Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "No wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hollow fiber ultrafilter membrane and its preparation method

InactiveCN102489170AImprove mechanical strengthExtended service lifeSemi-permeable membranesHollow fibreSolvent

The invention provides a hollow fiber ultrafilter membrane, which is obtained by a following mixture after film forming treatment: 14wt%-25wt% of film forming polymer, 0.1wt%-15wt% of meta aramid fiber, 6wt%-10wt of pore forming agent and 59wt%-80wt% of solvent. The invention also provides a preparation method of the hollow fiber ultrafilter membrane. The meta aramid fiber possesses high strength, and enables mutual interpenetration of different polymer chains, is capable of enhancing the mechanical strength of the film forming polymer, so that the hollow fiber ultrafilter membrane possesses high mechanical strength without wire facture, thereby the service life can be prolonged, the daily maintenance frequency can be minimized, and the water treatment cost can be reduced; The meta aramid fiber can increase the hydrophilic performance of the hollow fiber ultrafilter membrane, so that the contamination resistance is good, the flux is high and the attenuation speed is slow. The meta aramid fiber can enhance the heat resistance of the hollow fiber ultrafilter membrane and is more suitable for usage under rigorous condition.

Owner:CHONGQING DELING TECH

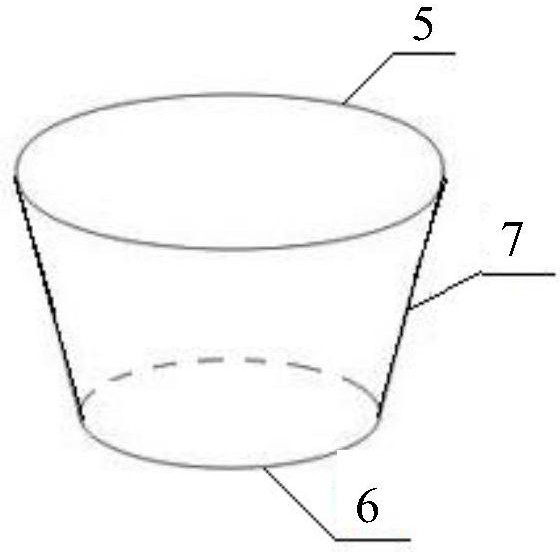

Preparation method of circular truncated cone-shaped side net for semi-submersible aquaculture platform

ActiveCN111642437AUnobstructed exchangeQuality is safe and reliableElectroconductive/antistatic filament manufactureSpinnerette packsNanoparticlePolyethylene glycol

The invention provides a preparation method of a circular truncated cone-shaped side net for a semi-submersible aquaculture platform. The preparation method comprises anti-fouling monofilament bundlepreparation, anti-fouling net sheet preparation, and circular truncated cone-shaped side net preparation. Preparation raw materials comprise PP resin, dioctyl phthalate, polyethylene glycol fatty acidester, cetyl phosphate, a grafted polyguanidine salt / polyethylene granular material, and surface modified copper-nickel alloy nanoparticles. When the anti-fouling net sheet is prepared, first the antifouling monofilament bundle is twisted to obtain an antifouling strand with the Z twist direction, then three antifouling strands with the Z twist direction are processed into an antifouling twistedthread with the S twist direction, then the antifouling twisted thread with the S twist direction is processed into a net sheet with double dead knots, and finally the net sheet is subjected to heat-setting with 0.22 times the longitudinal breaking strength of the net sheet as a pre-tension. When the circular truncated cone-shaped side net is prepared, knotting is performed in a circulation mannerof "single dead knot-single dead knot-double dead knot-double dead knot", then a net sheet is subjected to fan ring-shaped cutting, edge line and net line assembly, and edge strengthening, then mother lines at the left and right side of a fan ring-shaped net sheet are butted and stitched, and double dead knots are knotted at the same distance when butting and stitching are performed.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method of fibers for grid type purse net fishing net

ActiveCN106192049AImprove compositionGood spinnabilityClimate change adaptationArtificial filament heat treatmentCarbon blackWollastonite

The invention provides a processing method of fibers for a grid type purse net fishing net. The processing method is characterized by comprising the following steps: pre-mixing UHMWPE (Ultrahigh Molecular Weight Polyethylene) powder, silicone powder, nano silicon dioxide, HDPE (High-density Polyethylene) powder, a nano titanium dioxide silver-loaded antibacterial agent, an antioxidant B225, hydroxystearic acid, nano-grade diatomite, nano-grade white carbon black, nano-grade wollastonite and an ethylene-vinyl acetate copolymer, which are weighed according to a formula, and pouring the mixture into a high-speed kneading pot and carrying out high-speed kneading to obtain a UHMWPE modified material; fusing and extruding the UHMWPE modified material through a double-screw-rod extruder; fusing and extruding an extruded product from a spinneret hole through a metering pump which is additionally arranged on a double-screw-rod outlet; cooling, pre-stretching and hotly setting extruded freshly formed filaments and winding a fiber bundle through a fiber winding machine which utilizes a torque motor; dividing the fiber bundle into fibers through a fiber dividing machine, so as to obtain the fibers for the grid type purse net fishing net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

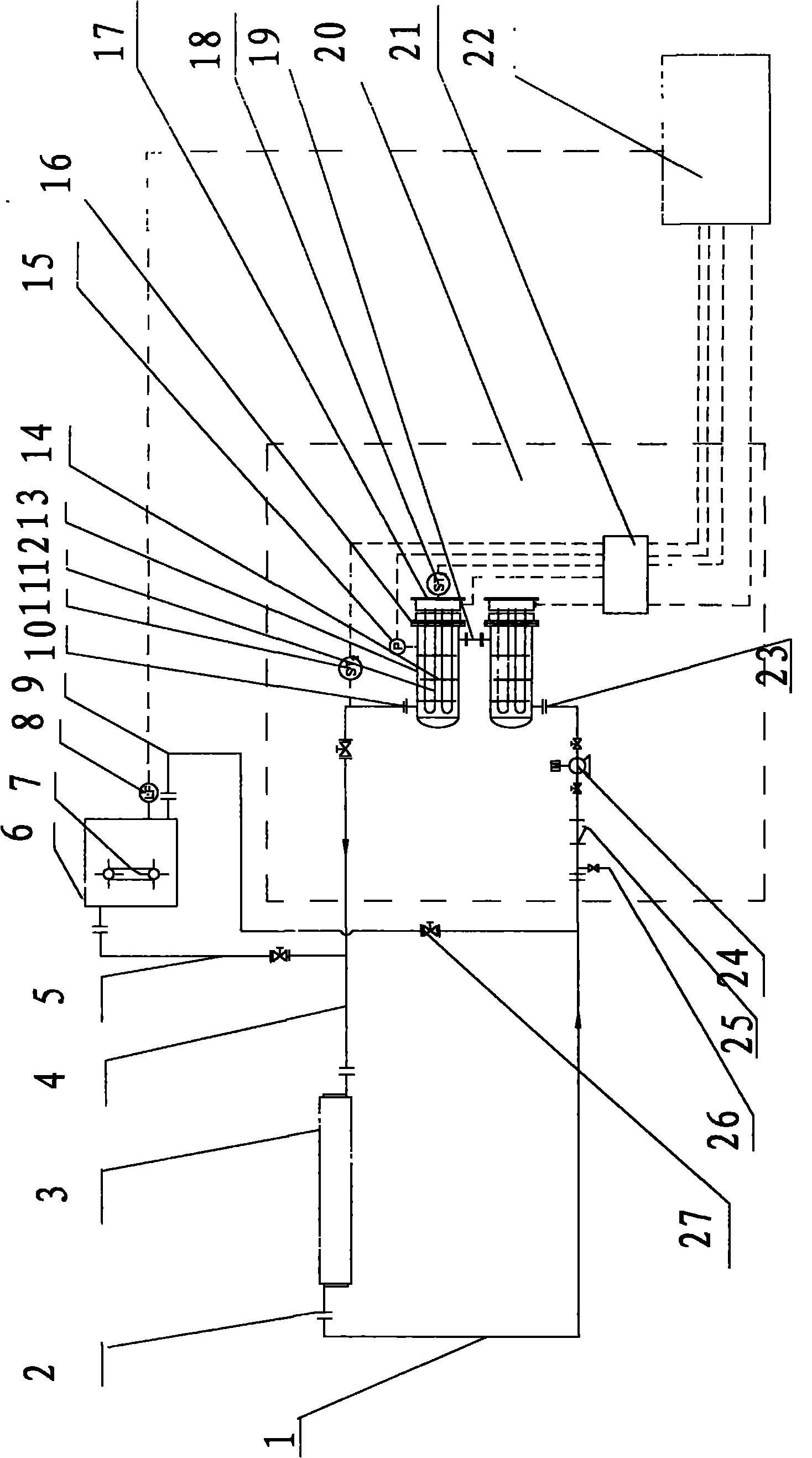

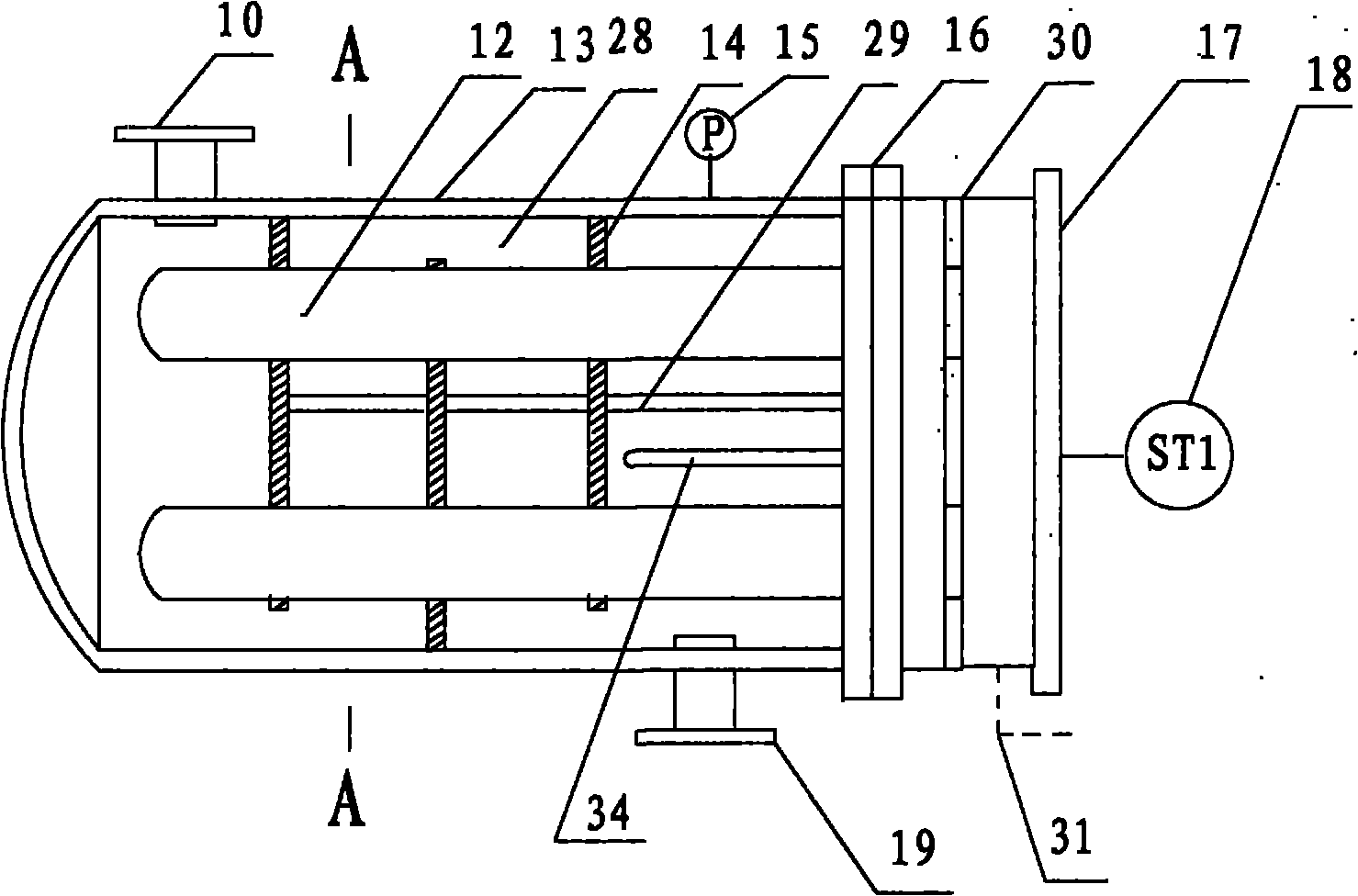

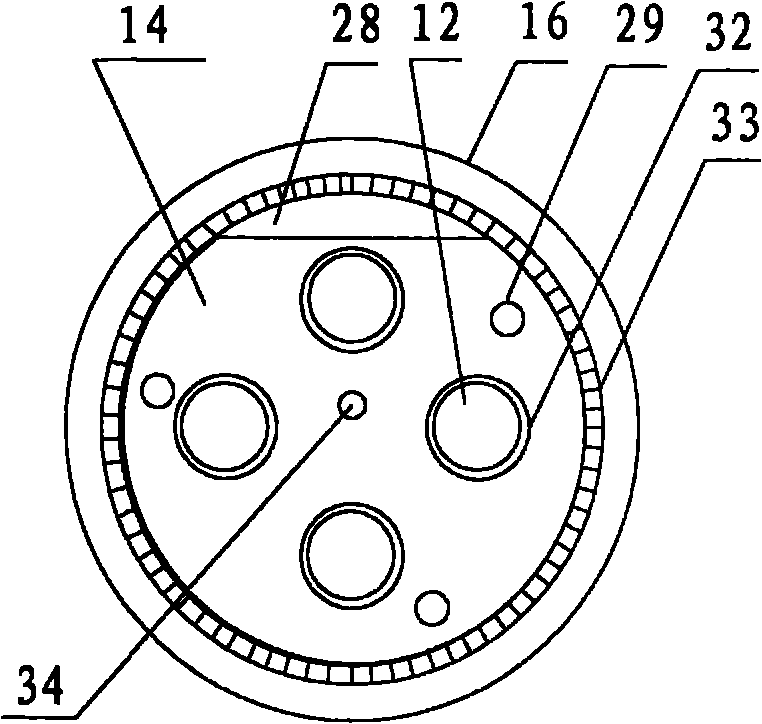

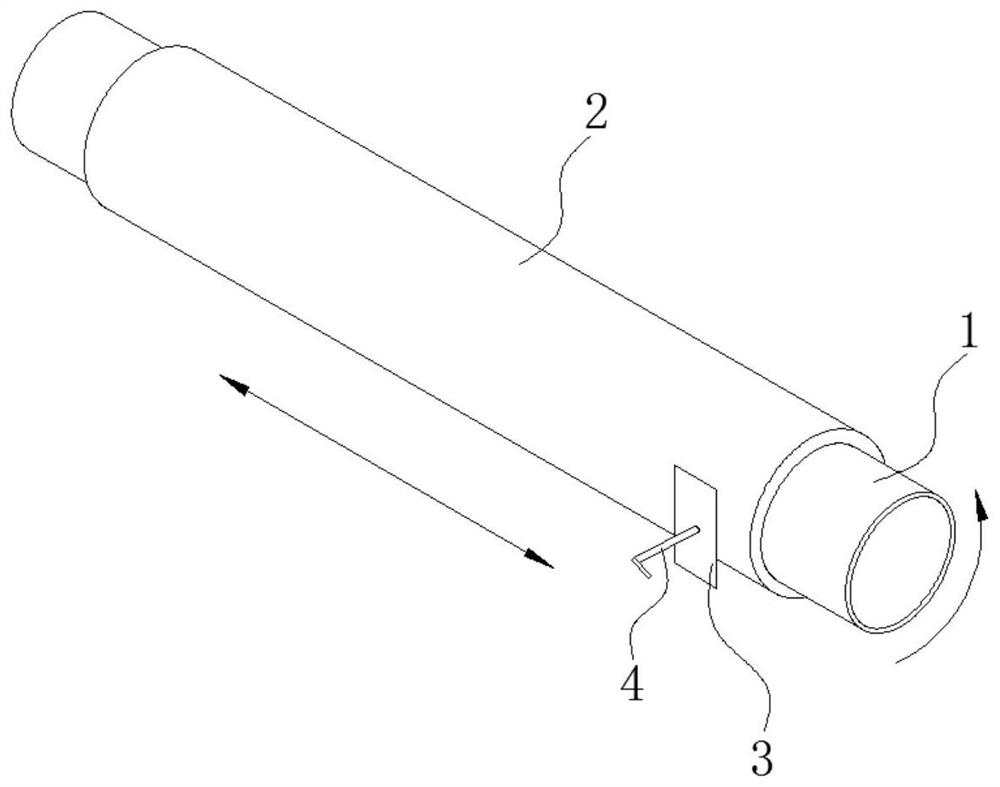

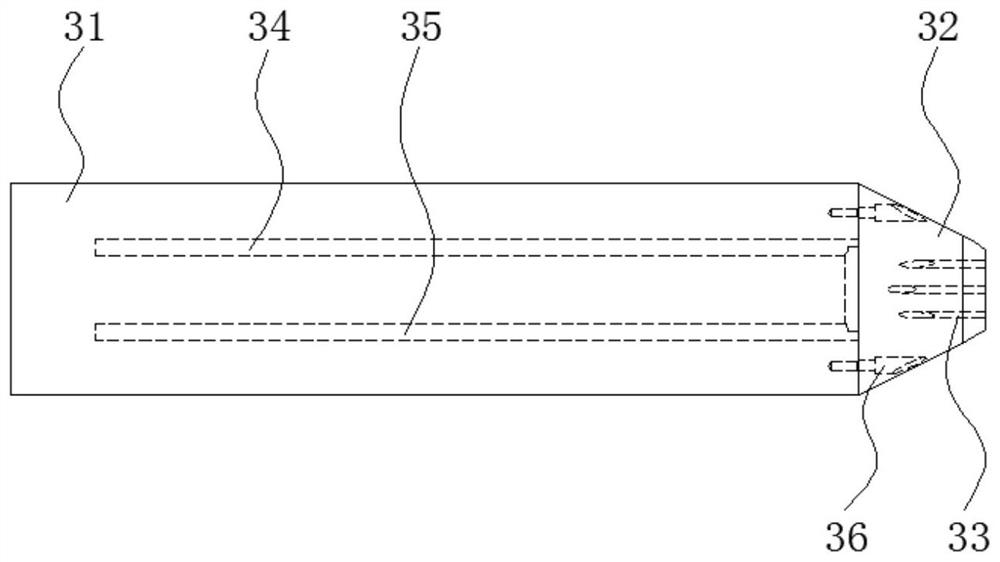

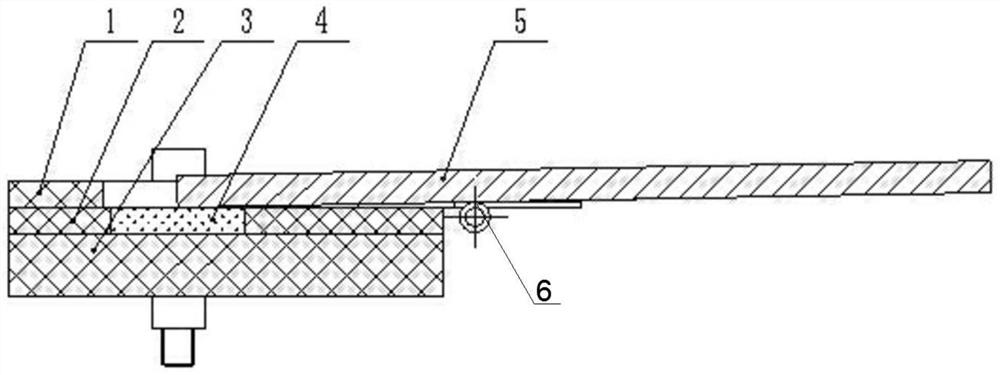

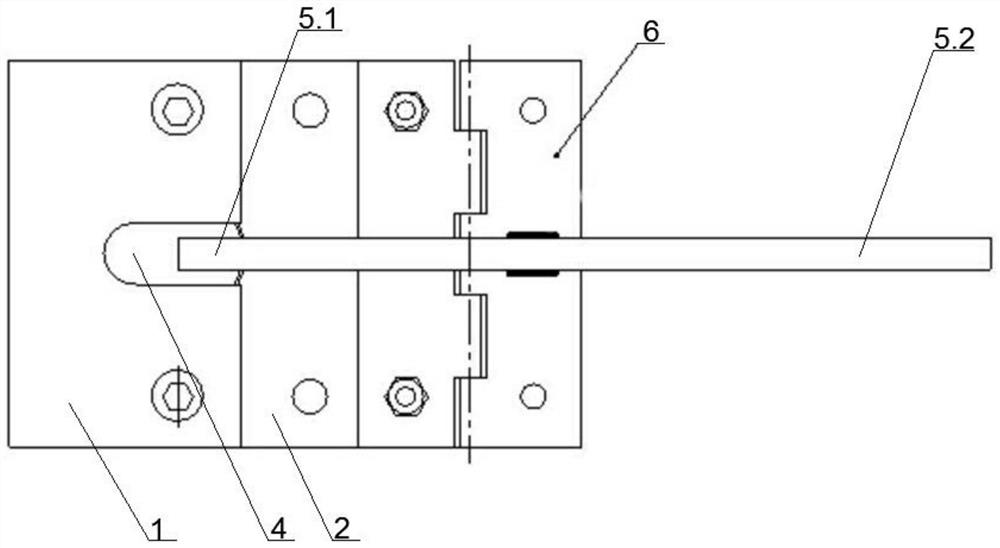

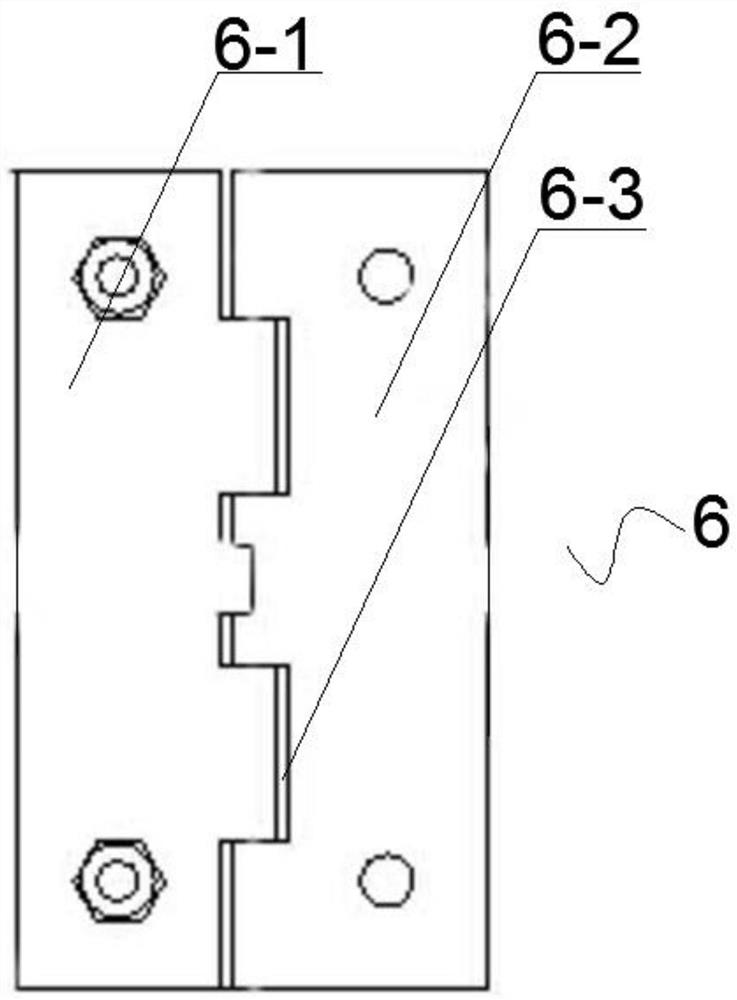

Jet type spinning machine

ActiveCN106284381ANo wire breakageThere will be no problem of cloggingLiquid seeding techniquesExcavationsThroatHigh pressure

The invention discloses a jet type spinning machine. The jet type spinning machine comprises a spinner, a filament leading-out device and a base, wherein the spinner is arranged on the base, and comprises a jet-in structure and at least one jet device connected with the jet structure; each jet device comprises a jet pipe body; each jet pipe body comprises a fluid inlet end and a fluid outlet end which are oppositely arranged; each jet pipe body comprises a negative pressure section, a throat section and a section diverging section which are sequentially connected; each negative pressure section is arranged by being close to the corresponding fluid inlet end; a section reducing pipe is arranged on each negative pressure section; each jet pipe body is provided with a filament inlet pipeline on the side wall of the corresponding negative pressure section; the filament leading-out device comprises a container for storing a filament spindle; the high-pressure fluid enters from the jet structure, then enters the jet devices through the corresponding fluid inlet ends, and sequentially passes through the negative pressure sections, the throat sections and the section diverging sections; filaments are drafted from the container of the filament leading-out device to an inlet of the filament inlet pipeline; under the action of the negative pressure, the filaments are sucked into, and then are jetted together with the high-pressure fluid from the spinning end, so that breaking and blocking of the filaments are avoided.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

Preparation method of cylindrical box body with antifouling property for deep and open sea net cage

ActiveCN111657197AGood antifouling effectAntifouling effectiveElectroconductive/antistatic filament manufactureClimate change adaptationOpen seaHigh density

The invention provides a preparation method of a cylindrical box body with the antifouling property for a deep and open sea net cage. The method comprises the following steps of A, preparing an antifouling netting, which comprises three aspects of preparing a modified high-density polyethylene composite material, preparing an antifouling monofilament bundle and processing the antifouling netting;B, preparing an anti-abrasion netting from a polyamide netting coated with a polyurea coating; and C, preparing the cylindrical box body, which comprises three aspects of side net processing, bottom net processing and cylindrical box body processing. According to the cylindrical box body with the antifouling property for the deep and open sea net cage obtained by the preparation method, the antifouling property of the cylindrical box body can be greatly improved and the water resistance of the cylindrical box body and the attachment area of fouling organisms can be reduced on the premise of keeping the netting strength of a side net unchanged, fouling organism attachment of the cylindrical box body and net breaking fish escape accidents under severe sea conditions can be greatly reduced, and green development and modern construction of the deep and open sea net cage culture industry are realized.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method for antifouling melt spinning for far-reaching-sea net cage or floating-rope surrounding net

ActiveCN106192030AImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

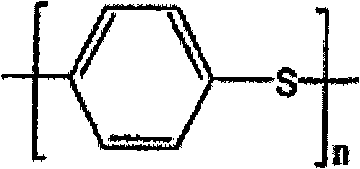

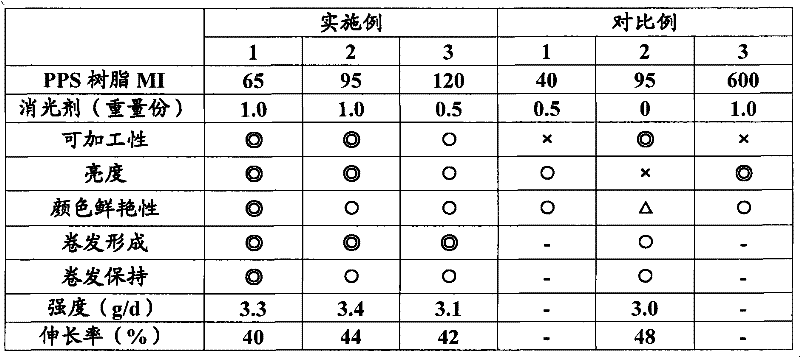

Polyphenylene sulfide synthetic hair filaments and processes for preparing the same

InactiveCN102345185AWith natural lusterImprove heat resistanceWigsMonocomponent synthetic polymer artificial filamentFiberInorganic particle

The present invention provides a polyphenylene sulfide synthetic hair filament. The synthetic hair filament comprises (A) a polyphenylene sulfide resin; and (B) an inorganic particle quencher additive, wherein said PPS resin melt index range is 60~110, wherein said inorganic quencher additive is added at 0.1~2.0 parts by weight on a 100 parts by weight PPS resin. The synthetic hair filament has a filament size of about 30 to about 80 dtex. The polyphenylene sulfide resin (A) has a p-phenylene sulfide repeating unit above 85% mole. The inorganic particle quencher additive may be of silicon dioxide, talc or the combinations thereof. A suitable inorganic particle quencher additive has an average diameter range of 0.01~3.0 [mu]m.

Owner:UNO CO LTD

Heating device of screw extruder

The invention relates to a heating device of a screw extruder, which comprises heat-conducting oil body arranged inside an interlayer of a machine body shell, a pipeline, a valve and a heat-conducting oil heating device, and is characterized in that the heat-conducting oil heating device comprises a heating oil tank, an electric heater, an oil pump and an electrical control system, wherein the electric heater and the heating oil tank are inserted and connected with a flange and jointed for location; and the electrical control system is controlled by a control cabinet according to the information given by a temperature sensor, an electro connecting pressure gauge and the like. The heating device of the screw extruder has simple structure, convenient maintenance and use, even heating temperature and low equipment investment; and by adopting the heating device, the quality of silk product produced by the extruder is improved, and the electricity is saved by more than 30% compared with the existing way.

Owner:JIANGSU SELF ENVIRONMENTAL SCI & TECHCO

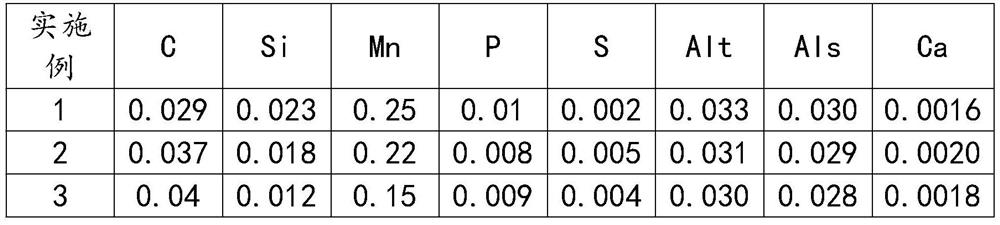

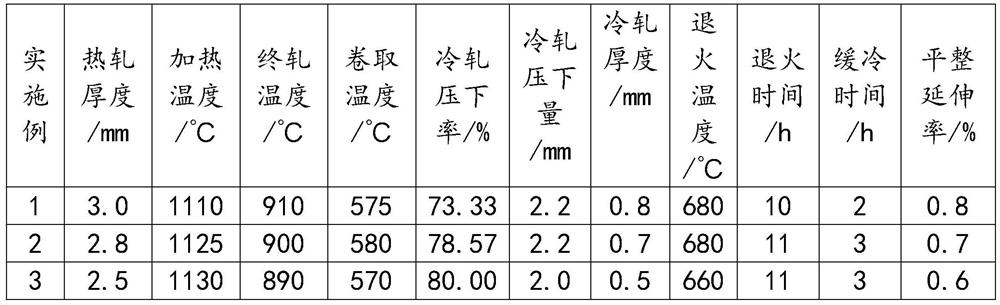

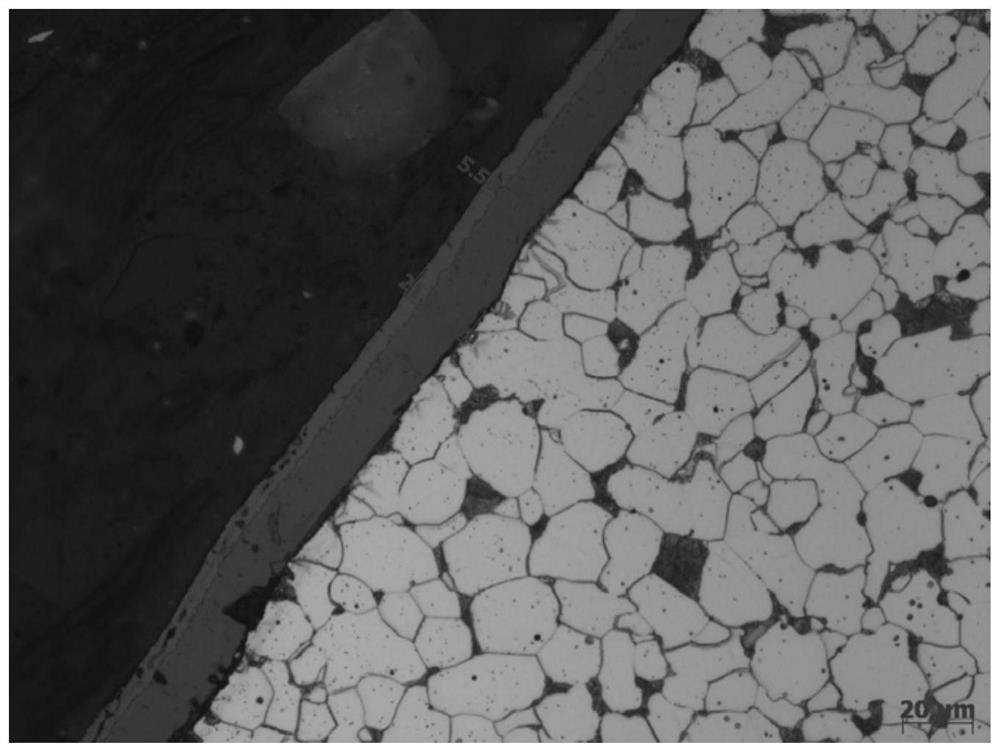

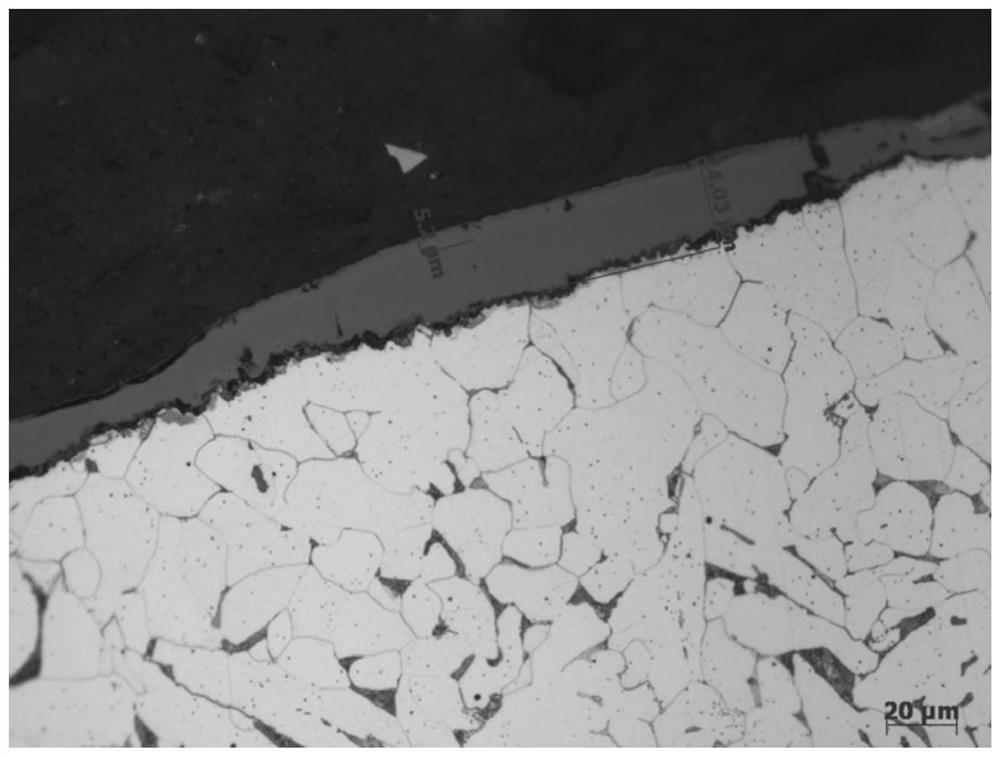

Preparation method of steel for flux-cored wire

PendingCN112760462AEasy to stretchModerate yield strengthFurnace typesHeat treatment furnacesTemperature controlSolid solution strengthening

The invention discloses a preparation method of steel for a flux-cored wire. According to the preparation method, the low-carbon component design is adopted, on the premise that solution strengthening elements are not increased, the content range of all elements is strictly controlled, the content of inclusions in the smelting and casting process is controlled, the steel quality is pure, meanwhile, the initial rolling temperature, the final rolling temperature and the coiling temperature in the rolling process are controlled, the total rolling reduction rate and rolling reduction of acid rolling, cover recrystallization annealing is used, and flattening rolling is carried out to obtain the cold-rolled steel strip with excellent tensile property.

Owner:BAOTOU IRON & STEEL GRP

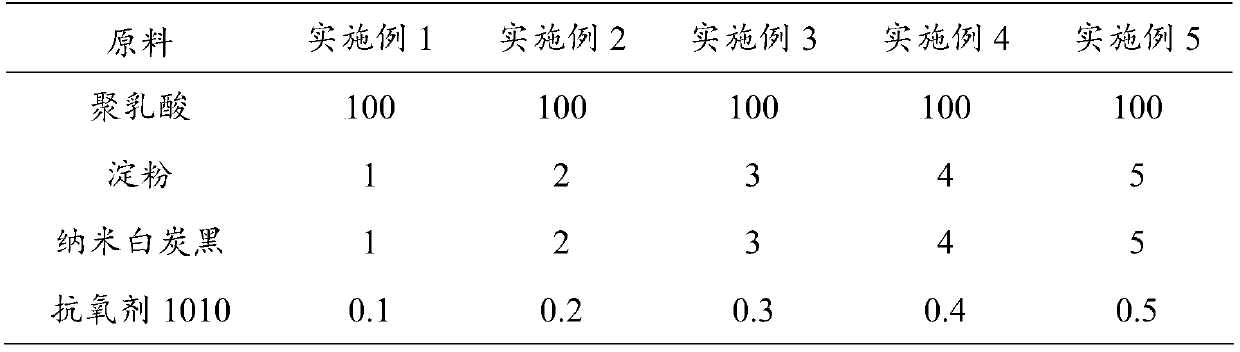

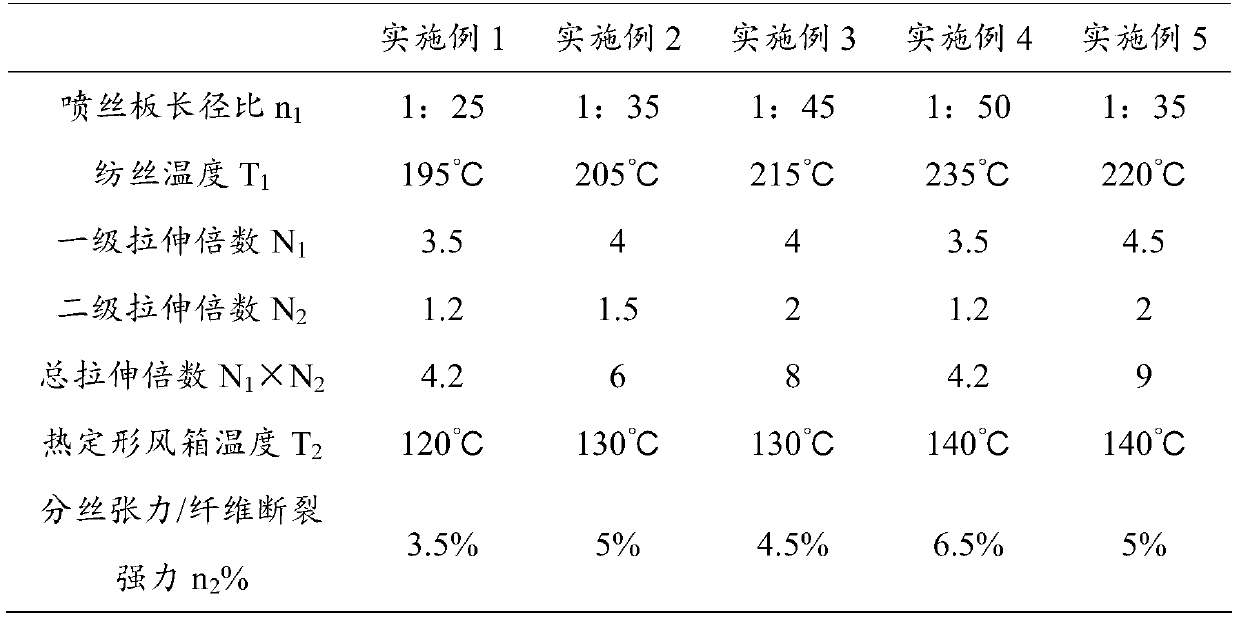

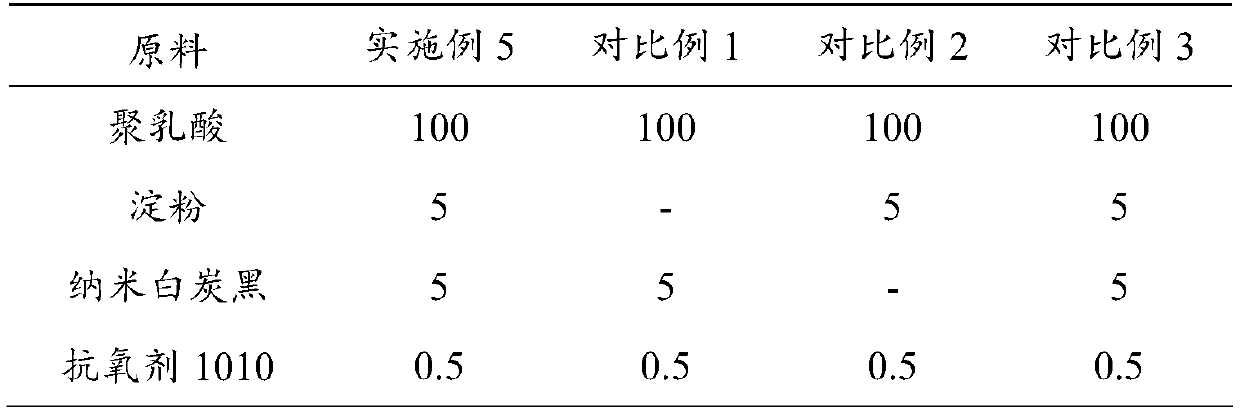

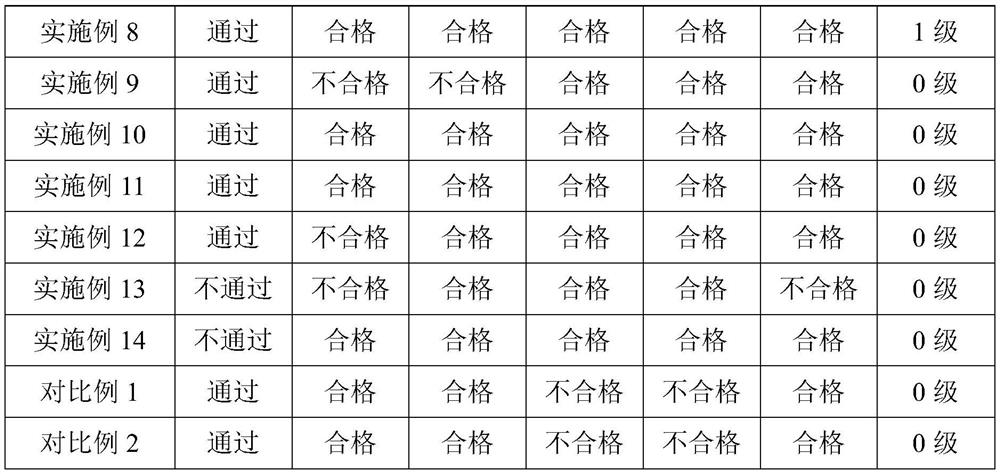

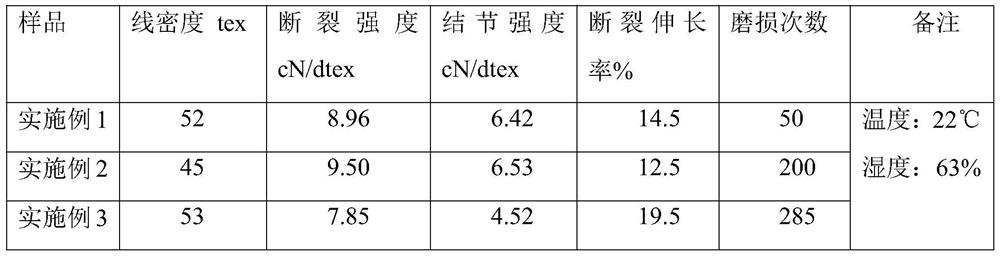

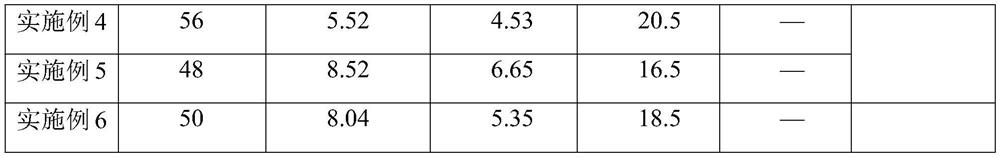

A kind of fish starch modified polylactic acid monofilament and preparation method thereof

ActiveCN107237001BHigh breaking strengthReduced breaking strengthArtificial filament heat treatmentMelt spinning methodsAnoxomerMaterials science

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for manufacturing monofilaments for energy-saving and emission-reduction type ocean fishing gear

InactiveCN104862798AHigh breaking strengthIncreased durabilityArtificial thread manufacturing machinesFilament/thread formingTorque motorPulp and paper industry

Disclosed is a method for manufacturing monofilaments for an energy-saving and emission-reduction type ocean fishing gear. MMWPE resin, PP resin, auxiliaries, a stirrer, a filament separating machine, a filament collecting machine, a single screw extruder and a twice drafting electric heating drafting machine are adopted. The method is characterized in that the MMWPE resin, the PP resin and the white oil auxiliaries are mixed and stirred with the stirrer evenly to obtain MMWPE / PP blended aggregates; melt extrusion is conducted on the MMWPE / PP blended aggregates through the single screw extruder, cooling and pre-drafting are conducted on spun filaments obtained through melt extrusion through low-temperature water in a cooling water tank and a first drafting roller, heat drafting is conducted twice on pre-drafted filaments through a first drafting water bath, a second drafting roller, a second drafting water bath and a third drafting roller, and blended monofilament beams are rolled through the filament collecting machine using a torque motor; filament separation is conducted on the blended monofilament beams through the filament separating machine to obtain the monofilaments for the energy-saving and emission-reduction type ocean fishing gear.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Compound stranded aluminum alloy cable and preparation method and application thereof

PendingCN113871089AReduced horizontal torsional forceReduce vertical forceClimate change adaptationPower cablesElectrical conductorElectric cables

The invention provides a compound stranded aluminum alloy cable and a preparation method and application thereof. The compound stranded aluminum alloy cable sequentially comprises a conductor, an insulating layer and a sheath from inside to outside along the radial direction, wherein the conductor is formed by twisting one central unit and six peripheral units in the left direction, and the central unit is located in the center of the peripheral units. The central unit is formed by leftwards twisting one steel wire rope and six category 5 aluminum alloy strands, and the steel wire rope is located in the center of the category 5 aluminum alloy strands; the peripheral unit is formed by leftwards twisting seven category 5 aluminum alloy strands; and the five types of aluminum alloy strands are formed by twisting 30-40 aluminum alloy monofilaments in a rightward bunching manner. The compound stranded aluminum alloy cable provided by the invention has relatively good torsion resistance, flame retardance, salt spray resistance and mildew resistance, and is suitable for being used as a cable for wind power generation.

Owner:JIANGSU HENGTONG POWER CABLE

Polyoxymethylene monofilament for fishing as well as preparation method and application of polyformaldehyde monofilament

ActiveCN110129921AGood spinnability and comprehensive performanceNo broken wireMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsChemistryMelt spinning

The invention discloses a polyformaldehyde monofilament for fishing. The polyformaldehyde monofilament is prepared from the following components in parts by weight: 75-90 parts of polyformaldehyde, 0.5-3 parts of graphene, 7.5-17 parts of thermoplastic polyurethane, 0.5-3 parts of an antioxidant, 0.5-1 part of a formaldehyde absorbent and 0. 5-1 part of a lubricant. According to the fishing polyformaldehyde monofilament, graphene and thermoplastic polyurethane are blended, then polyformaldehyde is reinforced, toughened and modified, and the polyformaldehyde monofilament for fishing is preparedby melt spinning, three-stage thermal stretching and heat setting processes. A preparation method has the advantages of simple operation process and low production cost. The prepared reinforced and toughened polyformaldehyde monofilament for fishing can be used for polyformaldehyde rope nets, ocean trawls, breeding nets, polyformaldehyde ropes and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Graphene/polyacrylonitrile composite fiber as well as spinning solution and preparation method thereof

PendingCN112680811AImprove spinnabilityNo cloggingElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention belongs to the field of high polymer materials, and particularly relates to a graphene / polyacrylonitrile composite fiber as well as a spinning solution and a preparation method thereof. The composite fiber is a copolymer of polyacrylonitrile, nano graphene and submicron graphene. The spinning solution for preparing the composite fiber is a solution in which the polyacrylonitrile is uniformly dissolved and the nano graphene and the submicron graphene are uniformly dispersed. The preparation method of the spinning solution comprises the following steps: uniformly mixing a part of solution in which the polyacrylonitrile is uniformly dissolved with a solution in which the nano graphene and the submicron graphene are uniformly dispersed to prepare a spinning precursor solution; and then uniformly mixing part or all of the spinning precursor solution with the rest of the solution in which the polyacrylonitrile is uniformly dissolved to prepare the spinning solution. The graphene / polyacrylonitrile composite fiber with antistatic, high-strength and antibacterial functions can be obtained by using the spinning solution for preparing the graphene / polyacrylonitrile composite fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olive green fibers capable of reducing water resistance of meshes and used for weaving net

ActiveCN104862821AWater resistance ensuresImprove spinnabilitySpinnerette packsFilament forming substance formingWater bathsLinear low-density polyethylene

Olive green fibers capable of reducing water resistance of meshes and used for weaving a net adopt LLDPE (linear low density polyethylene) resin, PP (polypropylene) resin, an olive green pigment, an auxiliary, an antioxidant 1010, a fiber winding machine, a fiber separating machine, a stirring machine, a single-screw extruder and an electrical heating draft machine capable of realizing two times of drafting. The olive green fibers are characterized in that the PP resin, the LLDPE resin, the antioxidant 1010, the olive green pigment and the white oil auxiliary are mixed and stirred by the stirring machine until the materials are stirred uniformly so as to obtain a blended granular material; the blended granular material is subjected to melt extrusion by the aid of the single-screw extruder, spun filaments obtained through melt extrusion are subjected to cooling and pre-drafting through low-temperature water in a cooling water tank and a first drafting roller, pre-drafted filaments are subjected to hot drafting for two times through a high-temperature first drafting water bath and a second drafting roller as well as a high-temperature second drafting hot oil bath and a third drafting roller, the total drafting multiple is controlled in a range from 9.5 to 10.2, and the fiber winding machine adopting a torque motor is used for winding fiber bundles; the fiber bundles are subjected to fiber separation by the aid of the fiber separating machine so as to obtain the olive green fibers capable of reducing water resistance of the meshes and used for weaving the net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Fiber processing method for mesh purse seine nets

ActiveCN106192049BImprove performanceSolving Melt Fracture ProblemsClimate change adaptationArtificial filament heat treatmentHydroxystearic AcidTorque motor

The invention provides a processing method of fibers for a grid type purse net fishing net. The processing method is characterized by comprising the following steps: pre-mixing UHMWPE (Ultrahigh Molecular Weight Polyethylene) powder, silicone powder, nano silicon dioxide, HDPE (High-density Polyethylene) powder, a nano titanium dioxide silver-loaded antibacterial agent, an antioxidant B225, hydroxystearic acid, nano-grade diatomite, nano-grade white carbon black, nano-grade wollastonite and an ethylene-vinyl acetate copolymer, which are weighed according to a formula, and pouring the mixture into a high-speed kneading pot and carrying out high-speed kneading to obtain a UHMWPE modified material; fusing and extruding the UHMWPE modified material through a double-screw-rod extruder; fusing and extruding an extruded product from a spinneret hole through a metering pump which is additionally arranged on a double-screw-rod outlet; cooling, pre-stretching and hotly setting extruded freshly formed filaments and winding a fiber bundle through a fiber winding machine which utilizes a torque motor; dividing the fiber bundle into fibers through a fiber dividing machine, so as to obtain the fibers for the grid type purse net fishing net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Plain carbon steel wire rod for wire drawing and production process

ActiveCN113680816AExcellent drawing performanceRapid coolingMetal rolling arrangementsWire rodSpinning

The invention discloses a plain carbon steel wire rod for wire drawing. The plain carbon steel wire rod has the steel mark of Q235L and comprises the following components of, by mass, 0.14%-0.18% of C, 0.12%-0.30% of Si, 0.40%-0.60% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, less than or equal to 0.005% of N, and the balance iron. The invention further discloses a production process of the plain carbon steel wire rod for wire drawing. The production process comprises the following steps of adjusting the initial rolling temperature from 980-1030 DEG C to 1000-1050 DEG C; adjusting the temperature of a finishing mill group from 950 + / -20 DEG C to 1000 + / -10 DEG C; adjusting the spinning temperature from 930 + / -20 DEG C to 1040 + / -10 DEG C; and adjusting the speed of an air cooling line roller way from 0.18 m / s to 0.40 m / s. After adjustment, the tensile strength of the wire rod produced by using the process is 437 MPa, the elongation is 32.5%, the grain size is 8.0 grade, and the thickness of scale on the surface of the wire rod is 24-30 microns; and the drawing wire breakage rate of a downstream user is reduced from 5-6 times per disc to 1-2 times per disc, or the phenomenon of wire breakage does not exist.

Owner:TIANJIN IRON & STEEL GRP

Metal wire preparation method

ActiveCN113523010AIncrease the lengthImprove silk production efficiencyPlaning/slotting toolsPlaning/slotting machinesSteel tubeIndium

The invention relates to the technical field of metal wires, and discloses a metal wire preparation method. The method comprises the following steps of uniformly casting molten indium on a stainless steel tube to form an indium rod; mounting the stainless steel tube containing the indium rod on a rotating device; and a grater is attached to the indium rod, the rotating device is started to drive the indium rod to rotate, and indium wire forming is achieved. By adopting the device for preparing the indium wire, the wire breakage is avoided, the length of the indium wire can be increased, the wire preparation efficiency is improved, the cross section of the grater is the same as the grater hole of the grater, the phenomenon that the outer skin is turned up is avoided, so that the condition that impurities are rolled into the core part of the wire is avoided, and the purity of the indium wire is ensured; and the method is simple to operate, good in using effect and easy to popularize and use.

Owner:先导薄膜材料有限公司

Olive green fiber for weaving nets to reduce water resistance of nets

ActiveCN104862821BWater resistance ensuresImprove spinnabilitySpinnerette packsFilament forming substance formingFiberYarn

Olive green fiber for net weaving to reduce the water resistance of the mesh, using LLDPE resin, PP resin, olive green pigment, auxiliary agent, antioxidant 1010, wire collecting machine, wire dividing machine, mixer, single screw extruder and two drafts Electric heating drawing machine, characterized by mixing PP resin, LLDPE resin, antioxidant 1010, olive green pigment, and white oil additives, stirring with a mixer until the materials are evenly stirred to obtain blended pellets; the blended pellets are passed through a single screw The extruder is melted and extruded, and the melted and extruded as-spun yarn is cooled and pre-drawn by the low-temperature water in the cooling water tank and the first drafting roller, and the pre-drawn yarn is passed through the high-temperature first drafting water bath and the second drafting roller, The high-temperature second drafting hot oil bath and the third drafting roller carry out two hot drafts, and the total drafting ratio is controlled at 9.5 times to 10.2 times, and the fiber tow is rewound by a torque motor winding machine; The machine-separated yarn is olive green fiber for weaving nets that can reduce the water resistance of the mesh.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method of rope for pelagic fishery

ActiveCN106283770BImprove spinnabilityImprove performanceAgriculture tools and machinesSpinnerette packsHydroxystearic AcidTorque motor

The invention discloses a machining method for a rope for distant-water fishery. The machining method is characterized by comprising the following steps: pre-mixing UHMWPE powder, silicone powder, an antioxidant 1010, a nano-silver-loaded titanium dioxide antibacterial agent, hydroxy stearic acid, nano-scale white carbon black, antioxidant aid DLTP, ethylene-vinyl acetate copolymer, nano-scale diatomaceous earth and white oil which are weighed according to a formula, and then pouring the mixture into a high-speed kneading pot for performing high-speed kneading to obtain a UHMWPE-modified compound material; melting and extruding the UHMWPE-modified compound material through a double-screw extruding machine; metering an extrudate through a metering pump which is additionally mounted at the outlet of the double-screw extruding machine, and melting and extruding the extrudate from spinning holes; cooling and pre-stretching the extruded as-spun fibres; after the pre-stretched fibres are subjected to heat setting, winding melt-spinning tows by a fibre winding machine using a torque motor; performing primary twisting on the melt-spinning tows to obtain an S-directional rope strand; machining three S-directional rope strands into a Z-twisted rope for the distant-water fishery through a three-strand rope twisting machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of polyoxymethylene monofilament for fishing and its preparation method and application

ActiveCN110129921BImprove spinnabilityImprove performanceMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsPolyoxymethylenePolymer science

The invention discloses a polyoxymethylene monofilament for fishing, which is made of the following components in parts by weight: 75-90 parts of polyoxymethylene, 0.5-3 parts of graphene, 7.5-17 parts of thermoplastic polyurethane, and 0.5 parts of antioxidant 3 parts, 0.5-1 part of formaldehyde absorbent, 0.5-1 part of formic acid absorbent, 0.5-1 part of lubricant. The polyoxymethylene monofilament for fishery provided by the present invention uses graphene and thermoplastic polyurethane to blend and then strengthens and toughens the polyoxymethylene. Polyoxymethylene monofilament has the advantages of simple operation process and low production cost. The reinforced and toughened polyoxymethylene monofilament for fishery prepared by the invention can be used in polyoxymethylene rope nets, ocean-going trawls, breeding nets, polyoxymethylene ropes and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

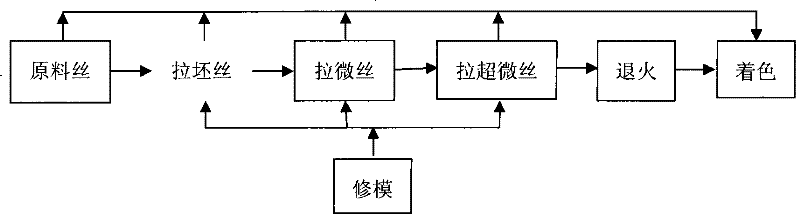

Production process of stainless steel superfine wire

InactiveCN101518789BReduce manufacturing costGuaranteed YieldDrawing diesFurnace typesUltra fineStainless steel wire

The invention relates to a production process of colored stainless steel microwires capable of drawing φ0.018mm stainless steel microwires, which includes a stainless steel wire drawing machine, and raw material selection: select φ0.2mm stainless steel wires as raw materials and draw them to φ0.035mm by the stainless steel wire drawing machine , as a blank wire drawing φ0.018mm~0.015mm; mold matching: a set of multiple wire drawing dies is matched with the forming die, and the inner diameters of the multiple wire drawing dies are 0.030, 0.027, 0.025, 0.023, 0.021, 0.020 , 0.019; Or 0.030, 0.027, 0.025, 0.023, 0.021, 0.020, 0.019, 0.018, 0.017, 0.016, the inner diameter of the forming die is 0.018 or 0.015, and the blank wire is drawn to obtain microfilaments through the above-mentioned cover die and forming die. The microfilaments pass through the high-temperature oxidizing atmosphere at a speed of less than 10 meters per second, and a transparent film with a thickness of tens to hundreds of nanometers is formed on the surface of the microfilaments. Films with different thicknesses and different compositions present different colors.

Owner:DUNLI GRP CO LTD

Processing method of antifouling melt-spinning for net cage or floating rope seine in deep sea

ActiveCN106192030BImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

A kind of polyoxymethylene monofilament and its preparation method and polyoxymethylene wear-resistant rope for ecological fence

ActiveCN110042498BPioneer compositionSmooth spinning productionAgriculture tools and machinesConjugated synthetic polymer artificial filamentsElastomerPolyoxymethylene

The invention discloses a polyoxymethylene monofilament, which is made of the following components in parts by weight: 100 parts of polyoxymethylene, 5-25 parts of polyethylene octene copolymerized elastomer, 0.5-10 parts of nano silicon dioxide, anti-oxidation 0.1-1 part of anti-oxidant, 0.1-1 part of antioxidant, 0.1-0.5 part of lubricant. The invention also discloses a polyoxymethylene wear-resistant rope for ecological fences prepared from the polyoxymethylene monofilament. The obtained rope has the advantages of good safety, low price, excellent wear resistance and high breaking strength, and has a certain Antibacterial antifouling effect.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

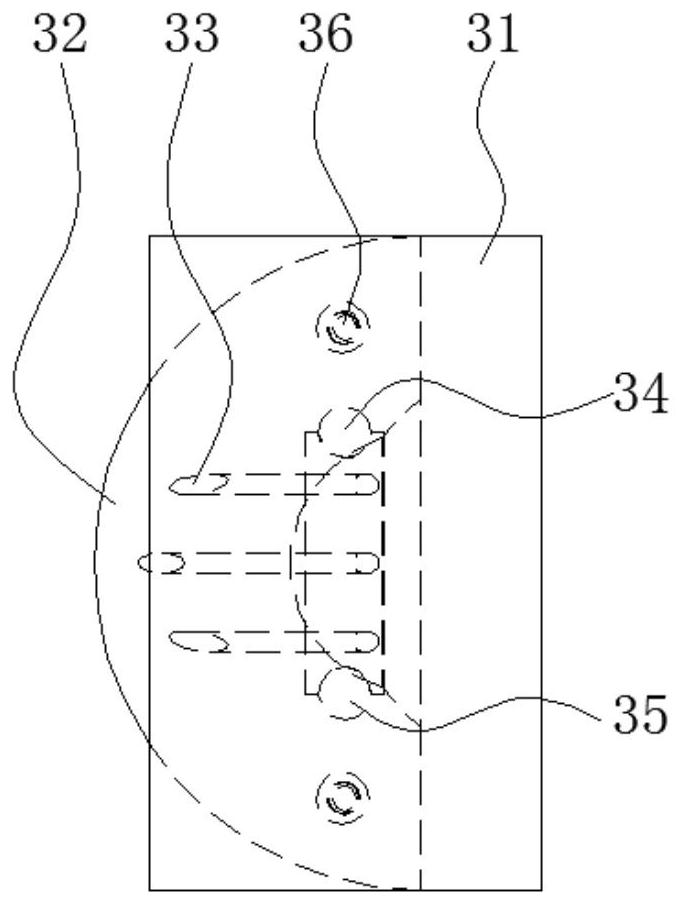

Arc height protection device

PendingCN113463419AGuarantee product qualityNo wire breakageRope making machinesStructural engineeringMachine tool

The invention discloses an arc height protection device. The device comprises a machine tool, a bottom plate fixedly arranged on the surface of the machine tool, a strong magnetic limiting plate located at the upper end of the bottom plate, a hinge device fixedly arranged together with the strong magnetic limiting plate, a contact rod connected with the hinge device, an alarm device, a PLC control panel and a power supply; a strong magnet is embedded in the strong magnetic limiting plate; one end of the contact rod is provided with a magnetic rod, and the other end of the contact rod is provided with a conductive rod; the magnetic rod and the strong magnet are magnetically attracted; the conductive rod is fixedly arranged together with the hinge device; the free end of the conductive rod extends out of the edge of the strong magnetic limiting plate; the hinge device is provided with a conductive contact; and the conductive contact is connected with the PLC control panel, the alarm device, the power supply and the machine tool through wires. According to the invention, in the paying-off process of the steel cord internal paying-off stranding machine tool, when the arc height of a steel cord is too large, the machine tool can give an alarm and stop in time, the phenomena of wire breakage and rope breakage of the steel cord are avoided, the product quality of the steel cord is ensured, and the loss is reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Method for preparing ultra-tensile strength fibers of ultra-high molecular weight polyethylene and isotactic polypropylene blends

InactiveCN111206296AEasy to manufactureStable wire diameter controlConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a method for preparing ultra-tensile strength fibers of ultra-high molecular weight polyethylene and isotactic polypropylene blends. In the method, ultra-high molecular weightpolyethylene resins and isotactic polypropylene resins are included. The ultra-high molecular weight polyethylene resins and isotactic polypropylene resins are blended at a certain ratio to form a mixture resin material, and then the resulting mixture resin is placed in an injection molding machine, followed by extrusion and wire drawing, to obtain the ultra-tensile strength fibers of ultra-high molecular weight polyethylene and isotactic polypropylene blends. In the invention, the mixed synthetic resin is easy to prepare fiber filaments, with stable diameter control, uniform thickness, no wire breakage during the preparation process, extremely fast drawing speed, and no deterioration of the environment. The prepared ultra-tensile strength fibers have the tensile strength and modulus not less than the ultra-high molecular weight polyethylene fibers.

Owner:东方交联电力电缆有限公司

Hollow fiber ultrafilter membrane and its preparation method

InactiveCN102489170BHigh strengthImprove hydrophilicitySemi-permeable membranesUltrasound attenuationHollow fibre

Owner:CHONGQING DELING TECH

A preparation method of a cylindrical box with antifouling performance for deep sea net cages

ActiveCN111657197BGood miscibilityImprove liquidityElectroconductive/antistatic filament manufactureClimate change adaptationHigh densityPolyamide

The invention provides a method for preparing a cylindrical box body for deep-sea net cages with antifouling properties, including A, preparation of antifouling net clothing, including preparation of modified high-density polyethylene composite materials, preparation of antifouling monofilament bundles, and antifouling Three aspects of dirty net processing; B. Anti-friction net preparation, made of polyamide net coated with polyurea coating; C. Cylindrical box preparation, including side net processing, bottom net processing and cylindrical box Three aspects of processing. According to the preparation method of the present invention, the cylindrical box body with antifouling performance for deep-sea net cages can greatly improve the antifouling performance of the cylindrical box body under the premise of keeping the strength of the side nets constant. It can also reduce the water resistance of the cylindrical box and the area of fouling organisms, which can greatly reduce the fouling of the cylindrical box and the fish escape accidents caused by broken nets under harsh sea conditions. Green development and modernization.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method of consumption-reducing and resistance-reducing filaments for marine ranch

ActiveCN111647960AImprove roundnessImprove liquidityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentProcess engineeringStearic acid

The invention provides a manufacturing method of consumption-reducing and resistance-reducing filaments for a marine ranch. The manufacturing method comprises three steps of raw material compounding,melt spinning and stretching and heat setting. The manufacturing method comprises the following specific steps: by taking POK granules, zinc stearate, silicone powder, an antioxidant and white oil asraw materials, acquiring a POK compound material first; and then carrying out extrusion by a twin-screw extruder, and performing spinning, stretching, heat setting and filament separating to obtain POK fibers. The POK fibers prepared by the manufacturing method of the consumption-reducing and resistance-reducing filaments for the marine ranch have excellent performance of surface smoothness, highstrength, wear resistance and the like. The manufacturing method is simple, low in carbon and friendly to environment in preparation process, and can lower the production cost obviously.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method of super antibacterial melt-spinning yarn for krill fishery or breeding seine

ActiveCN106192065BImprove performanceSolving Melt Fracture ProblemsSpinnerette packsFilament forming substance formingHydroxystearic AcidTorque motor

The invention relates to a manufacturing method of superstrong-bacterium-inhibiting melt-spun filaments for krill fishery or aquaculture purse seines. The manufacturing method is characterized by including: premixing UHMWPE powder, HDPE powder, nano titanium dioxide silver-loaded antibacterial agent, nano titanium dioxide, hydroxy stearic acid, ethylene-vinyl acetate copolymer, silicone powder, antioxidant 1010, nanoscale diatomite, nanoscale white carbon black, assistant antioxidant DLTP and white oil weighed according to the formula, and pouring into a high-speed kneading pot to perform high-speed kneading to obtain a UHMWPE composite material; extruding the UHMWPE composite material with a double-screw extruder in a melt manner, using a measuring pump mounted at the a double-screw outlet to measure the extruded material, extruding the measured material from a spinneret orifice in a melt manner, cooling and pre-drafting the extruded spun filaments, subjecting the pre-drafted filaments to thermoforming, using a filament collecting machine using a torque motor to wind melt-spun tows; separating the melt-spun tows with a filament separator to obtain the superstrong-bacterium-inhibiting melt-spun filaments for the krill fishery or aquaculture purse seines.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com