Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Meet the requirements of clean production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

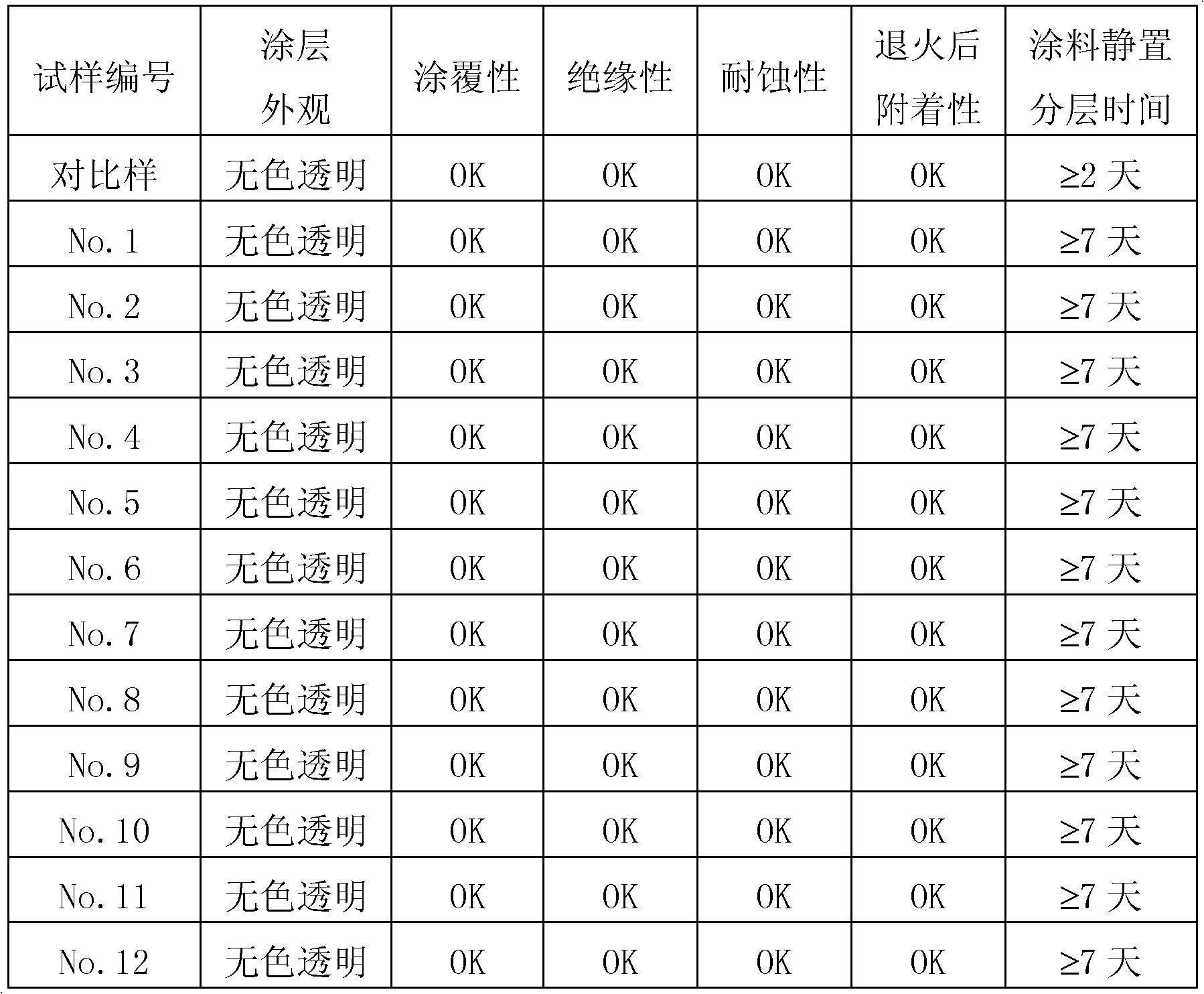

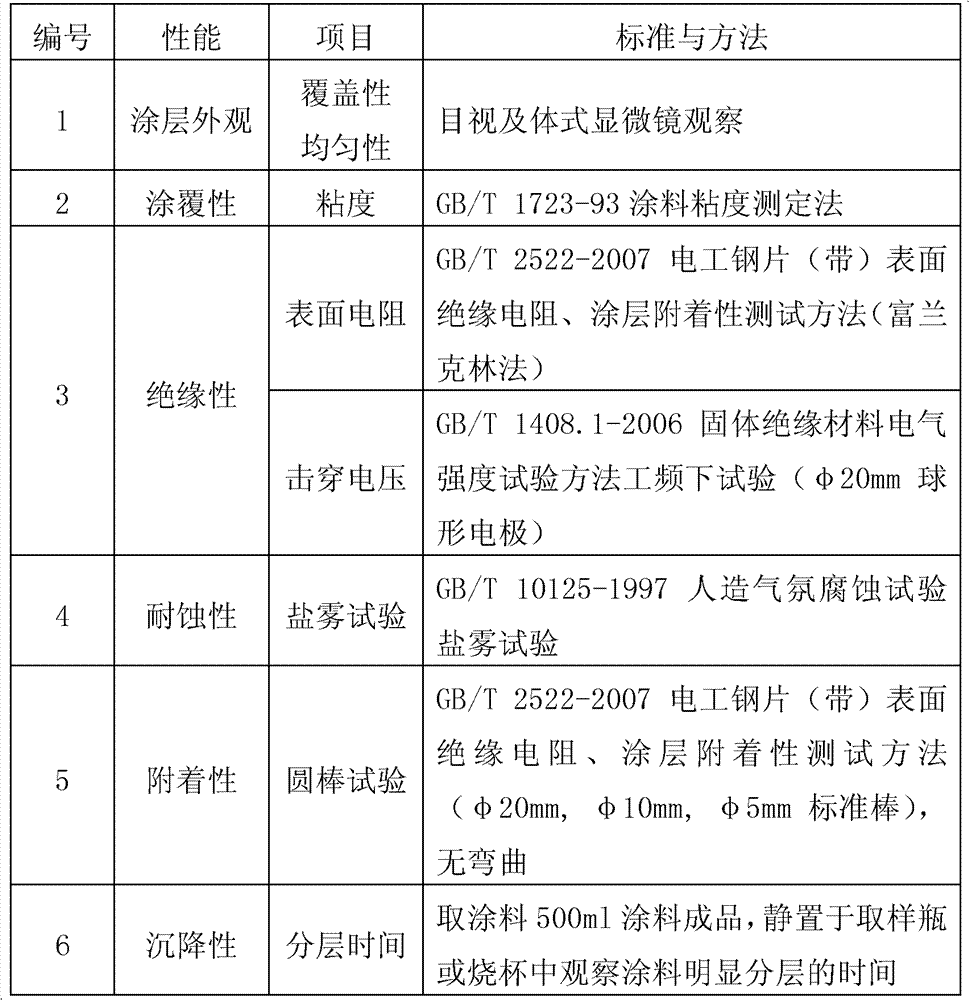

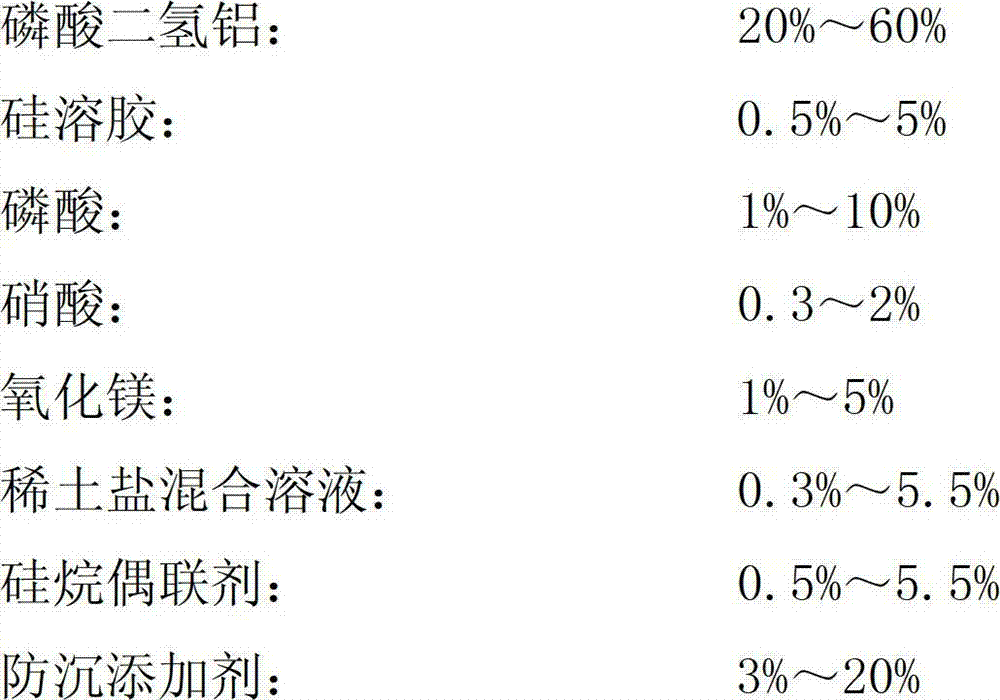

Aqueous environment-friendly insulation coating of anti-settling electric steel and preparation method thereof

InactiveCN102153896AImprove insulation performanceImprove corrosion resistanceMetallic material coating processesDispersityAdditive ingredient

The invention relates to an aqueous environment-friendly insulation coating of anti-settling electric steel and a preparation method thereof. The insulation coating is formulated from the following components by mass percent: 20-60% of aluminium dihydrogen phosphate, 0.5-5% of silica solution, 1-10% of phosphoric acid, 0.3-2% of nitric acid, 1-5% of magnesium oxide, 0.3-5.5% of rare earth-salt blended solution, 0.5-5.5% of silane coupling agents, 3-20% of anti-settling additives, and the balance of solvent water. In the invention, conventional roller painting technology is adopted for coatingand then a film can be made by proper high-temperature solidification. By multiple actions of physical covering, chemical passivation, phosphorization and the like, a surface insulation coating of a cold rolling electric steel plate without orientation has the advantages of good adhesiveness, high insulativity (namely resistance and puncture voltage between high-rises), high corrosion resistance,high temperature resistance and the like, as well as environmental protection without chrome or harmful ions. The insulation coating is widely applicable to the surface coating of the cold rolling electric steel plate without orientation, has a better anti-settling property, better dispersity and a better levelling property, leads coating operation on site to be more convenient and faster, and can effectively avoid the segregation of paint ingredients and the fluctuation of coating performances.

Owner:SHANGHAI QIJIA CHEM

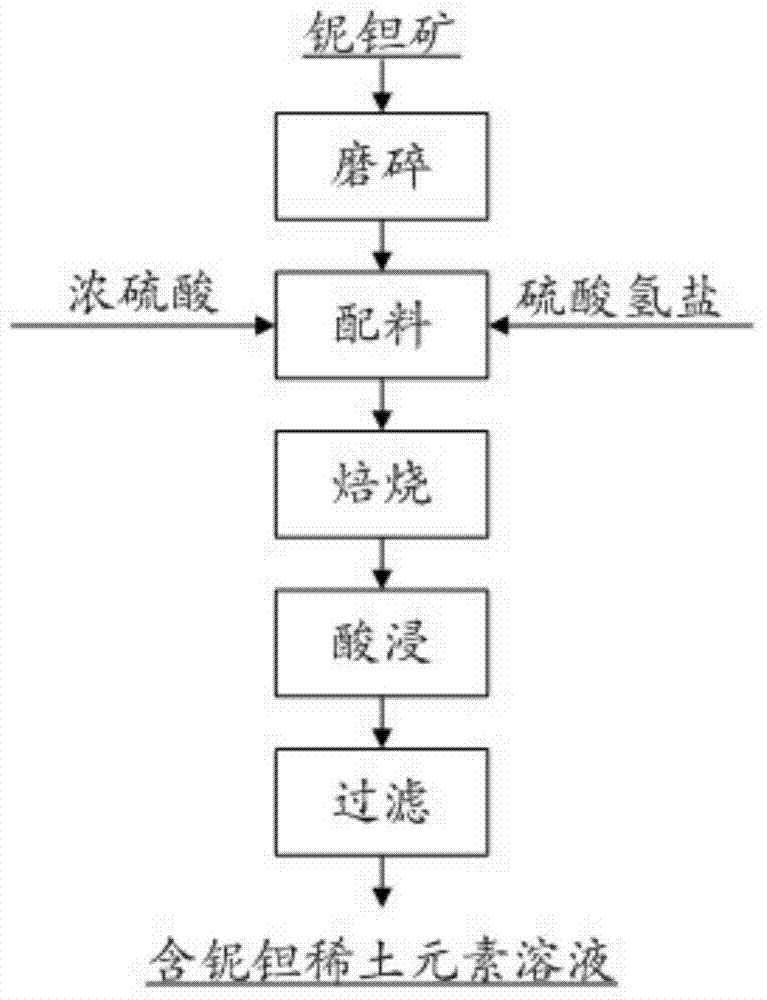

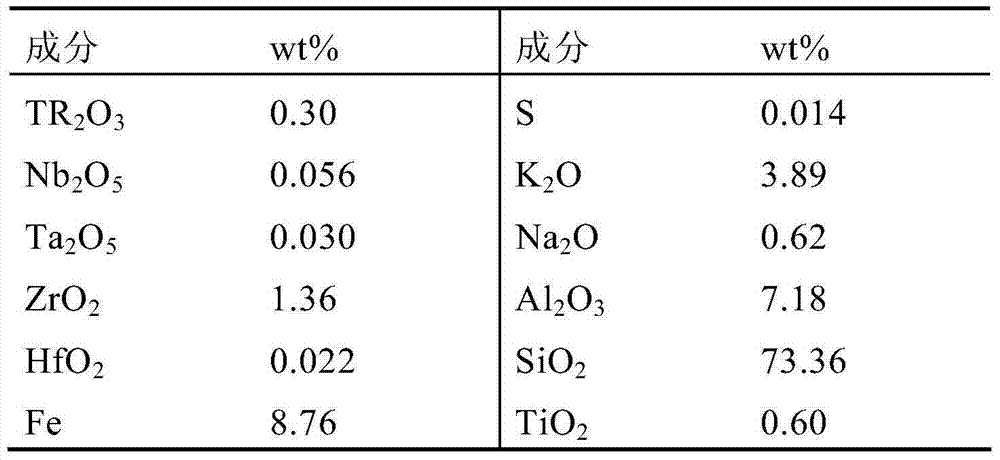

Method for extracting valuable metal elements in niobium-tantalum ore

InactiveCN104745807AEfficient leachingIncrease profitProcess efficiency improvementRare-earth elementSulfuric acid

The invention provides a method for extracting valuable metal elements in niobium-tantalum ore. The method comprises the following steps: (1) grinding the niobium-tantalum ore till the particle size is -200 to -500 meshes, and batching according to the mass ratio of the niobium-tantalum ore to concentrated sulfuric acid to disulfate being 1: (0.1-4):(0.1-4); (2) uniformly blending, and baking for 1-5 hours at the temperature of 200-800 DEG C to obtain a baked material; and (3) pickling the material obtained in the step (2) in sulfuric acid at the temperature of 30-100 DEG C, filtering, washing, and enabling niobium, tantalum and rare earth to enter a solution, wherein the concentration of the sulfuric acid is 0-40wt%, the leaching time is 1-4 hours. The method has the advantages that niobium, tantalum and rare earth elements are extracted simultaneously and efficiently, the leaching efficiency of the niobium and tantalum is above 95%, and the leaching efficiency of the rare earth element is approximate to 100%. The method is easy to operate and pollution-free and meets the requirements of environment-friendly metallurgy for cleaning production.

Owner:有研科技集团有限公司

Material with humidifying function and preparation method thereof

InactiveCN101711972ALow costWide variety of sourcesOther chemical processesDispersed particle separationNon toxicityMoisture absorption

The invention relates to a material with humidifying function and a preparation method thereof. An adopted organic-inorganic composite material comprises the following components in percentage by weight: 15 to 18 percent of mica, 70 to 75 percent of silica sol, 3 to 4 percent of kaolin, 1 to 2 percent of montmorillonite, 5 to 8 percent of cross linker and 0.1 to 0.2 percent of dispersant. The preparation method comprises the following steps: ball-milling the components for 12 to 24 hours and mixing the components uniformly, adding the cross linker into the mixture, stirring the mixture for 30 minutes, then molding the mixture according to the required product, and naturally drying the mixture to form the material with the humidifying function. The obtained material has the advantages of obvious moisture absorption effect, stable performance, low raw material cost, simple preparation process, non-toxicity and environmental protection, can reduce or cancel the running time and frequency of an indoor air moisture adjusting device and save the energy, and has good market prospect and popularization and application values.

Owner:JINGDEZHEN CERAMIC UNIV

Preparation method of 2-chloro-5-chloromethylpyridine

The invention discloses a preparation method of 2-chloro-5-chloromethylpyridine; with 2-chloro-5-methylpyridine as a raw material, the temperature rises to 80-160 DEG C, chlorine gas is introduced, a chlorination reaction is performed, and 2-chloro-5-chloromethylpyridine is obtained. The preparation process adopts heat chlorination, has no need of ultraviolet light catalysis having high energy consumption, also has no need of expensive catalysts, is friendly to the environment and high in product yield, meets the requirements of cleaning production, and is an effective method for preparing 2-chloro-5-chloromethylpyridine.

Owner:NANJING REDSUN BIOCHEM CO LTD

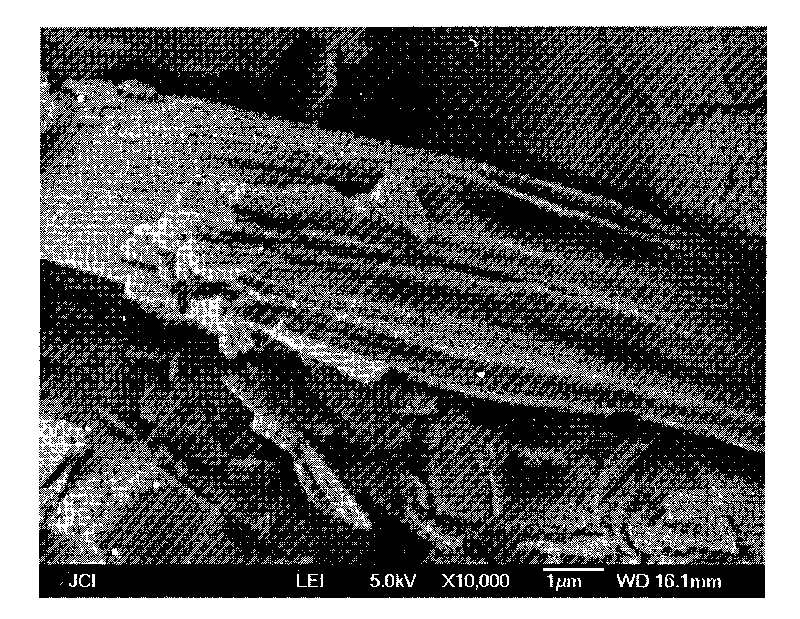

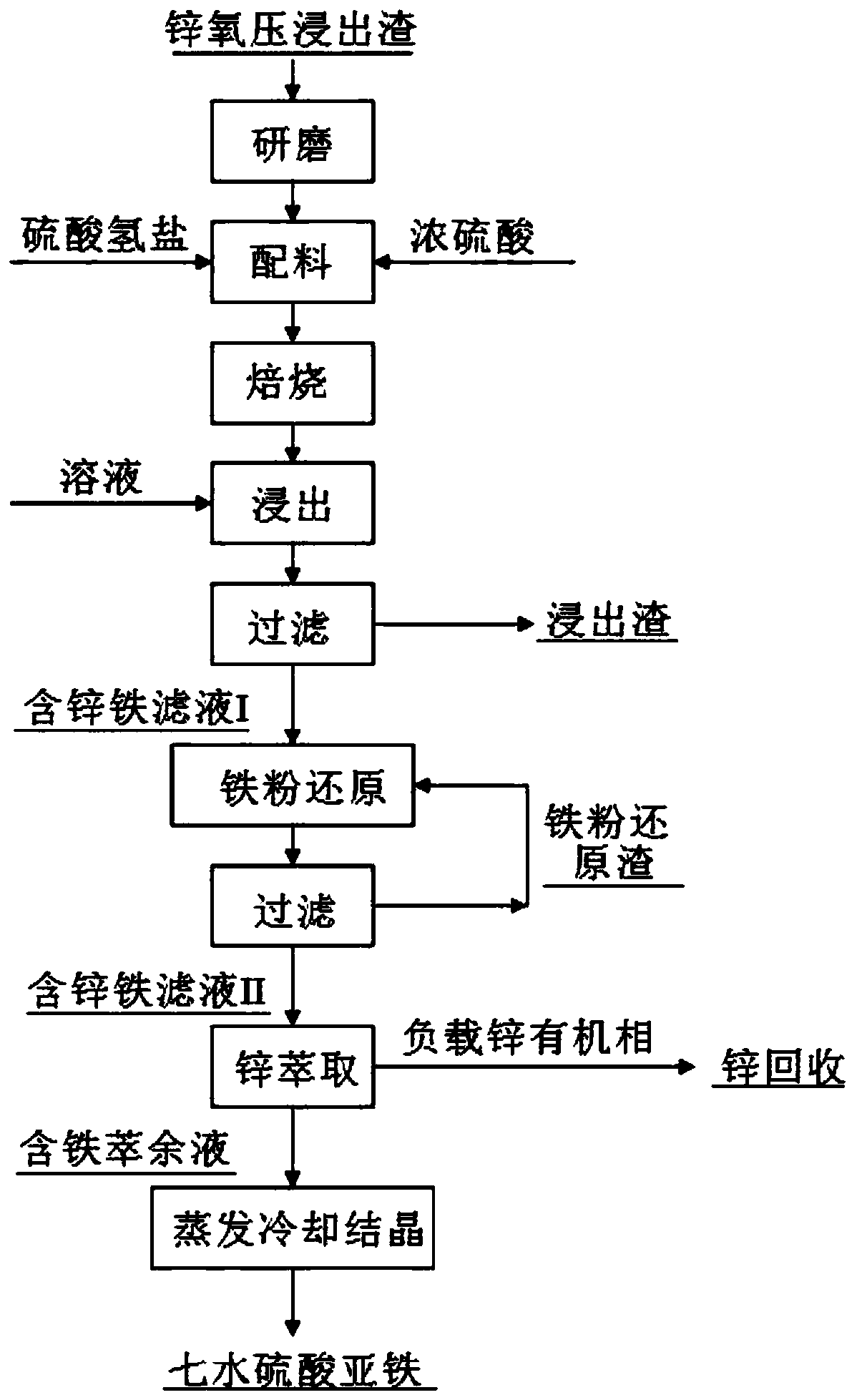

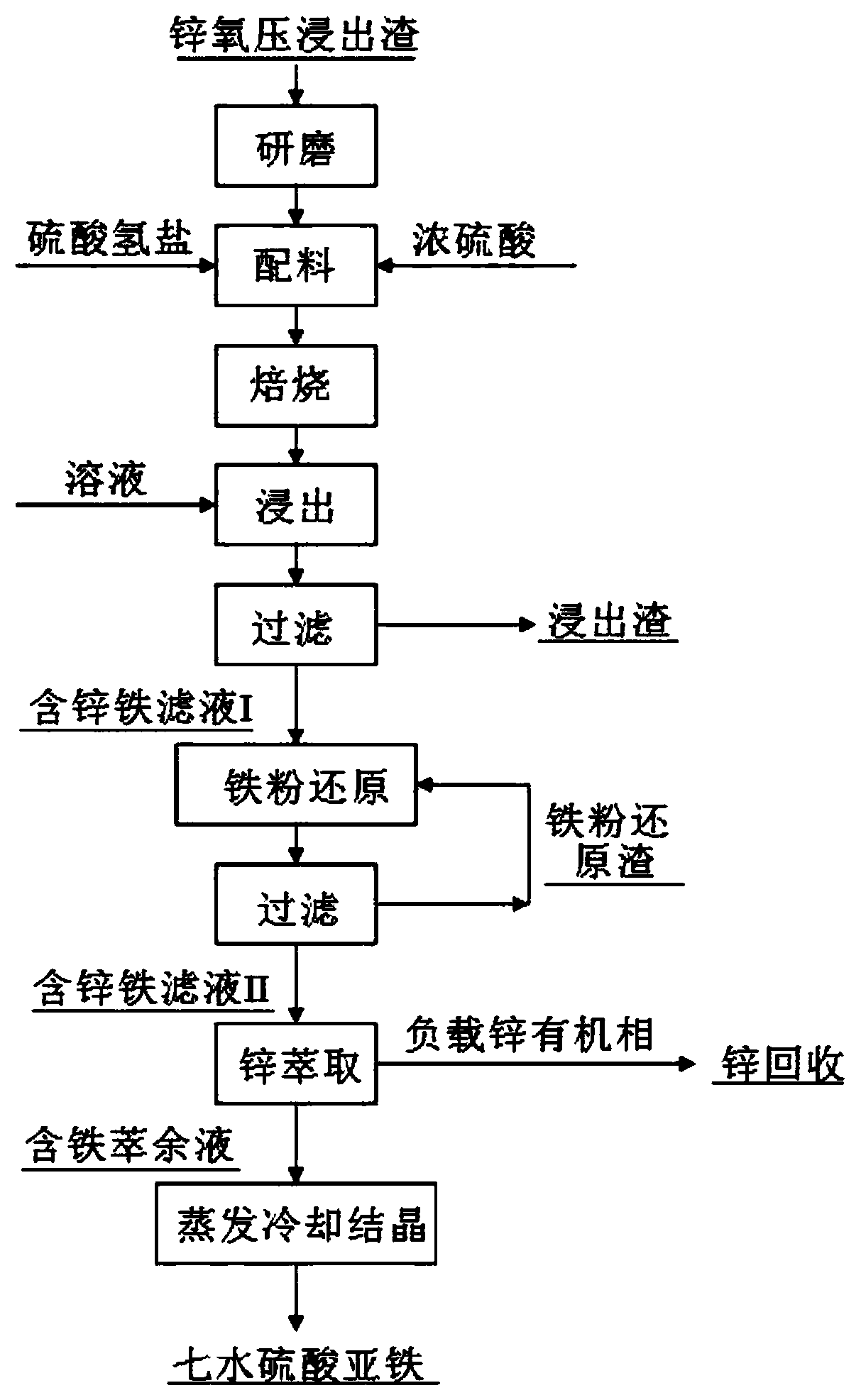

Method for recycling zinc and iron in zinc oxygen pressure leaching slag

ActiveCN109022759AWide variety of sourcesLow costProcess efficiency improvementFerrous sulfate heptahydrateCrystal

The invention provides a method for recycling zinc and iron in zinc oxygen pressure leaching slag. The method comprises the following steps that ingredient preparation is conducted according to mass ratio of zinc oxygen pressure leaching slag: concentrated sulfuric acid: bisulfate being 1: 0.4-2: 0.1-2; the ingredients are uniformly mixed, and roasting is conducted at 200-40 DEG C and lasts for 0.5-5 hours to obtain a roasted product; the roasted product is subjected to sulfuric acid solution leaching at 20-95 DEG C, concentration of the sulfuric acid solution is less than 5 wt%, and the leaching time is 0.5-4 hours; filtering is conducted, zinc and iron are placed into filter liquor I containing zinc and iron, iron powder is added into the filter liquor I containing zinc and iron, the Fe<3+> is restored to Fe<2+>, and filtering is conducted to obtain filter liquor II containing zinc and iron; and the filter liquor II containing zinc and iron is subjected to zinc extraction, and therefore zinc can be recycled. The rest liquor containing iron is subjected to evaporation, refrigeration and crystallization, and therefore byproduct ferrous sulfate heptahydrate crystal can be obtained.The zinc and iron in zinc oxygen pressure leaching slag can be efficiently extracted. The recycling rate of the zinc is greater than 96%, and the recycling rate of the iron is greater than 95%. The method has the advantages that recycling rate is high, operation is convenient, and energy consumption is low.

Owner:有研资源环境技术研究院(北京)有限公司 +2

Cyanide-free gold plating technology after nickel plating and priming of electronic component

The invention provides a cyanide-free gold plating technology after nickel plating and priming of an electronic component. The cyanide-free gold plating technology comprises the following steps of: taking the electronic component, soaking in hydrochloric acid, cleaning, carrying out chemical polishing, cleaning, neutralizing, clamping, cleaning and removing oil; activating, and cleaning with deionized water; carrying out impact nickel plating, wherein the impact nickel plating temperature is (10-30) DEG C, and the current density is (1-8) A / dm2; carrying out nickel electroplating, wherein thenickel electroplating temperature is (40-55) DEG C, and the current density is (0.1-1) A / dm2; recycling, cleaning with deionized water, and activating; carrying out gold plating (putting into a tank with electricity), wherein the gold plating temperature is (38-45) DEG C, and the current density is (0.1-0.3 ) A / dm2; recycling, cleaning with deionized water, unloading a clamp, dewatering, and drying; and carrying out heat treatment and after treatment. According to the technology, a gold-plating layer on a nickel-plating layer has good bonding force and good coating performance.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

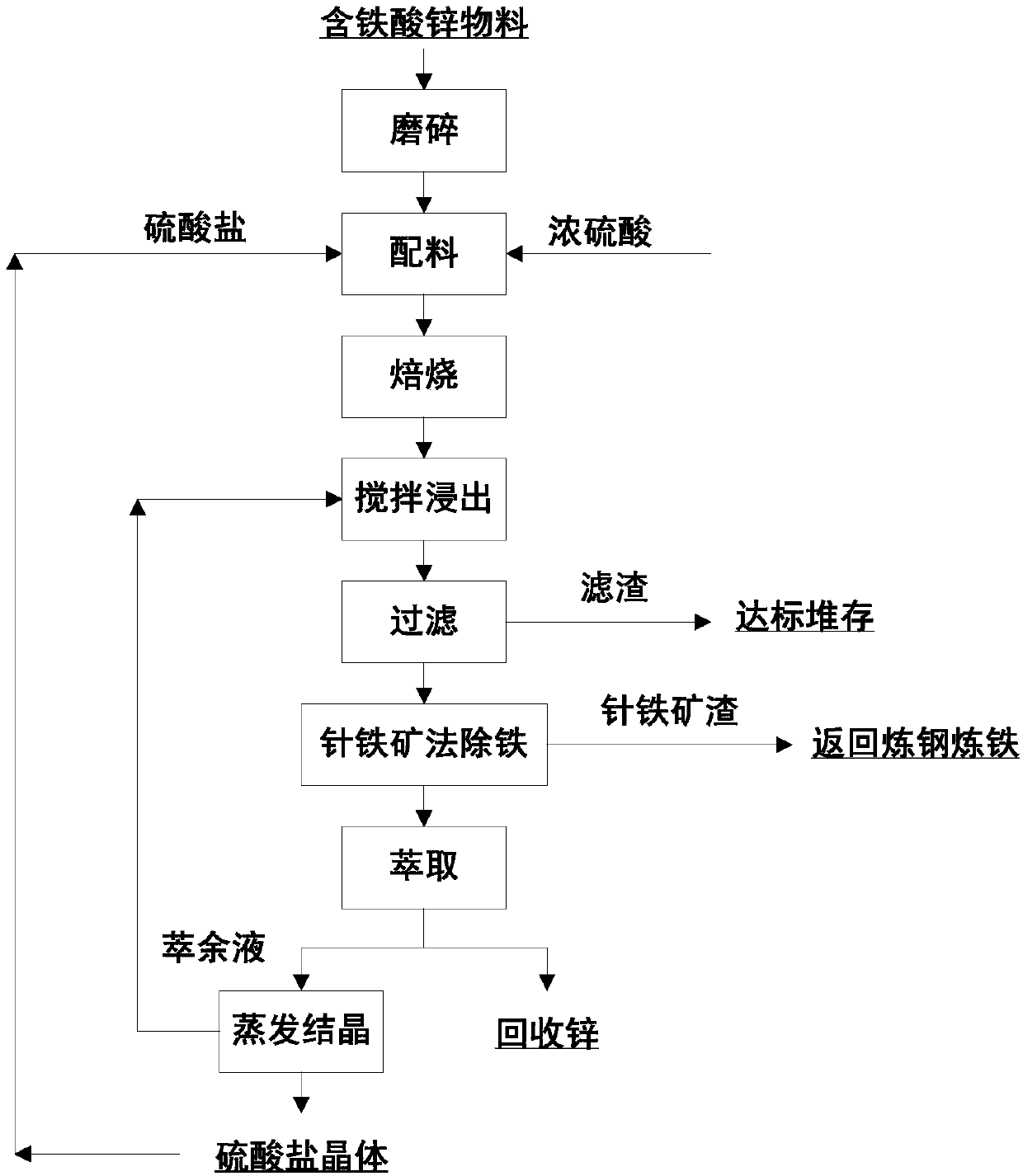

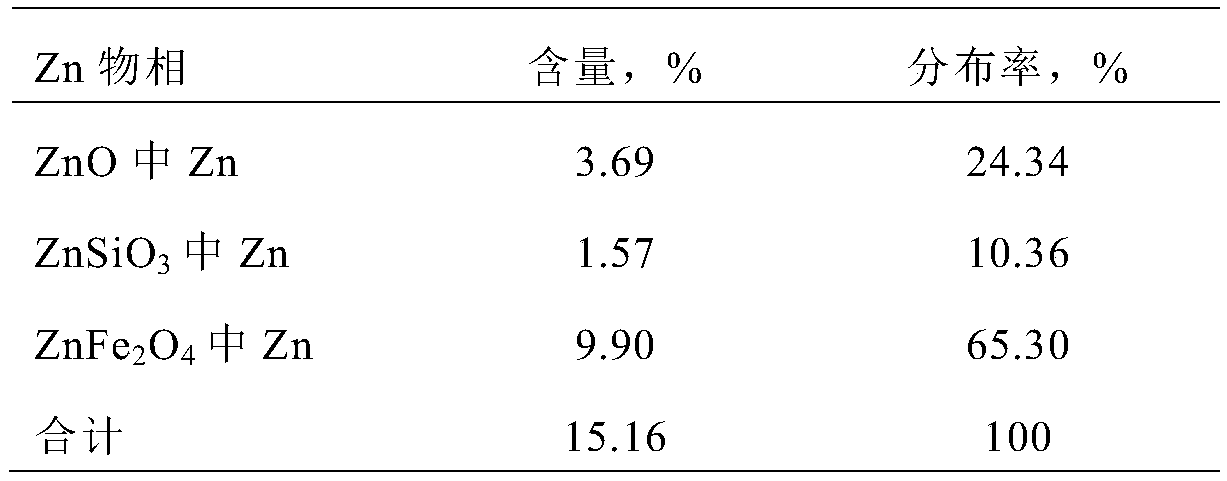

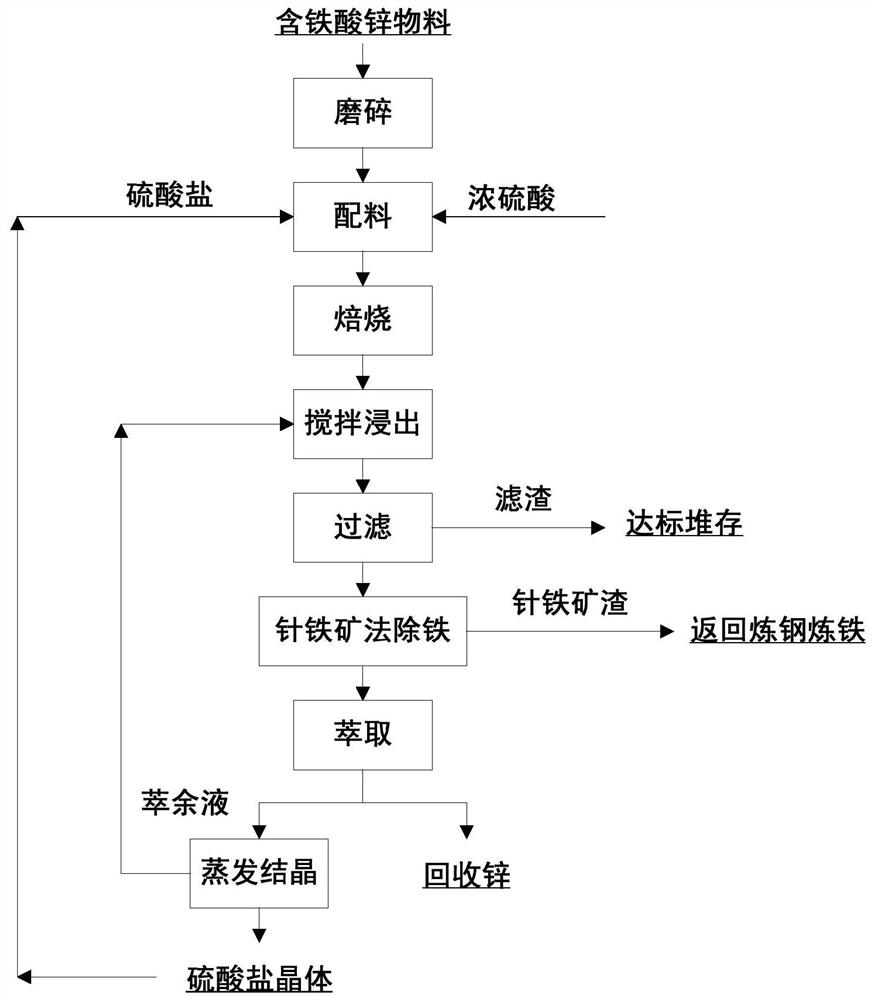

Method for efficiently recovering zinc and iron from zinc ferrite-containing material

The invention provides a method for efficiently recovering zinc and iron from a zinc ferrite-containing material. The method includes the following steps that the zinc ferrite-containing material is ground, and blending is performed according to the mass ratio of the zinc ferrite-containing material to sulfuric acid to sulfate being 1:(0.1-1):(0.01-1); the blended materials are mixed to be uniformand roasted for 0.5-4 hours at 150-400 DEG C; the roasted materials are subjected to agitation leaching for 0.5-4 hours at 25-90 DEG C, and filtration is performed to obtain a zinc-iron-containing solution and filtration residues; the zinc-iron-containing solution is subjected to iron removal through a goethite method to obtain goethite slag; and a zinc-containing solution obtained after iron removal is subjected to extraction electrodeposition to obtain an electrolytic zinc product, raffinate is cyclically subjected to agitation leaching, circuit opening is performed after many cycles for evaporative cooling crystallization to obtain sulfate crystals, and the sulfate crystals are returned to the blending section. The method can realize efficient decomposition, leaching and recovery of the zinc ferrite-containing material, the zinc recovery rate is greater than 98%, the iron recovery rate is greater than 95%, and the method has the advantages of being high in recovery rate, low in energy consumption, capable of recycling the solution and the like.

Owner:有研资源环境技术研究院(北京)有限公司

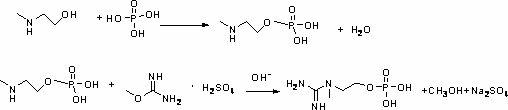

Method for synthesizing creatinol-o-phosphate

ActiveCN102584890AEnsure safetyNo pollution in the processPhosphorus organic compoundsSulfatePhosphoric acid

The invention discloses a method for synthesizing creatinol-o-phosphate, which comprises the steps as follows: (1) N-methyl-2-amino ethanol is taken as a raw material, and reacts with phosphoric acid so as to obtain N-methyl-2-amino ethanol phosphate ester; and (2) the N-methyl-2-amino ethanol phosphate ester obtained in the step (1) reacts with O-methyl isourea sulfate under an alkaline condition so as to obtain the creatinol-o-phosphate. The method is simple and feasible to operate, technological conditions are mild, the productivity and the purity of the obtained product are high, waste gas and waste acid are not generated during the whole process, the safety of equipment and operating staff are ensured, environment cannot be polluted, economical efficiency is achieved, and the requirements of clean production are satisfied.

Owner:JIANGSU YUANYANG PHARMA

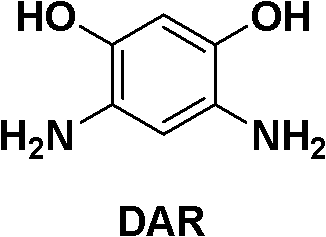

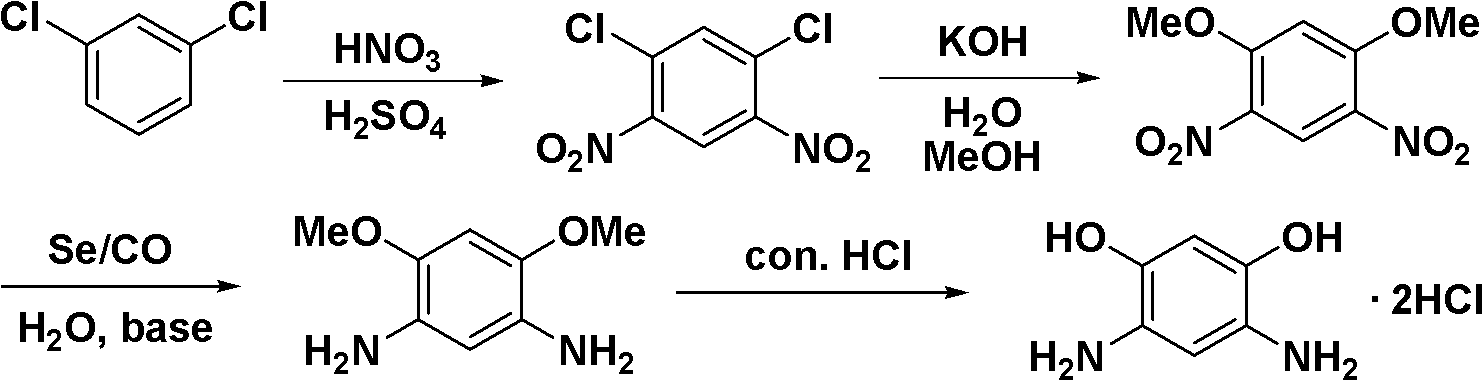

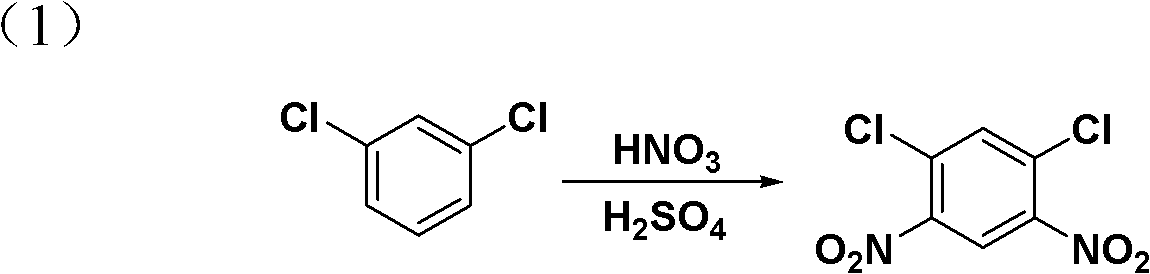

Method for synthesizing 4,6-diamino resorcinol dihydrochloride (DAR)

The invention discloses a method for synthesizing 4,6-diamino resorcinol dihydrochloride (DAR). The method for generating and producing DAR comprises four links of nitratlon reaction, alcoholysis, reduction and acidification, and the purity of products can meet the synthesis of PBO (poly (p-phenylenebenzobisoxazole) fiber. Compared with the prior art, the invention has the advantages of simpleness of synthesis and high reaction efficiency. A cheap selenium catalyst is adopted in the step with greatest difficulty and highest reaction cost, the selectivity of reaction is as high as 99 percent, and the reaction yield in the step is almost quantified. Crucially, the catalyst can realize multiple circulations by simple filtration. The production of by-products and isomers is reduced in the reaction process, and the purity of a final target compound 4,6-diamino resorcinol reaches 99,9 percent. The method disclosed by the invention has the advantages of simple whole process and low cost, meets the requirement of industrial production and is expected to realize industrialized application.

Owner:JIANGSU JIUJIUJIU TECH

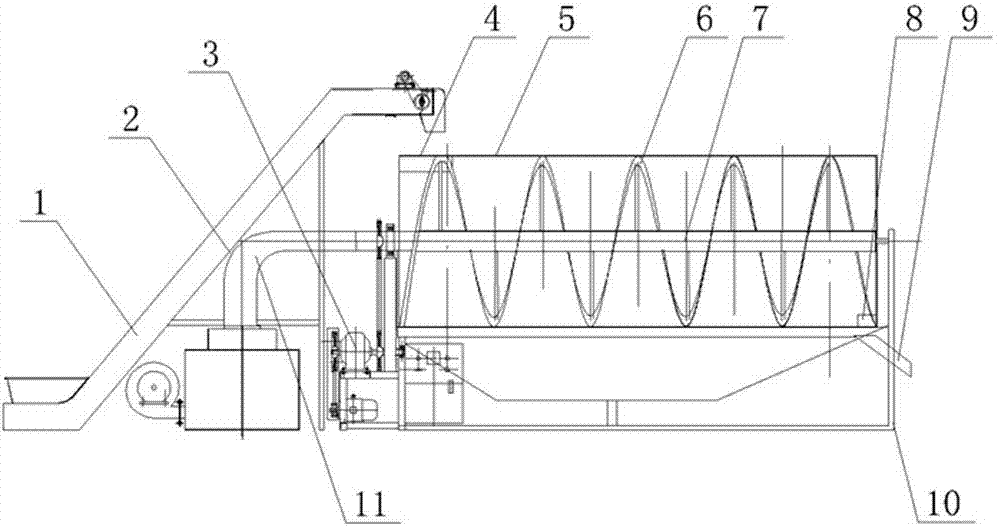

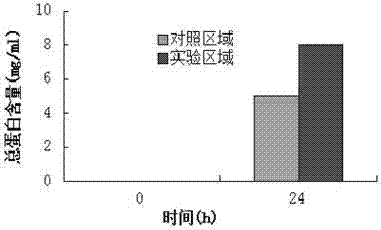

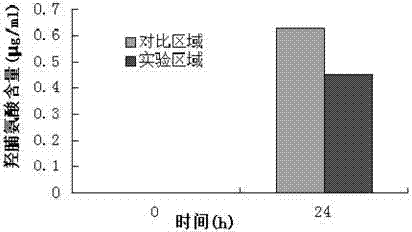

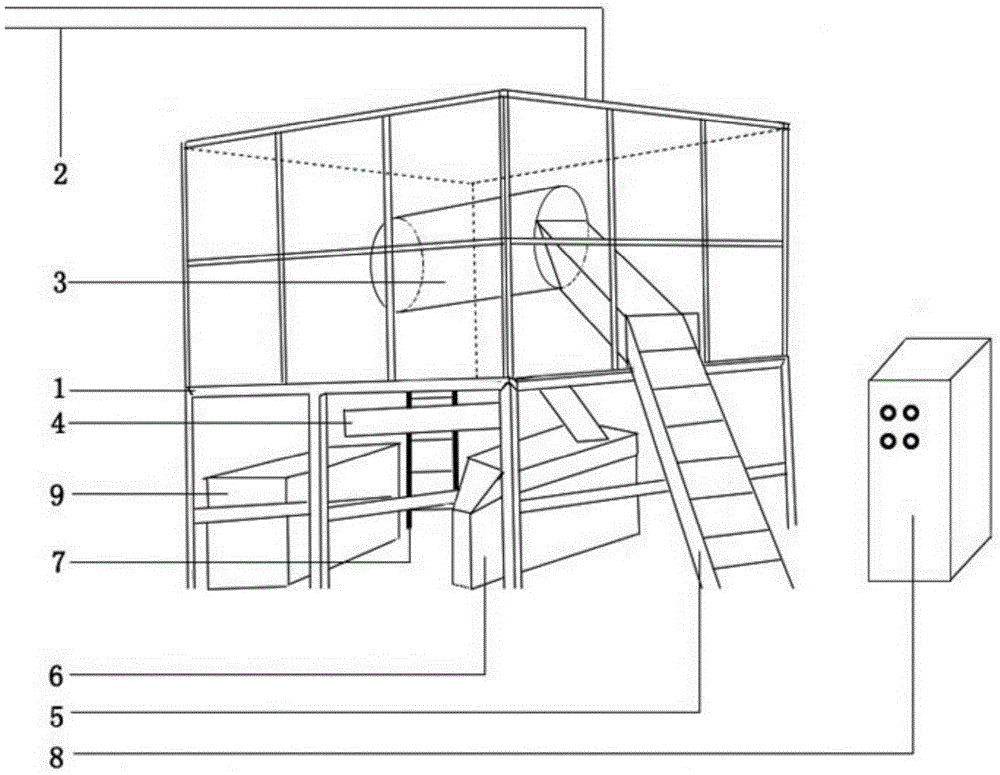

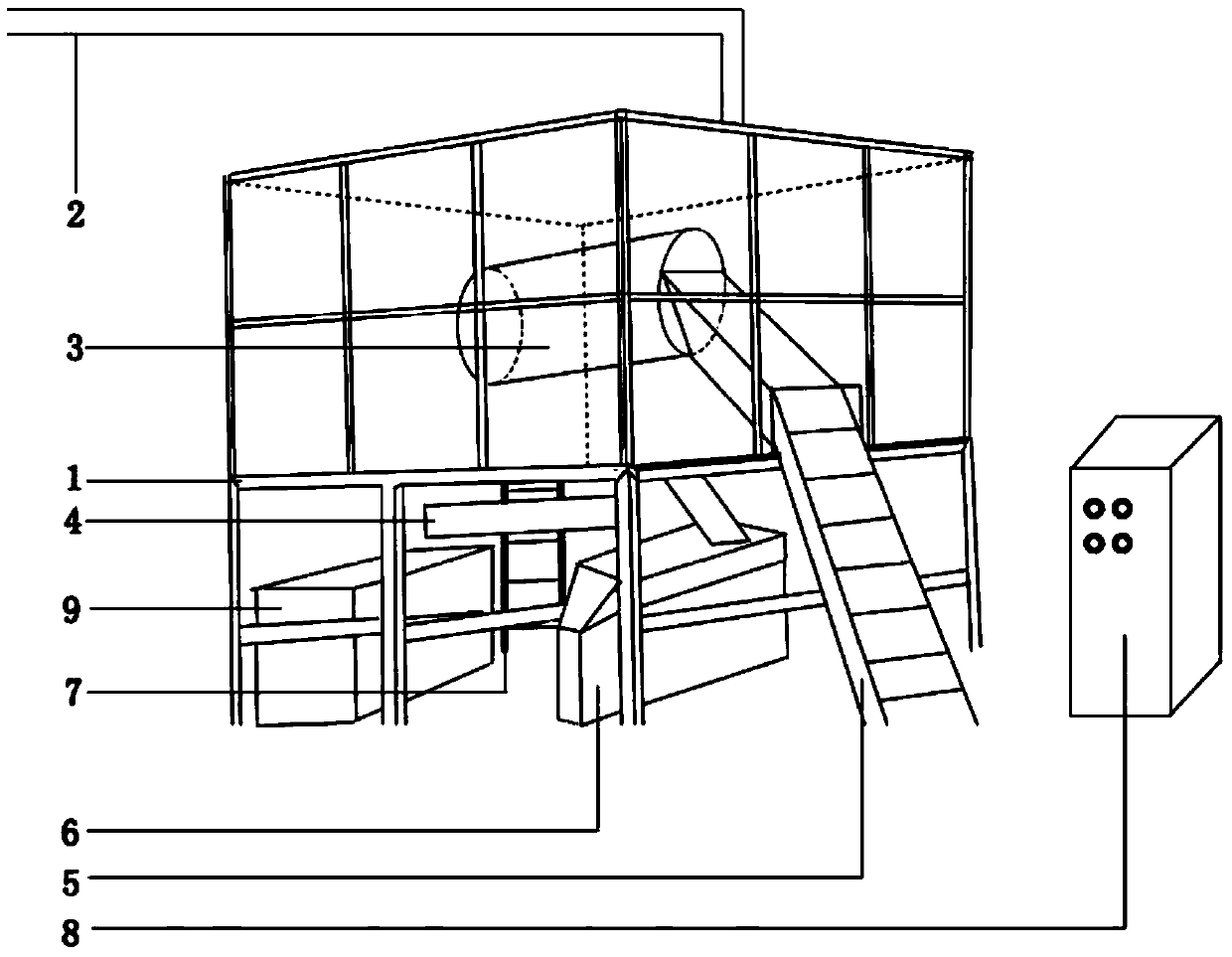

Automatic piling device for dark tea

ActiveCN102318696BJoyload conditionsRaise the gradePre-extraction tea treatmentEngineeringCleaner production

The invention belongs to a tea processing machine, and in particular relates to a dark tea piling technology. An automatic piling device for dark tea comprises a humid and hot air generator and a frame; the frame is provided with a piling barrel; a rotary shaft with spiral sheets is arranged in the piling barrel; the upper part of the front end of the piling barrel is provided with a tea inlet, and the tail end of the piling barrel is provided with a tea outlet; the rotary shaft is supported on the frame through a bearing; the humid and hot air generator is connected to the piling barrel through a pipe; the rotary shaft is driven by a power device; and door covers are arranged at the tea inlet and the tea outlet. Automatic piling operation is adopted in the device; in the whole piling process, the temperature and the humidity can be monitored and adjusted in real time, and optimal piling conditions of tea leaves can be created; meanwhile, because the device is provided with the spiralsheets for preventing agglomeration, the piling is not limited by external environmental conditions, the piling period is greatly shortened, and meanwhile, the tea has high grade, good quality and pure aroma; and the device meets the requirement of current clean production of tea.

Owner:ZHEJIANG ZHUFENG MACHINERY

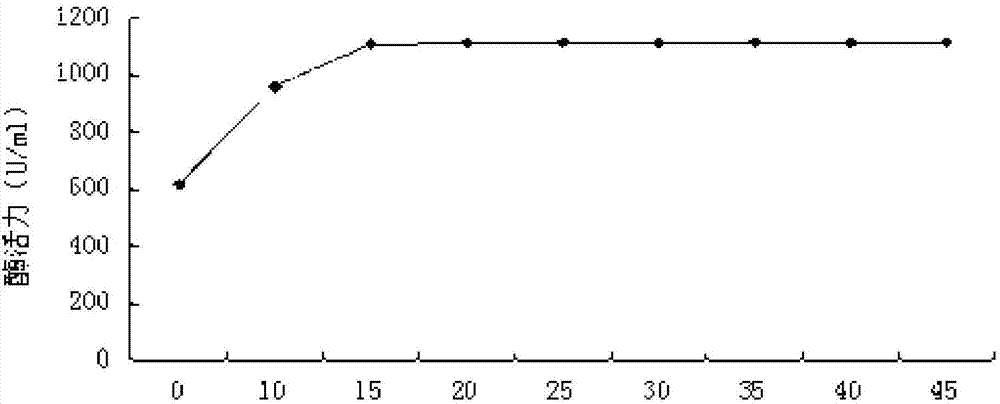

Enzyme unhairing assistant and preparation method thereof

ActiveCN104711380ALow chemical stabilityGood chemical stabilityPre-tanning chemical treatmentCalcium hydroxidePhosphate

The invention relates to an enzyme unhairing assistant in tanning production, particularly an enzyme unhairing assistant and a preparation method thereof. The enzyme unhairing assistant is prepared from effective quantities of potassium hydroxide, sodium percarbonate, sodium hydroxide, calcium hydroxide, composite phosphate and deionized water. The preparation method comprises the following steps: evenly mixing the sodium percarbonate and sodium hydroxide to prepare a mixture, preparing the calcium hydroxide into a 45-65 wt% water solution, adding the calcium hydroxide water solution and composite phosphate into the suspension prepared in the step A, adding the deionized water, stirring the room temperature, adding the potassium hydroxide and the rest of deionized water, and uniformly mixing to obtain the slightly alkaline enzyme unhairing assistant. The enzyme unhairing assistant solves the technical problem that the enzyme unhairing assistant in the prior art can not be easily popularized on a large area, can easily cause environmental pollution and the like, has the advantages of favorable unhairing effect, simple preparation method and the like, and satisfies the requirement for clean production in the unhairing process.

Owner:无极县景森皮革制品有限公司

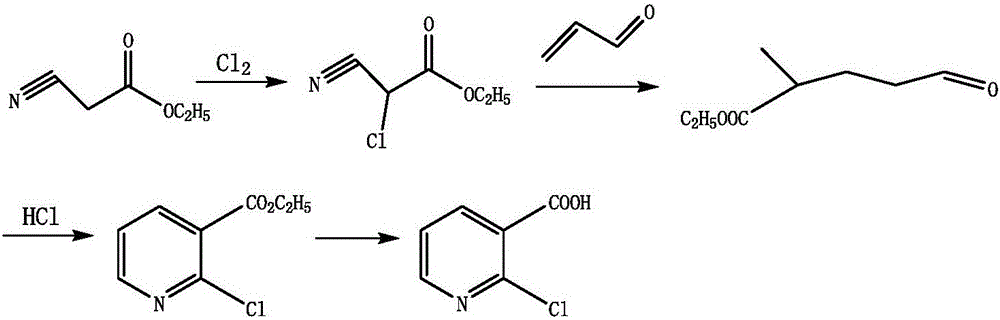

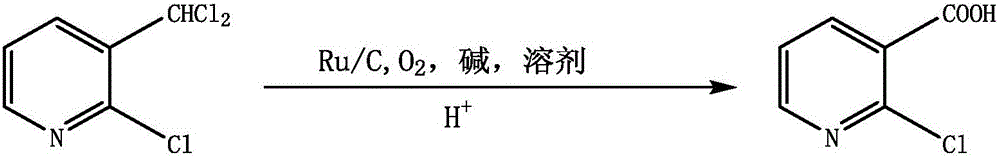

Method for one-step oxidation synthesis of 2-chloronicotinic acid

InactiveCN106243028AOxidation reactions are prone to occurHigh yieldOrganic chemistryOrganic solventFiltration

The invention discloses a method for one-step oxidation synthesis of 2-chloronicotinic acid. The method consists of: taking 2-chloro-3-dichloromethylpyridine as the raw material, adding alkali, using the mixture of water and a polar organic solvent as the solvent, adopting Ru / C as the catalyst, and carrying out oxygen oxidation to obtain a 2-chloronicotinic acid solution, then conducting acid precipitation, pumping filtration, washing and drying so as to obtain white solid powder 2-chloronicotinic acid. The method has the advantages of simple process, high yield up to 90% or more, use of oxygen as the oxidant, and environmental friendliness. The repeatedly applicable heterogeneous Ru / C catalyst is employed, and the product is easy to separate. The oxidation reaction system is a non-acidic system, overcomes the environmental pollution problem, and meets the requirements of clean production.

Owner:NANJING REDSUN BIOCHEM CO LTD

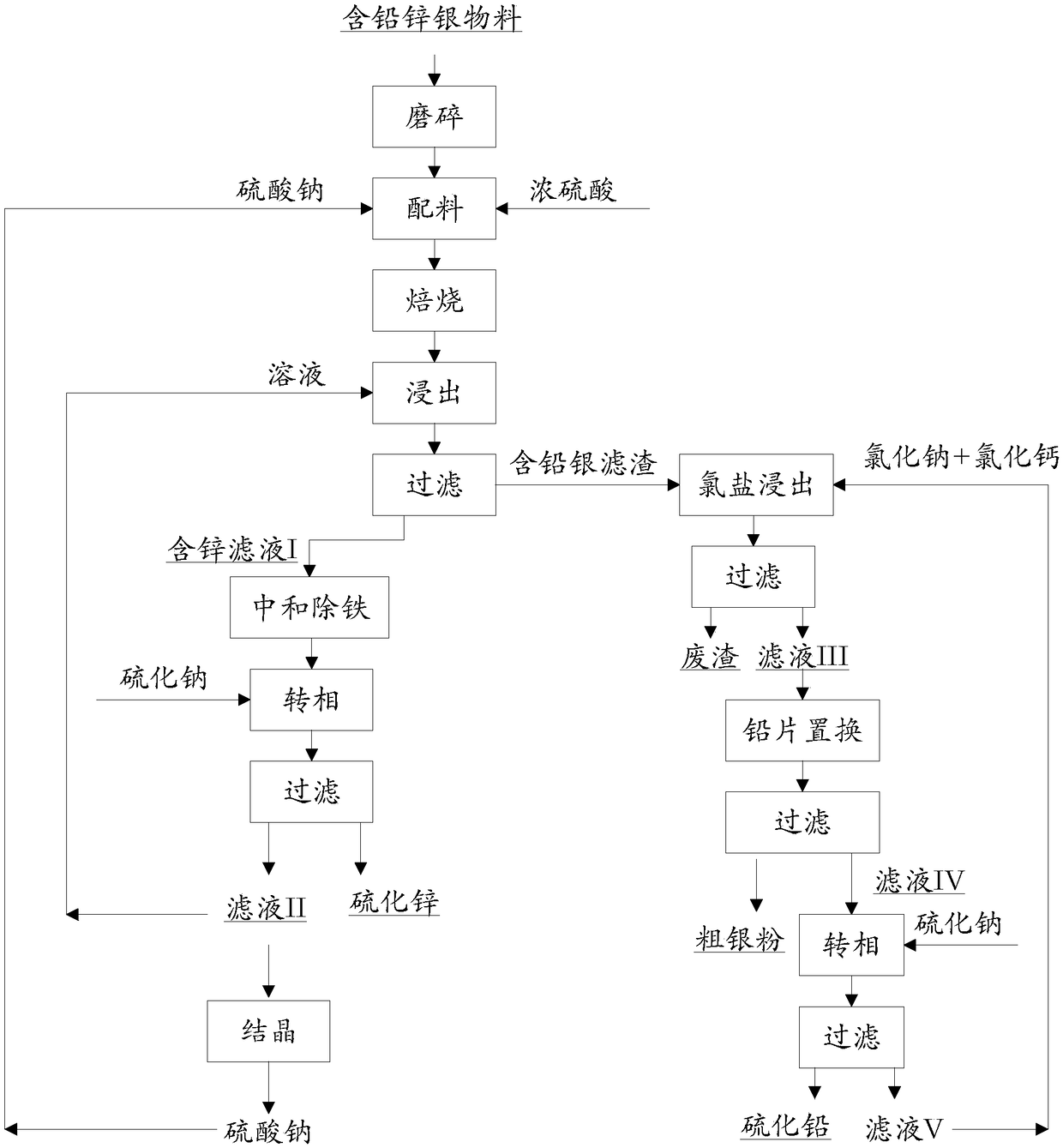

Method of comprehensively recovering valuable metals in lead, zinc and silver-containing material

The invention provides a method of comprehensively recovering valuable metals in a lead, zinc and silver-containing material. The method comprises the following steps: grinding the lead, zinc and silver-containing material, proportioning, roasting, leaching with a sulfuric acid solution and filtering, wherein zinc enters a solution I and lead and silver are left in slag; converting phase of the zinc-containing solution I after the zinc-containing solution I is neutralized and de-ironed, filtering the solution to obtain zinc sulfate and a filtrate II, smelting and recovering zinc sulfide, carrying out evaporative crystallization on the filtrate II to obtain sodium sulfate crystals which then enter a proportioning station; leaching the lead and silver-containing slag with a chlorine salt solution, filtering the solution while being hot to obtain a filtrate III; then adding a lead sheet into the filtrate III to replace silver, and filtering the filtrate to obtain coarse silver powder anda filtrate IV; and then converting phase of lead for the filtrate IV, filtering the filtrate IV to obtain lead sulfate and a filtrate V, smelting and recovering lead sulfate, supplementing calcium chloride for the filtrate V and feeding the filtrate V to a chlorine salt leaching station. The recovery rate of zinc is greater than 95%, the recovery rate of lead is greater than 98%, and the recoveryrate of silver is greater than 90%. The method has the advantages of being high in recovery rate, low in energy consumption, being recycled of the solution and the like.

Owner:有研资源环境技术研究院(北京)有限公司

Pretreatment technology for linen fabric

InactiveCN108716130AHigh whitenessFeel goodPhysical treatmentBiochemical treatment with enzymes/microorganismsPectinaseSlurry

The invention discloses a pretreatment technology for linen fabric, and belongs to the technical field of the dyeing and finishing pretreatment in the textile processing. The pretreatment technology comprises the following steps: firstly padding the linen fabric in complex enzyme solution containing amylase, pectinase and a non-ionic surfactant, and through steaming and piling, washing, squeezing,ozone-processing, hot-washing, and cold-washing, finally drying. The treated fabric has not residual impurities of starch slurry, hemicellulose, xylogen and pectin and the like, the loss of strengthis small, and the fabric has the fluffy, thick and soft effects. Compared with a traditional technology, because of the application of biological enzyme and a physical pretreatment technology, the pollutant discharge is remarkably reduced, the technology is beneficial to the environmental protection, and a water supply volume of washing the fabric can be reduced. Especially the ozone treatment hasthe remarkable energy-saving and water-saving effects because the treatment is performed in a room temperature and a damp state.

Owner:JIANGSU LIANFA TEXTILE +1

Water-dispersible granule and clean production method thereof

InactiveCN105831115AMeet the requirements of clean productionBiocideAnimal repellantsCold airEpoxiconazole

The invention relates to a water-dispersible granule and a processing method for clean production thereof. A certain amount of urea is added to the formula of the water-dispersible granule, and after air-flow crushing, the medicinal powder is heated to make the medicinal powder in a hot-melt state. After being granulated, it can be transferred to the vibrating fluidized bed for cooling by cold air; the invention saves the process of drying and drying the fluidized bed in the traditional water-dispersible granule preparation process, which greatly saves energy consumption , better environmental protection. The invention can prepare water-dispersible granules containing epoxiconazole, dimethomorph, pymetrozine, azoxystrobin, imidacloprid and other active ingredients.

Owner:GUANGDONG ZHONGXUN AGRI TECH

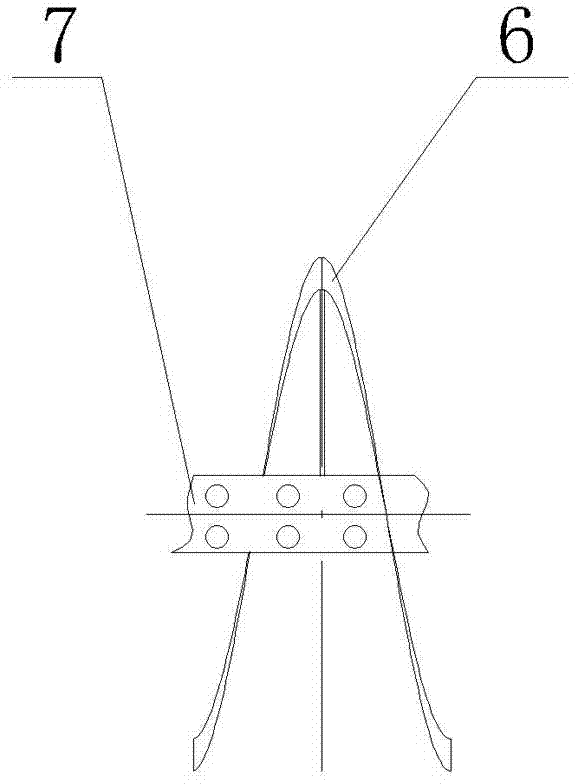

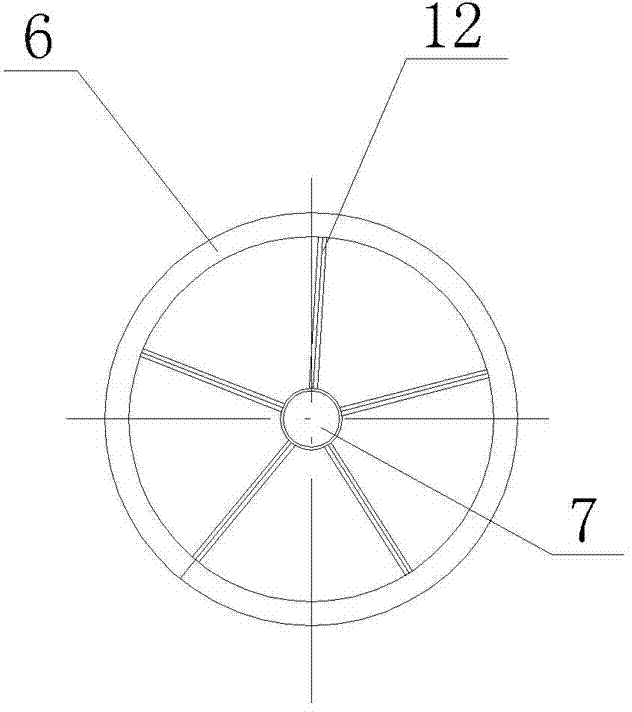

Tea peduncle, stem and leaf separation device

ActiveCN105344445ASmall footprintEasy to operatePre-extraction tea treatmentGrain treatmentsEngineeringMechanical equipment

The invention belongs to the field of mechanical equipment, relates to a tea refining device, and in particular to a tea peduncle, stem and leaf separation device. The tea peduncle, stem and leaf separation device comprises a frame, a dust removing device is arranged above the frame, and a circular screening machine is arranged at the bottom of the frame. A vibration screening machine is arranged on one side of the circular screening machine. A flat conveyor is arranged above the circular screening machine. A chopping machine is arranged above the flat conveyor. An inclined conveying lifting machine is arranged on one side of the chopping machine, and a control cabinet is arranged on one side of the frame. The tea peduncle, stem and leaf separation device is small in occupied space, the investment is only one tenth of the investment of an original whole set of refining equipment, the device is easy and convenient to operate, and only one worker can carry out operation. Meanwhile, after being suspended, the chopping machine is installed in a sealed box with the dust removing device, dust is avoided in the production process, and the requirement for the current cleaning production is met.

Owner:JIANGSU XINPIN TEA CO LTD

Aqueous environment-friendly insulation coating of anti-settling electric steel and preparation method thereof

InactiveCN102153896BImprove insulation performanceImprove corrosion resistanceMetallic material coating processesDispersityPhosphate

The invention relates to an aqueous environment-friendly insulation coating of anti-settling electric steel and a preparation method thereof. The insulation coating is formulated from the following components by mass percent: 20-60% of aluminium dihydrogen phosphate, 0.5-5% of silica solution, 1-10% of phosphoric acid, 0.3-2% of nitric acid, 1-5% of magnesium oxide, 0.3-5.5% of rare earth-salt blended solution, 0.5-5.5% of silane coupling agents, 3-20% of anti-settling additives, and the balance of solvent water. In the invention, conventional roller painting technology is adopted for coating and then a film can be made by proper high-temperature solidification. By multiple actions of physical covering, chemical passivation, phosphorization and the like, a surface insulation coating of a cold rolling electric steel plate without orientation has the advantages of good adhesiveness, high insulativity (namely resistance and puncture voltage between high-rises), high corrosion resistance, high temperature resistance and the like, as well as environmental protection without chrome or harmful ions. The insulation coating is widely applicable to the surface coating of the cold rolling electric steel plate without orientation, has a better anti-settling property, better dispersity and a better levelling property, leads coating operation on site to be more convenient and faster, and can effectively avoid the segregation of paint ingredients and the fluctuation of coating performances.

Owner:SHANGHAI QIJIA CHEM

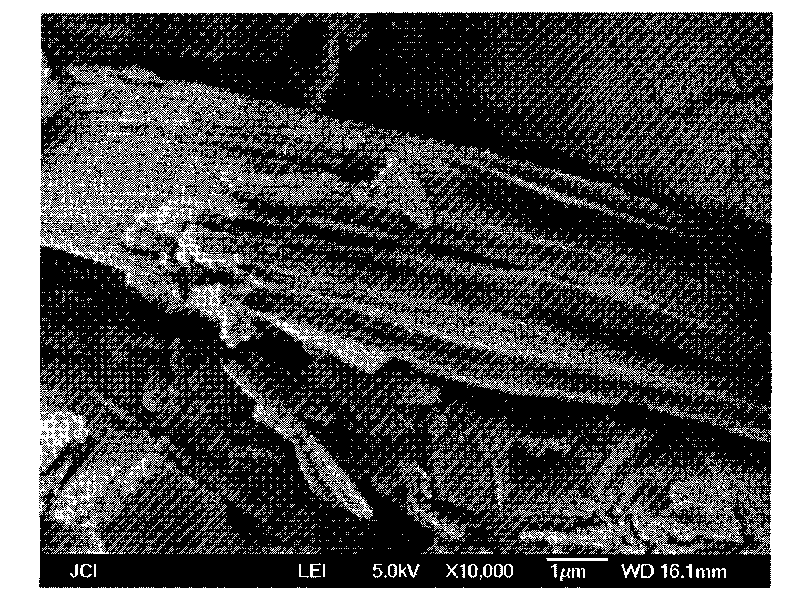

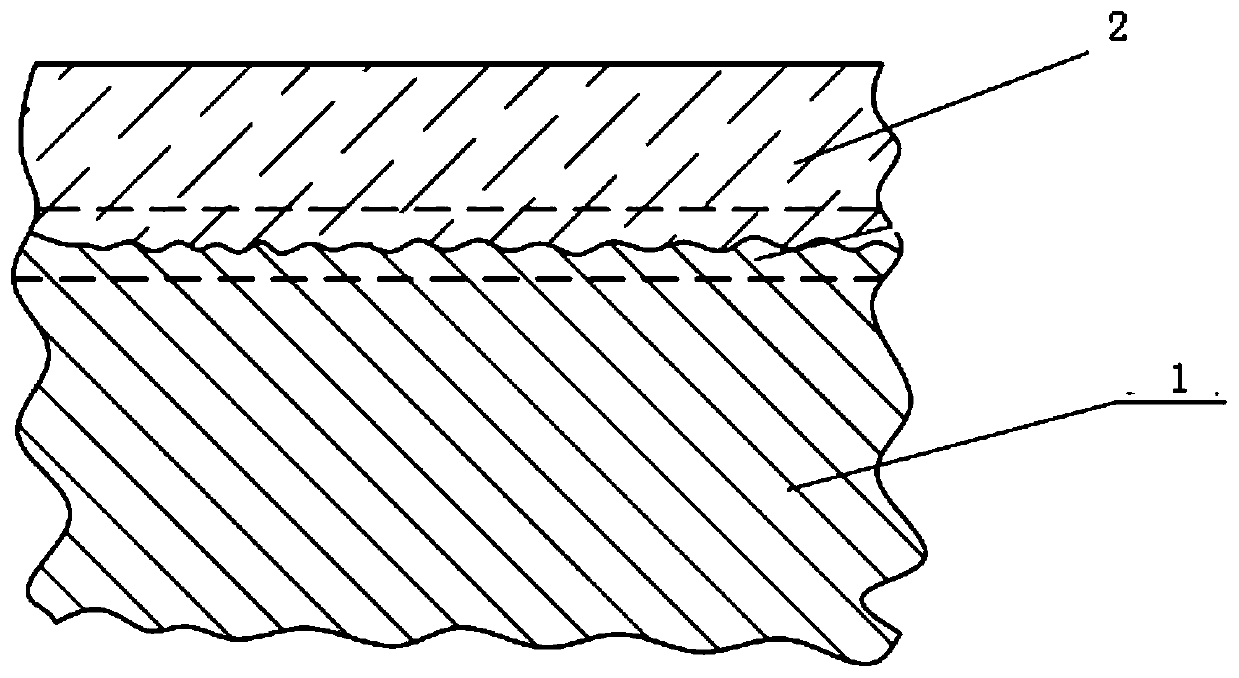

Electromagnetic pure iron part with transparent water-soluble protective film and preparation method of electromagnetic pure iron part

InactiveCN110201870ASolve Surface Protection ProblemsEmission reductionLiquid surface applicatorsCoatingsTectorial membraneMetallurgy

The invention discloses an electromagnetic pure iron part with a transparent water-soluble protective film. The electromagnetic pure iron part comprises an electromagnetic pure iron part body, whereinthe protective film wraps the outer surface of the electromagnetic pure iron part body and is a nano-thickness protective film. The preparation method of the electromagnetic pure iron part comprisesthe following steps: firstly, mixing higher fatty acid, polyol, organic amine, carboxylate and pure water, and uniformly stirring to obtain a protective solution; and secondly, putting the electromagnetic pure iron part body into the protective solution, completely wetting the surface of the electromagnetic pure iron part body, and naturally drying to obtain a finished product. By use of the electromagnetic pure iron part, the contact of a vacuum arc-extinguishing chamber and air is isolated so as to avoid the oxidation phenomenon; and the cleanness of a surface structure of the electromagnetic pure iron part is kept and existing defects on the surface can be observed with naked eyes.

Owner:SHAANXI BAOGUANG VACUUM ELECTRIC DEVICE

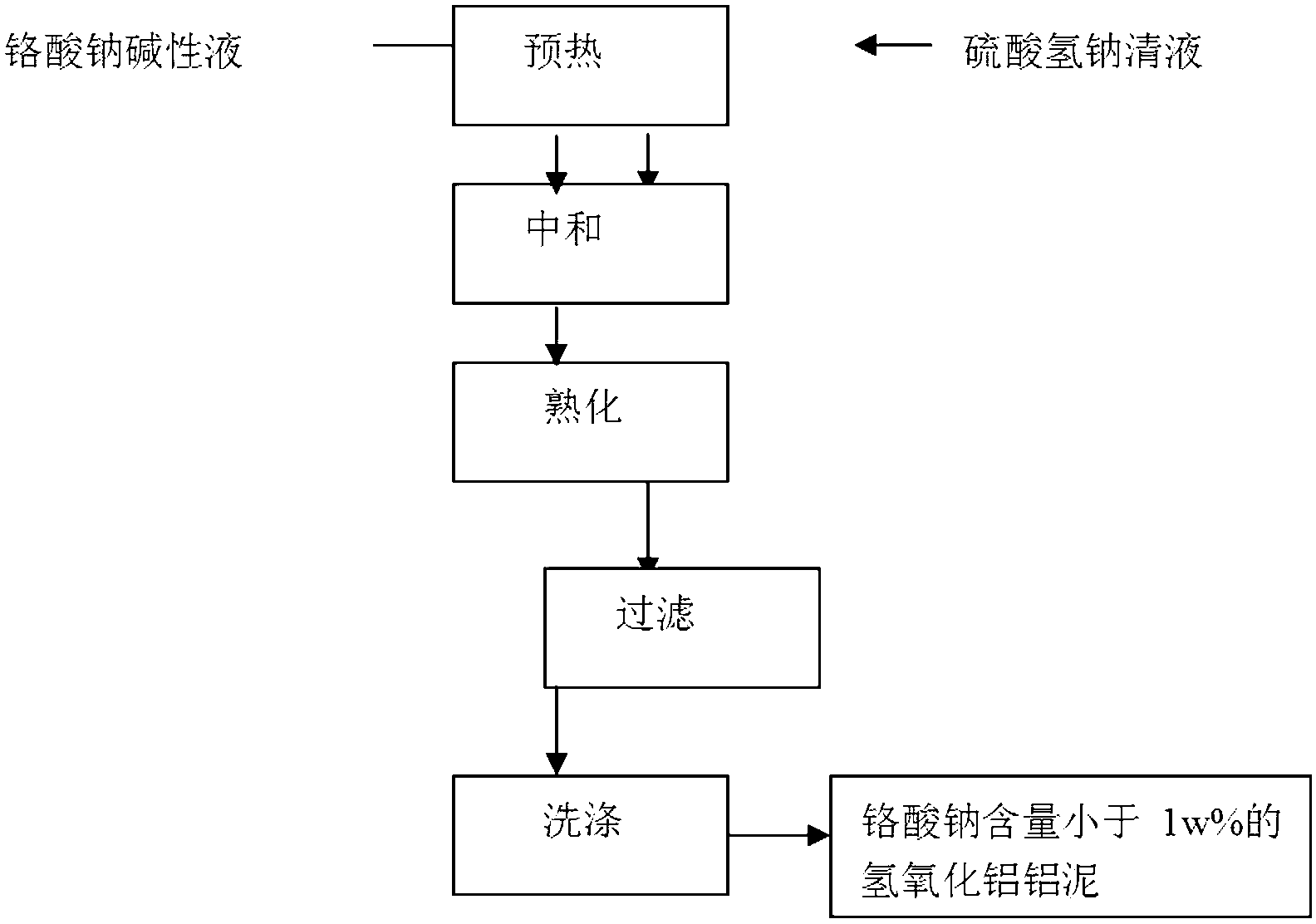

Method for removing aluminum by neutralizing sodium chromate alkali solution

ActiveCN102424422BAchieve reuseMeet the requirements of clean productionChromates/bichromatesLiquid-liquid reaction processesAluminium hydroxideSlurry

Owner:GANSU JINSHI CHEM

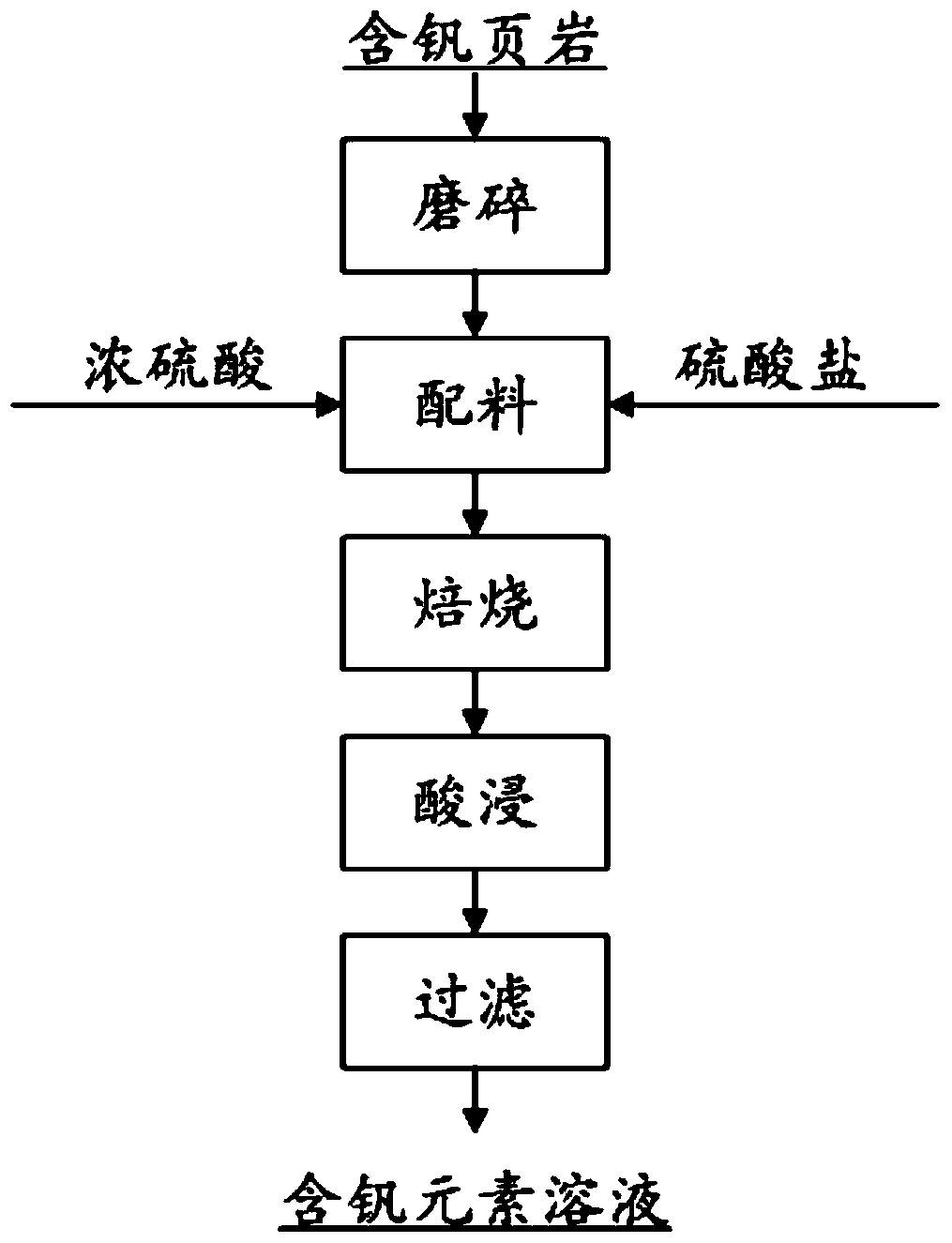

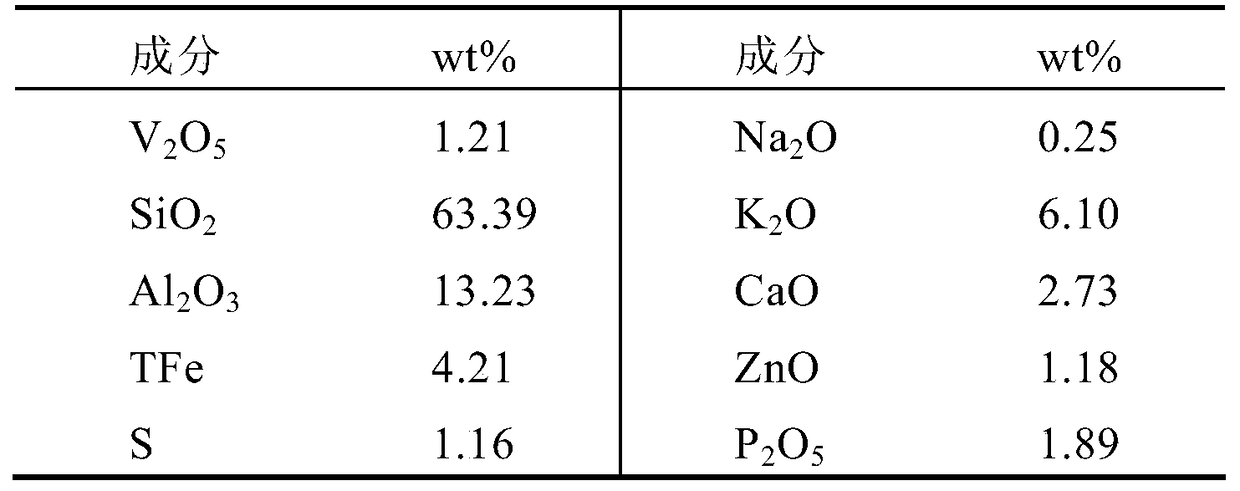

A method for roasting and extracting vanadium in vanadium-bearing shale

ActiveCN106521150BEfficient leachingIncrease profitProcess efficiency improvementEnergy consumptionCalcination

A method for extracting the vanadium element in vanadium shale through calcinations comprises the following steps that the vanadium containing shale is ground, and blending is carried out according to the mass ratio that the vanadium containing shale to concentrated sulfuric acid to sulfate is 1:(0.1-4):(0.1-4); the ingredients are mixed to be uniform, and calcination is carried out for 0.5 h to 5 h at the temperature of 200 DEG C to 400 DEG C; the calcined materials are subjected to sulfuric acid solution leaching at the temperature of 30 DEG C to 100 DEG C, the concentration of a sulfuric acid solution ranges from 0 wt% to 10 wt%, the leaching time ranges from 0.5 h to 4 h, filtering is carried out, and the vanadium element enters the solution. According to the method, the vanadium element in the vanadium shale can be efficiently extracted, the vanadium leaching rate is larger than 85%, and the beneficial effects of being high in recovery rate, easy and convenient to operate, low in energy consumption and the like are achieved.

Owner:有研资源环境技术研究院(北京)有限公司

Method for continuous purification of rubber vulcanization accelerator m by applying solvent

The invention discloses a method for continuously purifying a rubber vulcanization accelerator M by using a solvent, which comprises the following steps: adding a vulcanization accelerator M crude product into a toluene washing solution for perform purification, filtering, sending the filtrate into a toluene mother solution tank to cool and recover the accelerator M, distilling the residual mother solution to recover the toluene, washing the filter cake with the recovered toluene, and drying to obtain the rubber vulcanization accelerator M pure product, wherein the toluene washing solution cooled filtrate formed by washing the filter cake enters a washing solution collecting tank for extracting and purifying the vulcanization accelerator M crude product. The method is simple in process, and the toluene is recoverable, thereby reducing the total amount of the toluene mother solution, lowering the energy consumption and enhancing the yield. The method has the advantages of low cost and small environmental pollution, provides technical supports for continuous production of the accelerator M, has favorable economic and environmental benefits, and conforms to the requirements for national clean production.

Owner:山东戴瑞克新材料有限公司

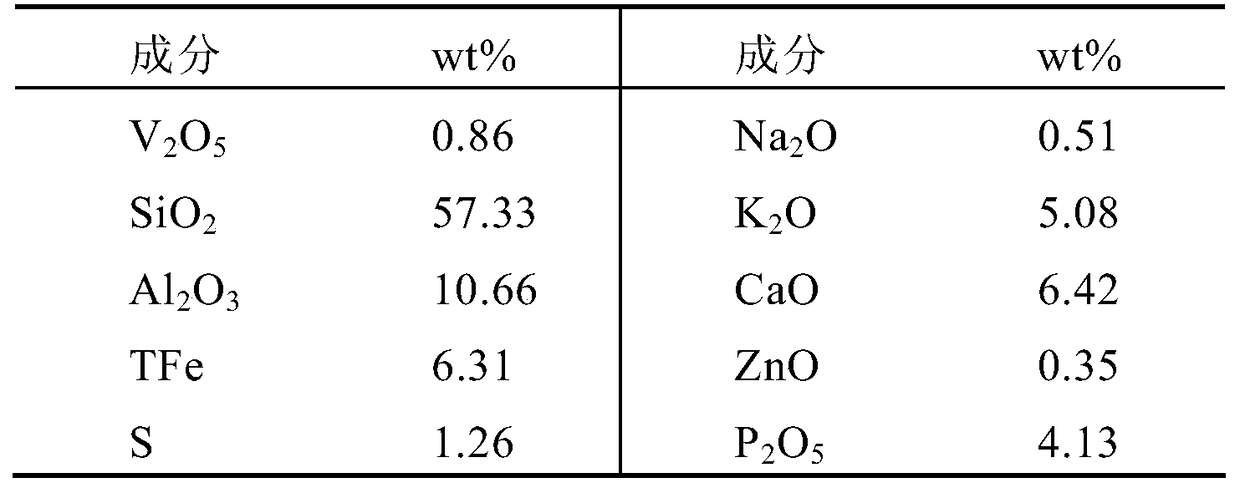

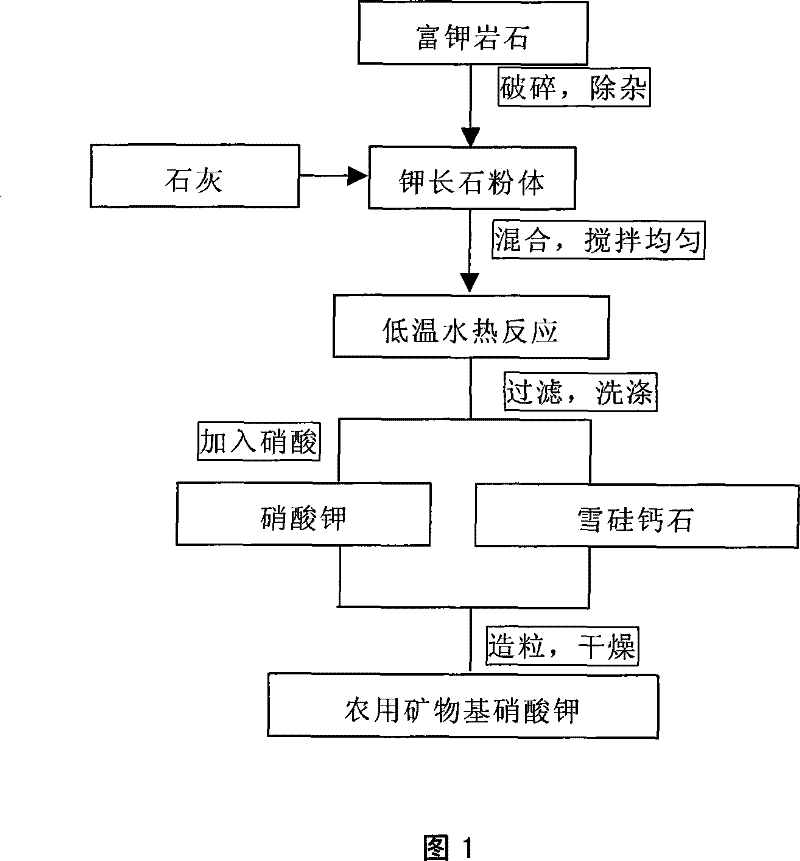

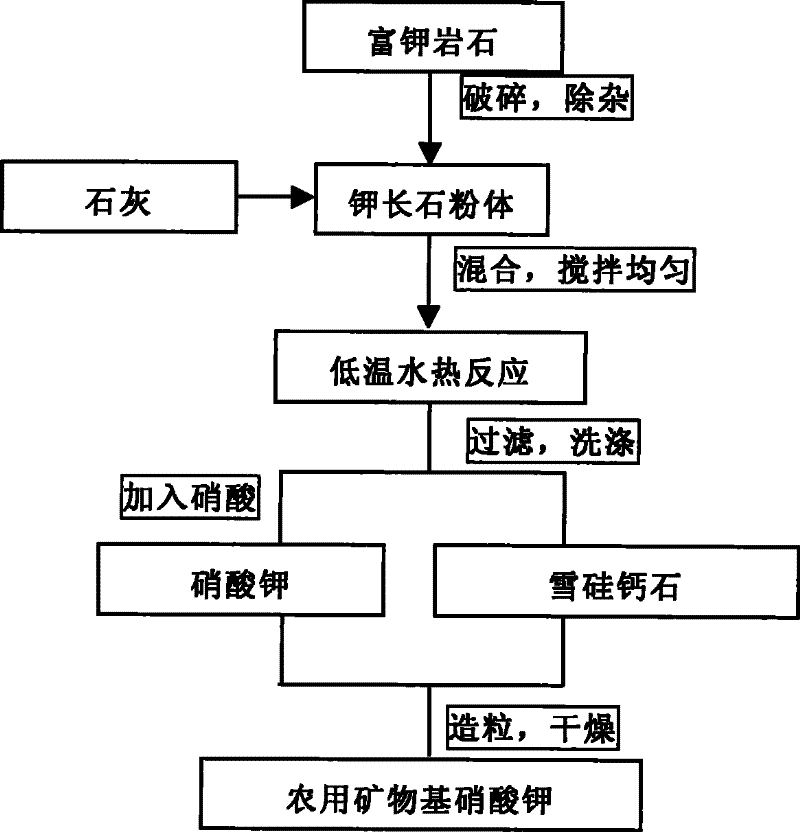

Method for producing agricultural mineral base potassium nitrate by using potassium-rich rock

ActiveCN101450874BHigh dissolution rateSimplified separation and purification processAlkali metal nitrate preparationPotassium fertilisersPotassium nitrateMaceral

The invention relates to a method for producing mineral-based potassium nitrate for agricultural use through rocks rich in potassium. The method comprises the following steps: crushing the rocks rich in the potassium, and milling the rocks after mineral dressing and trash extraction to obtain the powder with the main phase of potash feldspar; mixing the potash feldspar powder and lime according to the mass ratio of 1: 0.80-0.85, adding water according to the solid-liquid mass ratio of 1: 15-25, stirring and mixing the materials for reactions in a reaction kettle, carrying out a hydrothermal reaction on the condition of stirring at a temperature of between 180 and 250 DEG C, carrying out the reaction at constant temperature for 5 to 10 hours to obtain KOH solution and tobermorite; and preparing potassium nitrate through the obtained KOH solution, compounding the potassium nitrate with the tobermorite, and adding a binder for granulation and forming so as to obtain the novel mineral-based potassium nitrate for agricultural use. The KNO3 nutrient content can be adjusted in the range of between 22.0 and 58.6 percent.

Owner:SHAANXI DAQIN POTASSIUM CO LTD

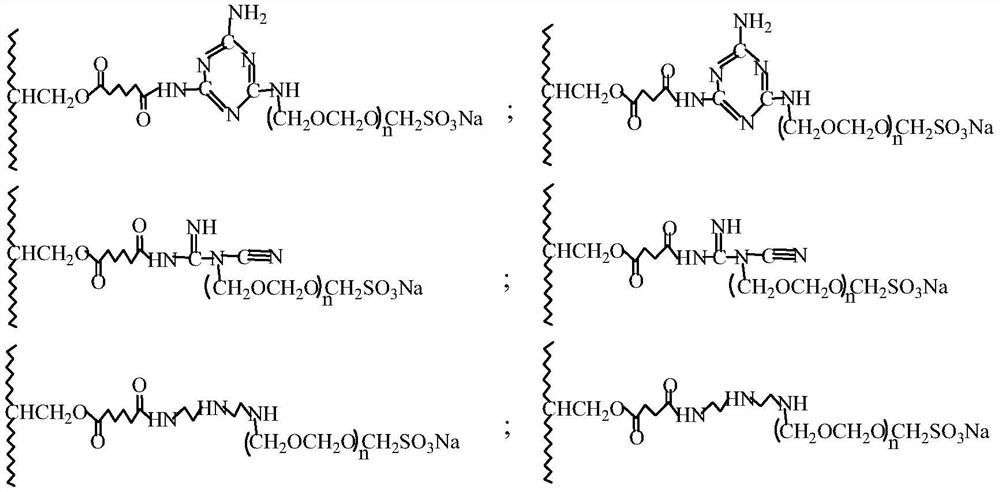

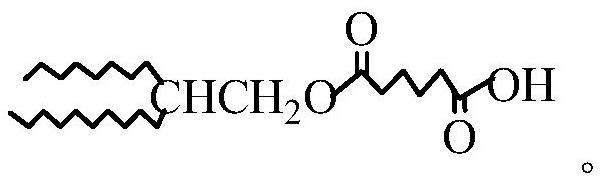

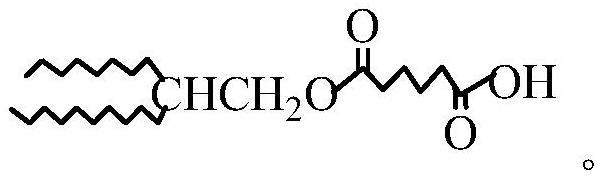

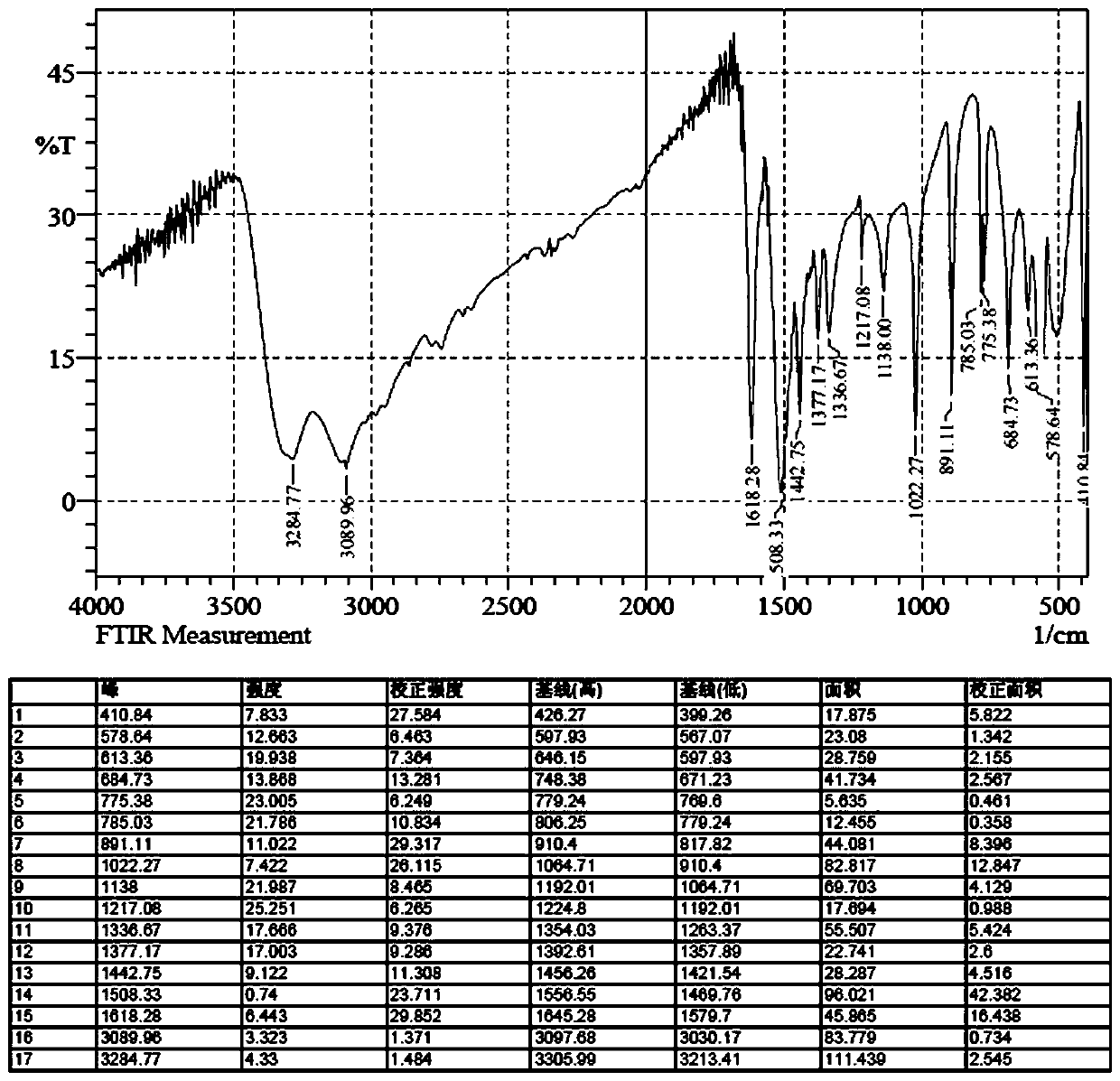

A kind of amino retanning and fatliquoring agent and preparation method thereof

The present invention provides an amino retanning and fatliquoring agent and a preparation method thereof. The amino retanning and fatliquoring agent of the present invention uses Guerbet alcohol, polybasic fatty acids, polybasic organic amines, sodium metabisulfite, formaldehyde, etc. as main raw materials. The amino retanning and fatliquoring agent prepared by esterification reaction, amidation reaction and condensation reaction can endow leather with better softness and surface feel, and has better fatliquoring performance and The finished leather has good firmness and fullness, and has very good retanning and filling performance; moreover, the amino retanning fatliquoring agent has good combination with chrome tanned leather fibers, high absorption efficiency, and meets the requirements of clean production.

Owner:山东黎宁科技新材料有限公司

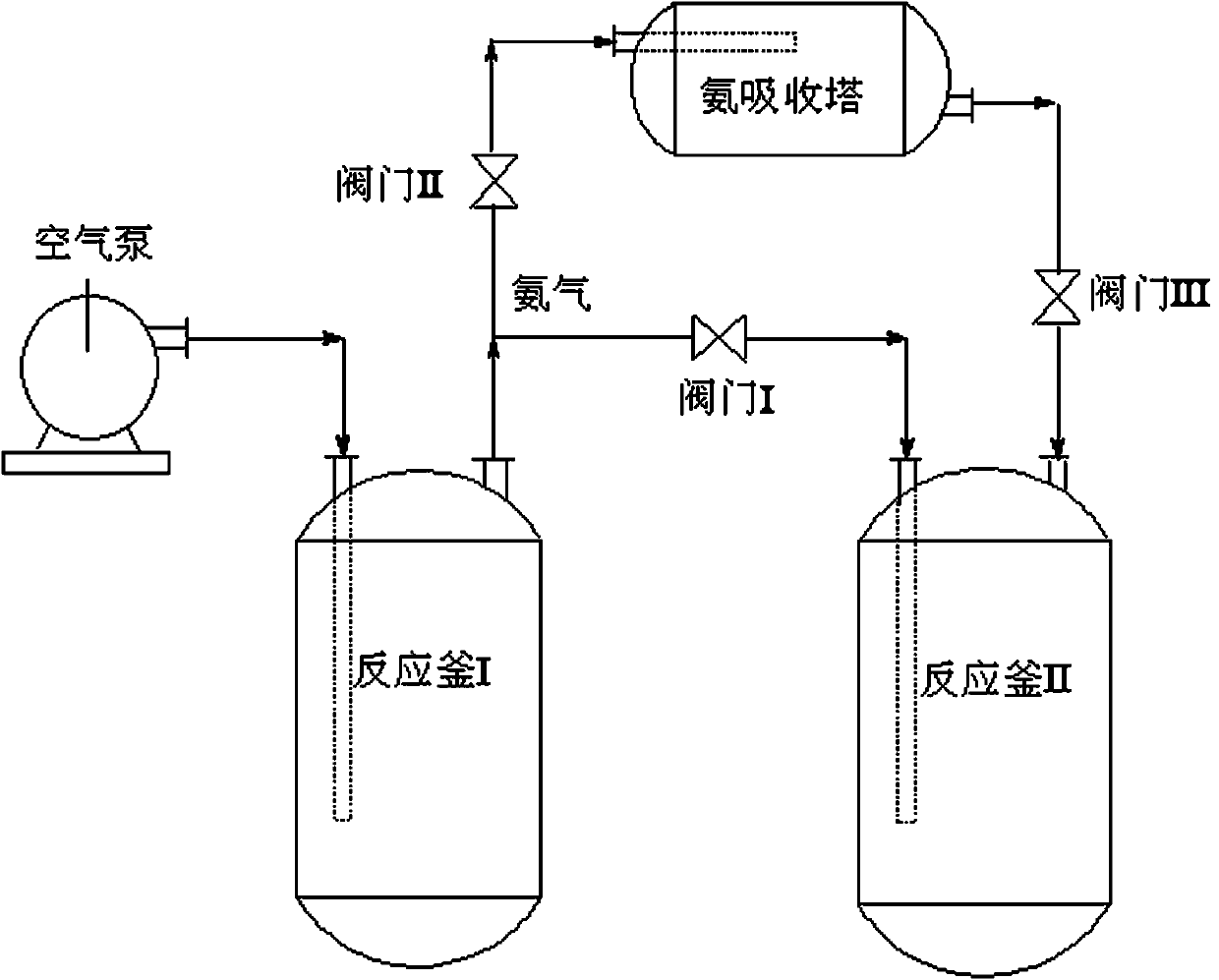

Method for reusing by-product ammonia gas produced in production process of cationic blue X-BL

InactiveCN110229122AEfficient use ofReduce production energy consumptionOrganic chemistryTowerAmmonia gas

The invention provides a method for reusing the by-product ammonia gas produced in production process of cationic blue X-BL. The production process of cationic blue X-BL comprises the preparation of the intermediate thiosemicarbazide and the intermediate 2-amino-1,3,4-thiadiazole. The method comprises the following concrete steps: applying a great amount of by-produced ammonia gas generated in a reaction for preparing thiosemicarbazide via an ammonia discharging process to a reaction vessel I, and when a reaction vessel II does not use ammonia gas, starting an air pump to bring the by-producedammonia gas to an ammonia absorption tower for generation of ammonia water which may be used as alkaline liquid for adjusting a pH value in the reaction vessel II; after completion of heating refluxof raw materials consisting of thiosemicarbazide, formic acid and hydrochloric acid in the reaction vessel II, opening a corresponding valve, introducing the by-produced ammonia gas or adding the ammonia water in the ammonia absorption tower and adjusting a pH value to 8-9; and carrying out cooling to obtain high-purity 2-amino-1,3,4-thiadiazole. The method of the invention effectively utilizes the by-product ammonia gas produced in production process of cationic blue X-BL, reduces the emission pollution of ammonia gas, reuses existing resources, has high product yield and is simple in operation.

Owner:HENAN CHEM IND RES INST +1

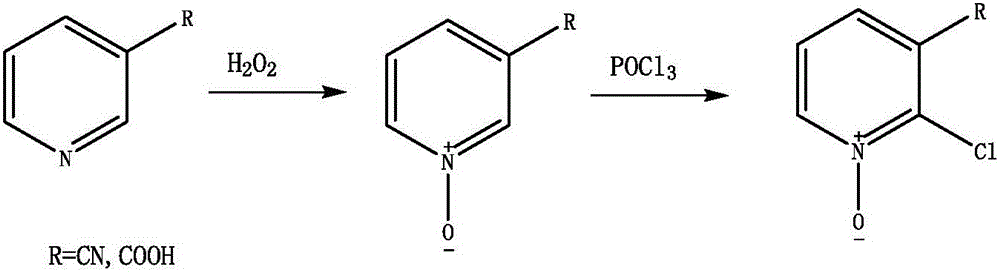

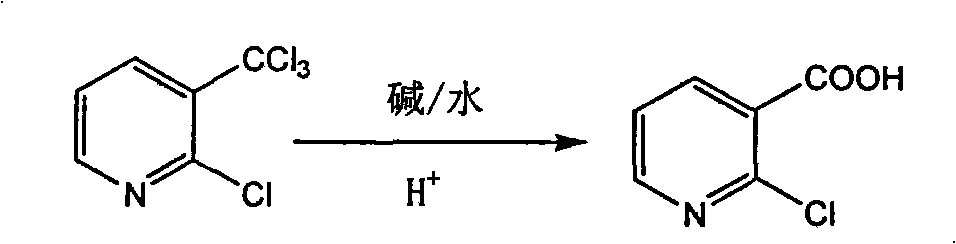

Novel method for synthesizing 2-chloronicotinic acid

The invention relates to a novel method for synthesizing 2-chloronicotinic acid. The method comprises the following steps of: taking 2-chloro-3-trichloromethylpyridine as a raw material, decomposing the 2-chloro-3-trichloromethylpyridine in alkaline water solution by heating, cooling down the alkaline water solution and adjusting the solution to acid to obtain a precipitate of the 2-chloronicotinic acid, suction-filtering, washing and drying the precipitate to obtain a white solid powder of the 2-chloronicotinic acid. The method has the advantages of simple and convenient production process and high yield, and the yield is 93 percent by taking the 2-chloro-3-trichloromethylpyridine as a basis.

Owner:JIANGSU ZHONGBANG PHARMA

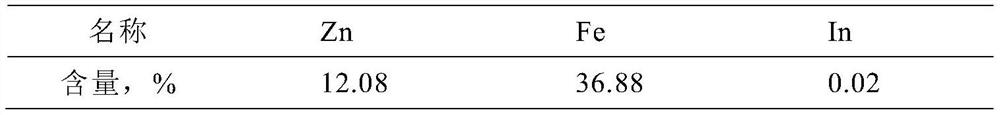

A method for efficiently recovering zinc and iron from materials containing zinc ferrite

The invention provides a method for efficiently recovering zinc and iron from zinc ferrite-containing materials, which comprises the following steps: grinding the zinc ferrite-containing materials, and according to the zinc ferrite-containing materials: sulfuric acid: sulfate = 1: 0.1~ 1: 0.01-1 mass ratio batching; mix the ingredients evenly, and roast at 150-400°C for 0.5-4h; stir and leach the roasted material at 25-90°C for 0.5-4h, filter, A zinc-iron solution and a filter residue are obtained; the zinc-iron solution is deironed by a goethite method to obtain goethite slag. The zinc-containing solution after iron removal can be extracted and electrowinning to obtain electro-zinc products, and the raffinate is circulated into stirring and leaching. After repeated cycles, the circuit is opened for evaporative cooling and crystallization to obtain sulfate crystals, which are returned to the batching section. The invention can realize high-efficiency decomposition, leaching and recovery of materials containing zinc ferrite, the recovery rate of zinc is more than 98%, and the recovery rate of iron is more than 95%, and has the advantages of high recovery rate, low energy consumption, recyclable solution and the like.

Owner:有研资源环境技术研究院(北京)有限公司

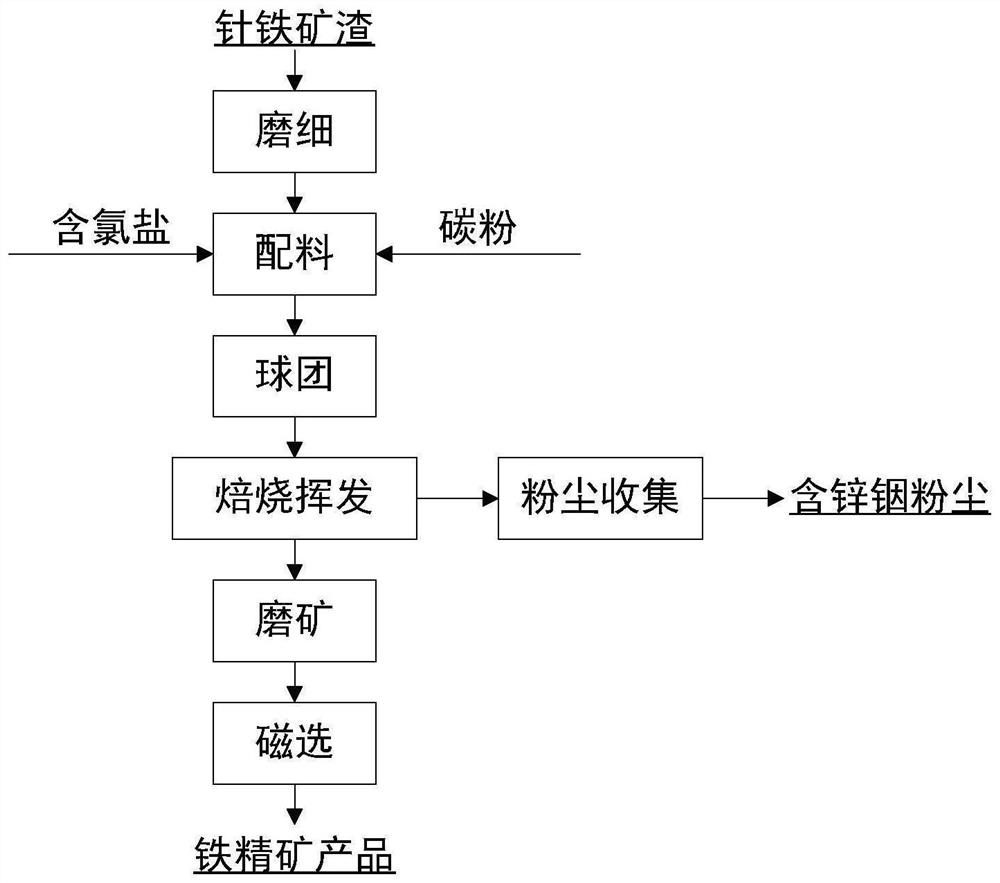

Method for comprehensively recovering valuable metals in goethite slag

The invention provides a method for comprehensively recovering valuable metals in goethite slag. The method comprises the following steps: levigating the goethite slag, and proportioning the goethiteslag, chlorine-containing salt and carbon powder according to the mass ratio of 1: (0.05-1.0): (0.05-1.0); uniformly mixing the proportioned materials, and pelletizing, wherein the pellet diameter is10-20 mm; roasting and volatilizing at 500-1100 DEG C for 1-6 hours; collecting zinc-indium-containing dust generated in the volatilization process, thereby obtaining the roasted product; and after the reaction finishes, cooling the roasted product to room temperature, and grinding to the particle size of undersize of a 200-mesh sieve; and carrying out magnetic separation on the ground material toobtain the iron ore concentrate product, wherein the magnetic field intensity is 160-350 mT. The method provided by the invention can implement high-efficiency volatilization recovery of valuable metals zinc and indium in the goethite slag in a low-temperature hot field, and is coupled with the magnetic field to obtain the iron ore concentrate product. The method has the characteristics of high valuable metal recovery rate, low energy consumption and the like, and is simple to operate.

Owner:有研资源环境技术研究院(北京)有限公司 +1

A device for separating tea stalks from stems and leaves

ActiveCN105344445BSmall footprintEasy to operatePre-extraction tea treatmentGrain treatmentsEngineeringMechanical equipment

Owner:JIANGSU XINPIN TEA CO LTD

A method for recovering zinc and iron in zinc oxygen pressure leaching slag

The invention provides a method for recycling zinc and iron in zinc oxygen pressure leaching slag. The method comprises the following steps that ingredient preparation is conducted according to mass ratio of zinc oxygen pressure leaching slag: concentrated sulfuric acid: bisulfate being 1: 0.4-2: 0.1-2; the ingredients are uniformly mixed, and roasting is conducted at 200-40 DEG C and lasts for 0.5-5 hours to obtain a roasted product; the roasted product is subjected to sulfuric acid solution leaching at 20-95 DEG C, concentration of the sulfuric acid solution is less than 5 wt%, and the leaching time is 0.5-4 hours; filtering is conducted, zinc and iron are placed into filter liquor I containing zinc and iron, iron powder is added into the filter liquor I containing zinc and iron, the Fe<3+> is restored to Fe<2+>, and filtering is conducted to obtain filter liquor II containing zinc and iron; and the filter liquor II containing zinc and iron is subjected to zinc extraction, and therefore zinc can be recycled. The rest liquor containing iron is subjected to evaporation, refrigeration and crystallization, and therefore byproduct ferrous sulfate heptahydrate crystal can be obtained.The zinc and iron in zinc oxygen pressure leaching slag can be efficiently extracted. The recycling rate of the zinc is greater than 96%, and the recycling rate of the iron is greater than 95%. The method has the advantages that recycling rate is high, operation is convenient, and energy consumption is low.

Owner:有研资源环境技术研究院(北京)有限公司 +2

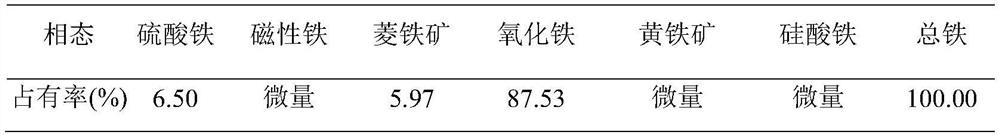

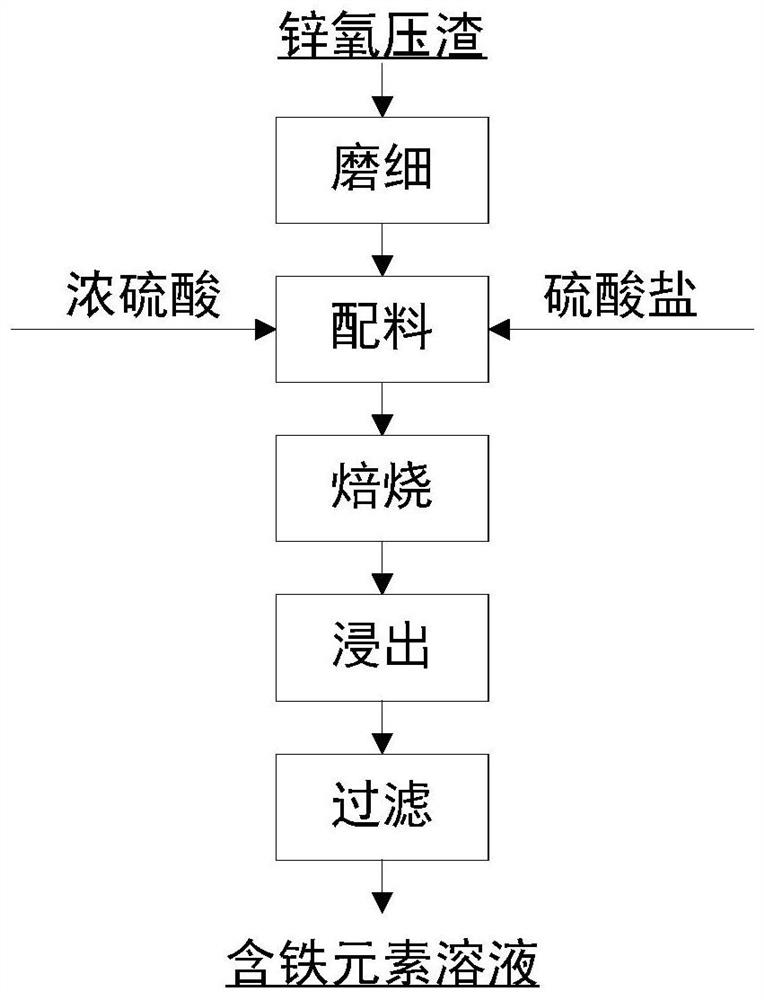

Method for intensively leaching iron complex phase in zinc oxygen pressure slag

PendingCN113122705ASolve problems that are difficult to economically and reasonably benefitLow costProcess efficiency improvementSulfateSlag

The invention discloses a method for intensively leaching an iron complex phase in zinc oxygen pressure slag. The method comprises the following steps: grinding zinc oxygen pressure slag, and carrying out proportioning according to the mass ratio of the zinc oxygen pressure slag to concentrated sulfuric acid to sulfate being 1:(0.1-2):(0-1.0); uniformly mixing the ingredients, and carrying out roasting at 200-400 DEG C for 0.5-5 hours; and leaching roasted materials through a sulfuric acid solution at the temperature of 30-100 DEG C, wherein the concentration of the sulfuric acid solution is 0-10 wt%, the solid-to-liquid ratio (g / mL) is 1:4-1:10, and the leaching time is 0.5-4 h; and carrying out filtering, and entering an iron element into the solution. According to the method, the iron complex phase in zinc oxygen pressure can be intensively leached, the leaching rate of iron is larger than or equal to 80%, and the method has the advantages of being high in recovery rate, easy and convenient to operate, low in energy consumption and the like.

Owner:有研资源环境技术研究院(北京)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com