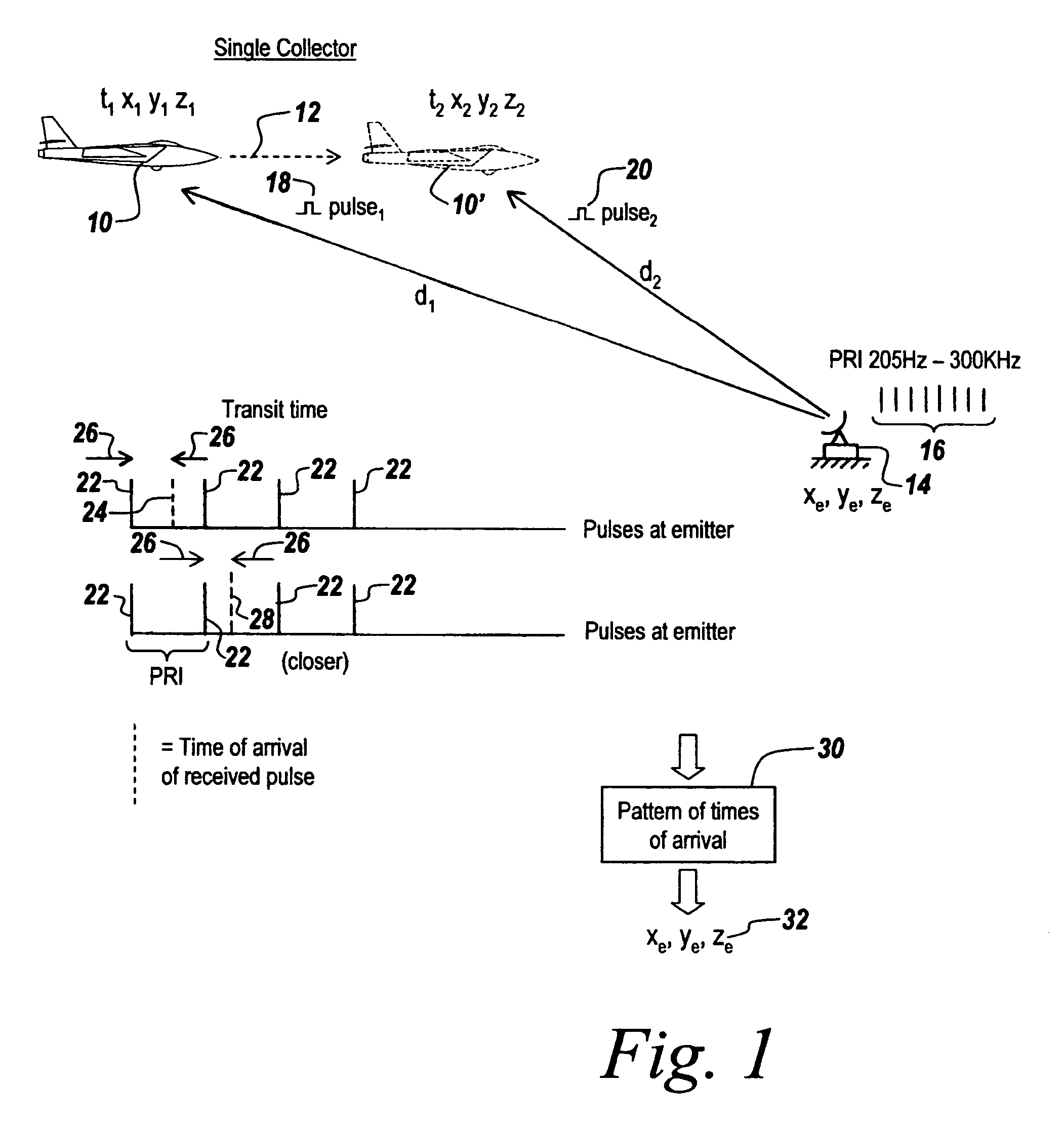

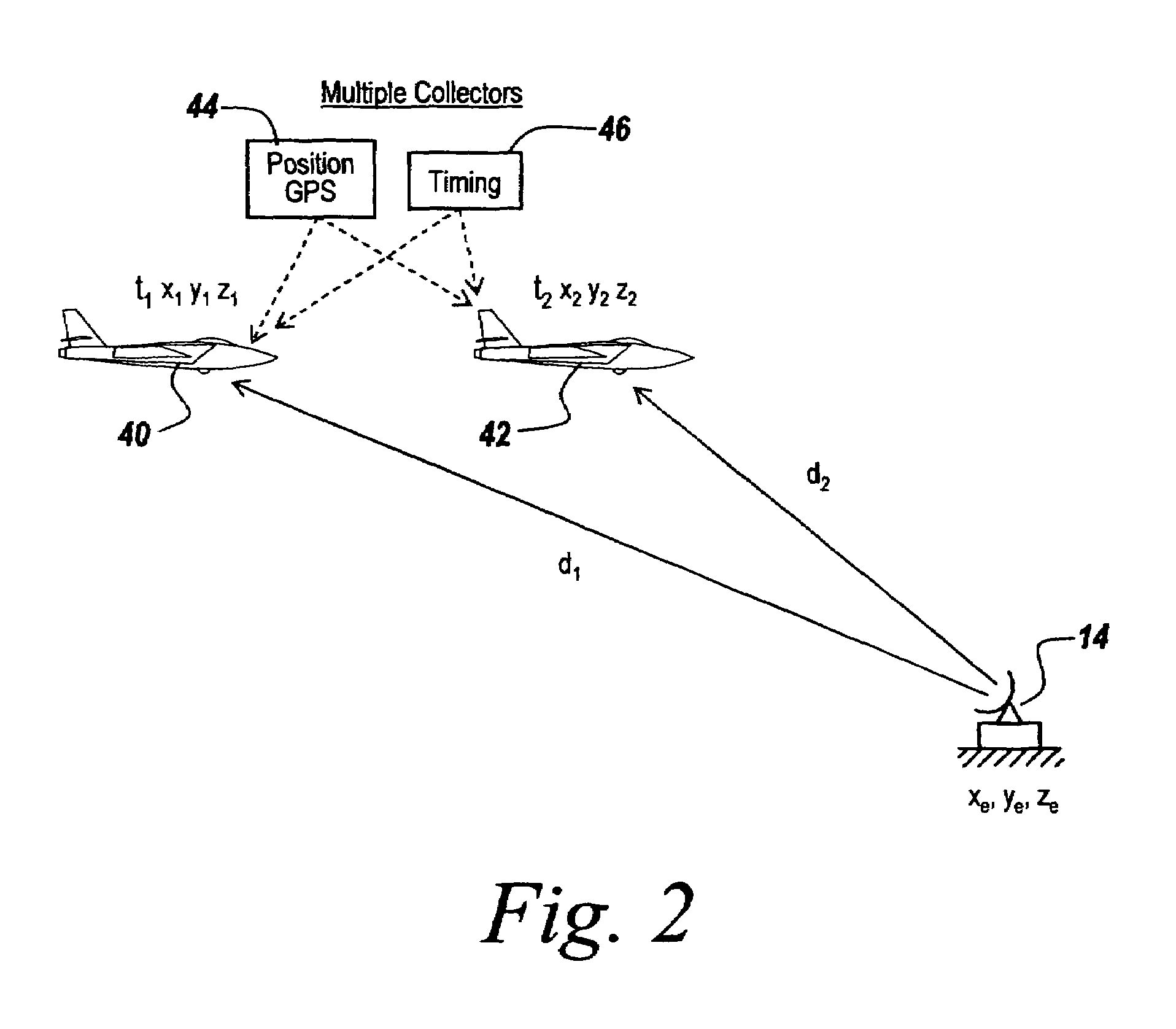

Multi-ship coherent geolocation system

InactiveUS6933888B1Less sensitivityLimit amount of usablePosition fixationBeacon systemsGeolocationPulse sequence

A system is provided for rapidly ascertaining the position of a pulse train emitter such as a radar using multiple collectors without requiring more than one platform to measure the same pulse. Thus time-of-arrival measurements at a number of collecting platforms are performed, with the positions of the platforms being accurately ascertainable using GPS data, and with time synchronization between the spaced-apart collectors performed by utilizing atomic clocks. In the multi-ship case, geolocation can be performed on ten milliseconds of data as opposed to 30 seconds of data for measurements involving a single platform. The subject system is preferable to conventional time-difference-of-arrival geolocation systems because those systems require that each of the collecting platforms measure the same pulse from the emitter, which severely constrains the flight paths of the collectors, limits the amount of usable data, and increases the system's sensitivity requirements.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

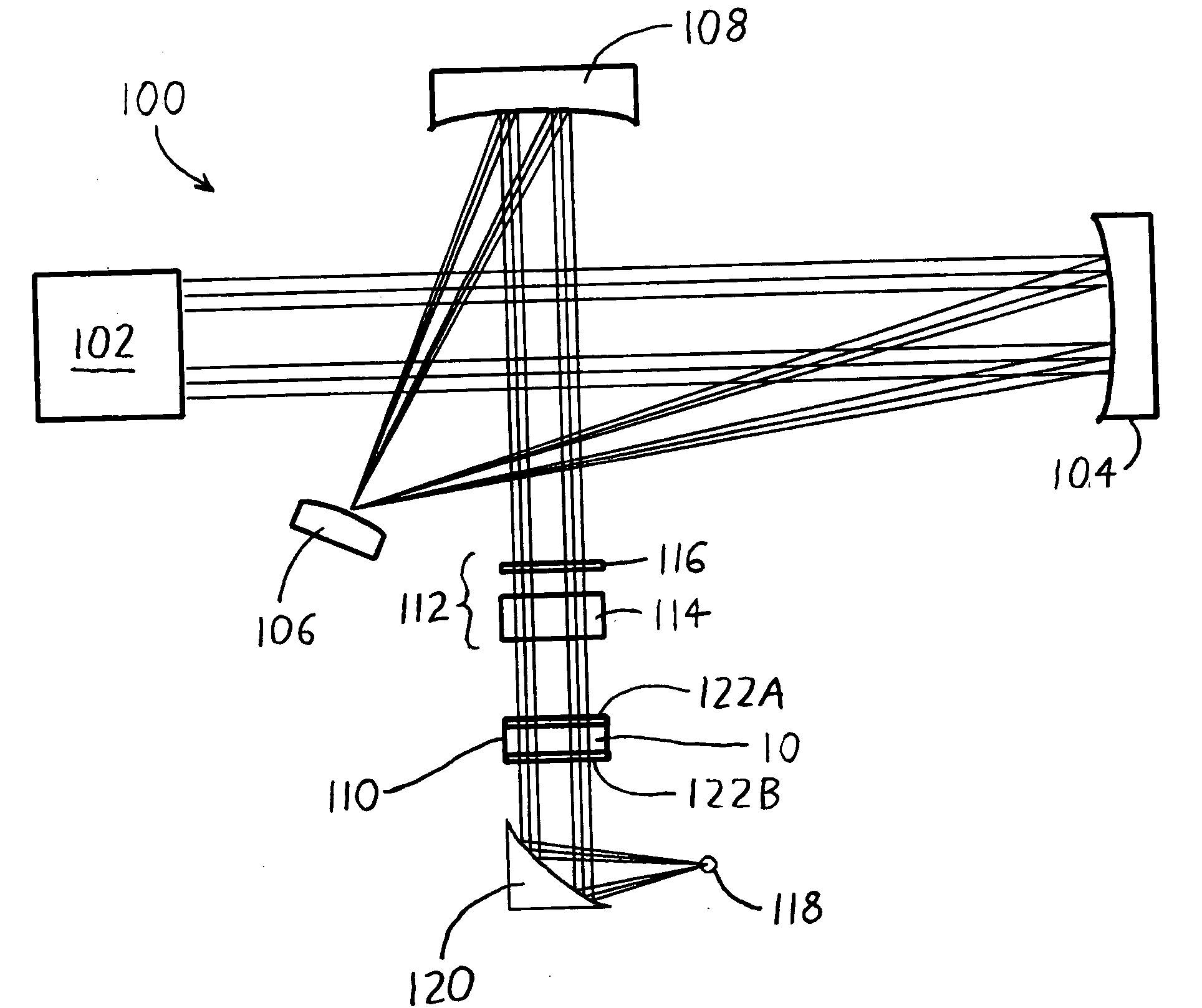

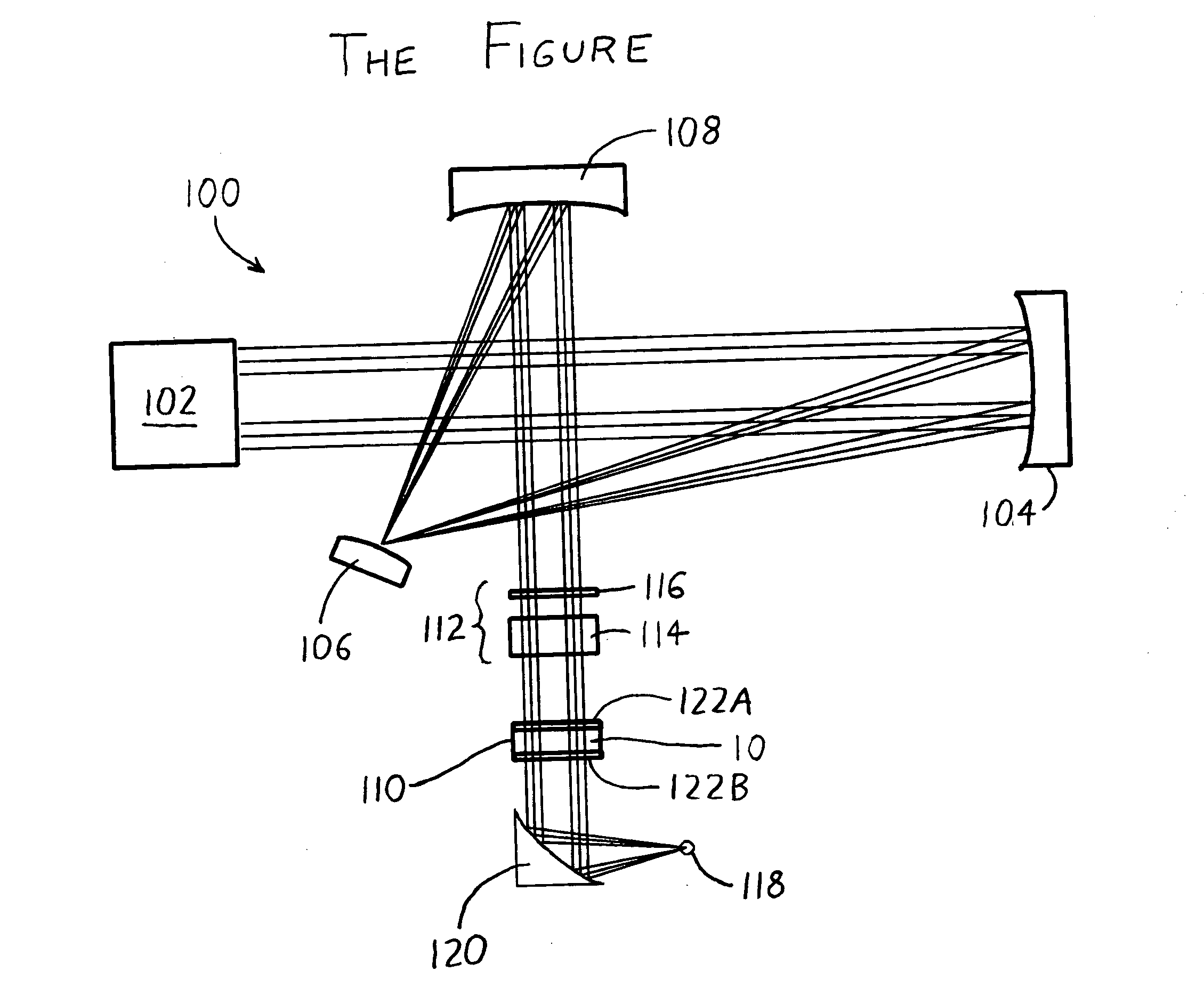

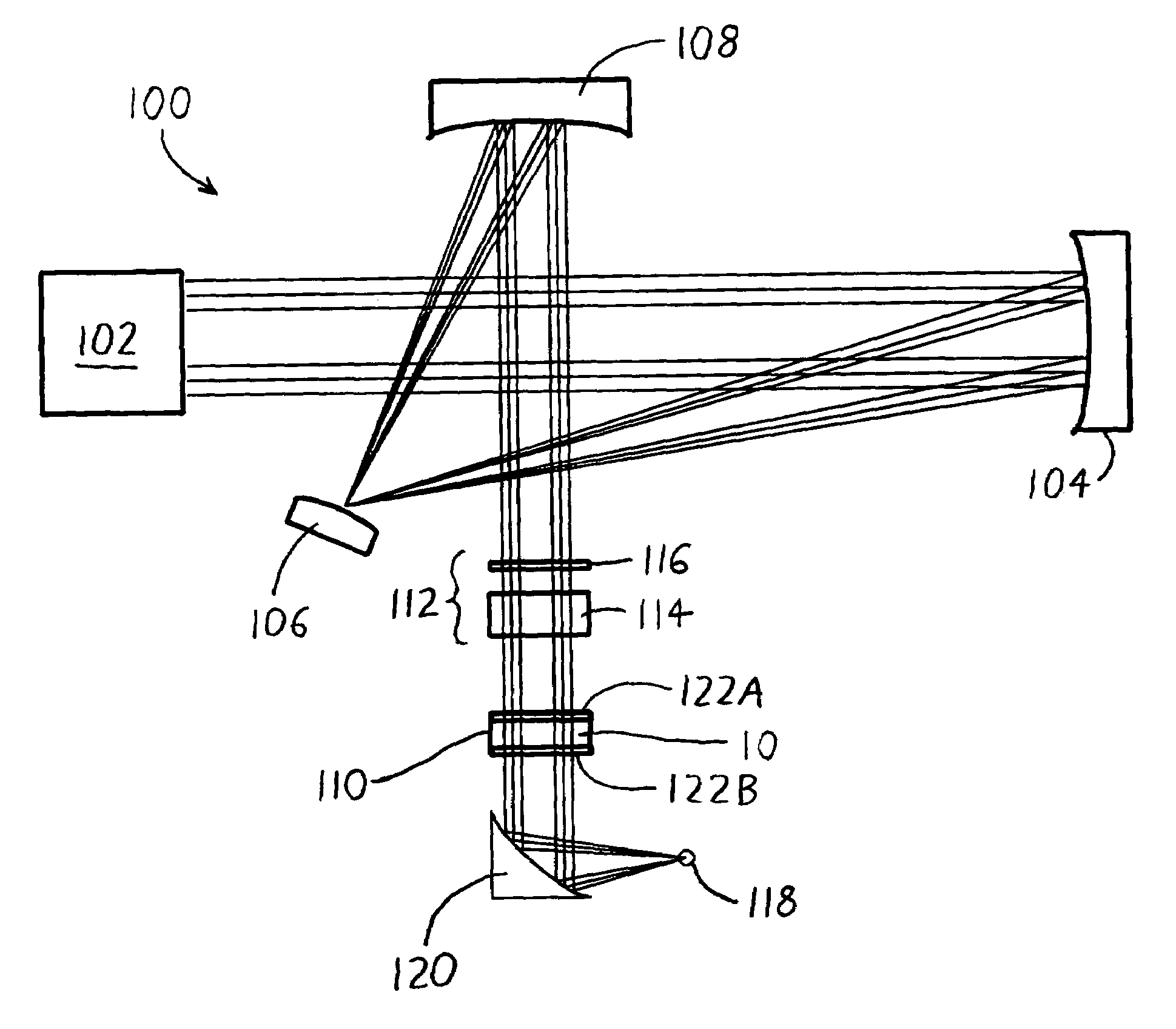

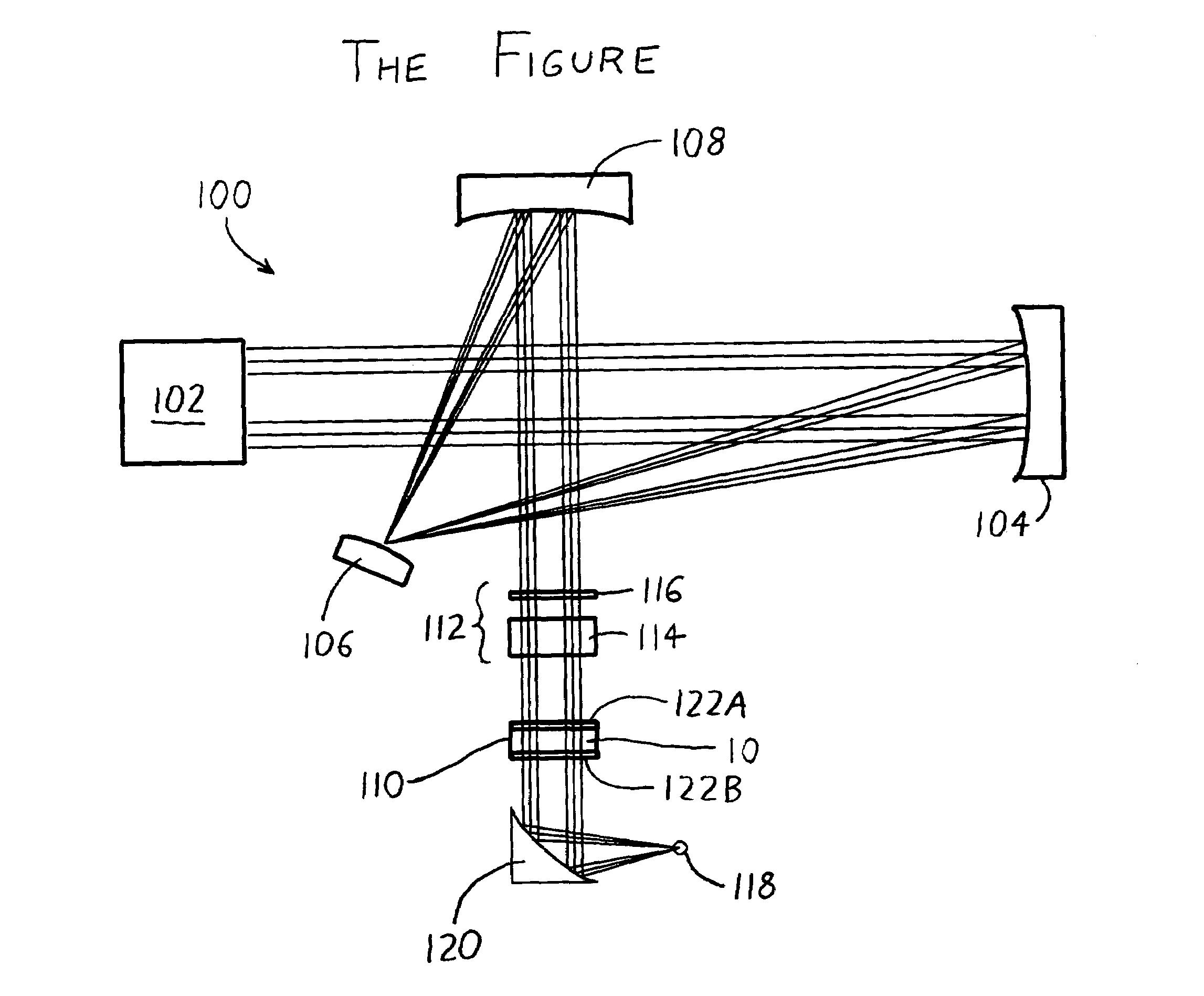

Vibrational circular dichroism spectrometer using reflective optics

InactiveUS20070222988A1Optimization rangeHigh strengthRadiation pyrometryPolarisation spectroscopySignal-to-noise ratio (imaging)Catoptrics

A spectrometer generates Vibrational Circular Dichroism (VCD) measurements having an exceedingly high signal-to-noise ratio, as well as a greater wavelength range over which measurements may be accurately provided. This is achieved by utilizing reflective optics (preferably solely reflective optics, i.e., no refractive elements) to supply a concentrated and collimated input light beam to a sample within a sample cell, and similarly collecting the light output from the sample cell via reflective optics for supply to a detector.

Owner:THERMO ELECTRONICS SCI INSTR LLC

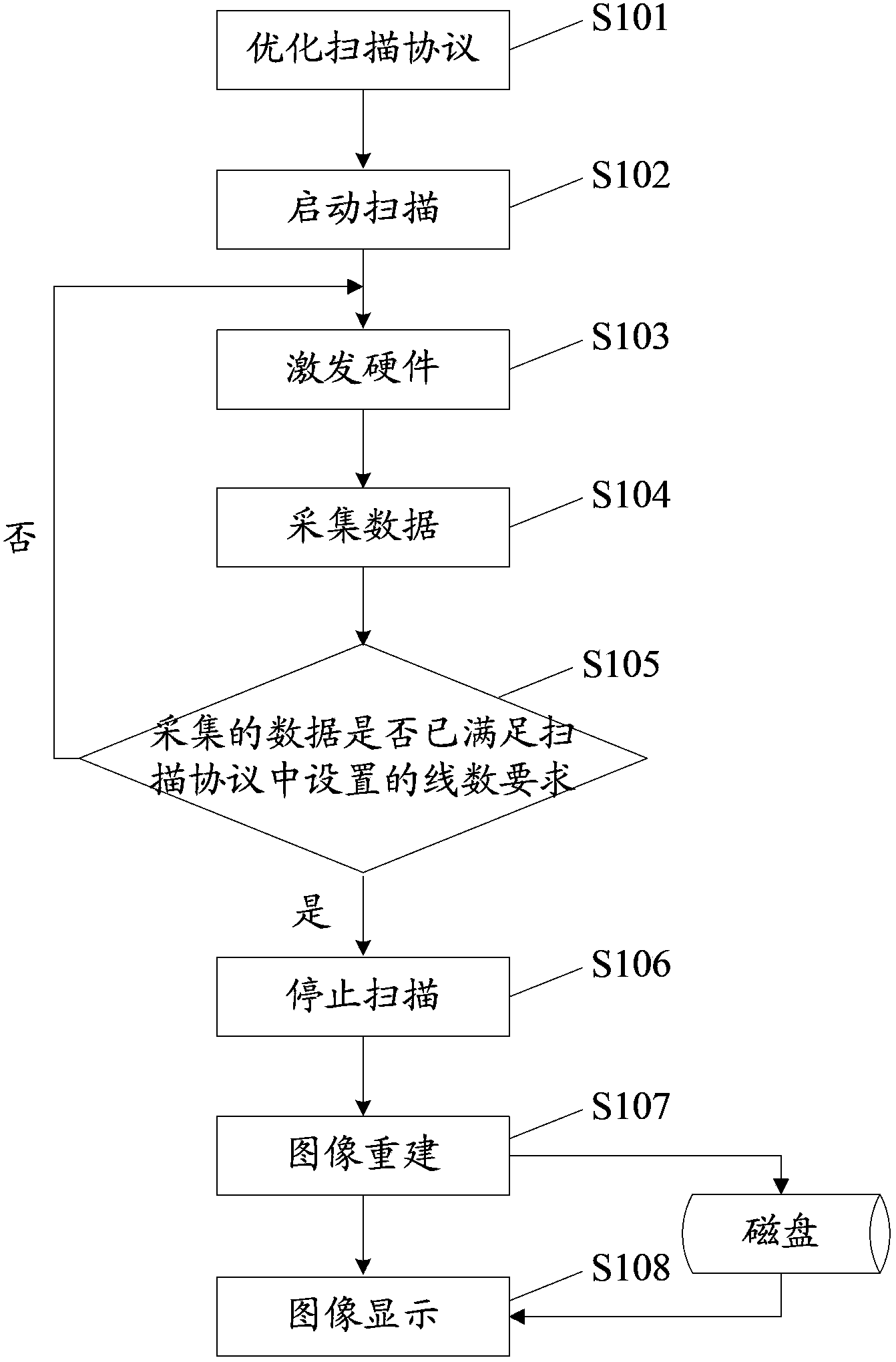

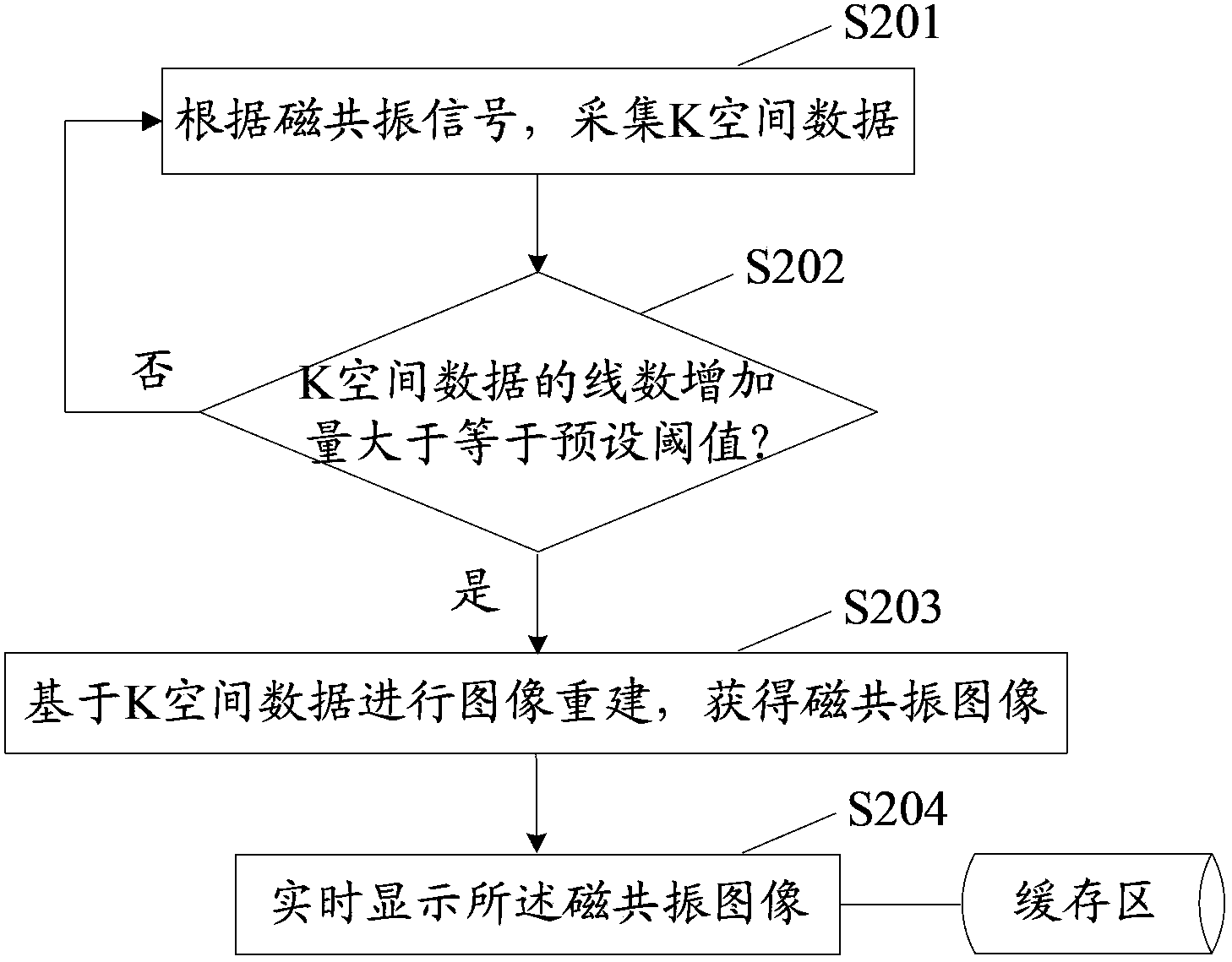

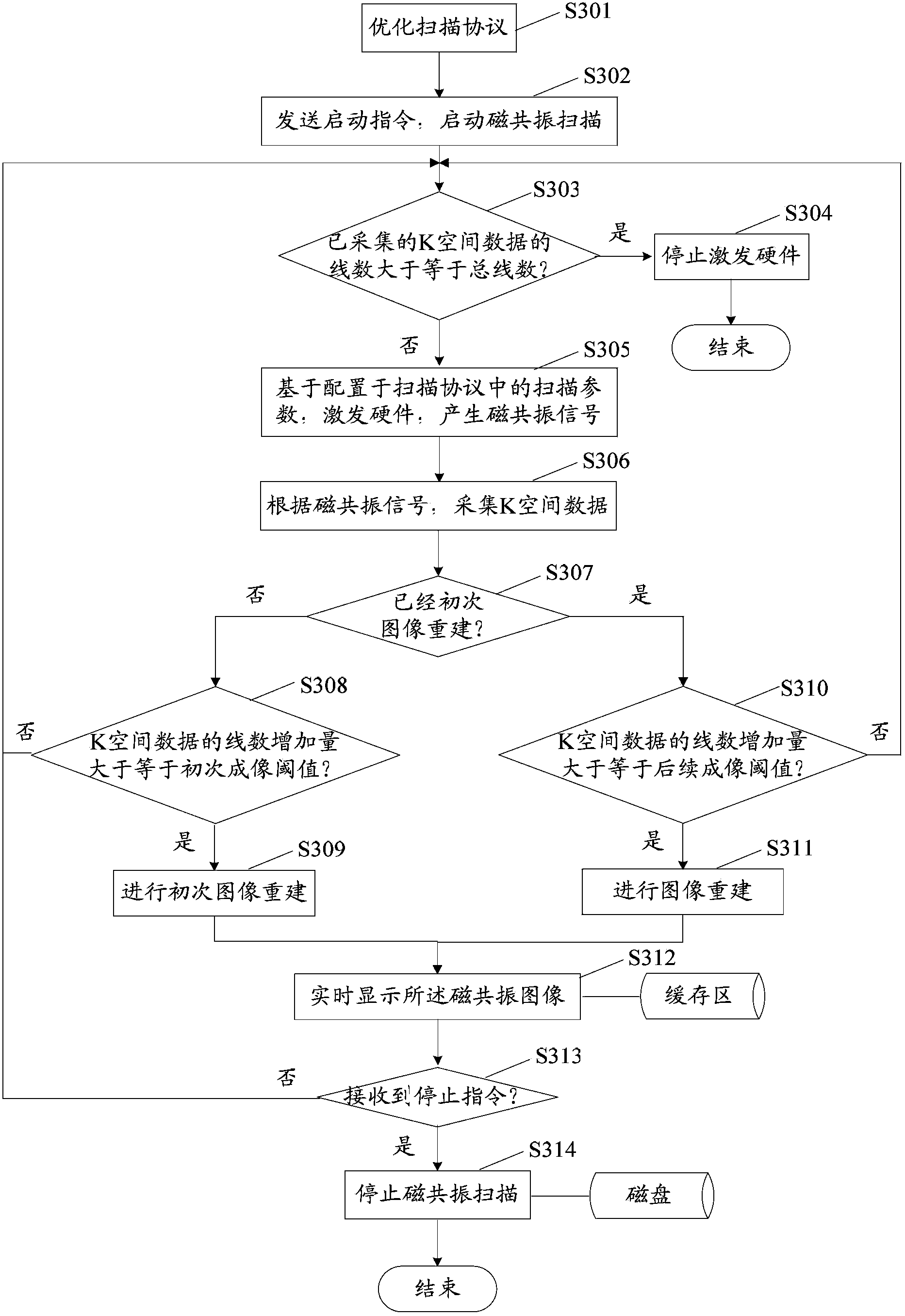

Magnetic resonance scanning imaging method and system

ActiveCN103901379AEasy to intervene and correctAvoid wastingMeasurements using NMR imaging systemsImaging qualityMri image

Provided are a magnetic resonance scanning imaging method and system. The method comprises the steps that according to magnetic resonance signals, K space data are collected; when the linear increment of the K space data is larger than or equal to a preset threshold value, based on the K space data, image reestablishing is carried out, and magnetic resonance images are obtained; and the magnetic resonance images are displayed in real time. The system comprises a sampling unit, a judging unit, an image reestablishing unit and an image displaying unit. The influence on scanning imaging speed caused by the fact that scanning parameters are not properly configured is avoided or lowered, and on the basis that the image quality requirement is met, scanning imaging speed is increased.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

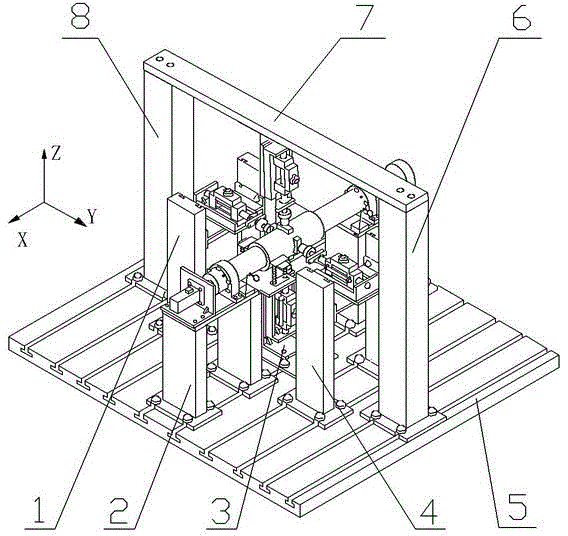

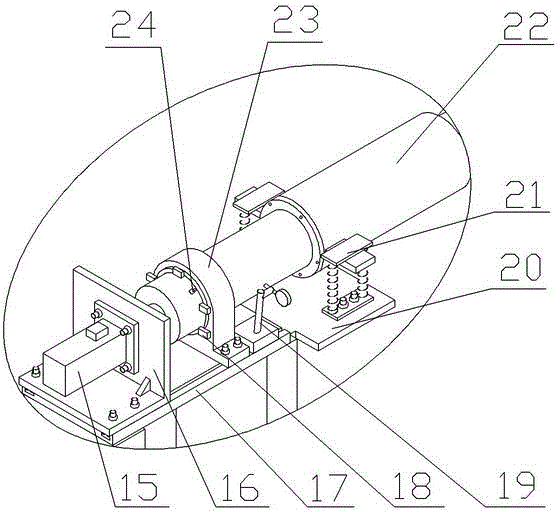

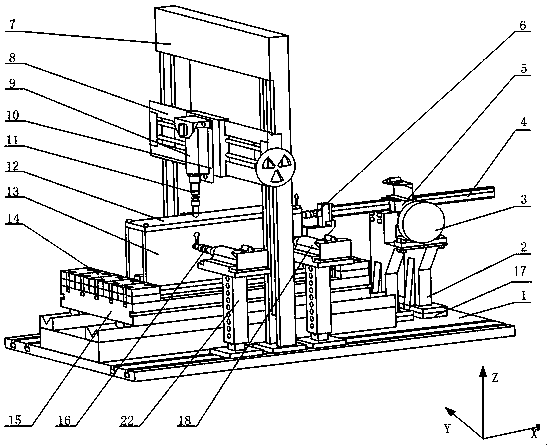

Reliability test platform for radial hydrostatic bearing

ActiveCN104677633AEasy to loadReal-time fault data collectionMachine bearings testingAutomatic controlTest platform

The invention discloses a reliability test platform for a radial hydrostatic bearing. The reliability test platform for the radial hydrostatic bearing comprises a test platform support, a radial hydrostatic bearing assisting device, a regular Z-directional loading device, a negative Z-directional loading device, a regular Y-directional loading device, a negative Y-directional loading device and an automatic control device. According to the test platform, four sets of hydraulic loading devices are adopted to simulate dynamic and static pressure load of the radial hydrostatic bearing as well as loading within 360 degrees in the radial direction; the reliability test simulating the real working condition is performed for the tested radial hydrostatic bearing; in addition, the fault data are acquired in real time; therefore, practical foundation data are provided for later reliability evaluation, reliability modeling and reliability predicating, and as a result, the data acquiring time can be greatly shortened.

Owner:JILIN UNIV

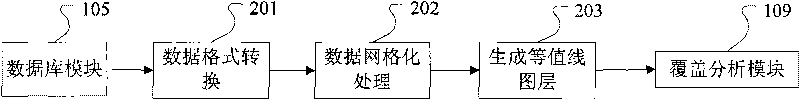

Electromagnetic wave automatic monitoring and analysis system based on GIS

InactiveCN101706536AReduce data collection timeEasy to compare and queryElectromagentic field characteristicsReal time acquisitionElectronic map

The invention provides a GIS-based electromagnetic wave automatic monitoring and analysis system, which comprises an electromagnetic wave field intensity indicator data acquisition and processing module, a manual input module, a GPS data acquisition and processing module, a real-time curve module, a database module, an electronic map display module, a data display module, an isoline module and a cover analysis module. The system realizes the real-time receiving and coverage analysis of electromagnetic signals, can complete the real-time acquisition process of the field intensity data and space orientation data, draws the real-time curve of the field intensity along with the change of time, and monitors the display of the driving track of a vehicle and the drawing of an overlay of the field intensity. Field intensity monitoring equipment, geographic information and the database are integrated on the monitoring vehicle so as to complete the automatic real-time acquisition and analysis work of the information, thus greatly shortening the data acquisition time and drawing accuracy, and being beneficial to the comparison and inquiry on historical data.

Owner:SHANDONG UNIV

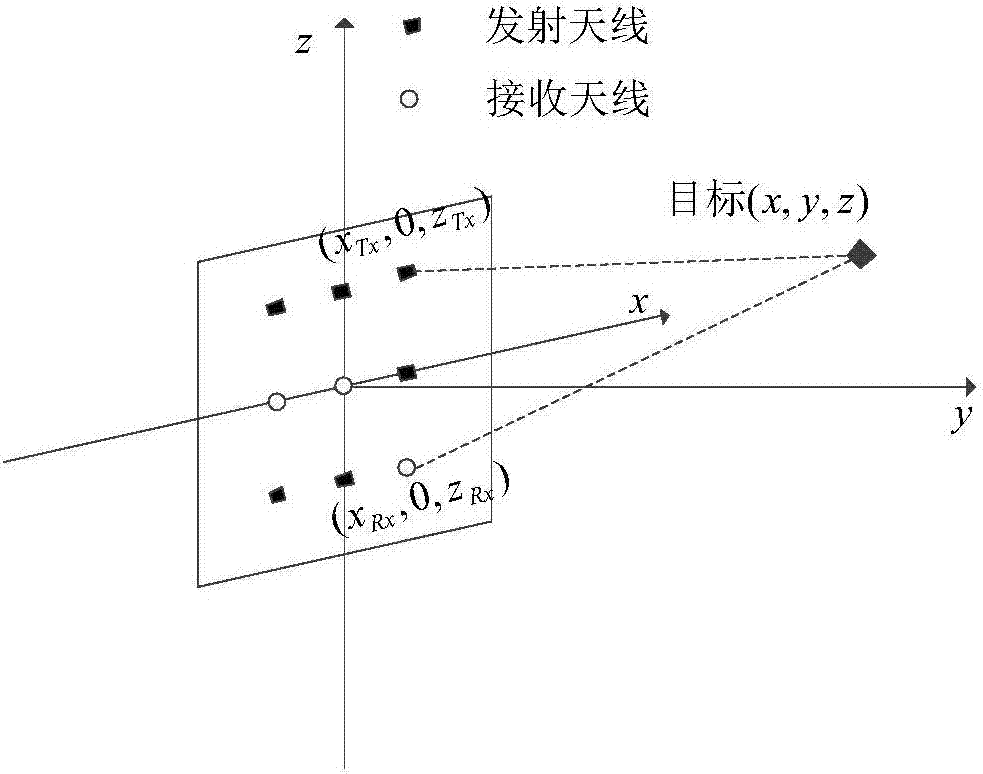

RCS extrapolation method based on near field MIMO imaging

InactiveCN107092017AReduce testing costsReduce data collection timeRadio wave reradiation/reflectionData acquisitionEngineering

The invention discloses an RCS extrapolation method based on near field MIMO imaging, belonging to the technical field of electronics. The building of a large anechoic chamber is not needed, and the testing cost is greatly saved. Compared with traditional RCS extrapolation technology, the near field MIMO imaging technology is used in the invention, a data acquisition time is significantly reduced, the testing speed is improved, and the application range is wider.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Vibrational circular dichroism spectrometer using reflective optics

InactiveUS7456956B2Optimization rangeHigh strengthRadiation pyrometryPolarisation spectroscopyCatoptricsSignal-to-noise ratio (imaging)

A spectrometer generates Vibrational Circular Dichroism (VCD) measurements having an exceedingly high signal-to-noise ratio, as well as a greater wavelength range over which measurements may be accurately provided. This is achieved by utilizing reflective optics (preferably solely reflective optics, i.e., no refractive elements) to supply a concentrated and collimated input light beam to a sample within a sample cell, and similarly collecting the light output from the sample cell via reflective optics for supply to a detector.

Owner:THERMO ELECTRONICS SCI INSTR LLC

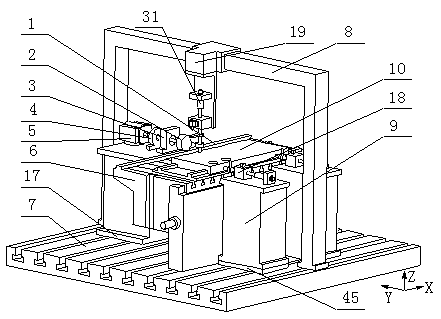

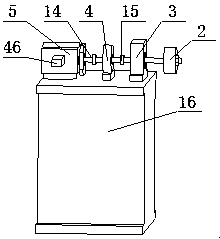

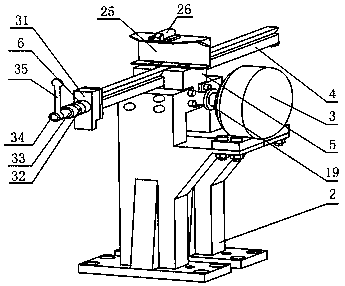

System for testing reliability of transverse working table of traverse-head contour shaping machine

ActiveCN107894332AReduce data collection timeReduce acquisition timeMachine part testingTorque sensorTesting reliability

The invention belongs to the technical field of mechanical machining equipment reliability tests, and relates to a system for testing the reliability of a transverse working table of a traverse-head contour shaping machine for simulating dynamic and static cutting loads. The defect that the loading reliability test problem of a transverse working table of a traverse-head contour shaping machine ina simulated actual working condition cannot be realized by an existing reliability test device in the prior art can be overcome. The system comprises a X-direction loading part, a Y-direction loadingpart, a Z-direction loading part and a loading auxiliary part. The X-direction loading part comprises a rack, a gear, a torque sensor and a hydraulic pump. The Y-direction loading part comprises twosets of Y-direction piezoelectric ceramic loading devices. One set of the Y-direction piezoelectric ceramic loading device is installed at the right upper corner position of a to-be-tested workbench.The other set of the Y-direction piezoelectric ceramic loading device is installed at the right lower corner position of the to-be-tested workbench. The Z-direction loading part comprises a Z-direction piezoelectric ceramic actuator, a Z-direction tension and pressure sensor, and a Z-direction linear bearing. The auxiliary loading workbench of the loading auxiliary part is fixed on the to-be-tested workbench.

Owner:BEIHUA UNIV

System and method for dense-stochastic-sampling imaging

ActiveCN102656442AReduce data collection timeReduce the number of intermediate imagesImage data processing detailsFluorescence/phosphorescenceIntermediate imageImaging processing

Embodiments of the present invention are directed to imaging technologies, and, in particular, to an imaging system that detects relatively weak signals, over time, and that uses the detected signals to determine the positions of signal emitters. Particular embodiments of the present invention are directed to methods and systems for imaging fluorophore-labeled samples in order to produce images of the sample at resolutions significantly greater than the diffraction-limited resolution associated with optical microscopy. Embodiments of the present invention employ overlapping-emitter-image disambiguation to allow data to be collected from densely arranged emitters, which significantly decreases the data-collection time for producing intermediate images as well as the number of intermediate images needed to computationally construct high-resolution final images.; Additional embodiments of the present invention employ hierarchical image-processing techniques to further resolve and interpret disambiguated images.

Owner:莱卡微系统 CMS +1

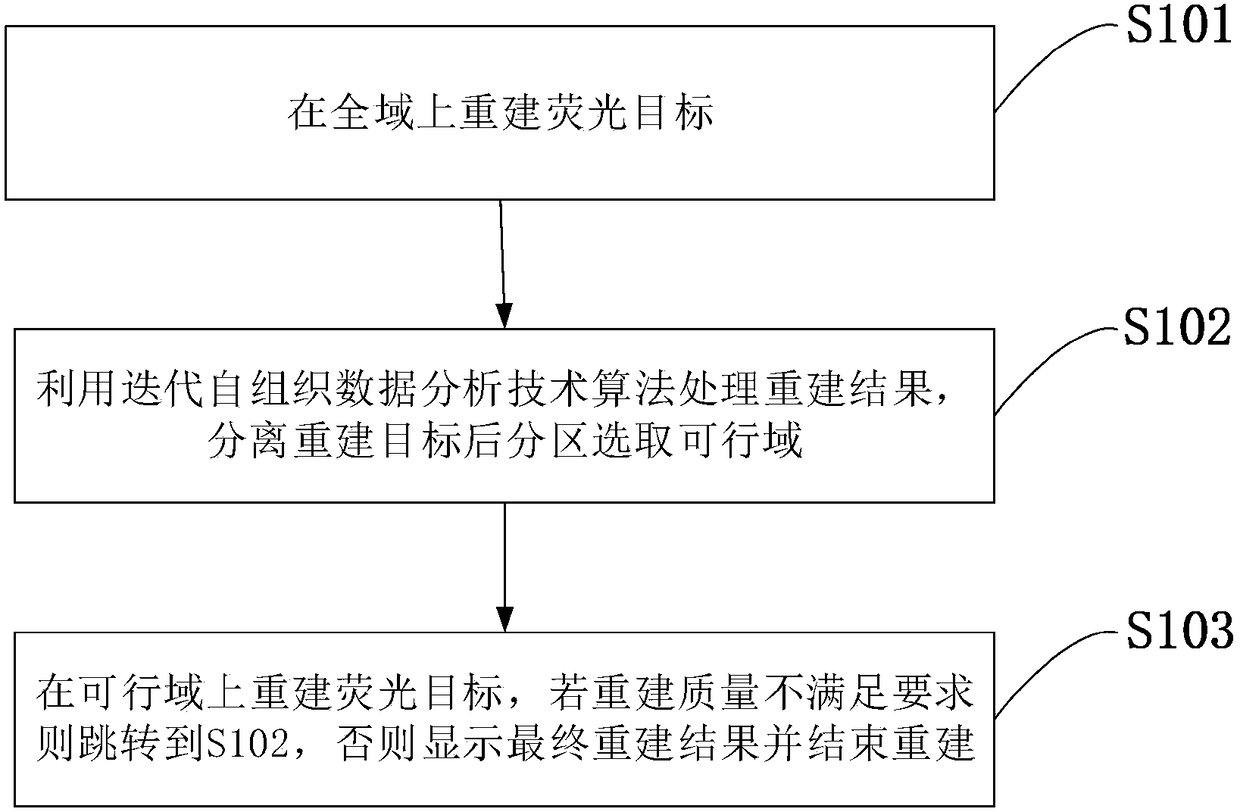

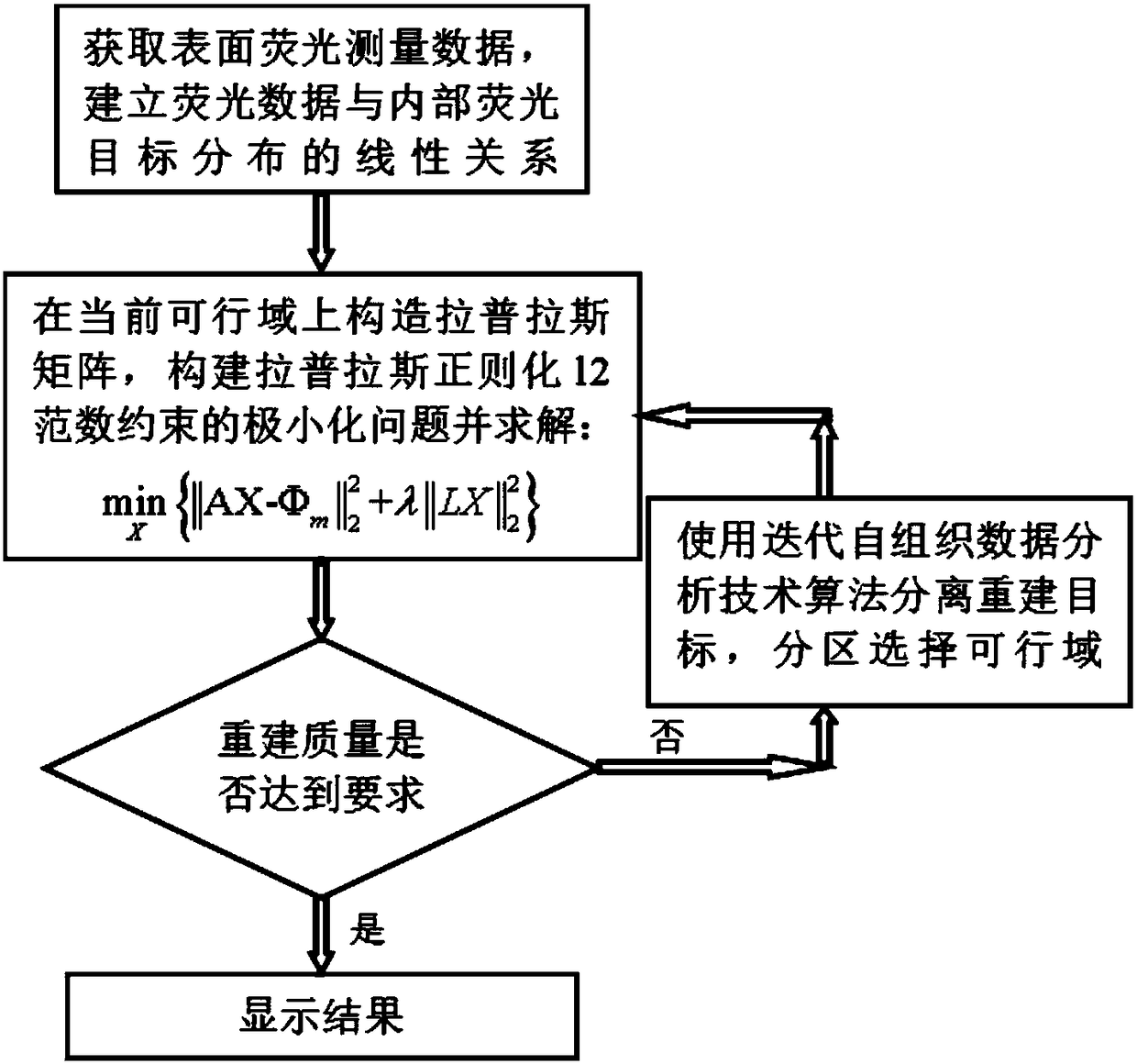

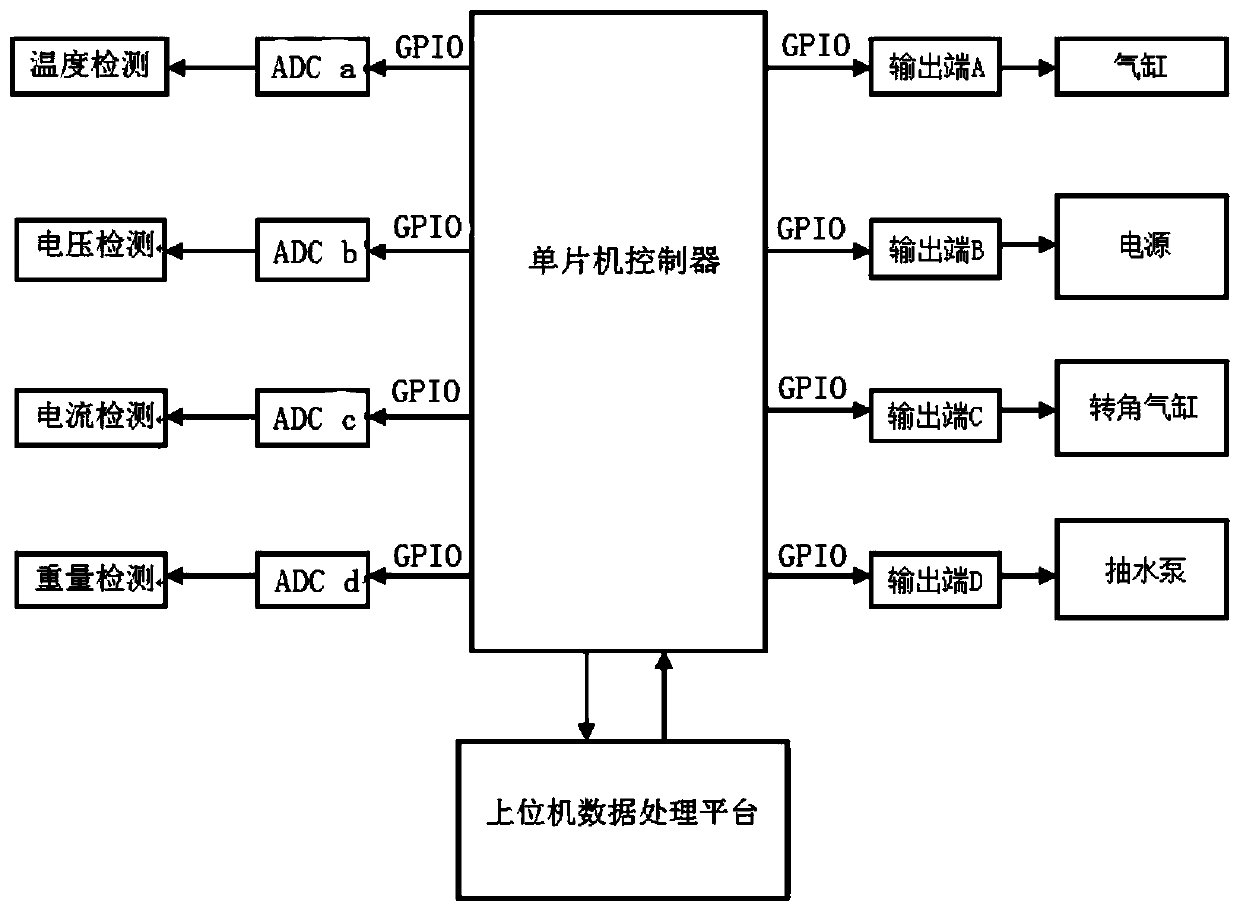

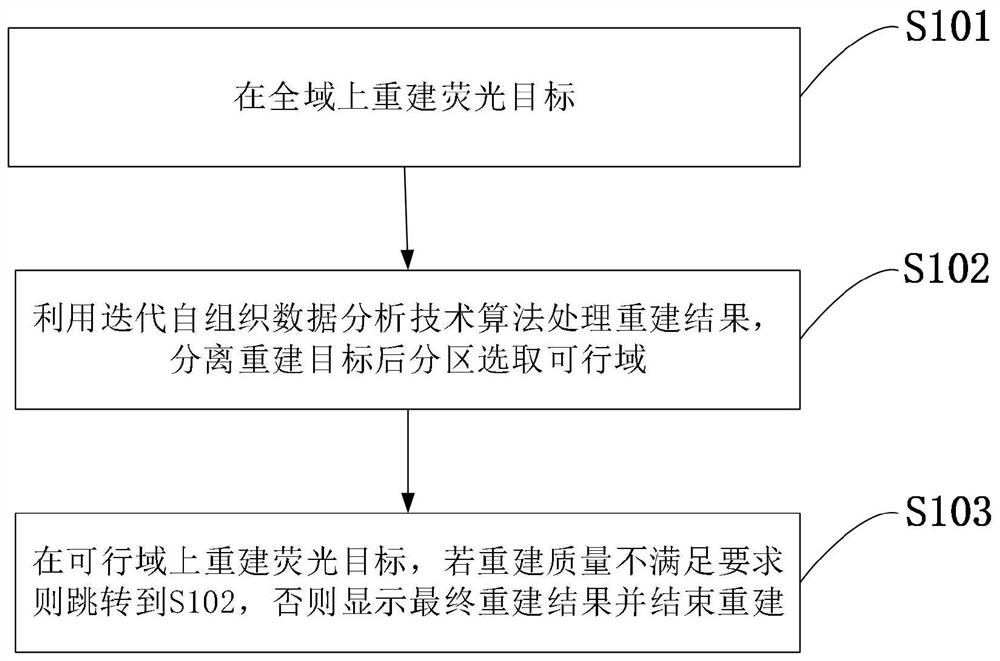

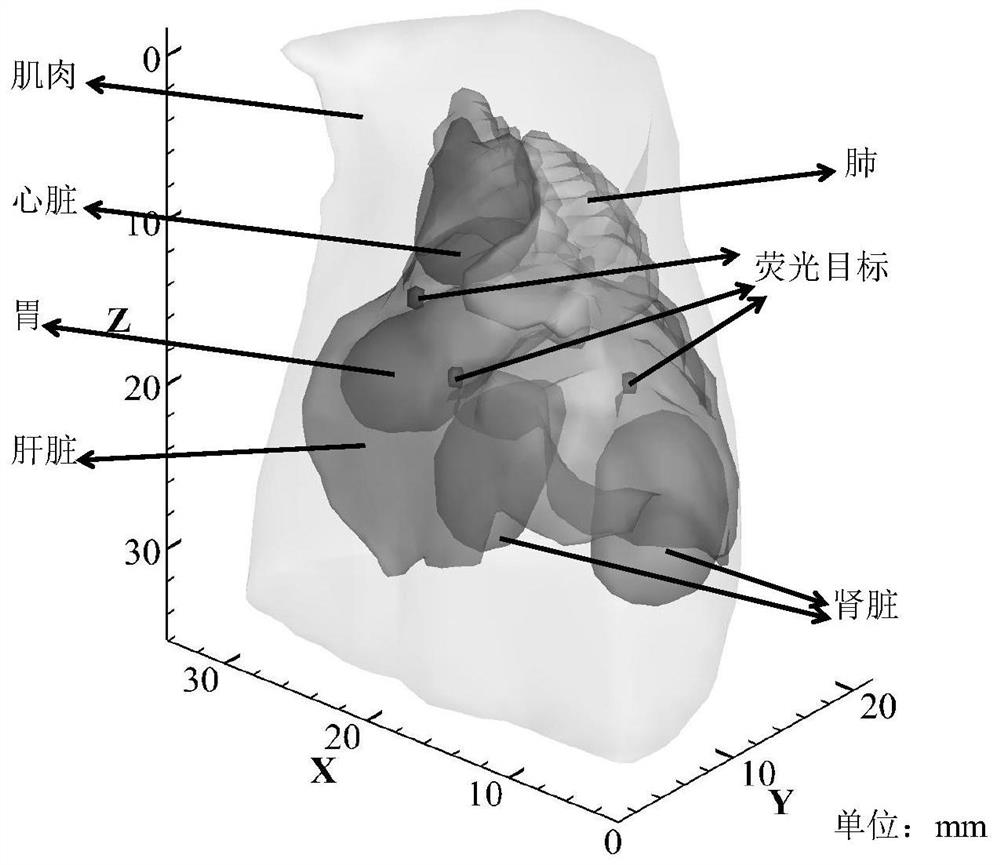

Method for selecting feasible regions of fluorescent molecular tomography objects

ActiveCN108095686AReduce data collection timeEnables real-time imaging and fast reconstructionDianostics using fluorescence emissionDiagnostics using tomographyFluorescencePhases of clinical research

The invention belongs to the technical field of molecular imaging, and discloses a method for selecting feasible regions of fluorescent molecular tomography objects. The method comprises the followingsteps: carrying out global reestablishment; selecting the feasible regions by using an iteration self-organization data analysis technology algorithm; reestablishing the fluorescent objects on the feasible regions, if the reestablishing quality can not satisfy the requirements, skipping to the iteration self-organization data analysis technology algorithm for selecting the feasible regions, otherwise, displaying the final reestablishment result, and finishing the reestablishment. The method is suitable for an optical molecular tomography imaging system for reestablishing multiple object fluorescence sources, the needed fluorescence measurement data is little, the iteration self-organization data analysis technology algorithm is adopted for carrying out partition selection of the feasibleregions, and thus the accuracy in selecting the feasible regions in the reestablishment of multiple objects is improved. According to the technical scheme, through multi-stage reestablishment, the pathogenicity of the reconstruction problem is reduced, the reestablishment quality of the fluorescent molecular tomography is effectively improved, and the method has the significant application value in the fields including the optical tomography three-dimensional reconstruction algorithm.

Owner:NORTHWEST UNIV

Heavy numerical control planing machine mobile workbench reliability test device

ActiveCN107830998AReduce data collection timeReal-time acquisitionMachine part testingAutomatic controlMagnetic powder

The invention relates to a heavy numerical control planing machine mobile workbench reliability test device, belongs to the technical field of heavy mechanical machining equipment reliability test, and overcomes the problem that only the no-load operation test or the field reliability test can be performed on the heavy numerical control planing machine at present. The test stand comprises a counterweight inertial loading part, a loading auxiliary part, an X-direction loading part, a Y-direction loading part, a Z-direction loading part and an automatic control part. X-direction, Y-direction andZ-direction high-frequency cutting force loading on the workbench can be realized by using the piezoelectric ceramic actuator, X-direction static and low-frequency cutting force loading on the workbench can be realized by using the magnetic powder brake and Y-direction and Z-direction static and low-frequency cutting force loading on the workbench can be realized by using the hydraulic servo oilcylinder.

Owner:BEIHUA UNIV

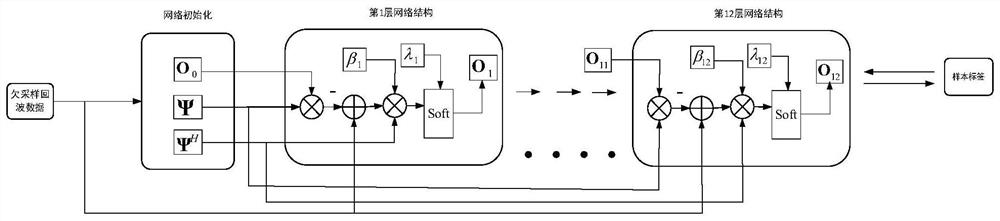

Ultra-wideband through-wall radar learning imaging method, device and system and readable storage medium

ActiveCN112198506ASave memoryReduce the amount of frequency domain data acquisitionRadio wave reradiation/reflectionNetwork modelFrequency domain

The embodiment of the invention relates to an ultra-wideband through-wall radar learning imaging method, device and system and a readable storage medium. The method comprises the following steps: acquiring echo scattering data of a hidden target; removing wall echo and noise of the echo scattering data; constructing a Fourier transform fast operator according to a diffraction tomography algorithm;constructing a compressed sensing sparse reconstruction model based on the echo scattering data and the Fourier transform fast operator; and expanding a sparse reconstruction iterative algorithm intoa multi-layer neural network structure, and training hyper-parameters in the network model through a training data set. Through the random downsampling of the echo data, the frequency domain data acquisition amount of the system is greatly reduced, and the data acquisition time of the system is reduced; a Fourier transform fast operator is constructed, so that the memory required by algorithm operation is reduced; through the data-driven intelligent learning of network model hyper-parameters, the calculation complexity is reduced, the limitation of iteration time consumption of a sparse reconstruction method is avoided, and the imaging quality is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Direction navigation method and device based on fingerprint recognition, and fingerprint image sensor

InactiveCN107563262AAccurate calculation of sliding speedSatisfy navigation needsCharacter and pattern recognitionInput/output processes for data processingPattern recognitionState variation

The invention relates to the field of integrated circuits, and provides a direction navigation method and device based on fingerprint recognition, and a fingerprint image sensor. The method comprisessteps of setting multiple navigation regions in a pixel region of the fingerprint sensor; scanning the navigation regions for many times successively, and correspondingly generating a group of navigation data for each scanning; according to each group of the navigation data, judging pressing states of each navigation region during each scanning; and according to change of the pressing states of the navigation region during the successive scanning, judging the navigation direction and executing navigation instructions. According to the invention, by setting the navigation regions in the sensor,and replacing the software with the hardware in a navigation data position reporting manner, the navigation direction is judged in an image comparison mode, so judgment of the navigation direction isachieved quite rapidly and precisely and precise calculation of finger sliding speed is achieved.

Owner:SHENZHEN CHIPSAILING TECH CO LTD

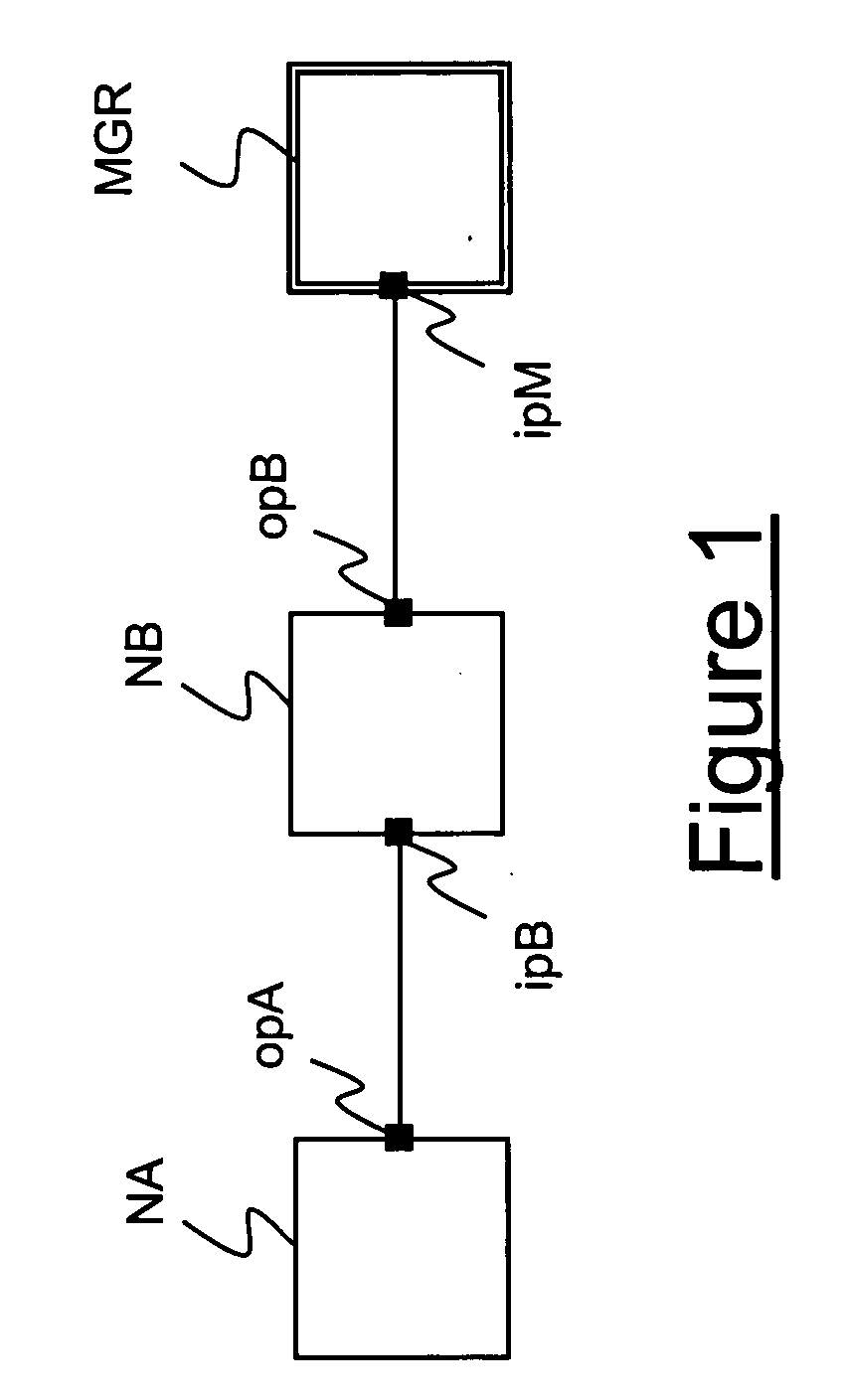

Data collection from network nodes in a telecommunication network

InactiveUS20070100853A1Reduce data collection timeDigital data processing detailsData switching networksTelecommunications networkData set

It is disclosed a method for collecting data from nodes of a telecommunication network, said network comprising a collecting node and an intermediate node, the method comprising the steps, which are performed by the intermediate node, of: receiving from said collecting node a first file comprising at least a first compressed data set and a first dictionary; generating a second file comprising at least a second compressed data set and a second dictionary; merging said first dictionary and said second dictionary into a resulting dictionary; and inserting said resulting dictionary, said first compressed data set and said second compressed data set into an overall file. Also disclosed are a network node and a network manager for implementing the method.

Owner:ALCATEL LUCENT SAS

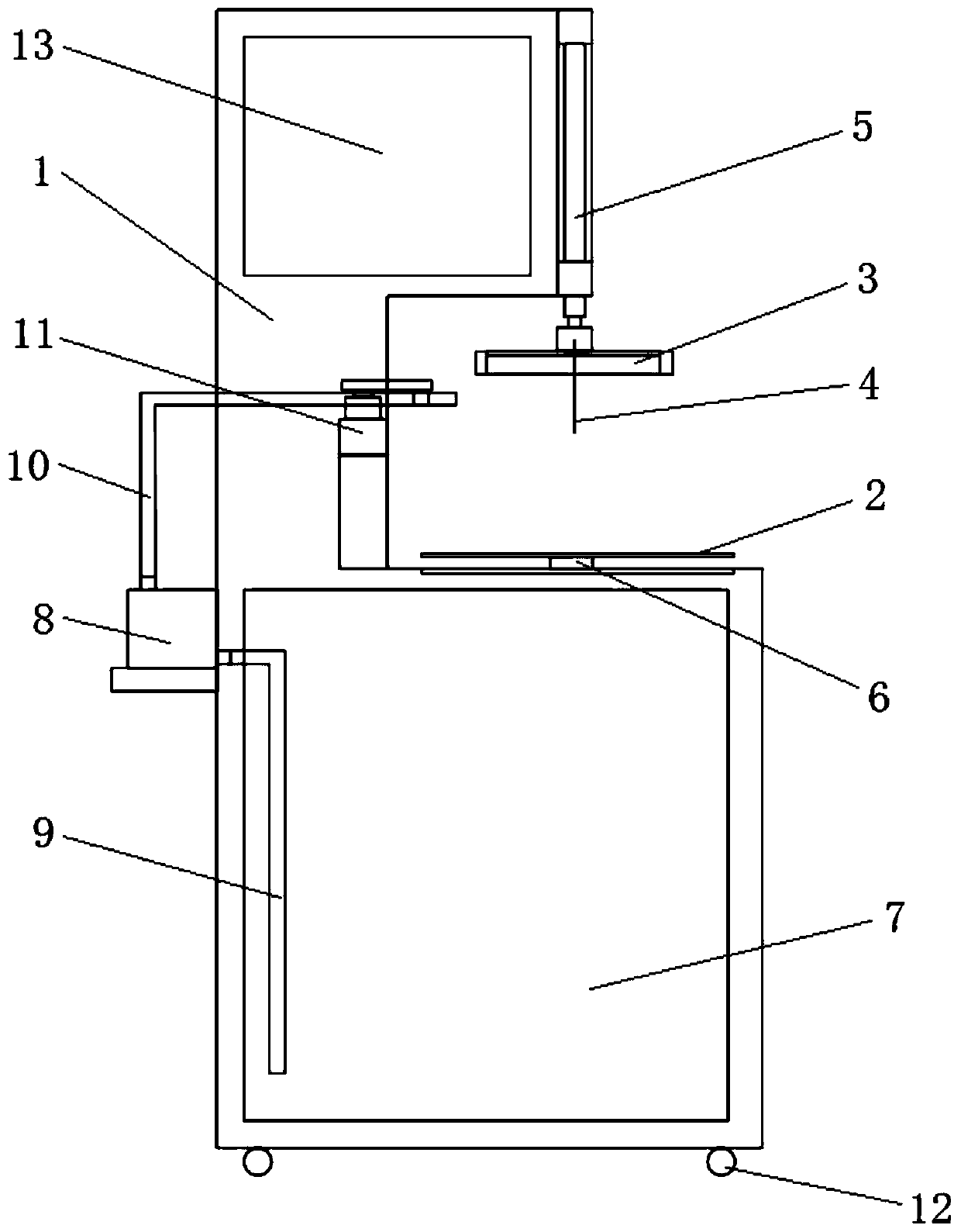

Intelligent detection device and system for energy efficiency of electric cooker

InactiveCN110926642AEasy to detectRealize functionThermometers using electric/magnetic elementsElectrical testingProcess engineeringElectric current flow

The invention relates to the technical field of electric cooker detection equipment, in particular to an intelligent detection device and a system for the energy efficiency of an electric cooker. Thedevice comprises a platform frame, the platform frame is provided with a placing plate used for horizontally placing the electric rice cooker, a cover body used for covering the electric rice cooker is arranged over the placing plate, and the cover body is movably arranged and moves up and down in the vertical direction; and a thermal resistance sensor for detecting the temperature of the inner container of the electric cooker is arranged at the bottom of the cover body. Meanwhile, the system is based on the device and comprises a controller, a temperature detection module, an electric quantity detection module and a weight detection module, and the temperature detection module, the electric quantity detection module and the weight detection module are electrically connected with the controller. The temperature detection module is controlled by the controller and used for detecting the temperature of water in an inner container of the electric cooker. The electric quantity detection module is controlled by the controller and comprises a current detection unit and a voltage detection unit which are respectively used for measuring the working current and the working voltage of the electric cooker; the weight detection module is controlled by the controller and used for measuring the weight of water in the electric cooker.

Owner:GUANGDONG OCEAN UNIVERSITY

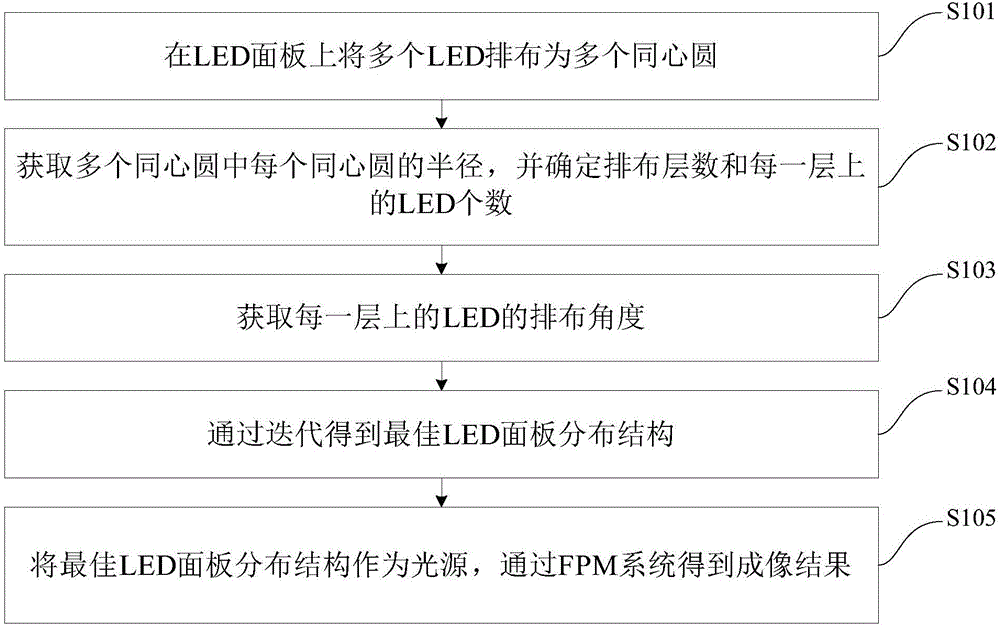

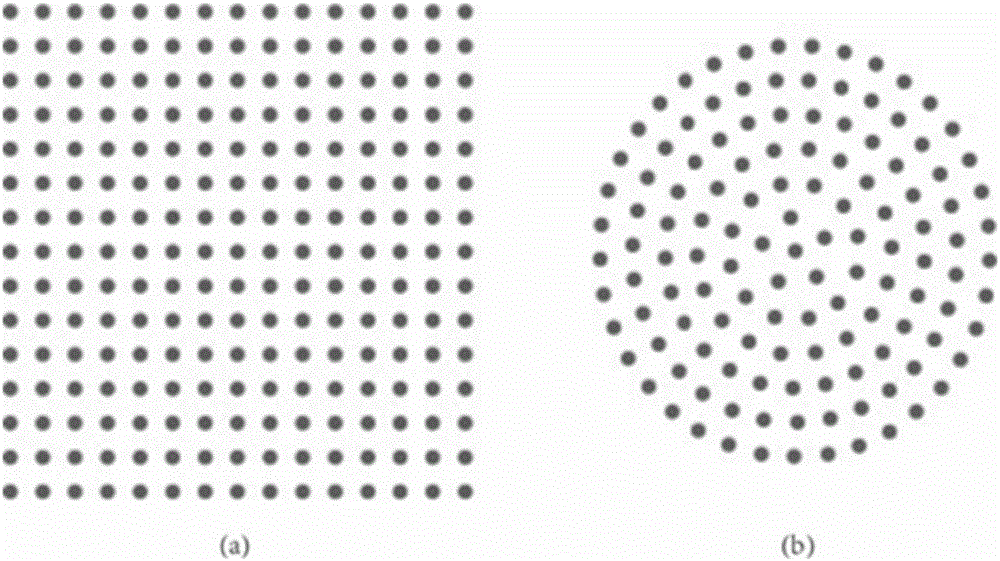

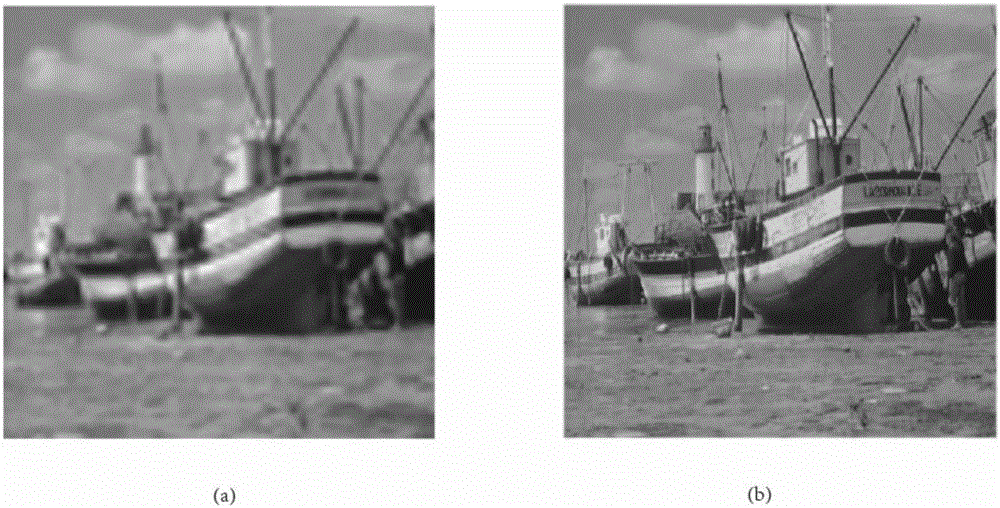

Method and system for wide view field micro-imaging based on FPM

The invention discloses a method and system for wide view field micro-imaging based on FPM. The method comprises the following steps: arranging a plurality of LEDs as a plurality of concentric circles on an LED panel; acquiring a radius of each concentric circle in the plurality of concentric circles and confirming the quantity of arranged layers and the quantity of the LEDs in each layer; acquiring the arranging angles of the LEDs in each layer; iterating, thereby acquiring an optimal LED panel distribution structure; taking the optimal LED panel distribution structure as a light source; and acquiring an imaging result through a frequency domain laminating splicing microscope FPM system. According to the method, a circular LED array is introduced, so that the exposure times are reduced, the imaging efficiency is increased, and the method is simple and is easily realized.

Owner:TSINGHUA UNIV

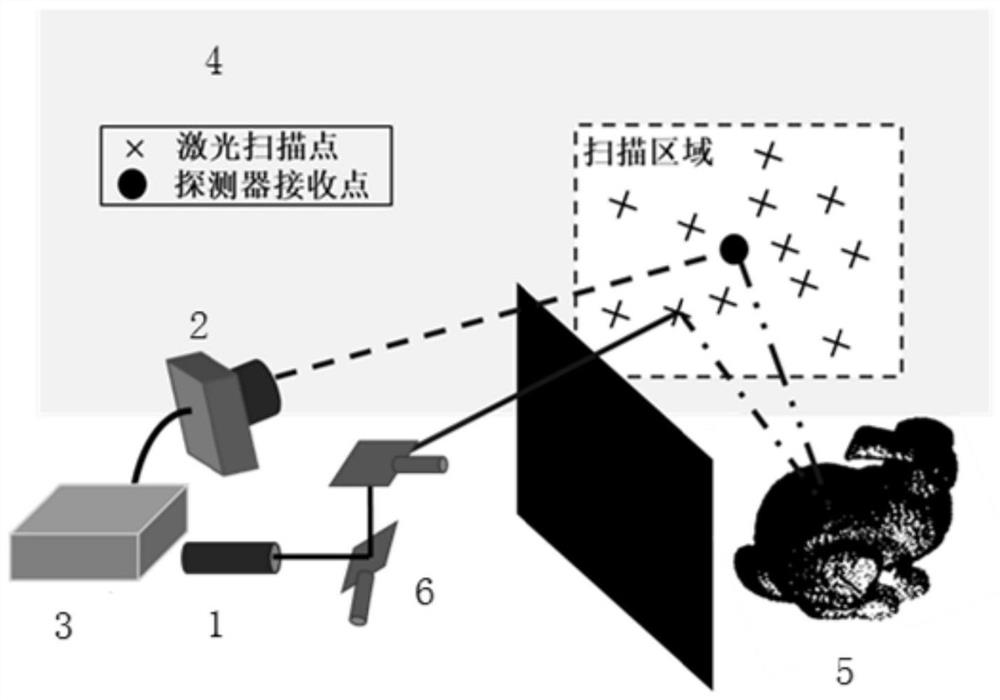

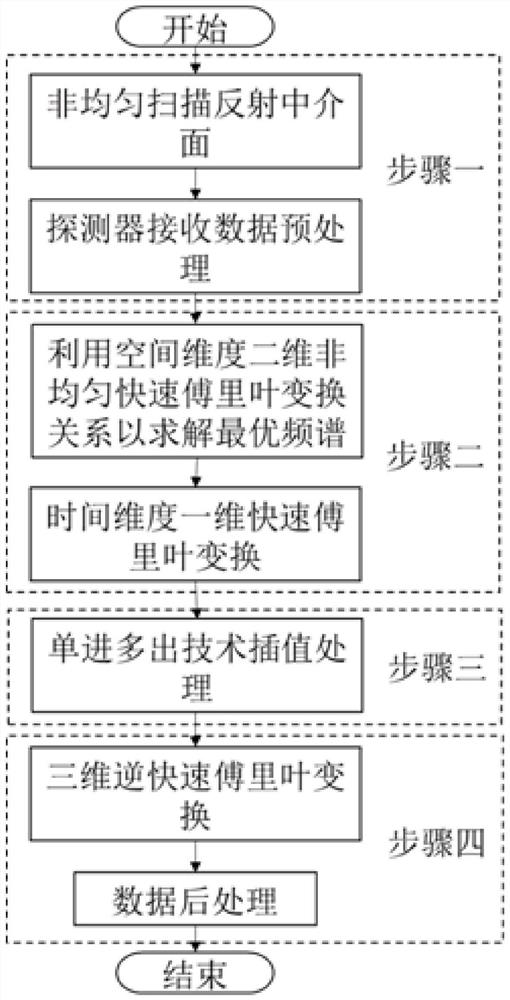

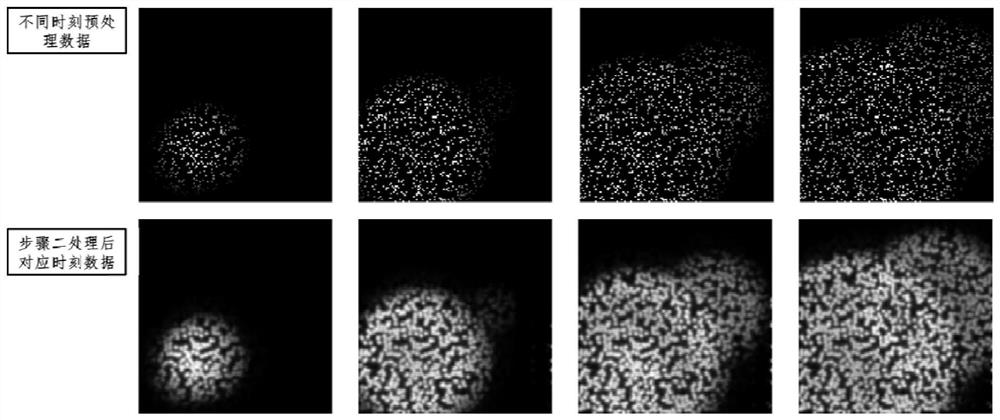

Non-visual-field single-input multiple-output three-dimensional reconstruction method for non-uniform fast Fourier transform

ActiveCN112540381AAvoid backprojection reconstructionIncrease speedElectromagnetic wave reradiationRapid imagingFast Fourier transform

The invention discloses a non-visual-field single-input multiple-output three-dimensional reconstruction method for non-uniform fast Fourier transform. A single-input multiple-output technology is introduced in the field of non-vision-field imaging for the first time, and an existing system is utilized to perform rapid imaging on a non-vision-field scene through non-uniform fast Fourier transform.The method comprises the following steps of non-uniformly scanning a reflection medium surface by adopting a laser, receiving a time-photon histogram of an echo by using a detector, preprocessing received data, and converting the received time-photon data into time-amplitude data, utilizing an optimization algorithm to solve the optimal time wave number spectrum for the preprocessed data througha two-dimensional non-uniform fast Fourier transform relation of the spatial dimension, and then performing one-dimensional fast Fourier transform on the time wave number spectrum in the time dimension, performing interpolation processing on the transformed frequency spectrum by using a single-input multi-output frequency domain algorithm, and performing inverse fast Fourier transform on the frequency spectrum after interpolation processing to obtain a non-vision-field scene three-dimensional reconstruction result.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

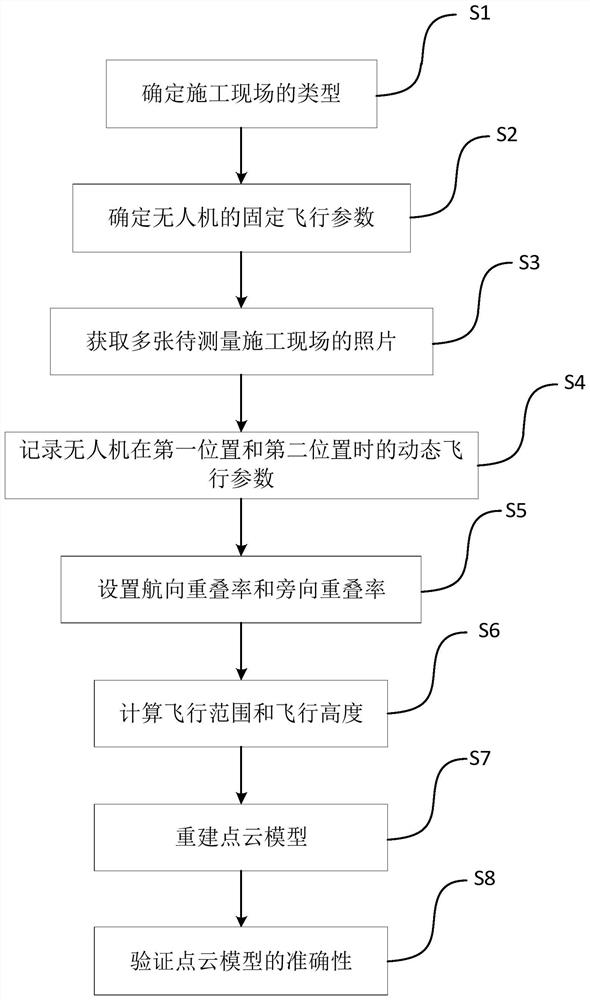

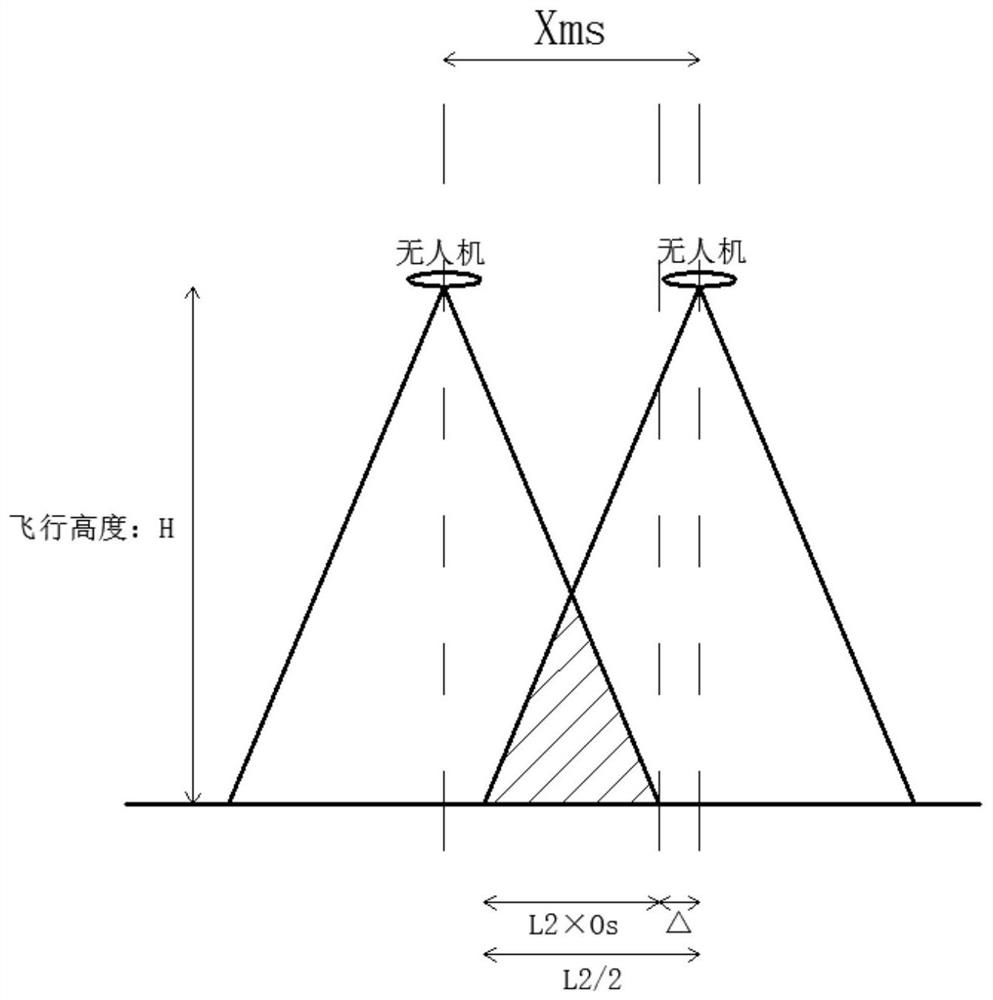

Single-lens unmanned aerial vehicle flight parameter setting method

ActiveCN111982076AReduce collectionReduce data collection timeNavigation instrumentsPicture interpretationFlight heightAerospace engineering

The invention discloses a single-lens unmanned aerial vehicle flight parameter setting method. The method comprises the steps of: determining the type of a construction site; acquiring a plurality ofpictures of a to-be-measured construction site; respectively recording dynamic flight parameters of the single-lens unmanned aerial vehicle at a first position and a second position in the heading direction and the lateral direction; calculating the course flight range, the lateral flight range and the flight height of the single-lens unmanned aerial vehicle; and establishing a point cloud model of the construction site according to the course flight range, the lateral flight range and the flight height set in the construction site. According to the method, the proper course flight range, theproper lateral flight range and the proper flight height are set according to different construction sites, the picture collection amount is reduced, the data collection time and the point cloud modelestablishing time are effectively shortened, the working efficiency is improved, and the established point cloud model meets the specification requirements and can be effectively applied to actual construction.

Owner:同炎数智科技(重庆)有限公司

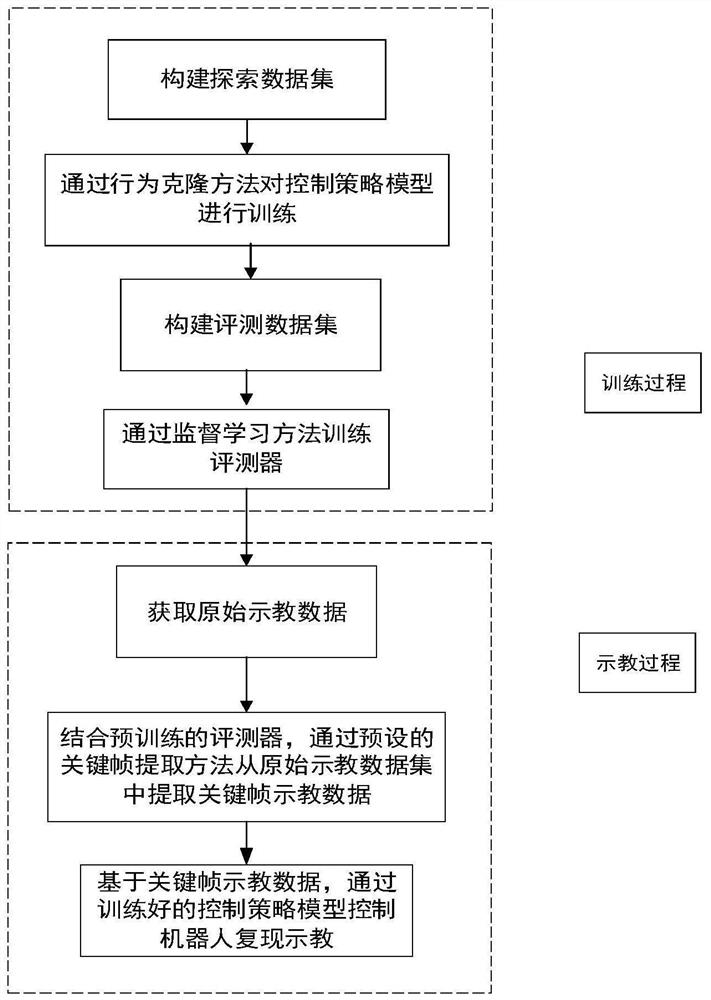

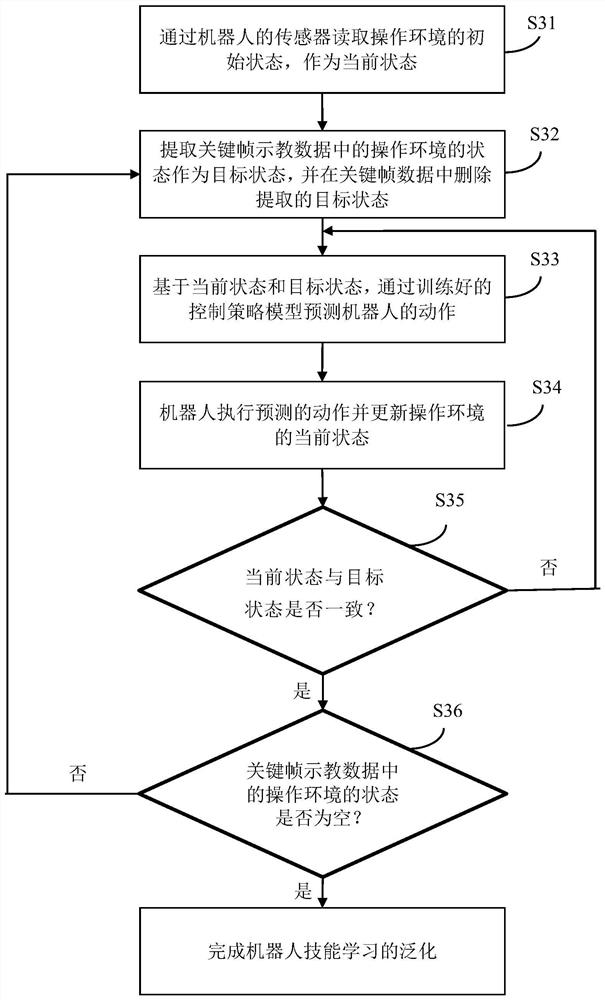

Quick imitation learning method, system and equipment for robot skill learning

ActiveCN113408621AImprove the efficiency of imitation learningSimplify the data collection processCharacter and pattern recognitionNeural architecturesData setSimulation

The invention belongs to the technical field of robots and artificial intelligence, particularly relates to a quick imitation learning method, system and equipment for robot skill learning, and aims to solve the problems that teaching data collection of an existing robot is time-consuming and complex, and when a demonstrator provides suboptimal teaching, the robot cannot optimize the execution process, and the teaching efficiency is high. The operation efficiency of the robot is reduced, and the operation time is prolonged. The system method comprises the following steps: collecting original teaching data; in combination with a pre-trained evaluator, extracting key frame teaching data from the original teaching data set through a preset key frame extraction method; and based on the key frame teaching data, controlling the robot to reproduce teaching through the trained control strategy model. According to the method, the data collection process during robot imitation learning can be simplified, the teaching track is optimized based on the performance of the robot control strategy model, the data collection time and the robot operation time are shortened, the efficiency of robot imitation learning is effectively improved, and the operation time is shortened.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

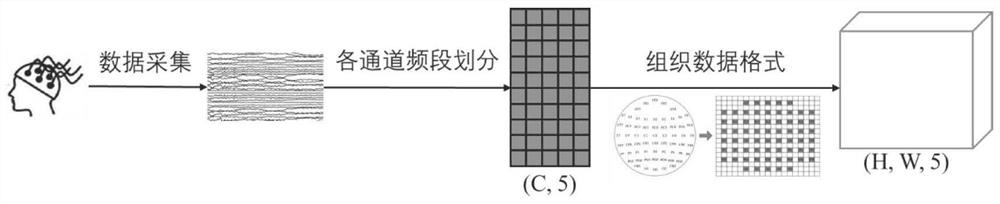

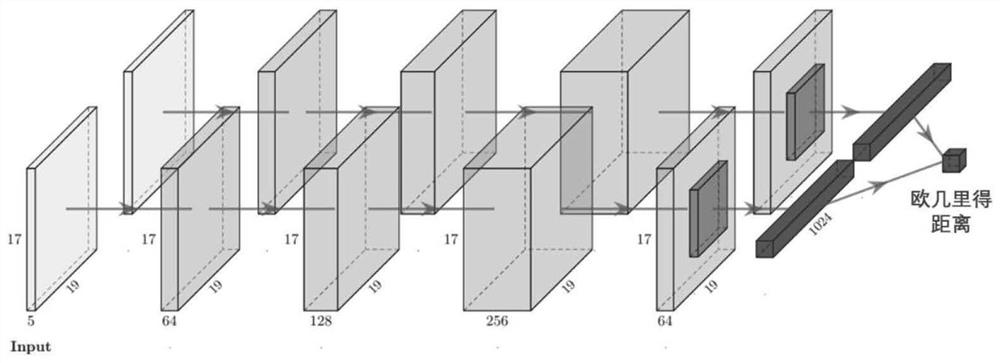

Cross-mode electroencephalogram signal identification method considering individual differences

PendingCN113627391AImprove practicalityAvoid negative promotionCharacter and pattern recognitionNeural architecturesPattern recognitionData set

The invention discloses a cross-mode electroencephalogram signal identification method considering individual differences. Unifying an electroencephalogram signal data format into a 3D tensor structure, then dividing electroencephalogram signals into a data set, and inputting the electroencephalogram signals into classifiers formed by branch networks for training so as to respectively extract background features and task features; using the extracted background features to calculate the similarity between different subjects, and screening data in the data set to avoid model negative lifting caused by electroencephalogram signal data of which a difference degree is greater than a threshold value in a training process; finally, inputting the screened data set into a multi-branch network model for training. According to the method, features of different subjects can be better extracted while a small amount of new subject data is collected as much as possible, so that the performance of the model in cross-subject tasks is improved.

Owner:HANGZHOU DIANZI UNIV

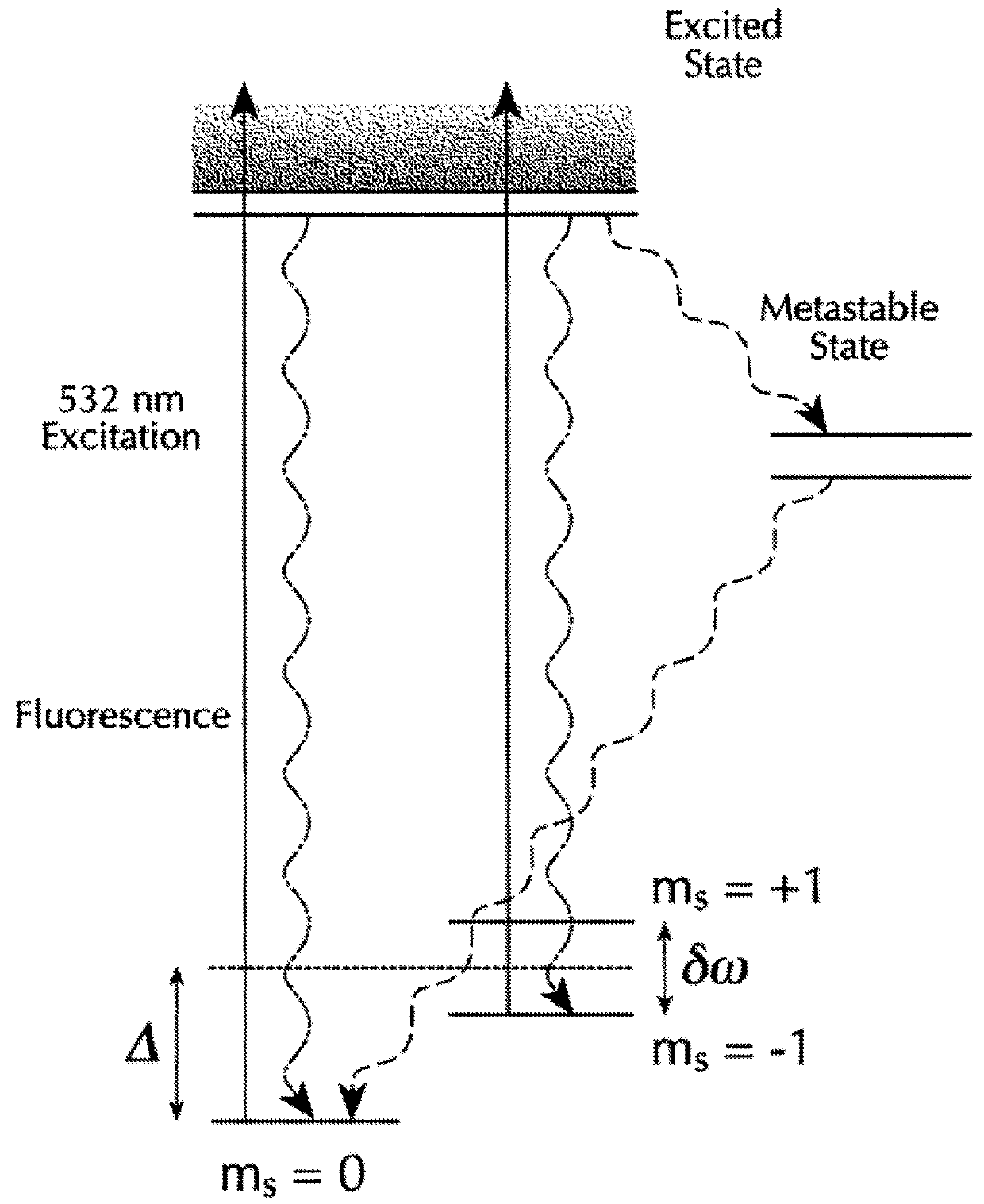

Nanoscale scanning sensors

ActiveUS10041971B2High sensitivityHigh resolutionMagnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesRelative motionFluorescent light

A sensing probe may be formed of a diamond material comprising one or more spin defects that are configured to emit fluorescent light and are located no more than 50 nm from a sensing surface of the sensing probe. The sensing probe may include an optical outcoupling structure formed by the diamond material and configured to optically guide the fluorescent light toward an output end of the optical outcoupling structure. An optical detector may detect the fluorescent light that is emitted from the spin defects and that exits through the output end of the optical outcoupling structure after being optically guided therethrough. A mounting system may hold the sensing probe and control a distance between the sensing surface of the sensing probe and a surface of a sample while permitting relative motion between the sensing surface and the sample surface.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

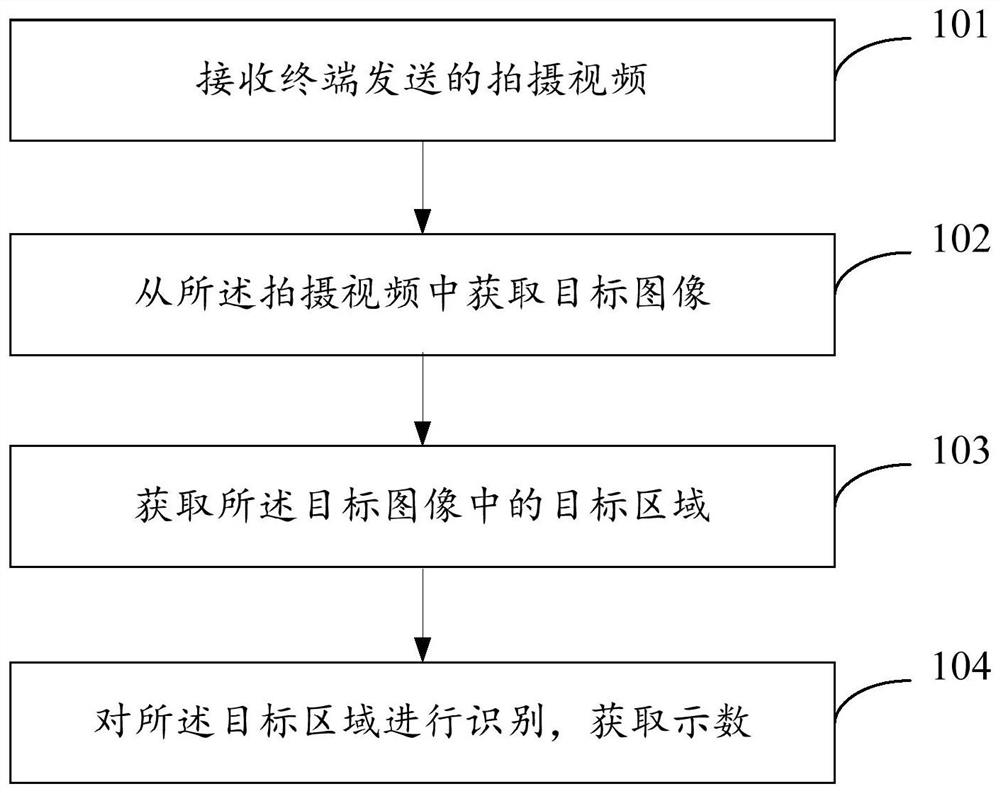

Meter reading method, meter reading device and electronic equipment

ActiveCN112770080AReduce data collection timeImprove meter reading efficiencyTelevision system detailsCharacter and pattern recognitionEmbedded systemElectricity meter

The invention provides a meter reading method, a meter reading device and electronic equipment. The method comprises the following steps: receiving a shot video sent by a terminal, wherein the shot video is obtained by shooting a display screen of a meter by the terminal; obtaining a target image from the shot video; obtaining a target area in the target image; and identifying the target area to obtain a reading. Therefore, the meter reading device can obtain the reading according to the shot video sent by the terminal, the time of a worker for carrying out data acquisition on the electricity meters one by one can be saved, and the meter reading efficiency is improved.

Owner:CHINA MOBILE M2M +1

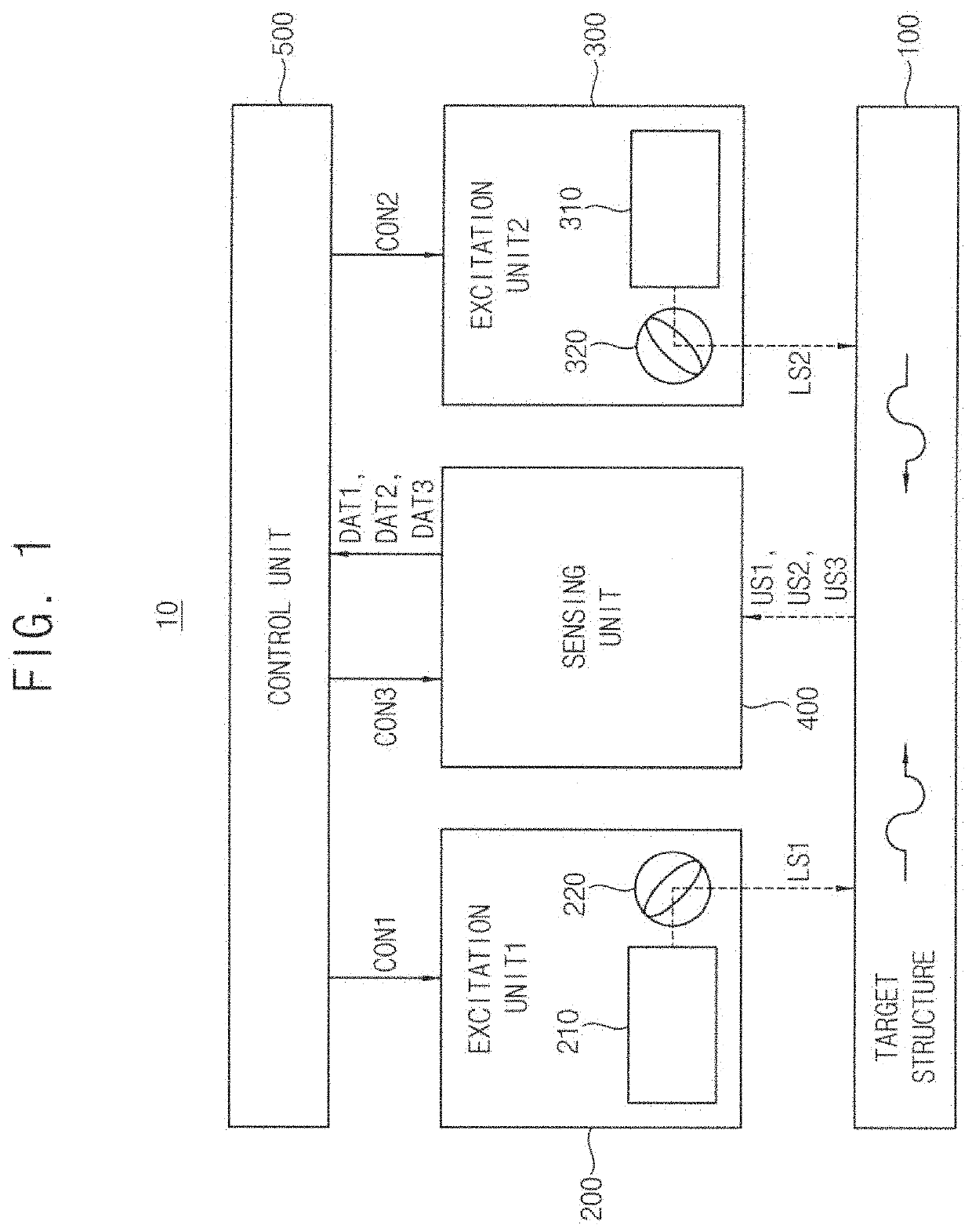

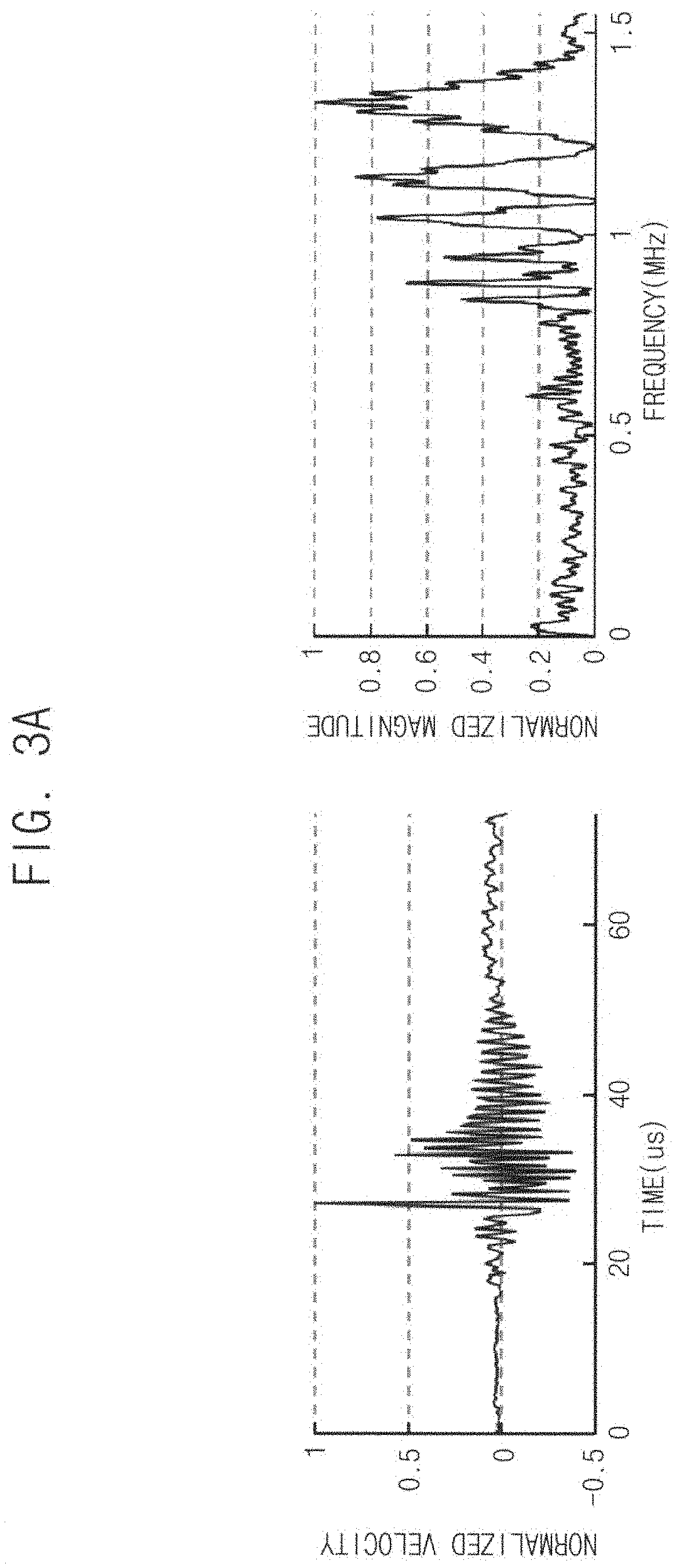

Method of inspecting structure and inspection system

ActiveUS20200011839A1Efficient inspectionEffective diagnosisAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationFrequency spectrumEngineering

In a method of inspecting a structure, a first ultrasonic signal generated from a target structure by a first laser beam is received. The first ultrasonic signal is generated by providing the first laser beam generated from a first excitation unit to the target structure. A second ultrasonic signal generated from the target structure by a second laser beam different from the first laser beam is received. The second ultrasonic signal is generated by providing the second laser beam generated from a second excitation unit to the target structure. A third ultrasonic signal generated from the target structure by the first and second laser beams is received. The third ultrasonic signal is generated by simultaneously providing the first and second laser beams to the target structure. It is determined whether the target structure is damaged based on first, second and third ultrasonic frequency spectra that are obtained by converting the first, second and third ultrasonic signals, respectively.

Owner:KOREA ADVANCED INST OF SCI & TECH

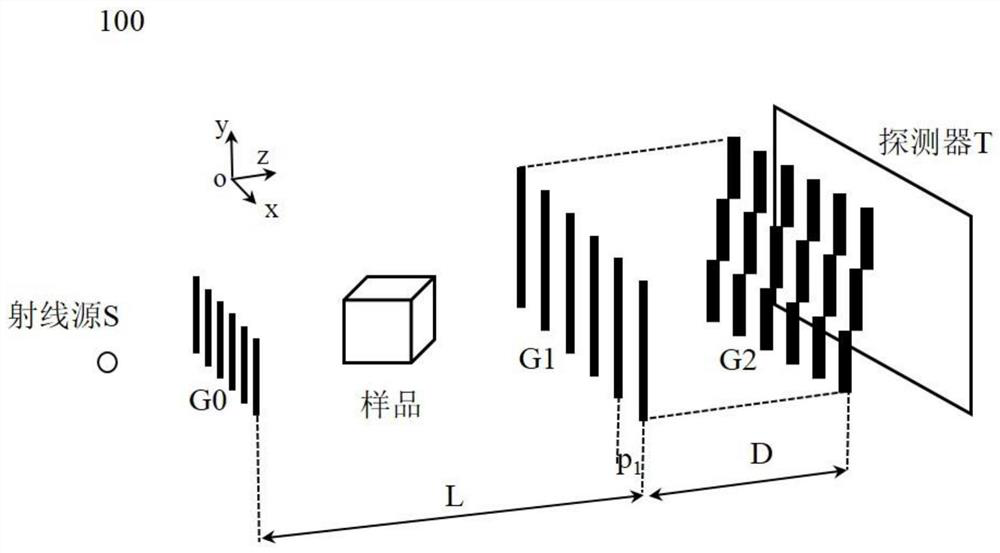

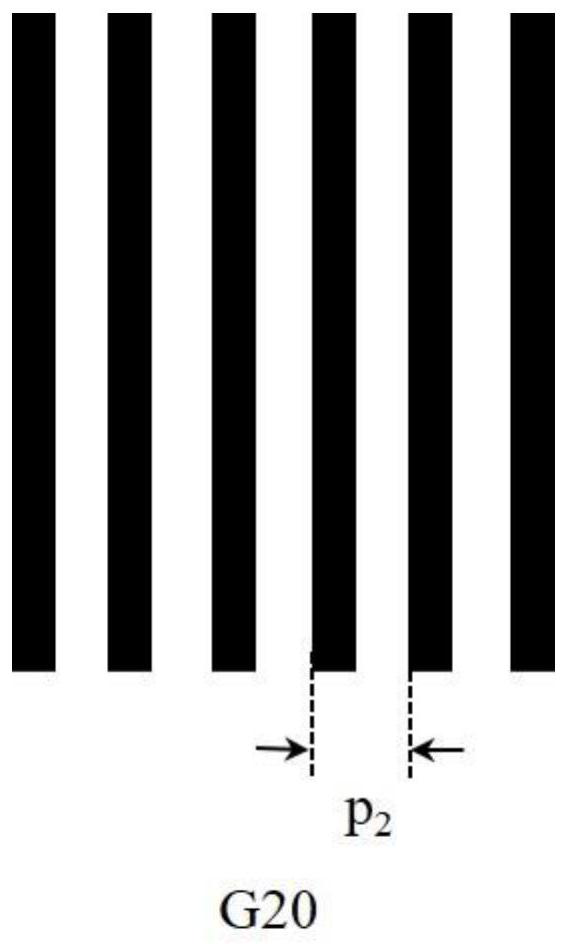

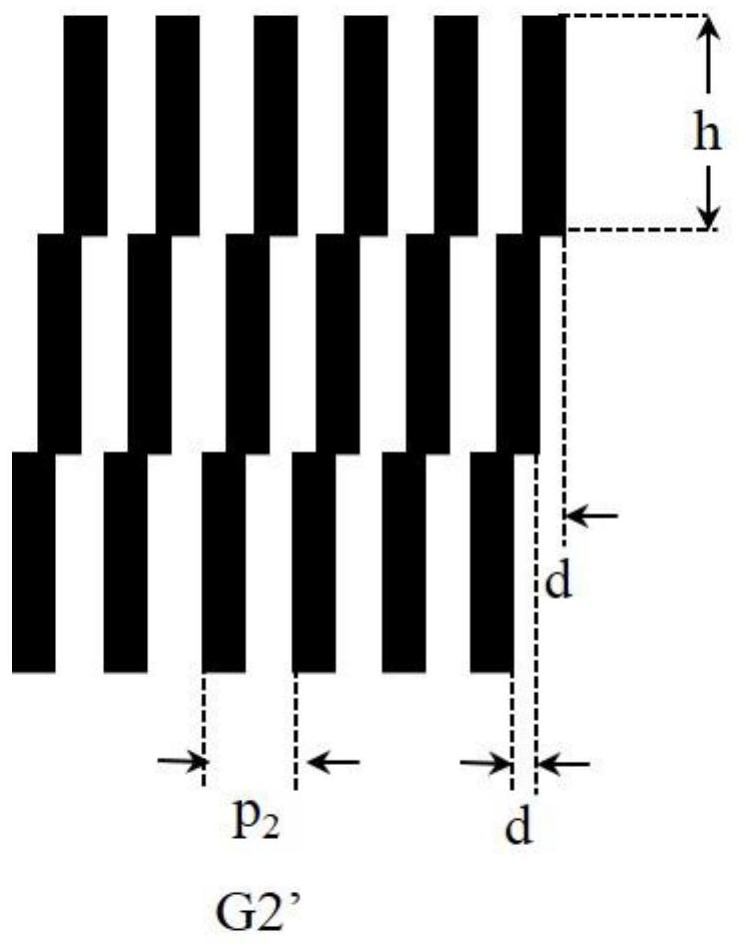

An optical phase contrast imaging system, method and computer readable medium

ActiveCN107607560BReduce acquisition timeGuaranteed Vertical ResolutionMaterial analysis by transmitting radiationFirst lightEngineering

The present application relates to an optical phase contrast imaging method and system. The optical phase contrast imaging method includes: acquiring a first light intensity value measured by a detector unit group after rays pass through the echelon grating block when there is an object to be measured; according to the first light intensity value, based on a fitting algorithm, determining at least one first parameter value used to characterize the first light intensity change curve when the object to be measured exists; acquiring the second light detected by the detector unit group after the ray passes through the echelon grating block when the object to be measured does not exist Intensity value; according to the second light intensity value, based on a fitting algorithm, determine at least one second parameter value for characterizing the second light intensity change curve when there is no object to be measured; based on the at least one first parameter value and at least one second parameter value to determine at least one physical information of the object to be measured.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

A Method for Selecting Feasible Regions of Targets in Fluorescence Molecular Tomography

ActiveCN108095686BReduce data collection timeFast rebuildDiagnostics using fluorescence emissionDiagnostics using tomographyOptical tomographyMolecular imaging

The invention belongs to the technical field of molecular imaging, and discloses a method for selecting a feasible region of a fluorescent molecular tomographic imaging target. If the reconstruction quality does not meet the requirements, jump to the iterative self-organizing data analysis technology algorithm to select the feasible region, otherwise display the final reconstruction result and end the reconstruction. The invention is suitable for reconstructing an optical molecular tomography system of multi-target fluorescence sources, requires less fluorescence measurement data, adopts an iterative self-organizing data analysis technique algorithm to partition and select feasible regions, and improves the accuracy of selecting feasible regions in multi-target reconstruction. The present invention reduces the morbidity of the reconstruction problem through multi-stage reconstruction, effectively improves the reconstruction quality of fluorescence molecular tomography, and has important application value in the fields of optical tomography three-dimensional reconstruction algorithm and the like.

Owner:NORTHWEST UNIV

Anti-foot-pressing detection method and terminal

PendingCN113687438AAvoid pressingReduce data collection timeOptical detectionUsing optical meansEngineeringStructural engineering

The invention discloses an anti-foot-pressing detection method and terminal, and the method comprises the steps: obliquely and downwards installing single-point lasers in front of a robot, and downwards installing the single-point lasers in the positions, close to the left and right rear wheels, in front of the left and right rear wheels and away from the left and right rear wheels, in front of the left and right rear wheels; the feet of a person can be detected through the single-point laser installed obliquely downwards and the single-point laser away from the left wheel and the right wheel, and due to the fact that the single-point laser for detecting the feet has a certain distance from the left wheel and the right wheel, timely braking after the feet of the person are detected is facilitated; in order to prevent foot pressing, the single-point laser close to the left and right wheels only detects the height of an obstacle, the time of data acquisition and data processing can be shortened, the robot can stop in time when the single-point laser close to the human foot and far away from the left and right wheels does not detect the human foot, the human foot suddenly stretching into the vehicle bottom is prevented from being pressed, and foot pressing accidents are avoided.

Owner:汤恩智能科技常熟有限公司

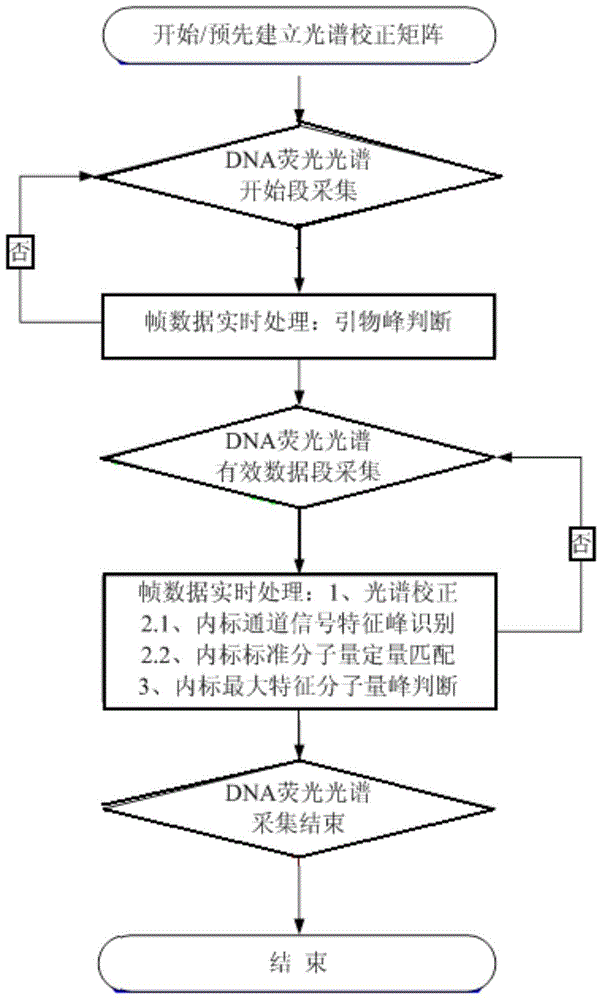

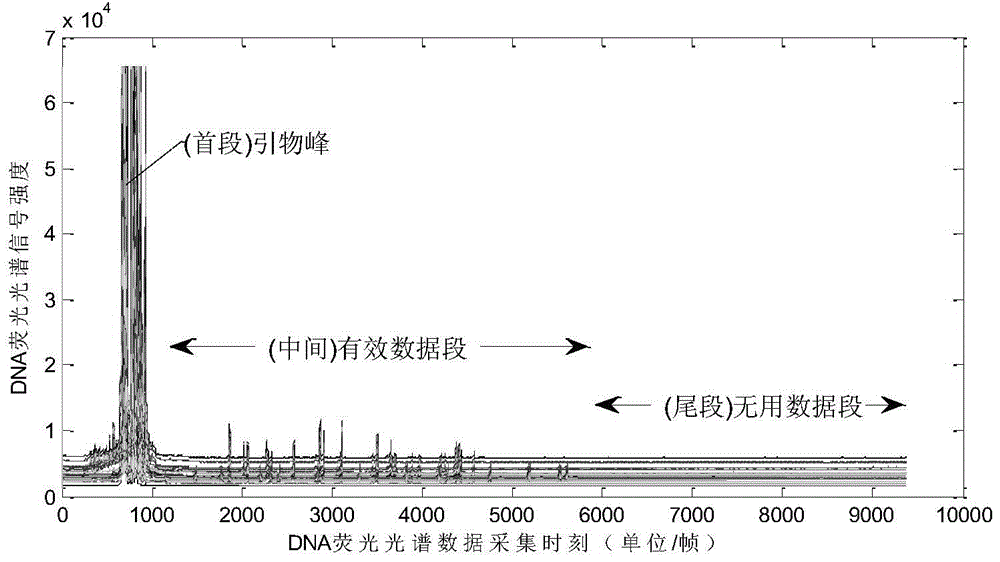

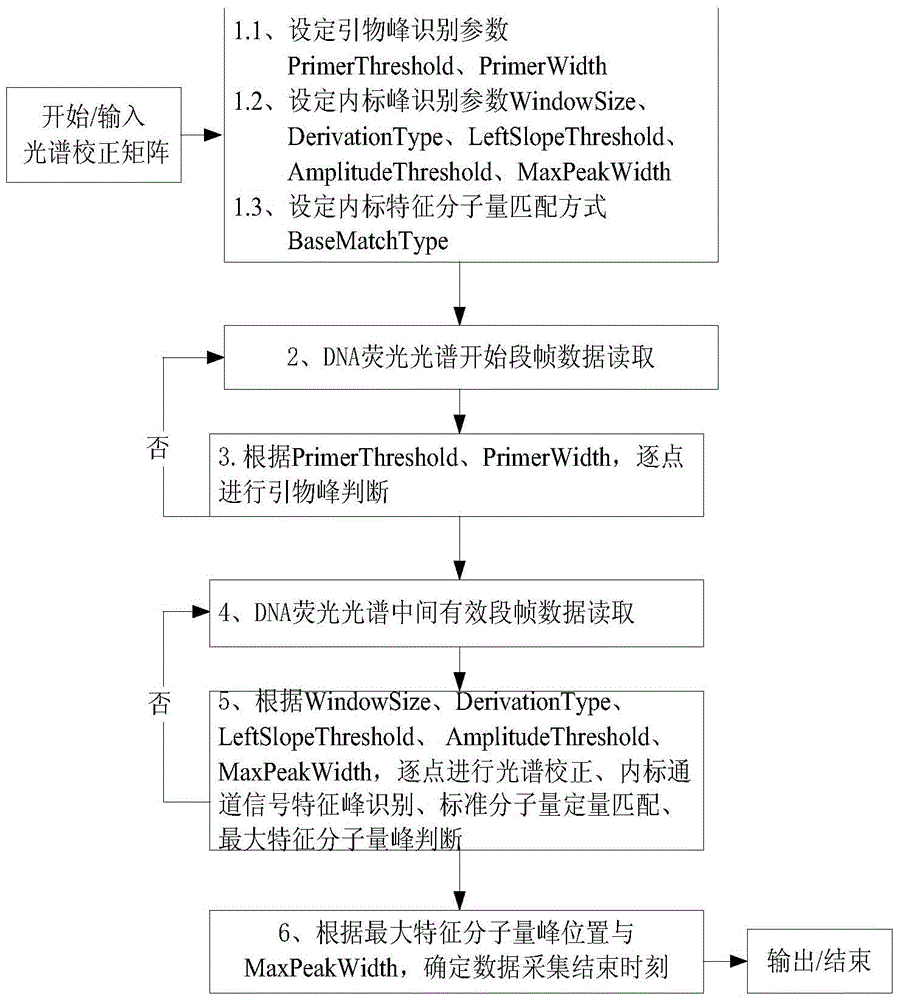

A DNA fluorescence spectrum acquisition method based on quantitative analysis of characteristic molecular weight internal standard

ActiveCN104458686BImprove identification work efficiencyReduce acquisition timeFluorescence/phosphorescenceFluorescence spectraInternal standard

The invention discloses a DNA fluorescence spectrum collecting method based on characteristic molecular weight interior label quantitative analysis. The method is used for performing data acquisition on a detecting sample which simultaneously contains an interior label sample-adding marker DNA fragment and unknown DNA fragment length information, and also used for performing real-time processing on the acquired initial data. The DNA fluorescence spectrum collecting method based on characteristic molecular weight interior label quantitative analysis comprises the following steps: firstly, performing primer peak identification; then, performing spectral correction point by point on the acquired signal after the primer peak, and performing peak identification on a corresponding interior label channel signal to match with a characteristic molecular weight peak until the characteristic peak with the greatest molecular weight of the interior label is extracted; and finally, according to the peak position corresponding to the greatest molecular weight, determining an ending moment of the DNA fluorescence spectrum data acquisition. The method can be used for reducing the DNA fluorescence spectrum data acquisition time, saving the internal storage occupied by source data, reducing the subsequent processed data and finally improving the DNA identification working efficiency.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

Modifying glass slide for fixing biomacromolecules and method thereof

ActiveCN103411818BReduce troubleReduce data collection timePreparing sample for investigationMicroscopesMicroscope slideMass ratio

The invention discloses a modifying glass slide for fixing biomacromolecules and a method thereof. The modifying glass slide comprises a glass slide and a cover glass, wherein a modifying layer which is connected with the surface of the glass slide by using a covalent bond is arranged between the glass slide and the cover glass; a liquid adding hole is formed in the glass slide; the modifying layer is bovine serum albumin marked with biotin or a polyethylene glycol derivative marked with the biotin; the glass slide is a quartz glass slide; the bovine serum albumin marked with the biotin can be 6-8 biotin molecules per albumin molecule; and the mass ratio of polyethylene glycol derivative marked with the biotin to polyethylene glycol derivative without being marked is between 3 and 10 percent. An intermediate dielectric layer is added by virtue of the liquid adding hole to be incubated at room temperature, and sample solutions are added again so as to realize fixation of biomolecules. By using the modifying glass slide, nucleic acid and protein biomolecules can be conveniently fixed, and biological single-molecule imaging data acquisition is realized.

Owner:苏州大猫单分子仪器研发有限公司

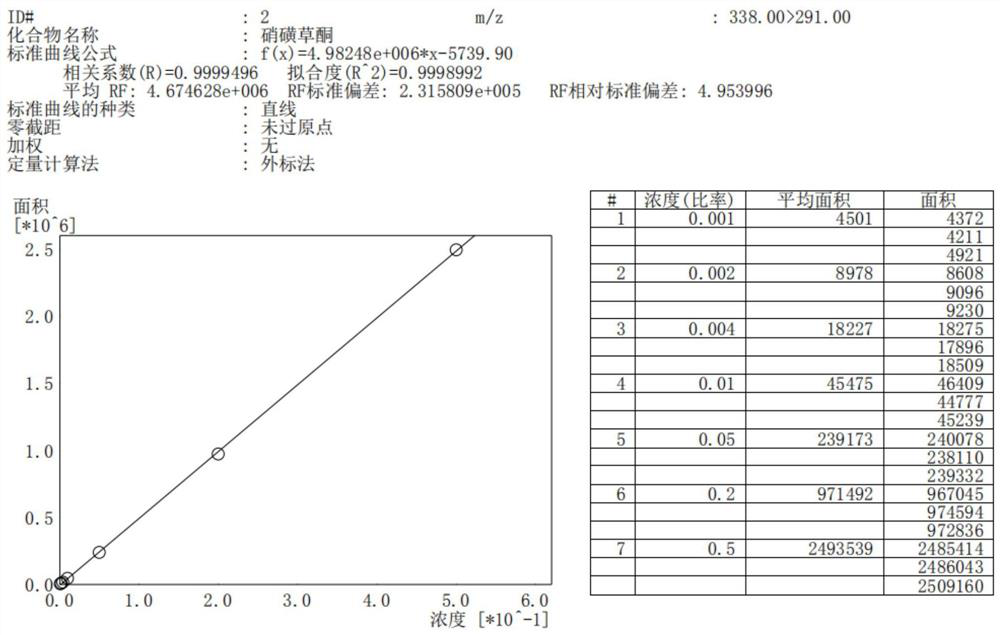

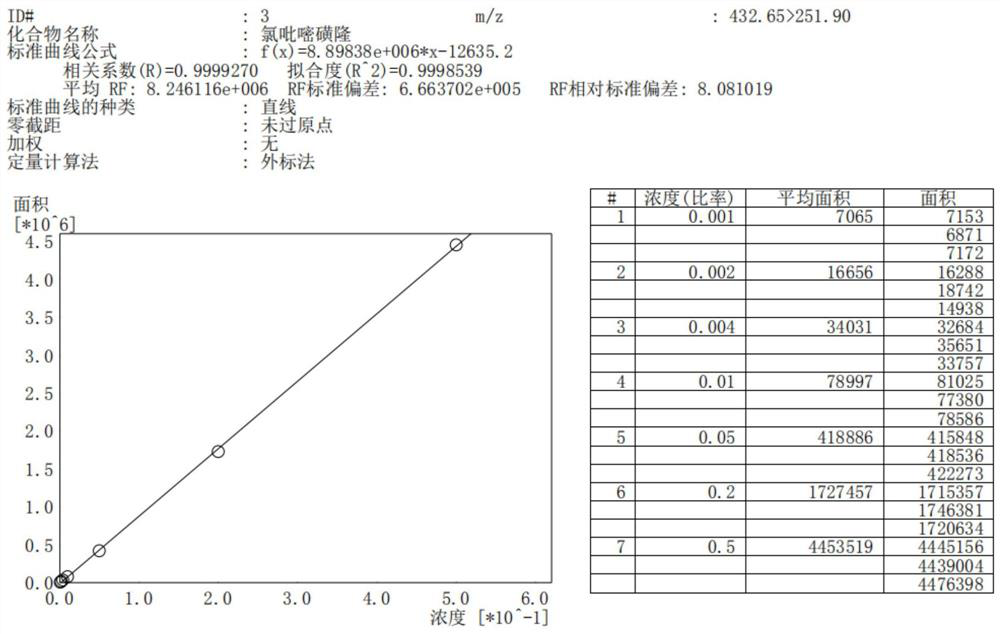

Method for detecting mesotrione, ametryn and halosulfuron-methyl in sugarcane

ActiveCN111965275AReduce data collection timeDetection is simple, fast and accurateComponent separationChemistryAnimal science

The invention discloses a method for detecting mesotrione, ametryn and halosulfuron-methyl in sugarcane. A high performance liquid chromatography-mass spectrometry method is adopted for detection, therecovery rate of mesotrione in a sugarcane matrix is 92.9%-103.0%, and RSD is 1.1%-1.4%; the recovery rate of the ametryn is 101.0%-103.0%, and the RSD is 0.6%-0.7%; and the recovery rate of the halosulfuron-methyl is 105.0%-114.0%, and the RSD of is 0.7%-2.0%. A reliable detection method is provided for researching the change condition of the residual quantity of sugarcane after the three medicines are applied, and meanwhile, the blank that mesotrione, ametryn and halosulfuron-methyl in a sugarcane matrix cannot be simultaneously detected by an existing method is filled.

Owner:安徽华辰检测技术研究院有限公司

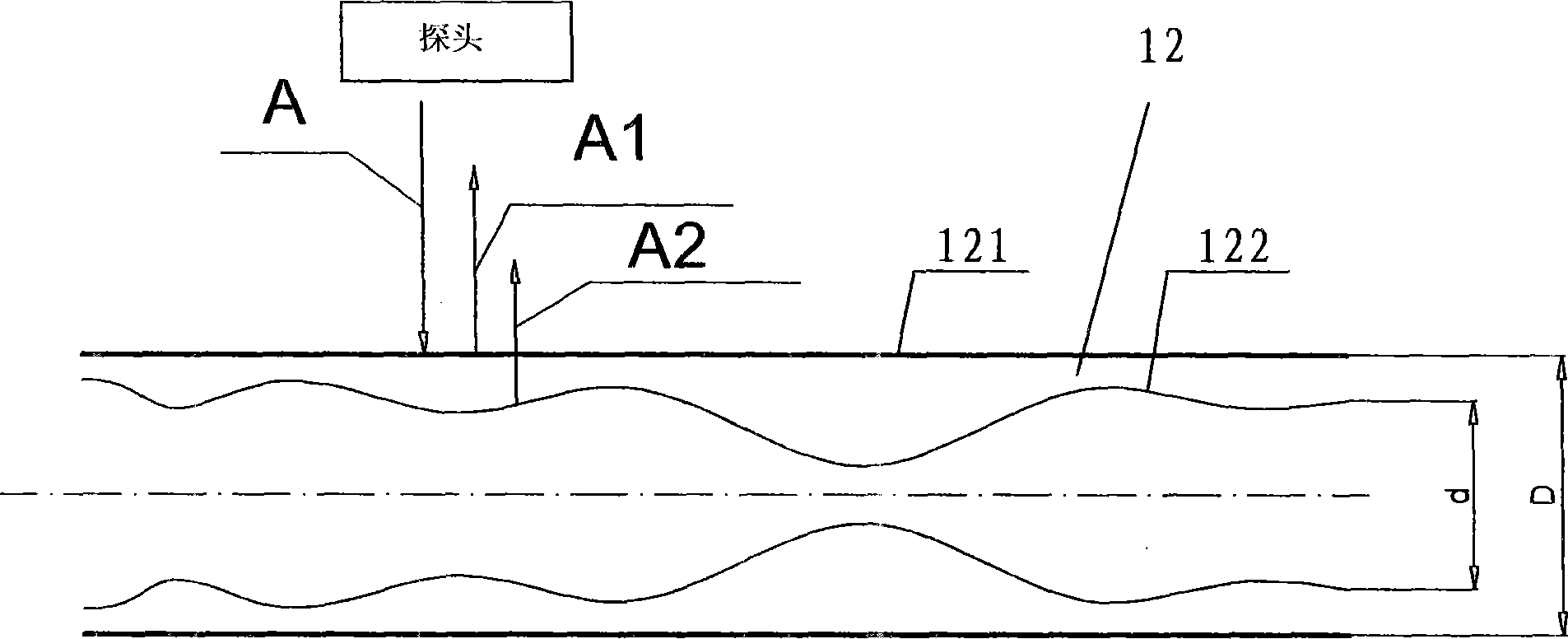

Core space dimension precision measurement apparatus based on ultrasound and method thereof

InactiveCN102494645BReal-time resultsThe detection process is fastUsing subsonic/sonic/ultrasonic vibration meansSonificationSynthetic data

The invention mainly discloses a core space dimension precision measurement apparatus based on ultrasound and a method thereof. An ultrasound measurement principle is employed to measure wall thickness of a piece to be measured, and through fusion processing of measurement data, core space dimension data of a measured piece is calculated. To a precision measurement problem of a slight inside dimension, the invention brings forward a core space dimension detection system based on ultrasound, and the system has the characteristics of a non-contact mode, fast detection speed, a simple principle, an accurate result and relative low cost. By utilizing multiple groups of ultrasonic probes, the wall thickness of the measured piece is subjected to non-contact measurement, extrusion and wearing of the measured piece are avoided, and measurement security is ensured. Simultaneously, fusion processing is carried out on the measurement data of the probes, through data of different angles, different times, different layers, different amplitudes and shapes and the like of the probes, an internal dimension, a shape and distribution of the measured object are determined, and comprehensive data of a core space dimension of the measured piece is provided.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com