Method for efficiently recovering zinc and iron from zinc ferrite-containing material

A technology of raw materials and acid zinc, which is applied in the field of recovering valuable metals and efficiently recovering zinc and iron. It can solve the problems of low zinc leaching rate, incomplete volatilization, high energy consumption, etc., and achieve improved utilization rate, simple operation and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

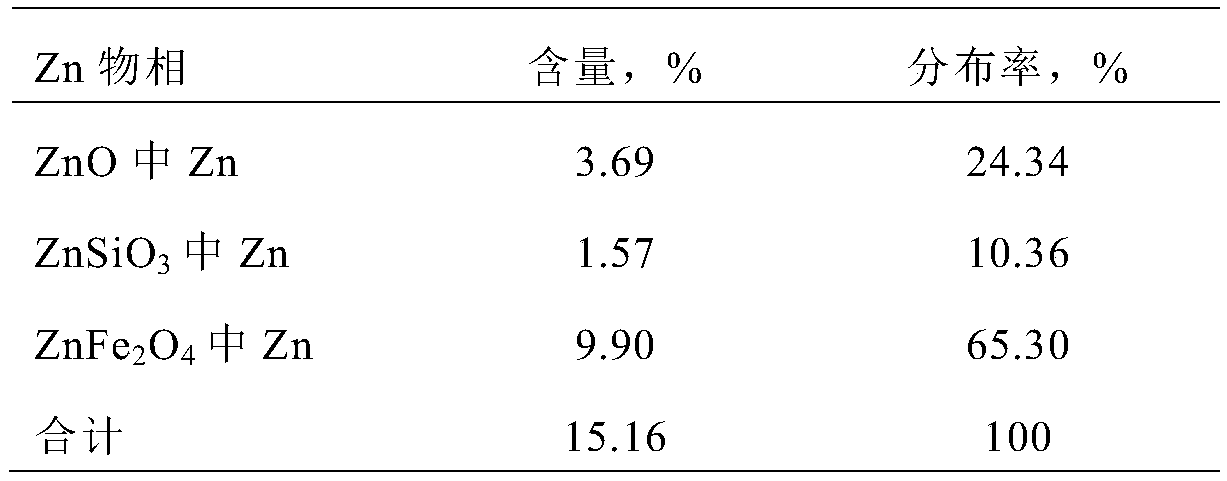

[0031] Table 1 Phase analysis of a certain zinc ferrite material

[0032]

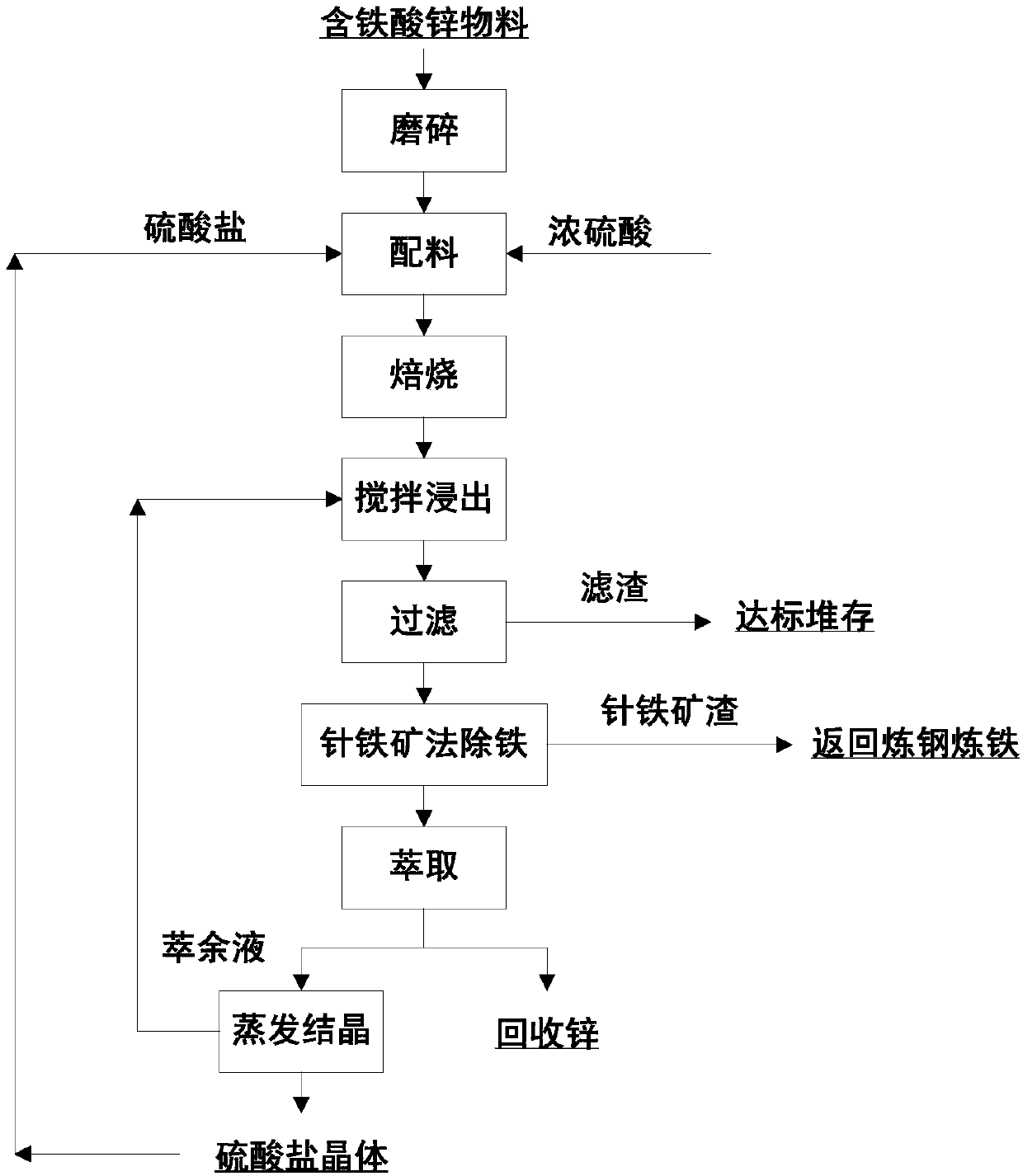

[0033] process such as figure 1 As shown, 100g of a zinc ferrite-containing material (Zn 15.16%, Fe 30.01%, see Table 1 for phase analysis) was ground to a particle size of -200 mesh to -400 mesh, and concentrated sulfuric acid (content 98%) 50g, Sodium sulfate 10g is batched and mixed evenly, put into a muffle furnace for roasting, the roasting temperature is controlled at 200°C, and the roasting time is 2h. After roasting, place the obtained calcined sand in water for stirring and leaching, the stirring speed is 200-300rpm, the solid-to-liquid ratio (g / mL) is 1:5, and after stirring for 1 hour at 50°C, filter to obtain a zinc-iron solution and leach residue. The zinc-containing iron solution uses hydrogen peroxide as the oxidant and sodium carbonate as the pH regulator to remove iron from goethite at 40°C; after iron removal, goethite slag and zinc-containing solution are obtained; the zinc-cont...

Embodiment 2

[0036] process such as figure 1 As shown, 100g of a zinc ferrite-containing material (Zn 15.16%, Fe 30.01%, see Table 1 for phase analysis) was ground to a particle size of -200 mesh to -400 mesh, and concentrated sulfuric acid (content 98%) 40g, Potassium sulfate 15g is batched and mixed evenly, put into a muffle furnace for roasting, the roasting temperature is controlled at 250°C, and the roasting time is 2h. After roasting, place the obtained calcined sand in water for stirring and leaching, the stirring speed is 200-300rpm, the solid-to-liquid ratio (g / mL) is 1:5, and after stirring for 1 hour at 40°C, filter to obtain a zinc-iron solution and leach residue. The zinc-containing iron solution uses hydrogen peroxide as the oxidant and potassium carbonate as the pH adjuster to remove iron by goethite method at 50°C; after iron removal, goethite slag and zinc-containing solution are obtained; zinc-containing solution is extracted and recovered for zinc, and extracted The ag...

Embodiment 3

[0039] process such asfigure 1 As shown, 100g of a zinc ferrite-containing material (Zn 15.16%, Fe 30.01%, see Table 1 for phase analysis) was ground to a particle size of -200 mesh to -400 mesh, and concentrated sulfuric acid (content 98%) 40g, 20 g of ammonium sulfate was prepared and mixed evenly, and then put into a muffle furnace for roasting. The roasting temperature was controlled to be 300° C., and the roasting time was 2 hours. After roasting, place the obtained calcined sand in water for stirring and leaching, the stirring speed is 200-300rpm, the solid-to-liquid ratio (g / mL) is 1:5, and after stirring for 1 hour at 40°C, filter to obtain a zinc-iron solution and leach residue. The zinc-containing iron solution uses hydrogen peroxide as the oxidant and ammonium carbonate as the pH adjuster to remove iron from goethite at 70°C; after iron removal, goethite slag and zinc-containing solution are obtained; the zinc-containing solution is extracted and recovered for zinc,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com