Method for intensively leaching iron complex phase in zinc oxygen pressure slag

A technology of enhanced leaching and zinc oxide, applied in the direction of improving process efficiency, etc., can solve the problems of low iron recovery rate, difficult tail gas treatment, high roasting temperature, etc., and achieve the effects of low raw material cost, easy operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

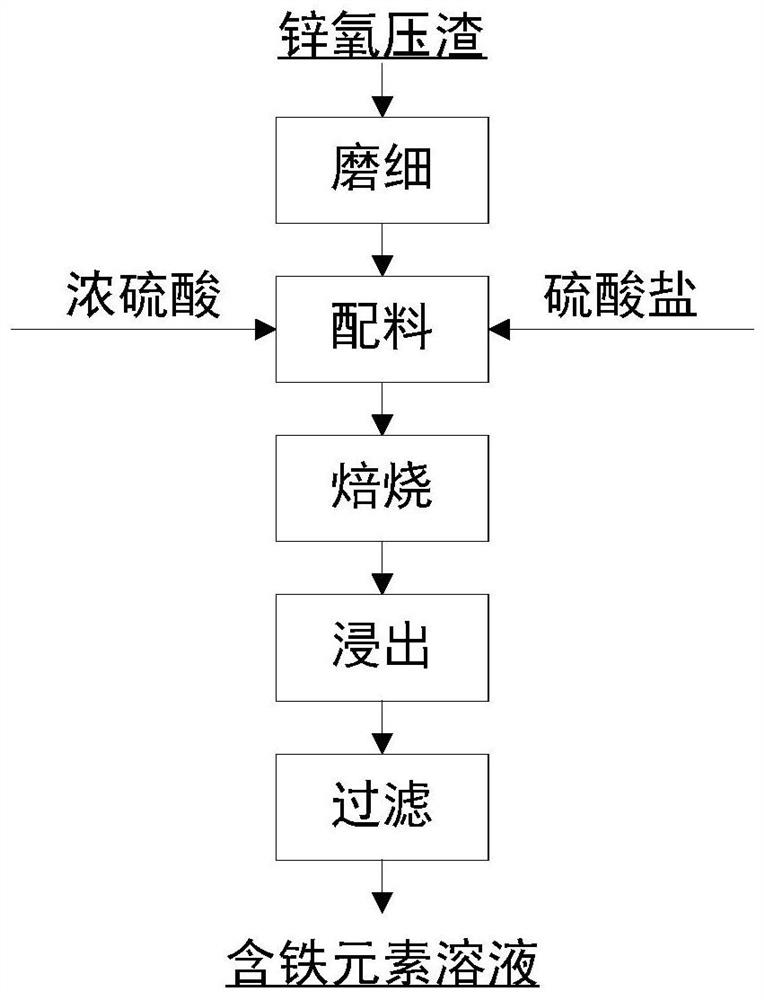

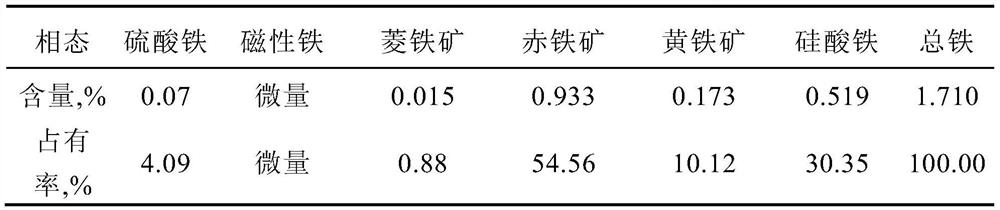

[0020] process such as figure 1 As shown, 100 g of a zinc-oxygen pressed slag in Shaoguan, Guangdong (the results of the iron complex phase phase analysis are shown in Table 1) were ground to a particle size of -200 mesh to -400 mesh, and then mixed with 40 g of concentrated sulfuric acid (content 98%). The ingredients are mixed evenly, put into a muffle furnace for roasting, and the roasting temperature is controlled at 250° C., and the roasting time is 2 hours. After roasting, the obtained material was added to sulfuric acid solution (concentration ~ 10wt%), the solid-to-liquid ratio (g / mL) was 1:4, stirred at 90°C for 1 hour, and then filtered to obtain a filtrate containing iron. The obtained filtrates were respectively transferred to volumetric flasks for constant volume, and the content of iron element in them was detected. In addition, the iron element in the filter residue also needs to be detected.

[0021] After calculation, the leaching rate of iron is 81.16%.

[...

Embodiment 2

[0025] Grind 100g of a zinc-oxygen pressed slag in Shaoguan, Guangdong (the results of the iron complex phase phase analysis are shown in Table 1) to a particle size of -200 mesh to -400 mesh, and mix it with 30g of concentrated sulfuric acid (98% content) and 10g of zinc sulfate Prepare ingredients and mix them evenly, put them into a muffle furnace for roasting, control the roasting temperature to 260° C., and roast for 2 hours. After roasting, the obtained material was added to sulfuric acid solution (concentration ~ 10wt%), the solid-to-liquid ratio (g / mL) was 1:5, stirred at 90°C for 1 hour, and then filtered to obtain a filtrate containing iron. The obtained filtrates were respectively transferred to volumetric flasks for constant volume, and the content of iron element in them was detected. In addition, the iron element in the filter residue also needs to be detected.

[0026] After calculation, the leaching rate of iron is 83.81%.

Embodiment 3

[0028] Grind 100g of zinc-oxygen compressed slag (the results of iron complex phase phase analysis are shown in Table 1) in Shaoguan, Guangdong to a particle size of -200 mesh to -400 mesh, and mix it with 50g of concentrated sulfuric acid (content 98%) and 20g of sodium sulfate Prepare ingredients and mix them uniformly, put them into a muffle furnace for roasting, control the roasting temperature to 270° C., and roast for 3 hours. After roasting, the obtained material was added to sulfuric acid solution (concentration ~ 10wt%), the solid-to-liquid ratio (g / mL) was 1:5, stirred at 90°C for 1.5h and then filtered to obtain a filtrate containing iron. The obtained filtrates were respectively transferred to volumetric flasks for constant volume, and the content of iron element in them was detected. In addition, the iron element in the filter residue also needs to be detected.

[0029] After calculation, the leaching rate of iron is 85.52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com