Compound stranded aluminum alloy cable and preparation method and application thereof

A technology of aluminum alloy and aluminum alloy monofilament, which is used in cable/conductor manufacturing, power cable, insulated cable, etc., can solve the problems of affecting product performance and appearance, easy wire breakage, high production cost, and achieve good salt spray resistance. , The effect of reducing vertical force and good mold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

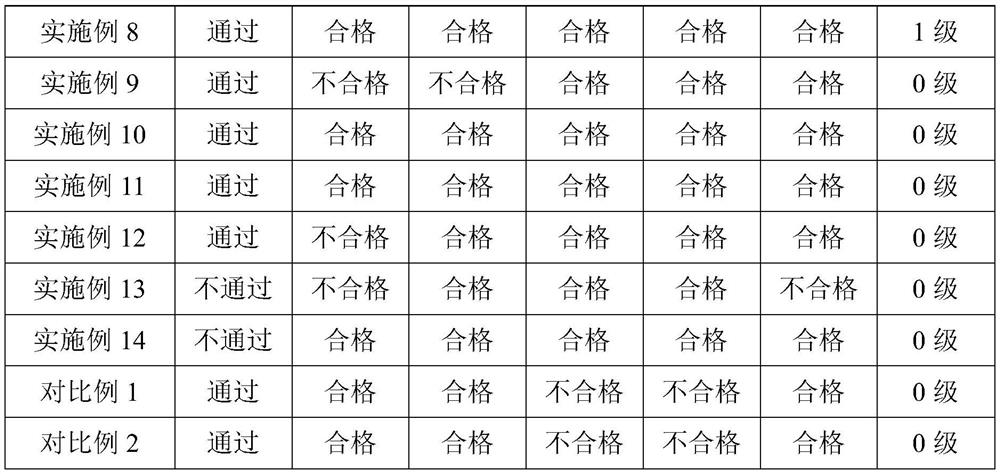

Examples

Embodiment 1

[0114] This embodiment provides a decayed aluminum alloy cable with a schematic view of figure 1 As shown, the decayed aluminum alloy cable is in the radial direction, including conductor, insulating layer, and sheath;

[0115] The conductor is derived from one central unit and six peripheral units, and the central unit is located at the center of the peripheral unit;

[0116] The central unit is thus strands from one steel wire rope and 6 5-class aluminum alloy strands, and the wire rope is located at a 5-class aluminum alloy strand center;

[0117] The peripheral unit is strangled from 7 5-class aluminum alloy strands;

[0118] The 5-class aluminum alloy shares were stranded by 35 aluminum alloy.

[0119] The aluminum alloy monofilament has a diameter of 0.40 mm, and the diameter of the wire rope is 2.5 mm;

[0120] The 5-class aluminum alloy shade has a magnification of 16 times, and the central unit is 15 times, and the diameter ratio of the peripheral unit is 15 times, and th...

Embodiment 2

[0141] The present embodiment provides a double stranded aluminum alloy cables, the difference is that Example 1:

[0142] The strands 5 type alloy obtained by the 30 alloy filaments twisted wire bundle to the left;

[0143] The diameter of the aluminum alloy monofilaments 0.51mm, 3.0mm diameter wire rope is;

[0144] Section 5 based alloy multiple strand diameter ratio of 18 times, the central unit multiples of pitch diameter ratio of 14 times, the pitch diameter ratio of the peripheral units is a multiple of 14 times, the conductor section diameter ratio multiple of 14 times;

[0145] The thickness of the insulating layer is 2.0mm, 2.0mm thickness of the sheath;

[0146] Raw material of the insulating layer comprises the following components by weight:

[0147] 45 parts EPDM rubber, 20 parts of talc, 20 parts of the kaolin, 3 parts of white carbon, 3 parts of rubber, paraffin oil, 4 parts of nano-zinc oxide, 4 parts of microcrystalline wax, 4 parts of titanium dioxide, sulfide B...

Embodiment 3

[0152] The present embodiment provides a double stranded aluminum alloy cables, the difference is that Example 1:

[0153] The strands 5 type alloy obtained by the 40 alloy filaments twisted wire bundle to the left;

[0154] The diameter of the aluminum alloy monofilaments 0.30mm, 4.0mm diameter wire rope is;

[0155] Section 5 based alloy multiple strand diameter ratio of 17 times, the central unit pitch diameter ratio of 16 times multiple of the peripheral unit multiples of pitch diameter ratio of 16 times, the diameter ratio of the conductor section is a multiple of 13 times;

[0156] The thickness of the insulating layer is 3.0mm, 4.0mm thickness of the sheath;

[0157] Raw material of the insulating layer comprises the following components by weight:

[0158] 55 parts of EPDM, 30 parts of talc, 30 parts of the kaolin, 7 parts of white carbon, 7 parts of rubber paraffin oil, 2 parts of nano-zinc oxide, 2 parts of microcrystalline wax, 2 parts of titanium dioxide, too 1 part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com