Method for comprehensively recovering valuable metals in goethite slag

A technology for goethite slag and valuable metals, which is applied in the field of comprehensive recovery of valuable metals in goethite slag, and can solve the problems of low volatilization rate of zinc and indium, high volatilization temperature of rotary kiln, and ineffective utilization of iron, etc. , to achieve huge environmental and economic benefits, realize resource utilization, and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

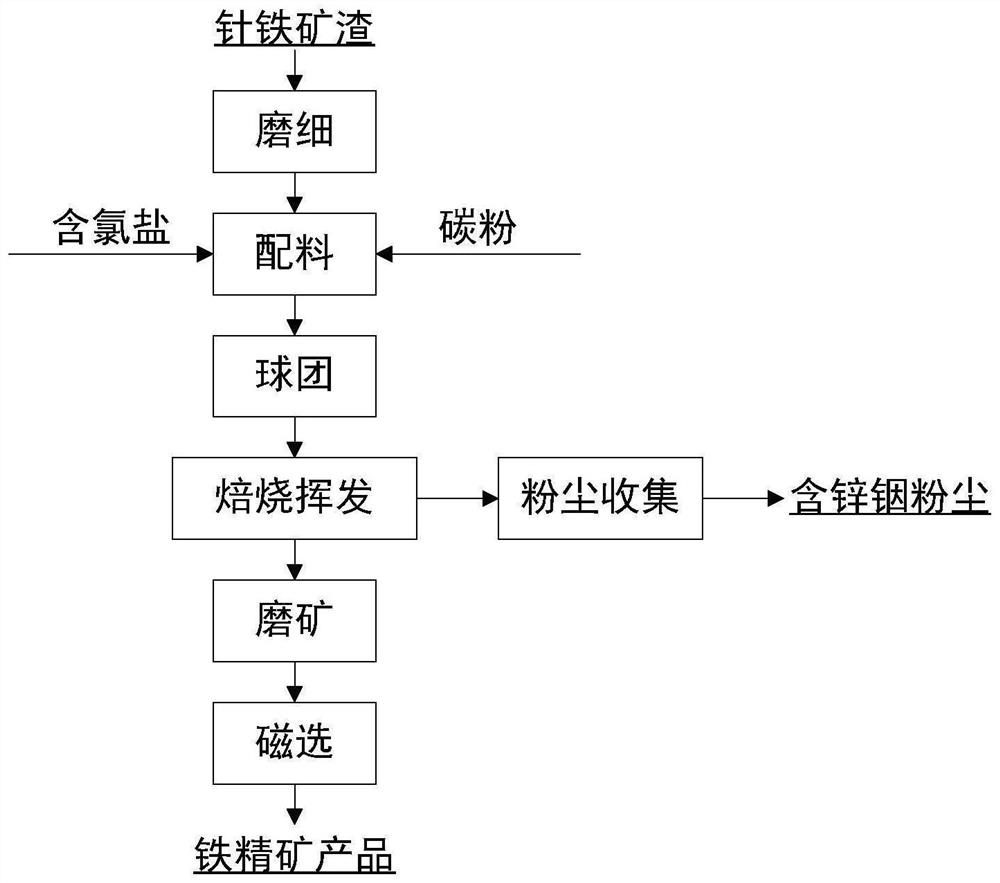

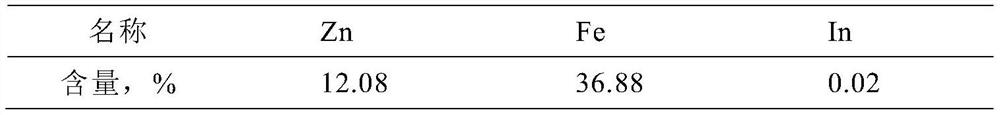

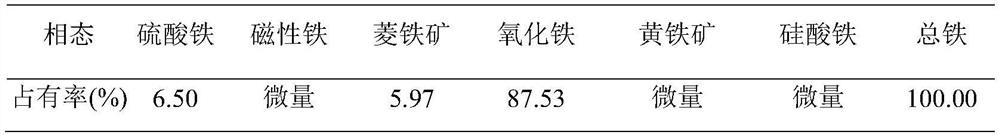

Embodiment 1

[0029] A goethite slag in Guangdong contains 36.88% iron, 12.08% zinc, and 0.02% indium. The main chemical test results and phase analysis results are shown in Table 1-3. The above-mentioned goethite slag 100g according to figure 1 As shown in the process flow, grind until the particle size is -200 mesh to -400 mesh, mix with calcium chloride 10g, carbon powder 45g and pelletize, the pellet particle size is 10-20mm, put it into the tube furnace for roasting , control the calcination temperature to 900°C and the calcination time to 2h. The volatilized zinc-indium dust is collected during the roasting process. After roasting, the obtained material is ground to a particle size of -200 mesh, and subjected to magnetic separation at a magnetic field strength of 200mT to obtain an iron ore concentrate product. During the experiment, it is necessary to detect and analyze the contents of zinc, indium and iron on the roasted materials, zinc-indium-containing dust, iron concentrate and...

Embodiment 2

[0038] A goethite slag in Guangdong contains 36.88% iron, 12.08% zinc, and 0.02% indium. The main chemical test results and phase analysis results are shown in Table 1-3. The above-mentioned goethite slag 100g according to figure 1 As shown in the process flow, grind until the particle size is -200 mesh to -400 mesh, mix with 5g of sodium chloride and 50g of carbon powder and pelletize, the pellet particle size is 10-20mm, put it into a tube furnace for roasting , control the calcination temperature to 900°C and the calcination time to 2h. The volatilized zinc-indium dust is collected during the roasting process. After roasting, the obtained material is ground to a particle size of -200 mesh, and subjected to magnetic separation at a magnetic field strength of 160mT to obtain an iron ore concentrate product. During the experiment, it is necessary to detect and analyze the contents of zinc, indium and iron on the roasted materials, zinc-indium-containing dust, iron concentrat...

Embodiment 3

[0041] A goethite slag in Guangdong contains 36.88% iron, 12.08% zinc, and 0.02% indium. The main chemical test results and phase analysis results are shown in Table 1-3. The above-mentioned goethite slag 100g according to figure 1 As shown in the process flow, grind until the particle size is -200 mesh to -400 mesh, mix with potassium chloride 15g, carbon powder 40g and pelletize, the pellet particle size is 10-20mm, put it into the tube furnace for roasting , control the calcination temperature to 900°C and the calcination time to 2h. The volatilized zinc-indium dust is collected during the roasting process. After roasting, the obtained material is ground to a particle size of -200 mesh, and subjected to magnetic separation at a magnetic field strength of 240mT to obtain an iron ore concentrate product. During the experiment, it is necessary to detect and analyze the contents of zinc, indium and iron on the roasted materials, zinc-indium-containing dust, iron concentrate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com