Method for cooperatively detecting particles in laser welding plume through multiple laser beams

A technology for detecting lasers and laser beams, applied in measuring devices, particle size analysis, individual particle analysis, etc., can solve problems such as poor counting, undetectable, and many interference fringes, and achieve easy adjustment, no external interference, and compact system The effect of easy collimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

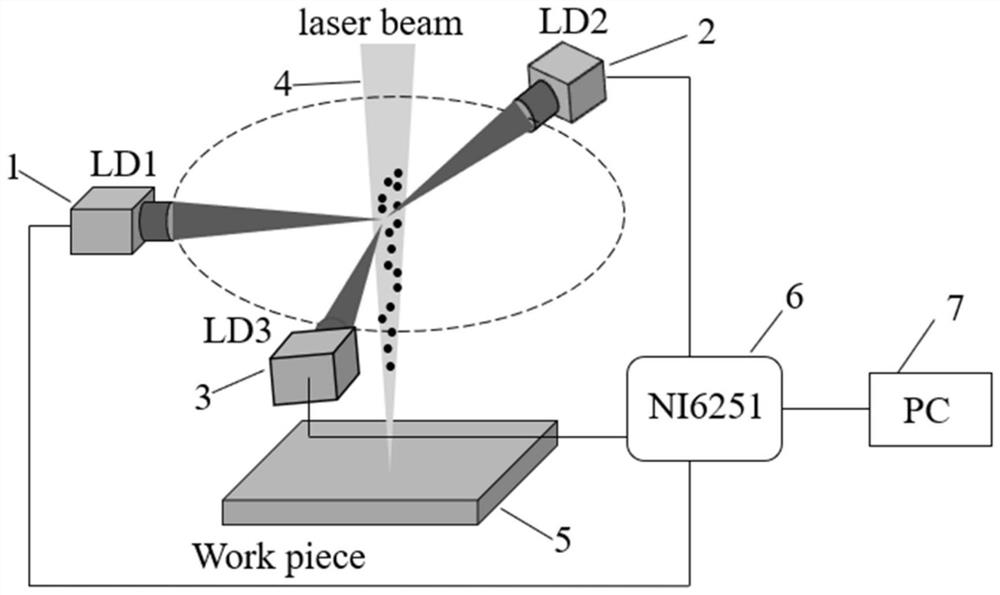

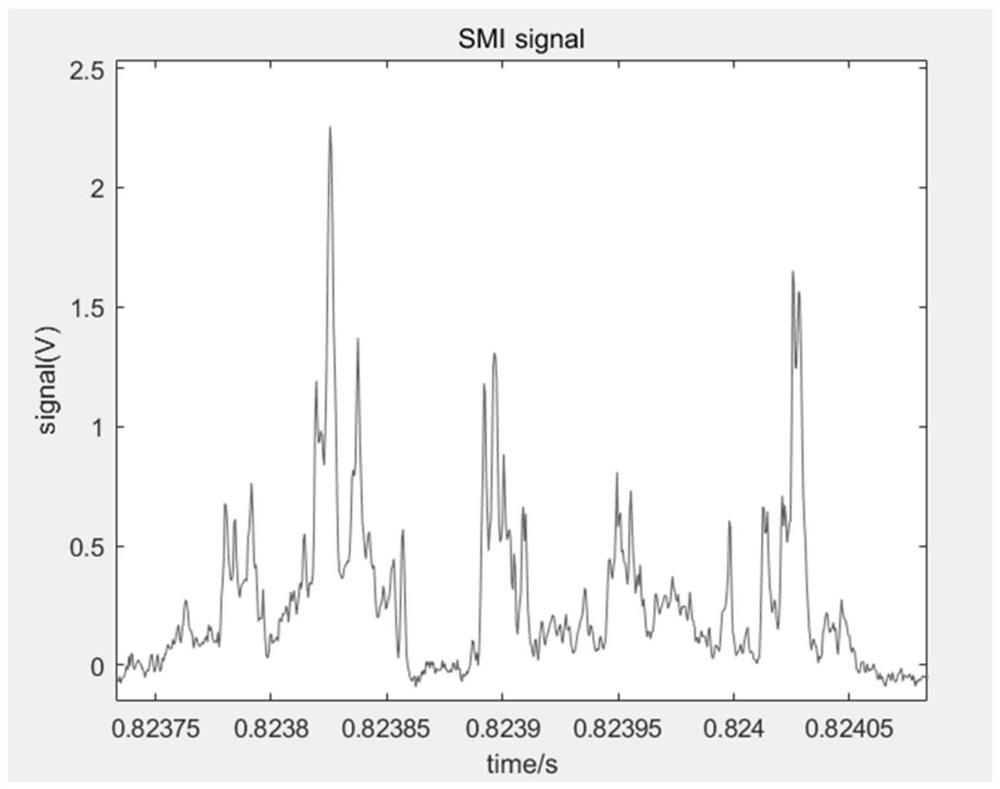

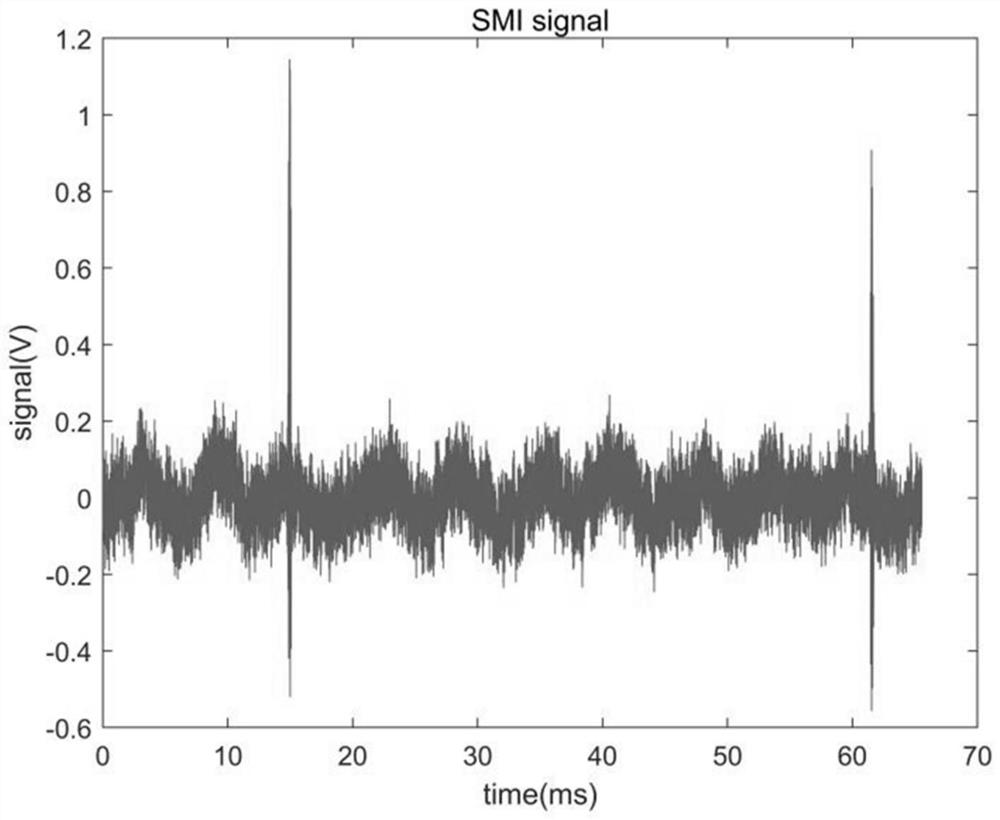

[0014] In this example, YLS-6000 fiber laser is used for welding. The welding plate is 10mm thick low-carbon steel that has been ground and polished. The processing parameters are: welding speed 2m / min, laser power 1kW, spot diameter 1.06mm, spot effect on the surface of the board. The wavelengths of the detection lasers are 639nm and 1310nm respectively, after being focused by a lens with a focal length of 100mm, the laser power is 500mW; the data acquisition card model 6251 of National Instruments is used to collect and store the signals, and the signal is processed by Matlab software to obtain the voltage spectrum Such as figure 2 and 3 shown. By reading the number of interference fringes in the image and measuring the relationship between particle diameter, interference fringes, and detection laser wavelength, the particle size, number distribution, and velocity changes in the plume can be obtained.

[0015] The above descriptions are only preferred embodiments of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com