Core space dimension precision measurement apparatus based on ultrasound and method thereof

A precision measurement and inner cavity technology, which is used in measurement devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., to solve the problem that deep holes or blind holes cannot complete the measurement task, the measurement results cannot fully describe the workpiece, and the measurement process cannot be carried out, etc. problem, to achieve the effect of fast detection, avoid extrusion and wear, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

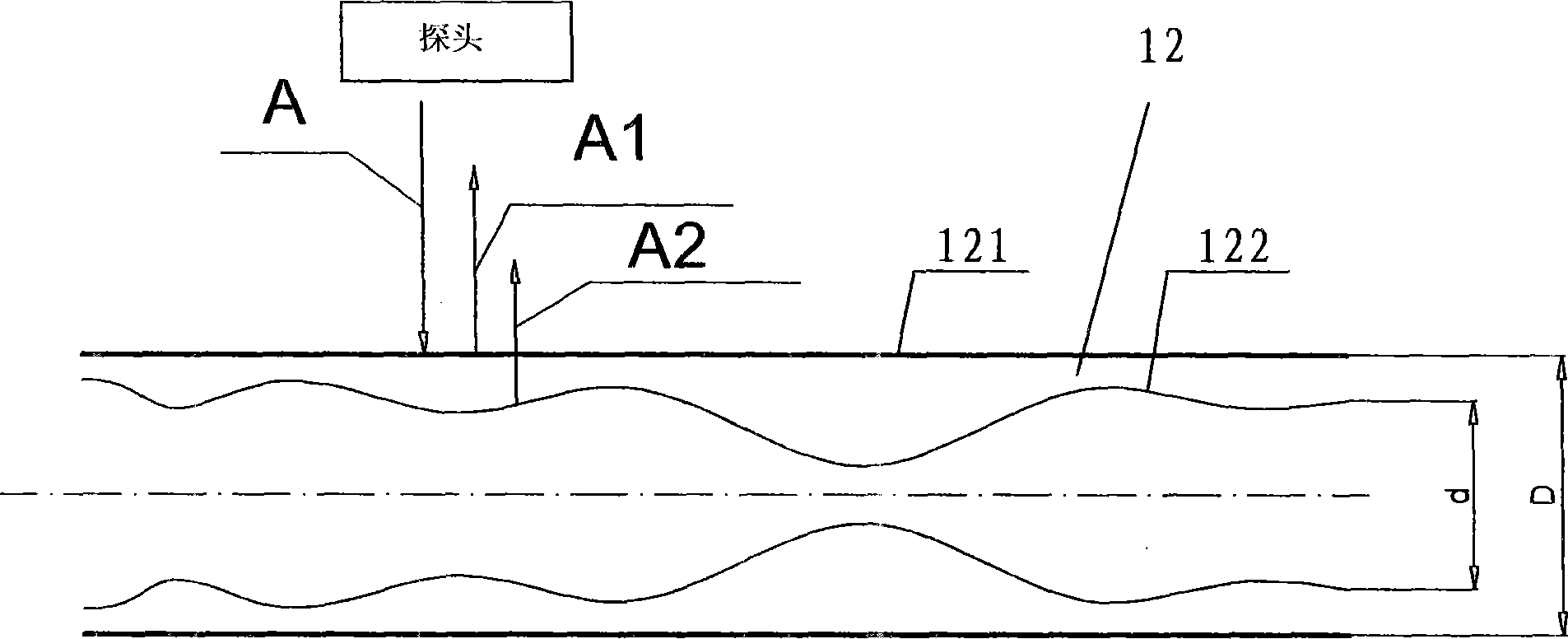

[0039] like figure 1 As shown, the principle of the present invention is to radiate ultrasonic waves to the object to be tested, and calculate the size of the inner cavity according to the ultrasonic reflections formed by different interfaces. According to this principle, several parts such as data acquisition, data processing and display, and system mechanical device need to be involved.

[0040] combine image 3 , a precision measurement device for inner cavity size based on ultrasound, which belongs to the mechanical device part of the present invention, and the main components involved include fixture 1, probe box 2, track 3, motor M1, motor M2, water storage tank 4, water supply Box 5, water pump 6, water storage tray 7, industrial computer 8, upper water pipe 9, probe box water supply pipe 10, and lower water pipe 11.

[0041] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com