Method for reusing by-product ammonia gas produced in production process of cationic blue X-BL

A technology of X-BL and production process, which is applied in the direction of organic chemistry, can solve the problems of waste of resources and increase of enterprise costs, and achieve the effects of reducing production energy consumption, easy operation, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the method for the present invention, the cationic blue X-BL production process includes the preparation of intermediate thiosemicarbazide and intermediate 2-amino-1,3,4-thiadiazole; the specific method steps are as follows:

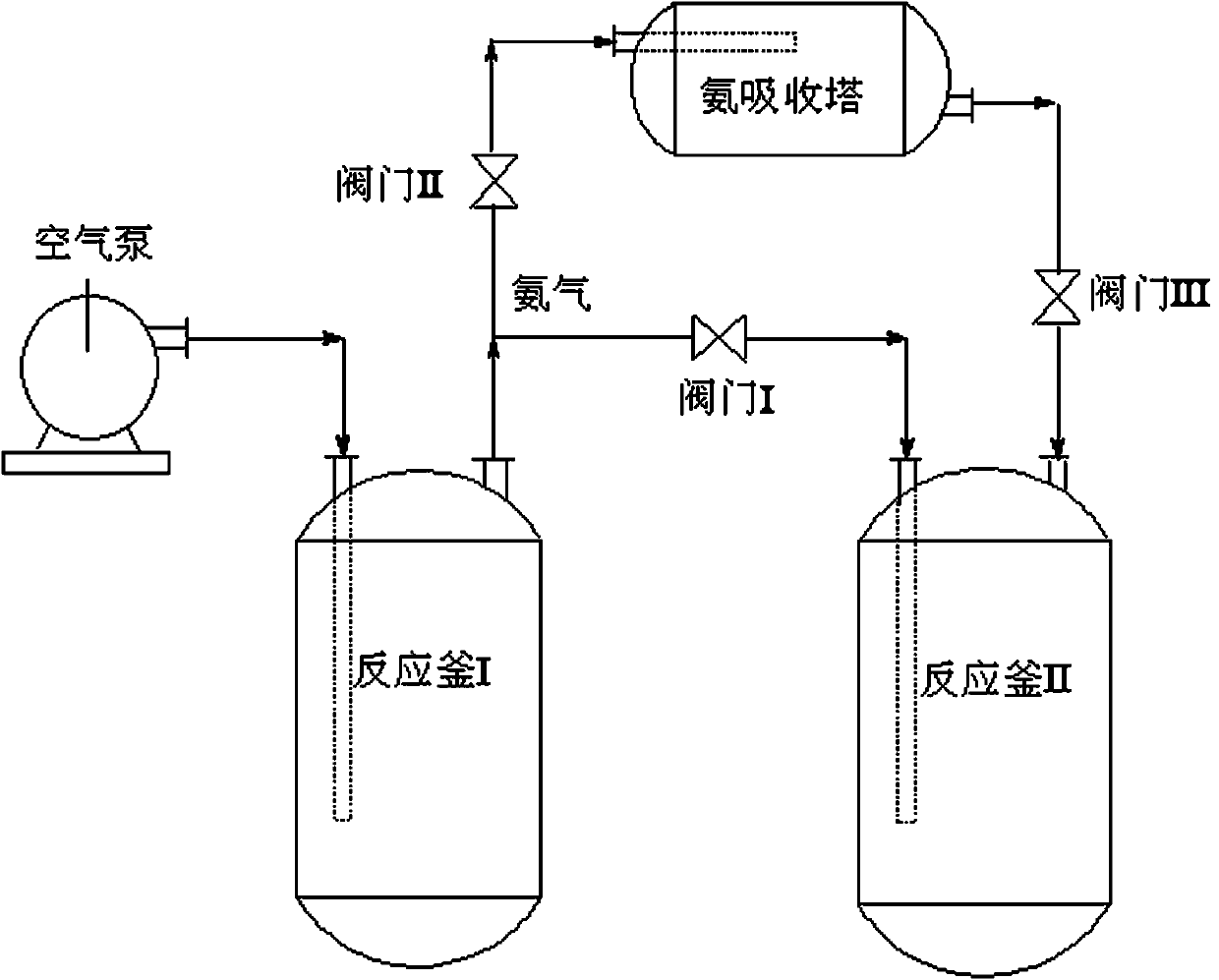

[0019] a. Add the raw materials ammonium thiocyanate and hydrazine hydrate into the reactor I, start heating and stirring, when the temperature of the reactor rises to 82 o Open the air pump during C; when the reactor II is not neutralized, open the valve II connecting the reactor I and the ammonia absorption tower, and pass the generated by-product ammonia into the ammonia absorption tower for subsequent use;

[0020] b. Put 920 g of thiosemicarbazide, 800 mL of hydrochloric acid and 600 g of formic acid into the reaction kettle II, turn on the heating and heat up to 80 o C, after the solid is completely dissolved, continue to heat up to 110 o C, reflux for 4.5 h, after cooling, close the valve II connecting the reactor I and the ammonia abso...

Embodiment 2

[0024] In the method for the present invention, the cationic blue X-BL production process includes the preparation of intermediate thiosemicarbazide and intermediate 2-amino-1,3,4-thiadiazole; the specific method steps are as follows:

[0025] a. Add the raw materials ammonium thiocyanate and hydrazine hydrate into the reactor I, start heating and stirring, when the temperature of the reactor rises to 80 o Open the air pump during C; when the reactor II is not neutralized, open the valve II connecting the reactor I and the ammonia absorption tower, and pass the generated by-product ammonia into the ammonia absorption tower for subsequent use;

[0026] b. Put 920 g of thiosemicarbazide, 600 mL of hydrochloric acid and 600 g of formic acid into the reaction kettle II, turn on the heating and heat up to 80 o C, after the solid is completely dissolved, continue to heat up to 105 o C, reflux for 4.5 h, after cooling, close the valve II connecting the reactor I and the ammonia abso...

Embodiment 3

[0030] In the method of the present invention, the cationic blue X-BL production process includes the preparation of intermediate thiosemicarbazide and intermediate 2-amino-1,3,4-thiadiazole; the specific method steps are as follows:

[0031] a. Add the raw materials ammonium thiocyanate and hydrazine hydrate into the reactor I, start heating and stirring, when the temperature of the reactor rises to 85 o Open the air pump during C; when the reactor II is not neutralized, open the valve II connecting the reactor I and the ammonia absorption tower, and pass the generated by-product ammonia into the ammonia absorption tower for subsequent use;

[0032] b. Put 1002 g of thiosemicarbazide, 800 mL of hydrochloric acid and 600 g of formic acid into the reaction kettle II, turn on the heating and heat up to 85 o C, after the solid is completely dissolved, continue to heat up to 115 o C, reflux for 4.5 h, after cooling, close the valve II connecting the reactor I and the ammonia abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com