Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet the processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

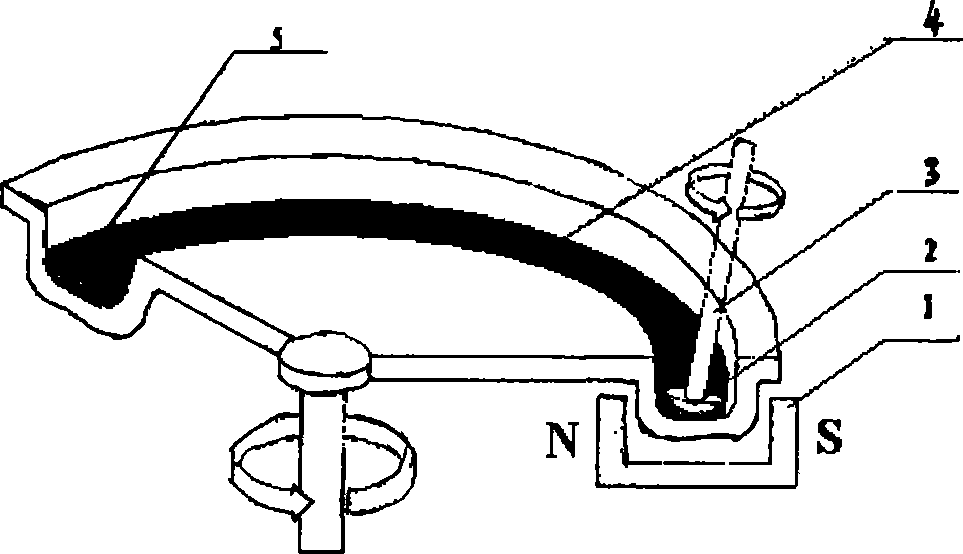

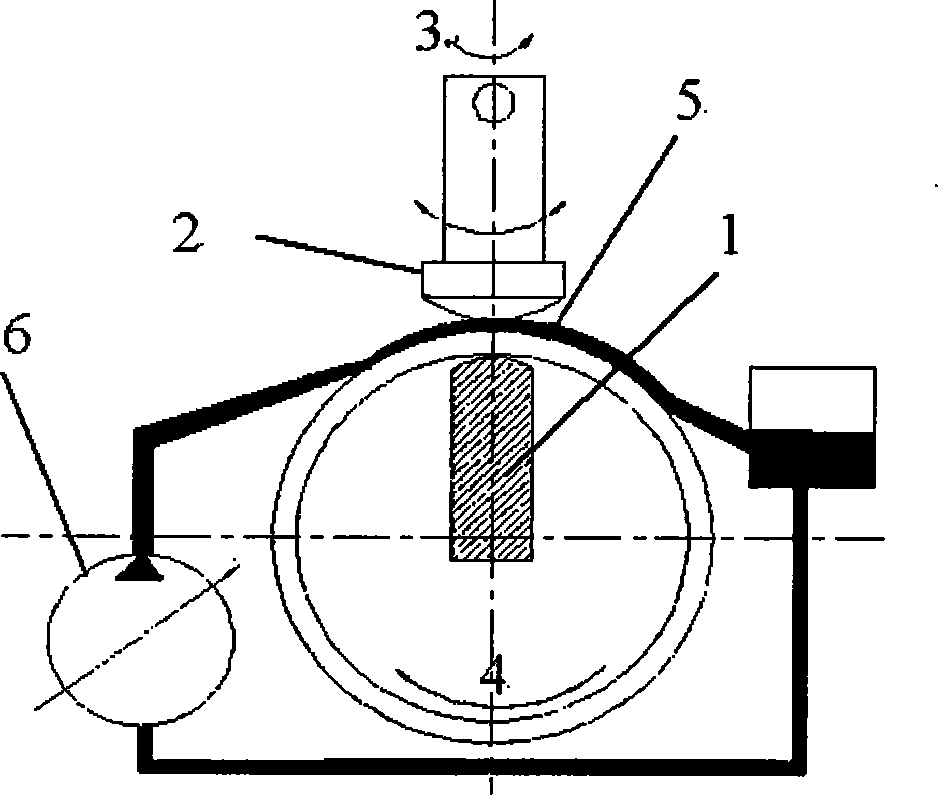

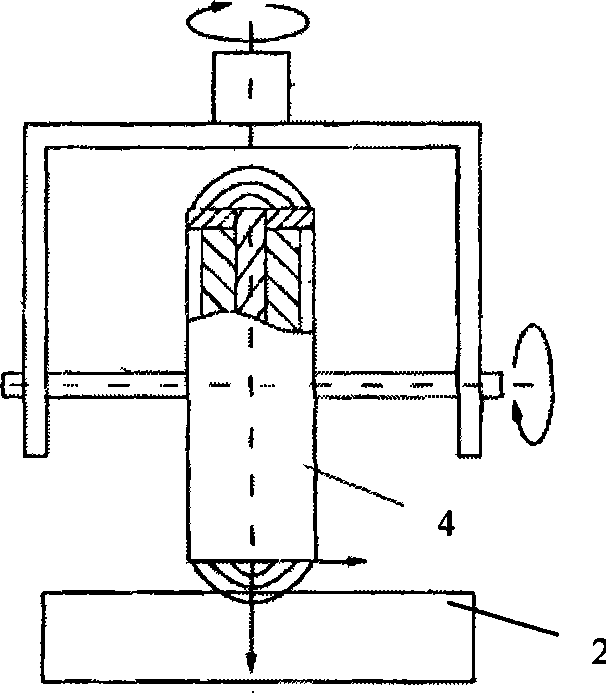

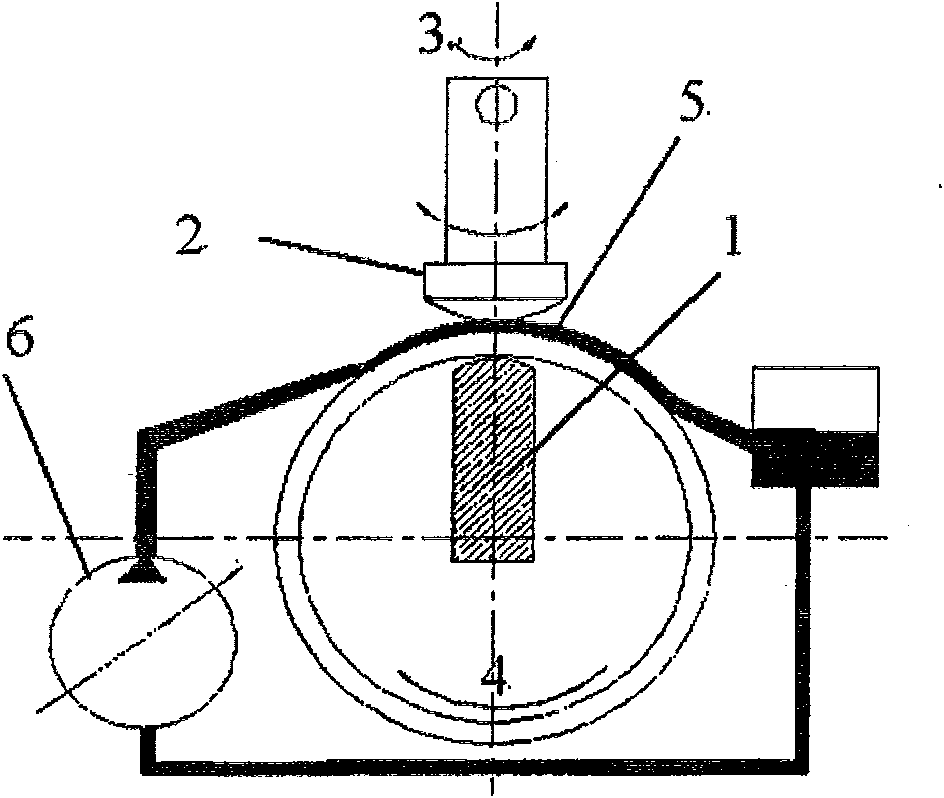

Magnetic current changing polishing device for large caliber aspheric surface optical part

InactiveCN101249626AWorkpiece clamping is simple and convenientMeet the processing capacityGrinding carriagesOptical surface grinding machinesMagnetic currentMachine tool

The invention discloses a magnetorheological finishing device for large-caliber aspheric optical parts. The magnetorheological finishing device comprises a machine tool, a finishing device, a magnetorheological finishing liquid circulating system for providing the finishing liquid with stable performance, and a control system connected with the components described above. The machine tool has four or more than four degrees of freedom. The finishing device is fixed on the machine tool and is positioned over the workpiece on the machine tool to be processed. The device has the advantages of simple and compact structure, low cost, simple control, wide range of application, and strong processing capacity, and is used for large-caliber aspheric optical parts.

Owner:NAT UNIV OF DEFENSE TECH

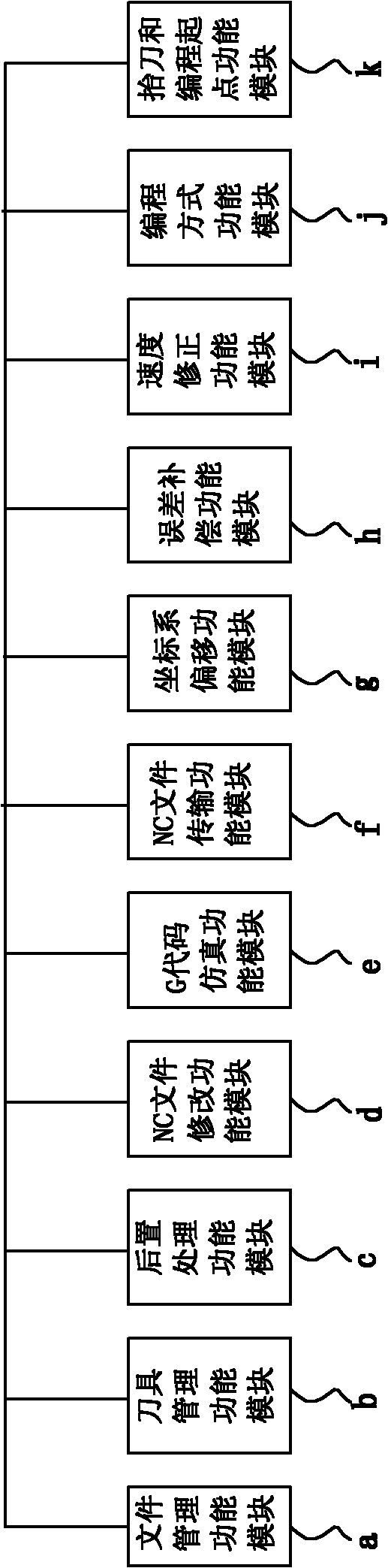

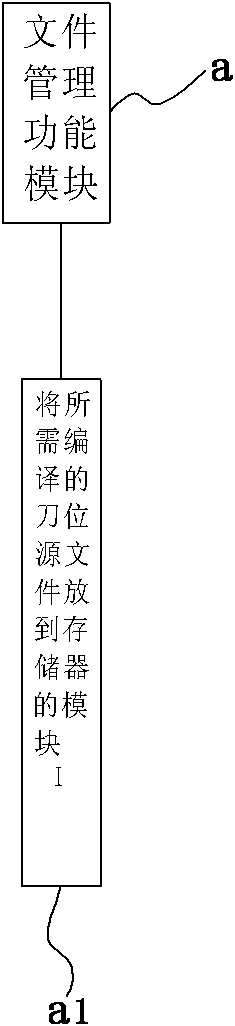

Five-axis linkage numerical control (NC) machining post processor and processing method thereof

InactiveCN102023613ARealize simulationRealize serial communicationProgramme controlComputer controlPost processorManagement functions

The invention discloses a five-axis linkage numerical control (NC) machining post processor and a processing method thereof, and relates to a post processor for an NC machining program and a processing method. The processor comprises computer program software which is used for processing a cutter location source file generated by a workpiece shape characteristic and a machining process, wherein the computer program software comprises a file management function module, a cutter management function module, a postprocessing function module, an NC file modification function module, a G code simulation function module, an NC file transmission function module, a coordinate system offset function module, an error compensation function module, a speed modification function module, a programming mode function module and a cutter-lifting and programming staring point function module. The processing method comprises the steps of setting a file, arranging a cutter, processing a programming mode, processing data of machine tool motion parameters, processing data of cutter dynamic cutting speed, outputting a G code file and the like. By the processor and the processing method, machining dynamic speed, speed compensation, non-linear error compensation and analog simulation of G code five-axis linkage can be realized.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Modified chemical fiber using natural protein fiber superfine powder and production process thereof

InactiveCN1594682AMeet the processing performanceGood hygroscopicityConjugated synthetic polymer artificial filamentsProtein fiberMelt spinning

The object of the invention is to provide a modified chemical fiber using natural protein fiber superfine powder and production process thereof. The modified chemical fiber is processed by superfine protein powder and chemical fiber material, in which the protein powder is 5-10%, fiber material is 90-95%. The modified chemical fiber using natural protein fiber superfine powder has an improved wettability, a good anti-static property, a good dyeing performance, and has the effects of wool-like and silk-like. The material is natural protein fiber material with a low price and broad source. The melt spinning and wet spinning will not change the processing craft of the traditional chemical fiber and has a good economic performance.

Owner:WUHAN TEXTILE UNIV

Low-temperature curing color coiled material paint and method for preparing same

ActiveCN101531860ASuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

The invention relates to a paint composition, in particular to a low-temperature curing paint used for manufacturing color steel plates and a method for preparing the same. The method comprises the following steps: adding 45 to 60 weight percent of saturated polyester resin, 3 to 5 weight percent of fully-methylated amino resin and 3 to 5 weight percent of partially-methylated amino resin into a reaction kettle; while stirring, adding 3 to 5 weight percent of propylene glycol ether acetate, 2 to 5 weight percent of binary acid dimethyl ester, 2 to 0.5 weight percent of closed cooling catalyst, 0.2 to 0.5 weight percent of open cooling catalyst, 5 to 10 weight percent of trimethyl benzene solvent to the mixture; after stirring the mixture evenly, adding 0.3 to 0.8 weight percent of dispersant to the mixture, and then adding 20 to 40 weight percent of filling pigment and 0.3 to 0.8 weight percent of wax powder while stirring; and after the mixture is dispersed evenly, performing sanding in a sand mill, and then performing paint and color mixing process to obtain the finished product, namely the low-temperature curing color coiled material paint. The method can solve the problems that the prior high-temperature baking curing paint has high curing temperature to cause energy sources waste.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Production method of glass fiber SMC yarn

The invention discloses a production method of glass fiber SMC yarn, which comprises the following steps: 1) preparation of an impregnating agent; 2) dosing; 3) melting in a kiln; 4) bushing; 5) coating with the impregnating agent; 6) drawing; 7) drying; 8) roving winding; 9) inspection and storage. According to the method disclosed by the invention, by adopting the complete-performance glass component and the special impregnating agent, the need of the drawing operation is met in the drawing technology while the processability of a later unwinding process is also guaranteed, thus the glass fiber SMC yarn has good acid resistance and water resistance, relatively high strength and good electric properties and mechanical properties.

Owner:JIANGSU ZHONGYA NEW MATERIAL

Low temperature curing color coil suede coating

InactiveCN101857767AHigh reactivityProduce a suede effectPolyester coatingsMulticolor effect coatingsLacquerLow temperature curing

The invention relates to a low temperature curing color coil coating, in particular to a low temperature curing color coil suede coating which comprises paint and a curing agent, wherein the paint and the curing agent are stored individually. The formula of the paint comprises the following components by weight proportion: 50% to 70% of saturated polyester resin, 5% to 8% of completely methylated melamine-formaldehyde resin, 1% to 2% of ethylenediamine surface active agent, 0.5% to 0.8% of closed p-toluenesulfonic acid catalyst, 5% to 20% of rutile titanium pigment, 5% to 19% of pigment, 3% to 5% of propylene glycol aether acetate, 2% to 5% of dibasic acid dimethyl ester, 5% to 10% of aromatic hydrocarbon solvent, 0.3% to 0.8% of dispersant and 0.3% to 0.8% of polytetrafluoroethylene wax.

Owner:JIANGSU LANLING COATING TECHN RES INST

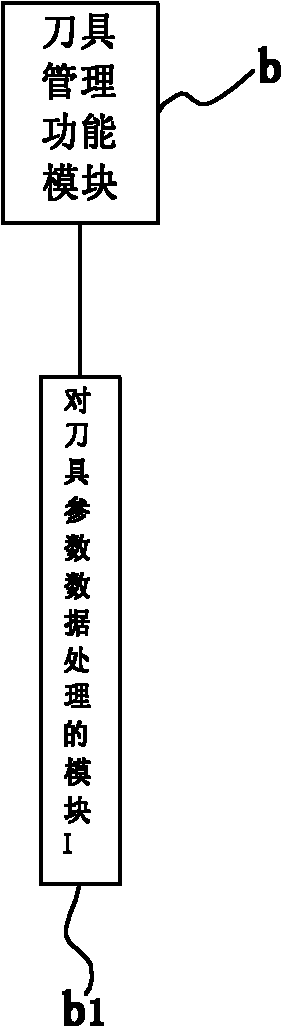

Stainless steel tooth zipper and manufacture method thereof

InactiveCN102672077AHigh bonding strengthMeet the processing performanceSlide fastenersWire rodEngineering

The invention relates to a stainless steel tooth zipper and a manufacture method thereof. The stainless steel teeth include pairs of bilaterally-symmetrical tooth bodies, concave surface portions and tooth point portions, wherein the concave surface portions and the tooth point portions are connected in a consubstantiality mode and arranged on the tooth bodies. The concave surface portion is matched with the tooth point portion on the other tooth body in a buckled mode, external clamping convex portions are arranged at the ports on the inner sides of the tooth bodies, and internal clamping convex portions are arranged in the middle of the inner sides of the tooth bodies. The manufacture method of the stainless steel tooth zipper is that a stainless steel wire processed by softening is pull-rolled into a stainless steel wire with a Y-shaped section, then arrangement of teeth is performed by a tooth arrangement machine, and post-processing combination is performed to obtain a stainless steel tooth zipper product. The product has the advantages of being high in corrosion resistance, large in tensile strength, good in quality, high in grade and the like. In addition, the cost of the product is reduced.

Owner:广东辉丰科技股份有限公司

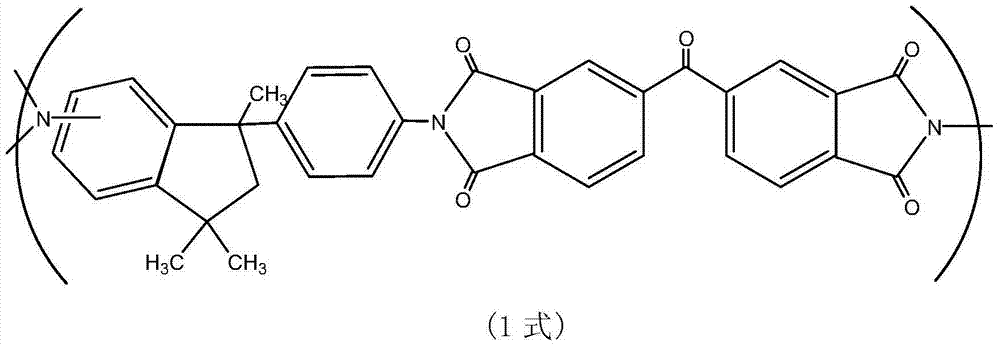

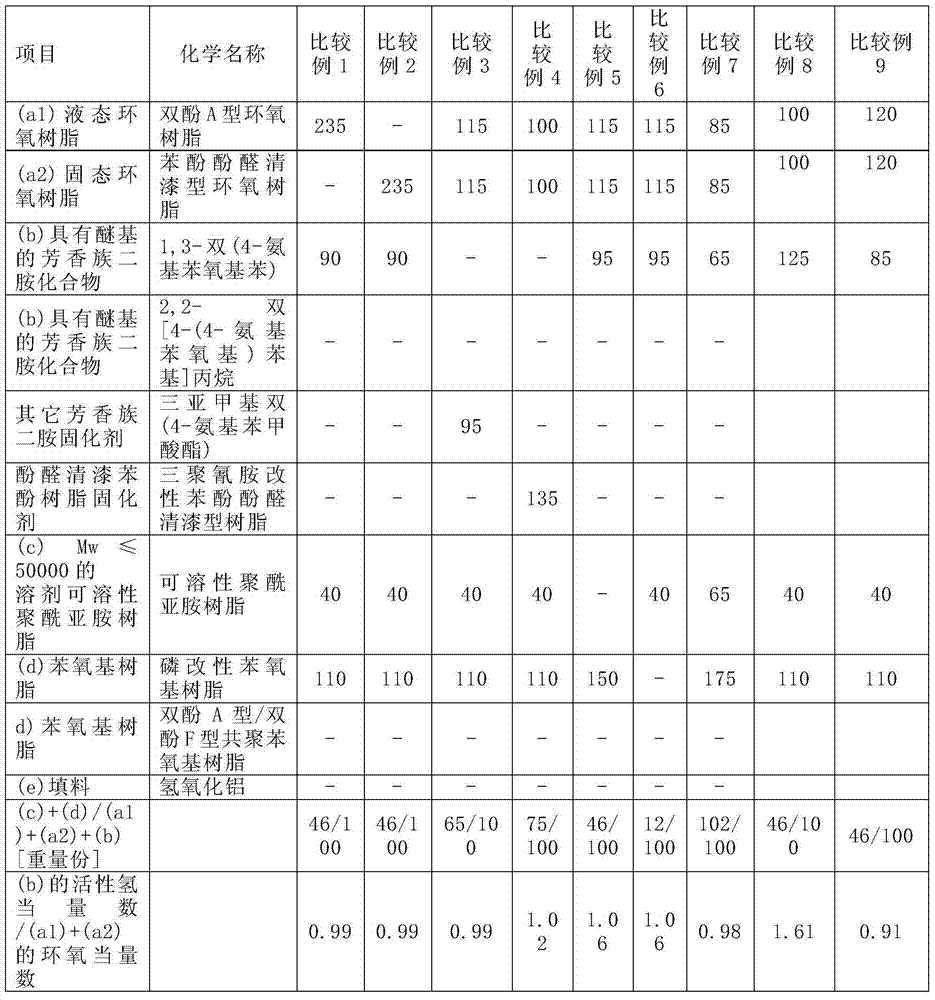

Thermosetting resin composition, b graded resin film, metal foil, copper-clad board and multi-layer lamination substrate

InactiveCN103665762AMeet bending performanceMeet reliabilitySynthetic resin layered productsMetal layered productsEpoxyInsulation layer

The invention aims to provide an epoxy thermosetting resin composition that can be bent and have a film insulation layer, has reliability and processing characteristic that compare favourably with halogen-free FR-4, and is low in fluidity in a vacuum pressing process. The thermosetting resin composition includes (a1) liquid epoxy resin; (a2) solid epoxy resin; (b) aromatic diamidogen compound with ether group; (c) solvent soluble polyimide resin with weight-average molecular weight below 50000; and (d) phenoxy resin. The amount of (c) solvent soluble polyimide resin with weight-average molecular weight below 50000 and (d) phenoxy resin is more than 15 parts by weight and less than 100 parts by weight when the total amount of the (a1) liquid epoxy resin, (a2) solid epoxy resin, (b) aromatic diamidogen compound is arranged to be 100 parts by weight.

Owner:TAMURA KK

Colorful fingerprint-resisting coating, preparation method and use method thereof

InactiveCN101914332ACorrosion resistanceSatisfy processabilityPretreated surfacesMulticolor effect coatingsSilane compoundsWater based

The invention discloses a colorful fingerprint-resisting coating, which comprises the following components in parts by mass: 50-70 parts of water-based macromolecular latex, 5-10 parts of deionized water, 15-25 parts of pigment, 5-10 parts of resin, 0.1-1 part of wetting agent, 0.5-1 part of flatting agent, 0.1-1 part of antifoaming agent and 1-5 parts of silane compound. Accordingly, the invention discloses a preparation method and a use method of the colorful fingerprint-resisting coating. The colorful fingerprint-resisting coating does not contain metal ions, and has excellent environmental conservation, decay resistance and fingerprint resistance.

Owner:上海丰野表面处理剂有限公司

Low-temperature curing primer-topcoat coil coating back paint and preparation method thereof

InactiveCN105419575AMeet the hardness and toughnessCorrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses low-temperature curing primer-topcoat coil coating back paint and a preparation method thereof. The low-temperature curing primer-topcoat coil coating back paint is prepared from the following components in mass ratio by stirring and mixing under the rotating-speed stirring condition: 40-48% of saturated polyester resin, 4-8% of amino resin, 2-6% of epoxy resin, 18-25% of pigment, 6-10% of functional anticorrosion pigment, 6-10% of filler, 10-20% of a solvent, 0.4-1.1% of a dispersing agent, 0.3-0.6% of a leveling agent, 0.1-0.5% of a defoaming agent, 2-4% of an adhesion promoter and 0.4-0.8% of a catalyst. The low-temperature curing primer-topcoat coil coating back paint product has low curing temperature and can meet hardness, toughness, corrosion resistance, acid resistance, alkali resistance, heat resistance and processability required by a galvanized steel sheet, and a single coating has excellent adhesive force, machinability and anti-corrosion property. The low-temperature curing primer-topcoat coil coating back paint product is simple in preparation technology, is applicable to being coated on the surfaces of a hot galvanized steel sheet, an electro-galvanized steel sheet and a cold-rolled steel sheet, so as to form a colorful coating protective film, and is also applicable to continuous roller painting of a continuous coating high-speed production line.

Owner:陕西宝塔山油漆股份有限公司

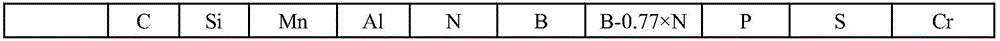

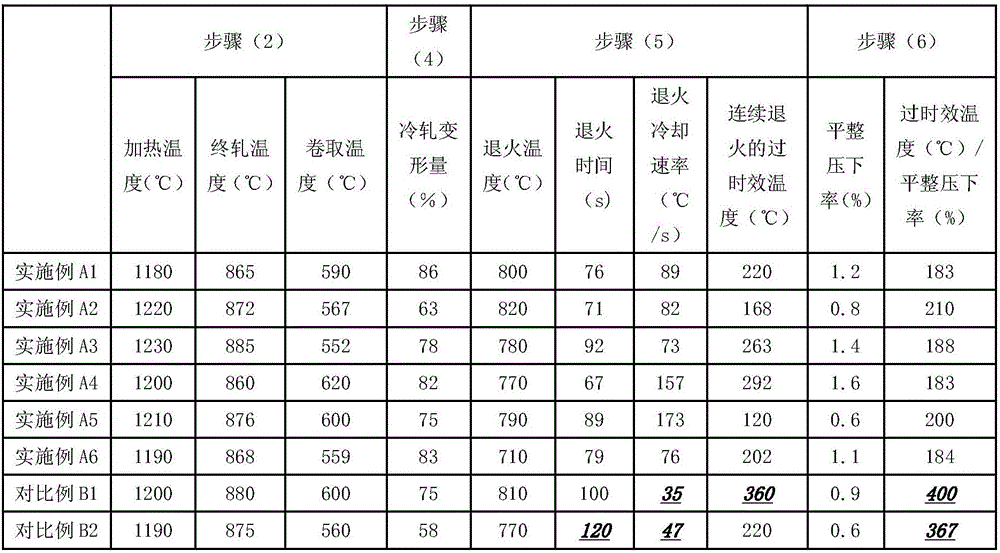

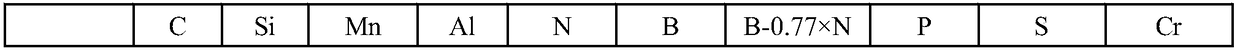

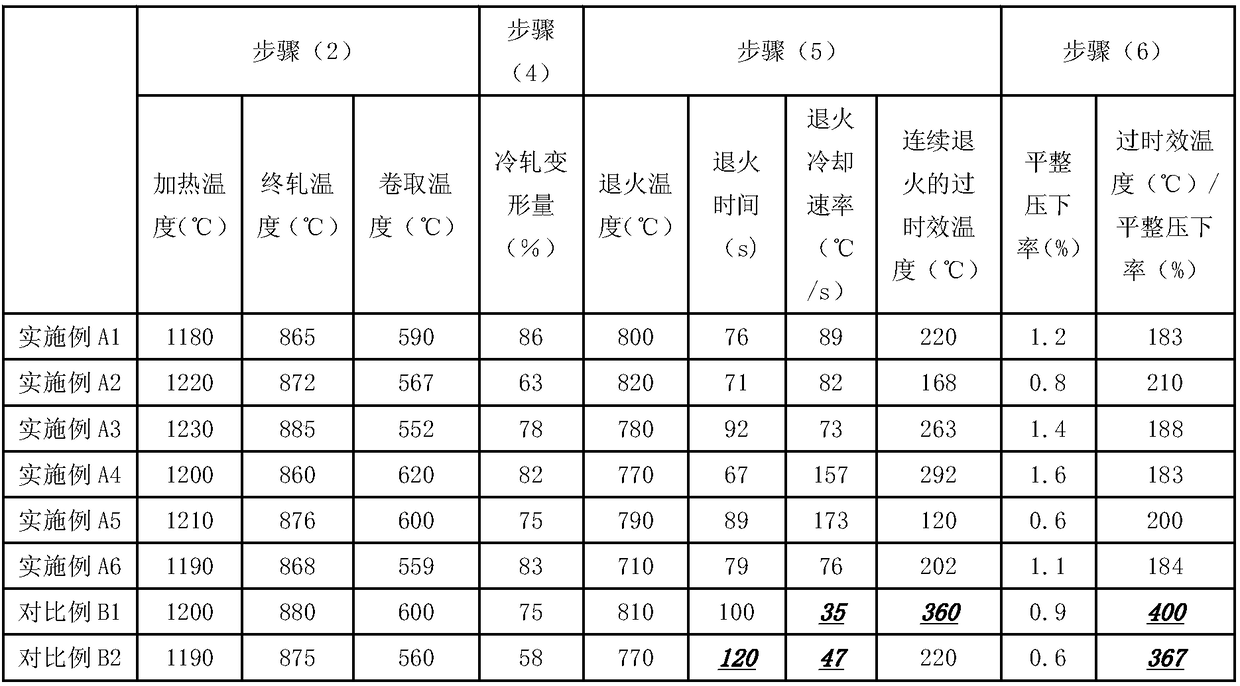

Bake hardening type high-strength steel and manufacturing method thereof

The invention discloses bake hardening type high-strength steel. The bake hardening type high-strength steel comprises, by mass percentage, 0.05 to 0.13% of C, 0.05 to 0.20% of Si, 0.50 to 1.50% of Mn, 0.02 to 0.06% of Al, larger than 0 and not larger than 0.0050% of N, and the balance iron and other inevitable impurities, and in addition, the condition that B-0.77*N is larger than or equal to 0.0005 and smaller than or equal to 0.0020% should be met. According to the bake hardening type high-strength steel, under the condition of not adding precious metals such as Mo, Cr, Ti and Nb, by controlling the mass percentage of carbon, manganese and boron, the technological processes and the technological parameters, the steel which is high in strength, low in cost, high in surface quality and of which the machining performance meets the requirements of automotive parts is manufactured.

Owner:BAOSHAN IRON & STEEL CO LTD

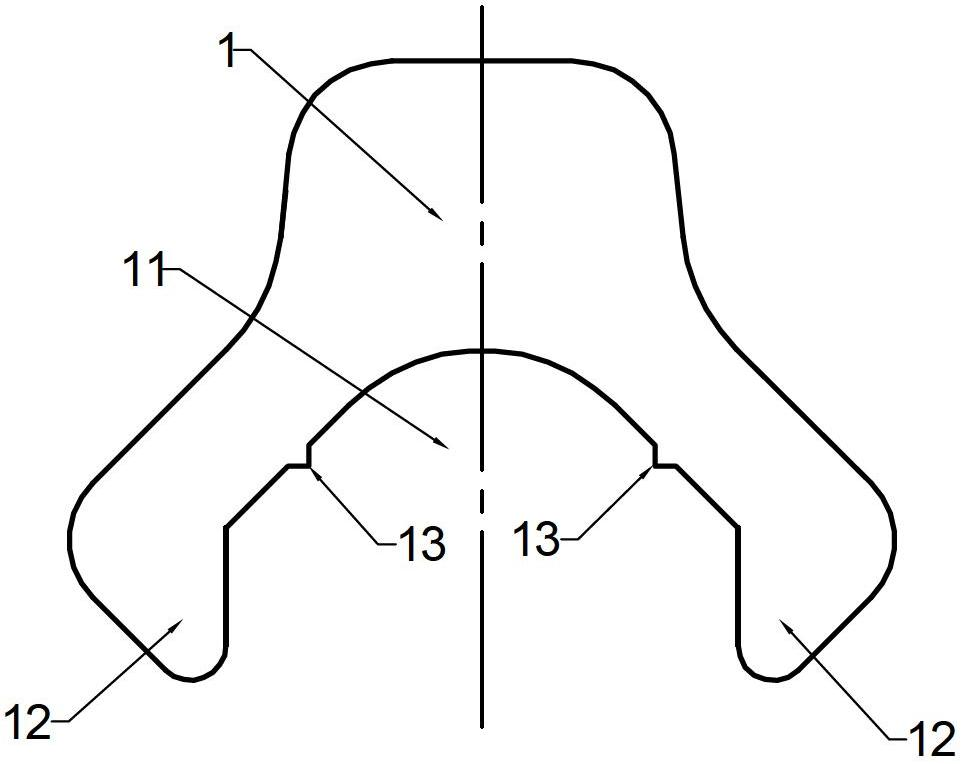

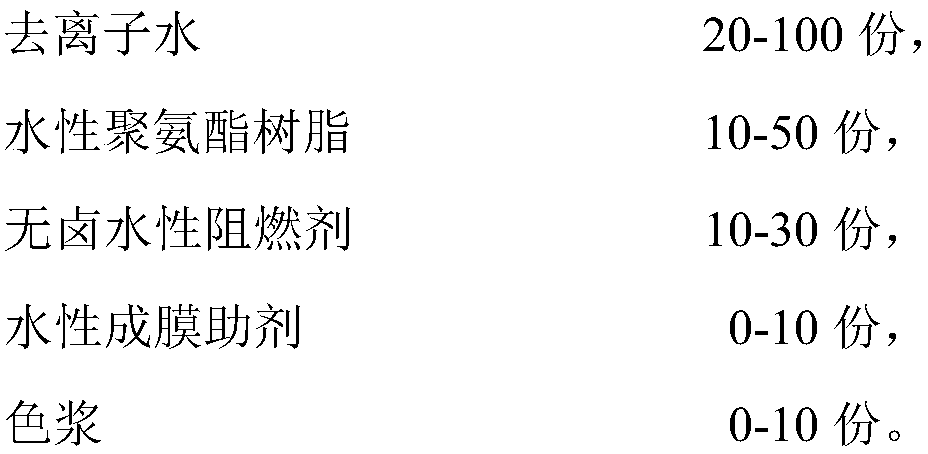

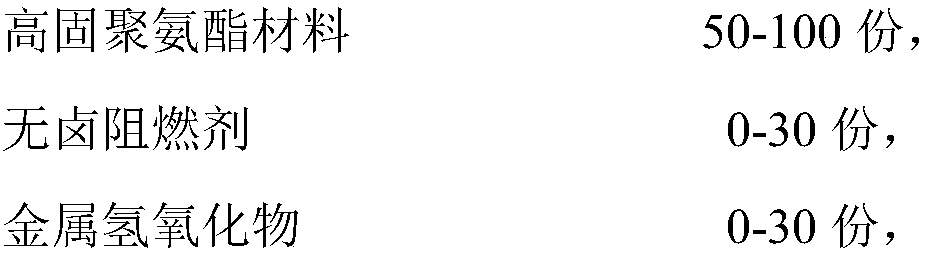

Method for preparing environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather

InactiveCN109056356AMeet the processing performanceMeet the test requirementsRoad vehiclesTextiles and paperPolyurethane membranePhysical strength

The invention relates to a method for preparing environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather. The method comprises the following steps: firstly, cospinning a bio-based raw material and chinlon to obtain bio-based base cloth, and carrying out dipping, extrusion and drying to obtain a bio-based basic material with flame retardancy; preparing a halogen-free flame-retardant high-solid polyurethane membrane in a release paper membrane transferring mode, and peeling off the release paper membrane to obtain a high-solid membrane with flame retardancy; finally compounding the bio-based basic material with the high-solid membrane, thereby obtaining a finished product. The environmentally-friendly flame-retardant bio-based automobile chair polyurethane synthetic leather prepared with the method has flame retardancy which meets requirements of grade B provided by 'GB 8410-2006 combustion property of automotive trim material'. Meanwhile, the leather has the advantages of low VOC (volatile organic compound), good environment protection, flexible and full hand feelings, good surface skin friendliness, high physical strength, oil resistance, aging resistance, and the like.

Owner:ANHUI ANLI MATERIAL TECH

Finishing withdrawing-straightening tension control method for deep-draw galvanized steel sheet

ActiveCN103934282AImprove surface qualityGuaranteed surface qualityTension/compression control deviceSheet steelEconomic benefits

The invention belongs to the technical field of galvanized steel sheet production methods, and relates to a finishing withdrawing-straightening tension control method for a deep-draw galvanized steel sheet for guaranteeing the steel sheet performance and the surface quality. According to the technical scheme, the tension set values before and after the finishing withdrawing-straightening are adjusted, and the matching relation between steel plates with different thicknesses and the tension before and after the finishing withdrawing-straightening is adopted, wherein the tension before finishing conforms to the formula: T(strip steel thickness)*(25-30)KN, and the tension after finishing and withdrawing-straightening conforms to the formula: T(strip steel thickness)*(27.5-33)KN. According to the finishing withdrawing-straightening tension control method, the surface quality of the deep-draw galvanized product can be guaranteed, the performance is not greatly affected, the requirement for machining and using performance of a user is met, and the performance aggravating effect brought by increasing the finishing rolling force to guarantee the surface of the deep-draw galvanized product is avoided. The performance judgment amending ratio of the deep-draw galvanized product is greatly reduced, the surface quality and the profit space of the deep-draw galvanized product are greatly improved, the competitiveness of enterprises is enhanced, and considerable economic benefits are brought to the enterprises.

Owner:HEBEI IRON AND STEEL

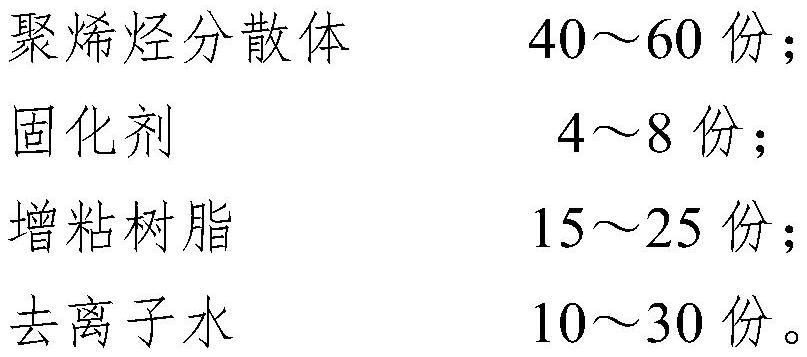

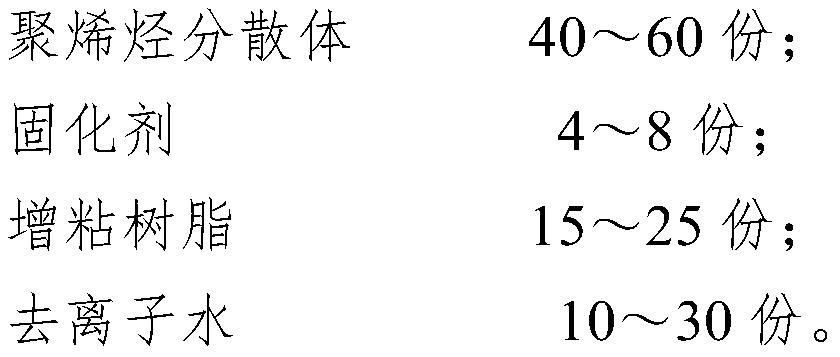

Heat-sealing coating for aluminum foil meal box and preparation method of heat-sealing coating

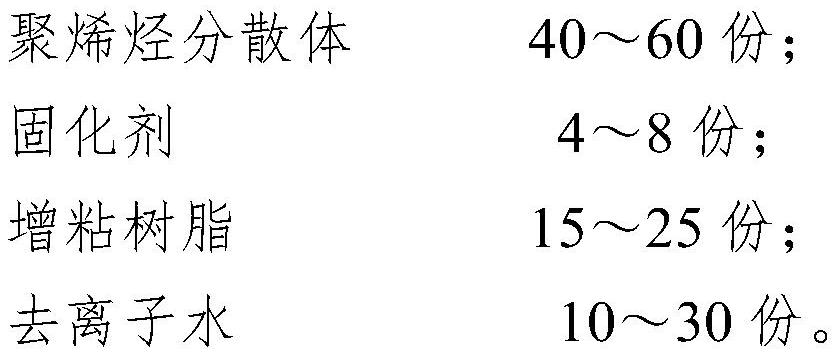

In order to overcome the problems of low heat-sealing strength of the existing aluminum foil meal box heat-sealing material on PP and PE films and poor boiling resistance, steaming resistance and acid resistance, the invention provides a heat-sealing coating for an aluminum foil meal box, the heat-sealing coating comprises the following components in parts by mass: 40-60 parts of polyolefin dispersion; 4-8 parts of a curing agent; 15-25 parts of tackifying resin; and 10-30 parts of deionized water. The invention also provides a preparation method of the heat-sealing coating for the aluminum foil meal box. The heat-sealing coating obtained by coating the inner wall of the aluminum foil meal box with the heat-sealing coating has excellent flexibility, meets the tensile deformation capacity of the aluminum foil meal box in use, is excellent in high-temperature boiling resistance and acetic acid boiling resistance, can be subjected to heat-sealing adhesion with PP and PE laminated adhesives at 160-230 DEG C, and the meal box after heat sealing has excellent air tightness.

Owner:清远慧谷新材料技术有限公司

Preparation method of anti-puncture high-barrier co-extrusion film

PendingCN111421934ASolve the tensile resistanceAddress performance requirementsSynthetic resin layered productsFlat articlesBlow moldingTear resistance

The invention provides a preparation method of a puncture-resistant high-barrier co-extrusion film, relates to the technical field of packaging materials, and solves the technical problems that a PE film and a PP film in the prior art are low in puncture resistance, poor in tensile resistance and low-temperature resistance and prone to bag breaking and poor sealing. The co-extrusion film comprisesa composite layer, a first core layer, a second core layer and a heat sealing layer, and the co-extrusion film is formed by blow molding and co-extrusion of the composite layer, the first core layer,the second core layer and the heat sealing layer which are sequentially arranged. The co-extrusion film provided by the invention integrates a series of mechanical properties such as puncture resistance, stretching resistance, impact resistance, tear resistance and the like, and in addition, on the premise of ensuring the mechanical properties, the processability of a product and the use performance of a client need to be met at the same time.

Owner:DALIAN JUTONG PLASTIC PRODS

Low-temperature curing color coiled material paint and method for preparing same

ActiveCN101531860BSuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

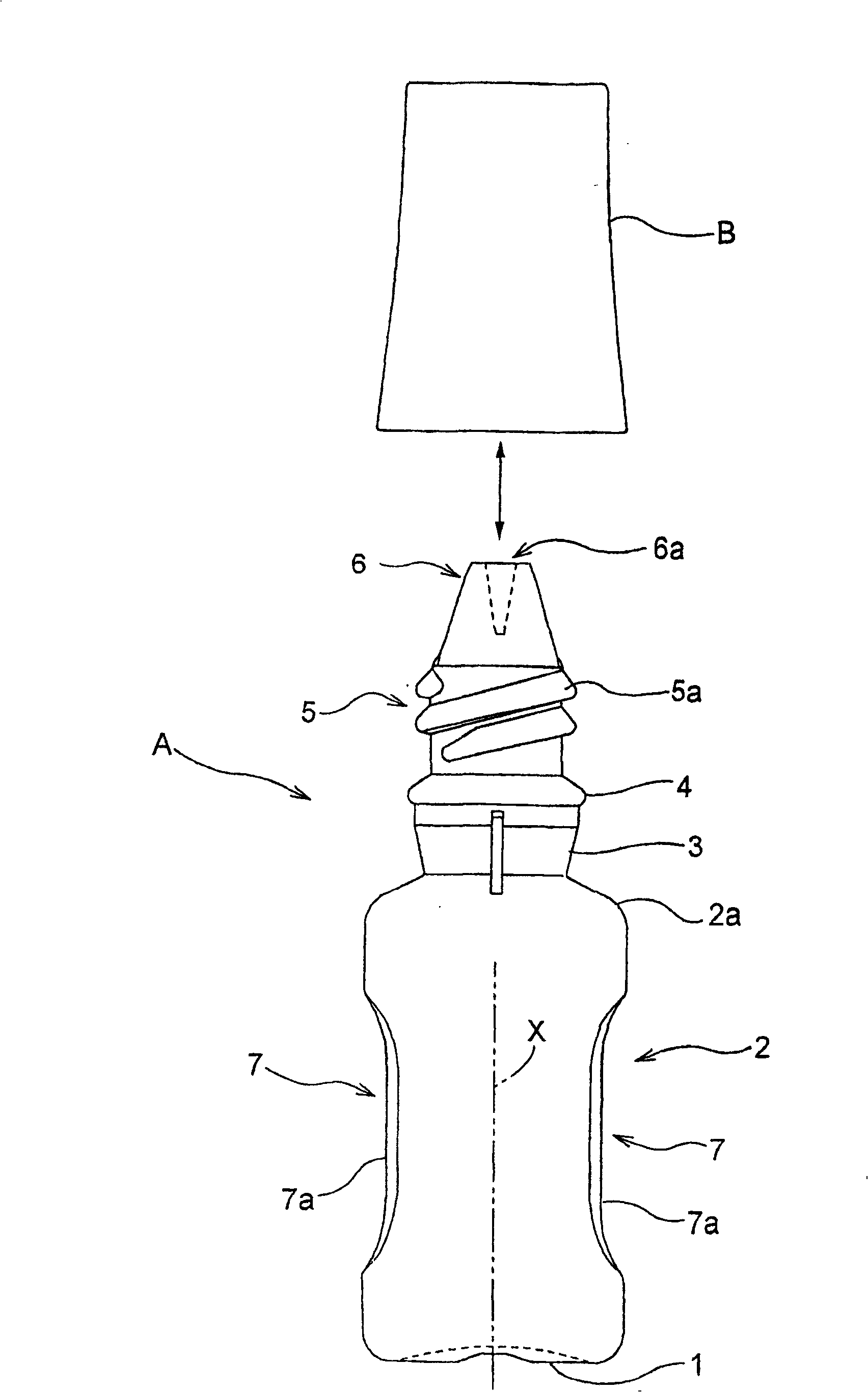

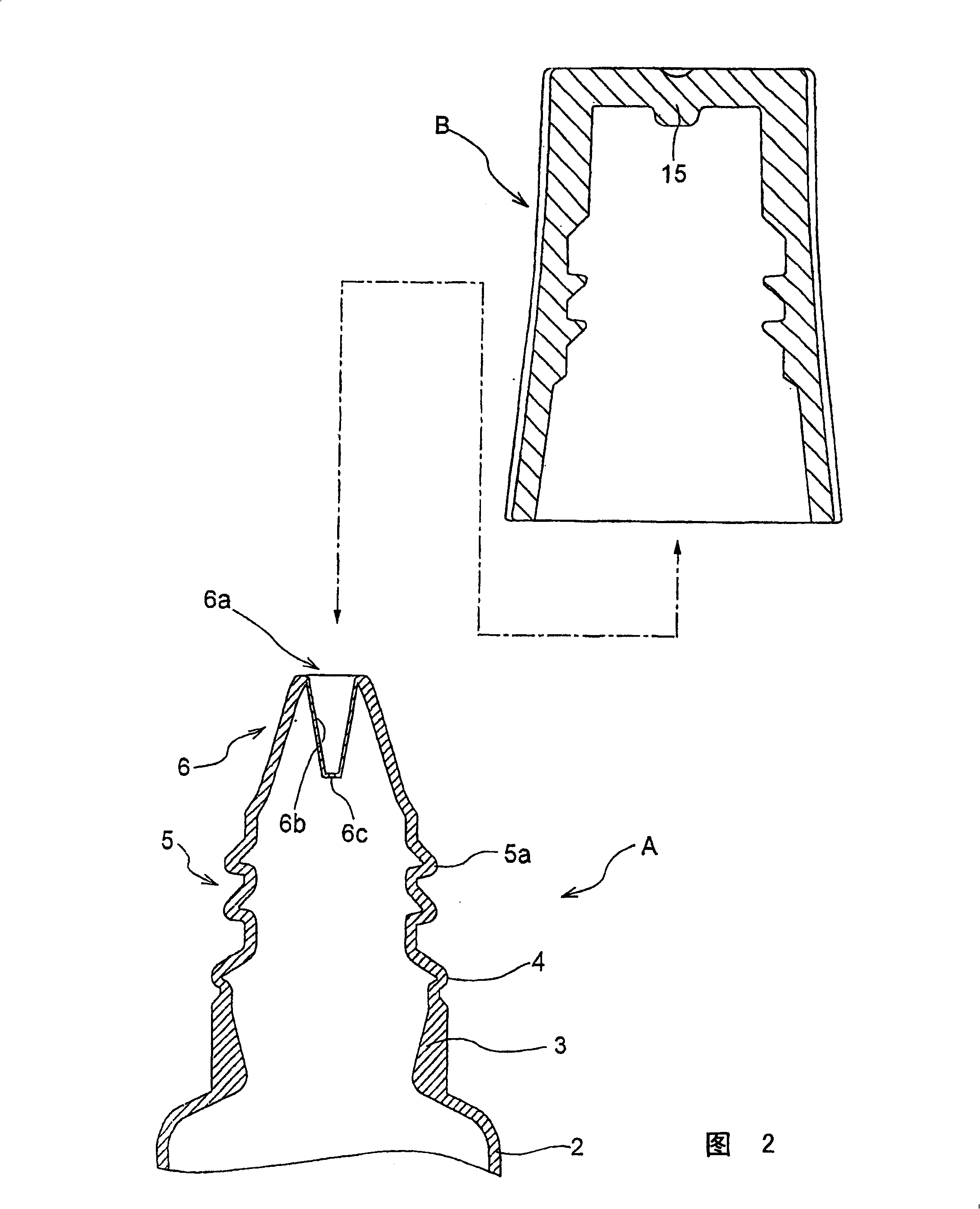

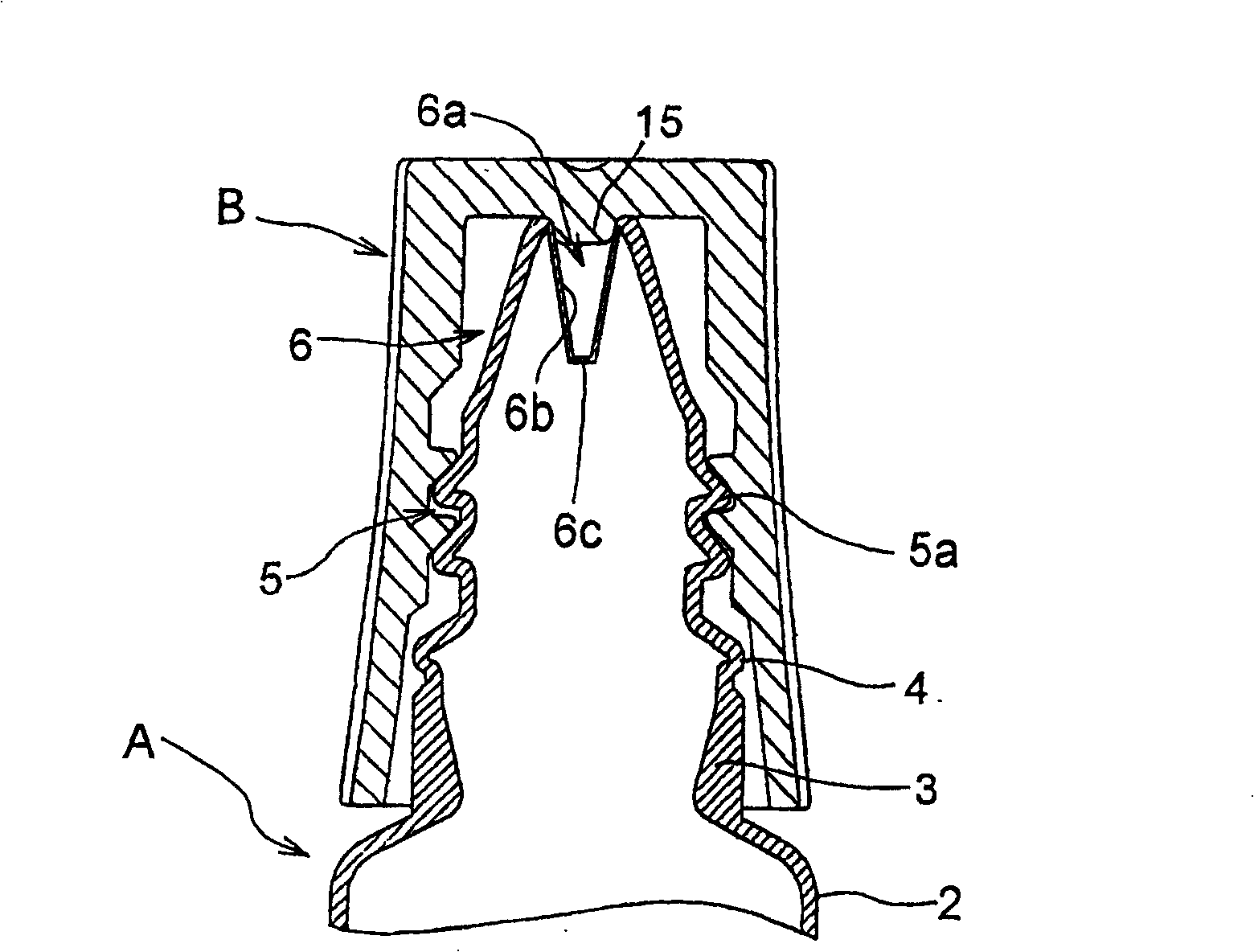

High temperature sterilized eye drop applicator

The invention provides an eyedrops container which is easy to manufacture and easy to sterilize, ensures a sterile guarantee, and moreover is excellent in instilling operability, the eyedrops container is integrally formed of a resin material that does not melt or deform in time of sterilization performed under a condition of approximately 121 DEG C, for approximately 20 minutes.

Owner:SANTEN PHARMA CO LTD

Magnetic current changing polishing device for large caliber aspheric surface optical part

InactiveCN100566935CProcessing size is not limitedEasy to set upGrinding carriagesOptical surface grinding machinesMagnetic currentControl system

Owner:NAT UNIV OF DEFENSE TECH

A bake-hardening high-strength steel and its manufacturing method

The invention discloses bake hardening type high-strength steel. The bake hardening type high-strength steel comprises, by mass percentage, 0.05 to 0.13% of C, 0.05 to 0.20% of Si, 0.50 to 1.50% of Mn, 0.02 to 0.06% of Al, larger than 0 and not larger than 0.0050% of N, and the balance iron and other inevitable impurities, and in addition, the condition that B-0.77*N is larger than or equal to 0.0005 and smaller than or equal to 0.0020% should be met. According to the bake hardening type high-strength steel, under the condition of not adding precious metals such as Mo, Cr, Ti and Nb, by controlling the mass percentage of carbon, manganese and boron, the technological processes and the technological parameters, the steel which is high in strength, low in cost, high in surface quality and of which the machining performance meets the requirements of automotive parts is manufactured.

Owner:BAOSHAN IRON & STEEL CO LTD

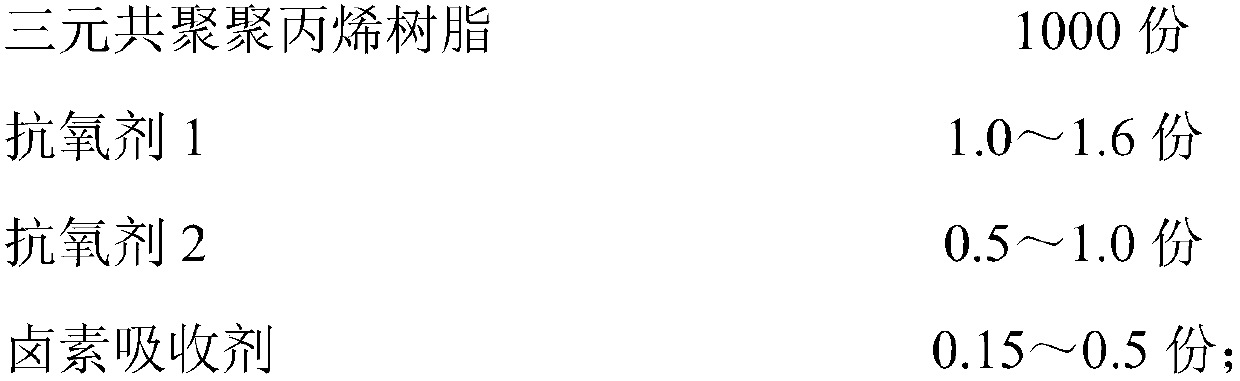

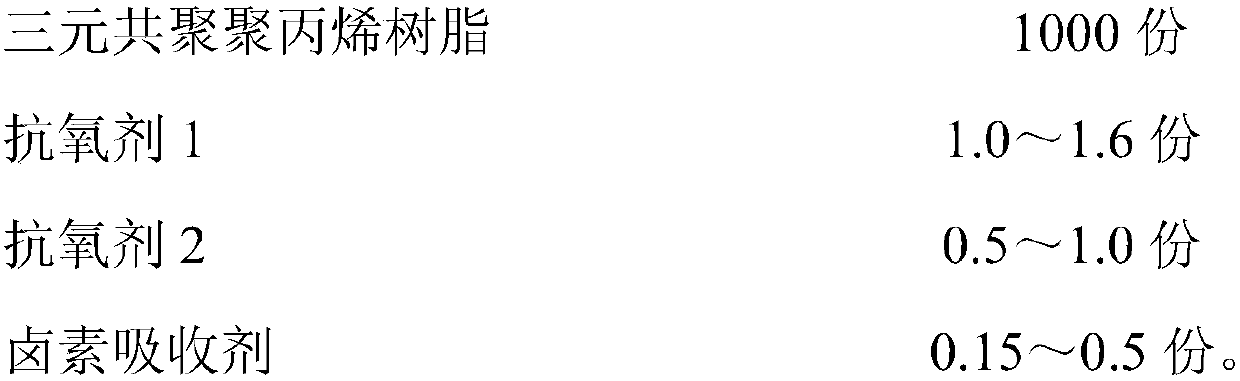

Aluminum-plated ternary copolymerized polypropylene casting film resin composition

InactiveCN109721856AMeet the processing performanceMeet the optical performanceHalogenOptical property

The invention relates to an aluminum-plated ternary copolymerized polypropylene casting film resin composition, which comprises the following raw materials by weight: 1000 parts of a ternary copolymerized polypropylene resin, 1.0-1.6 parts of an antioxidant 1, 0.5-1.0 part of an antioxidant 2, and 0.15-0.5 part of a halogen absorbent, wherein the ternary copolymerized polypropylene resin comprises5.5-10 wt% of 1-butene, 0.5-1.5 wt% of ethylene, and the balance of propylene. According to the present invention, the ternary copolymerized polypropylene composition has characteristics of excellentimpact strength, excellent rigidity and low n-hexane extract under the premise of meeting of the processing property, the aluminum plating property, the optical property and the thermal adhesive property of food-grade aluminum-plated films, and can completely meet the production requirements of high-end casting film packaging manufacturers on metalize cast polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

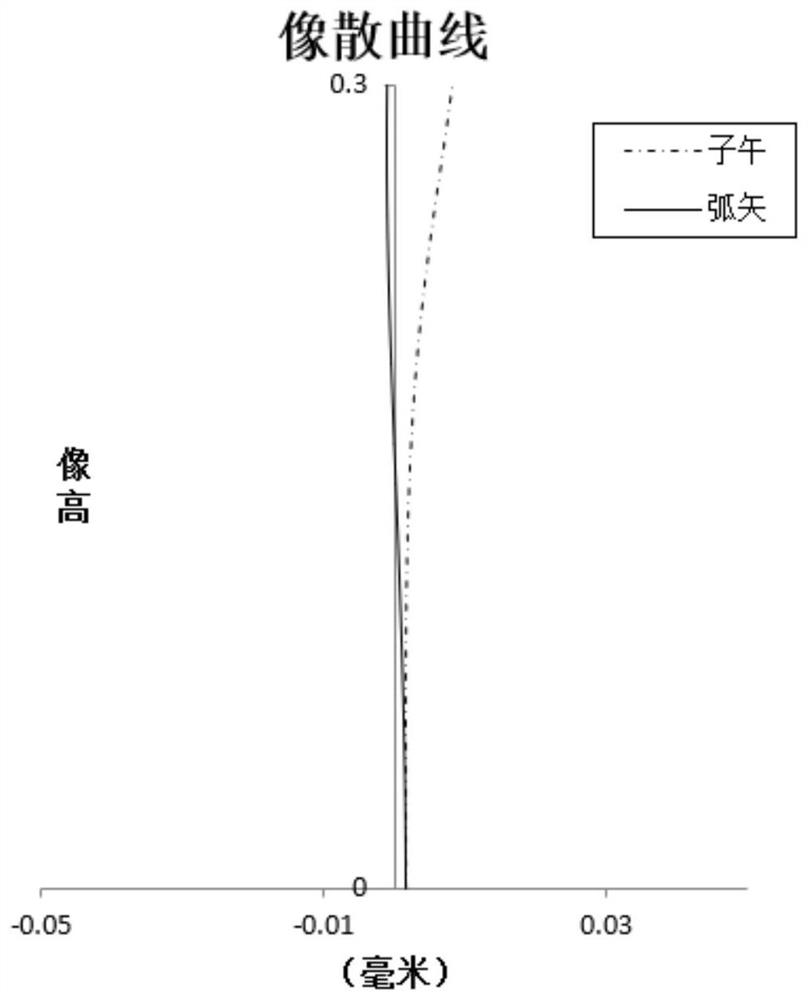

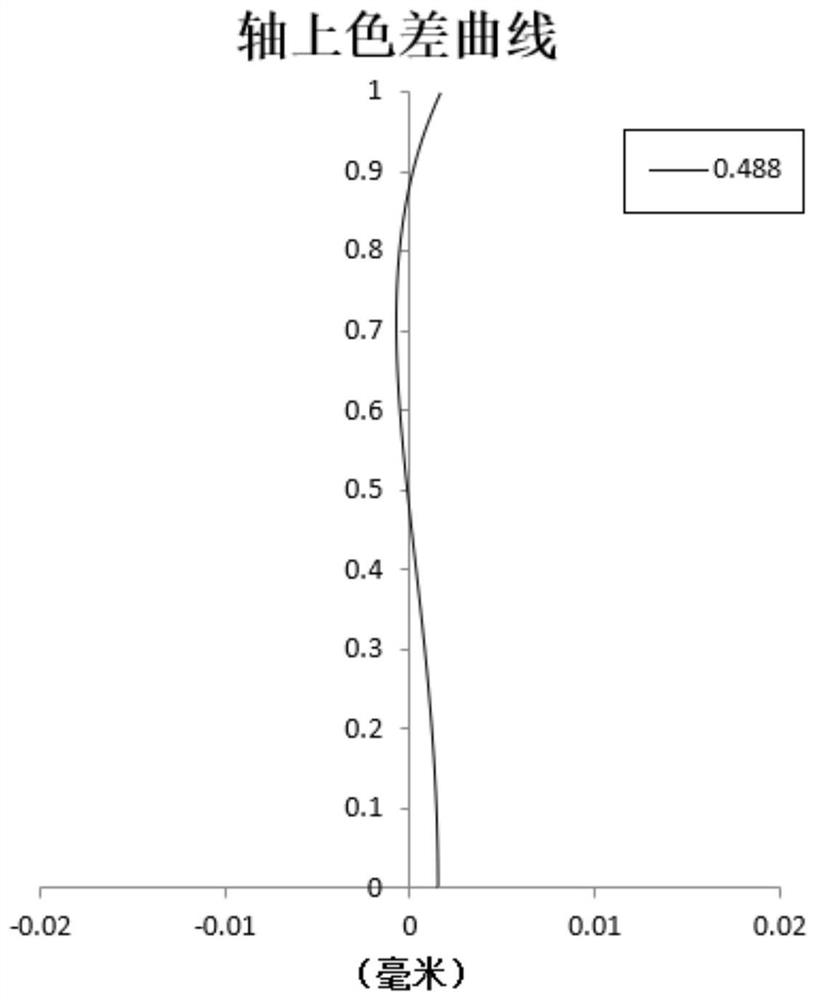

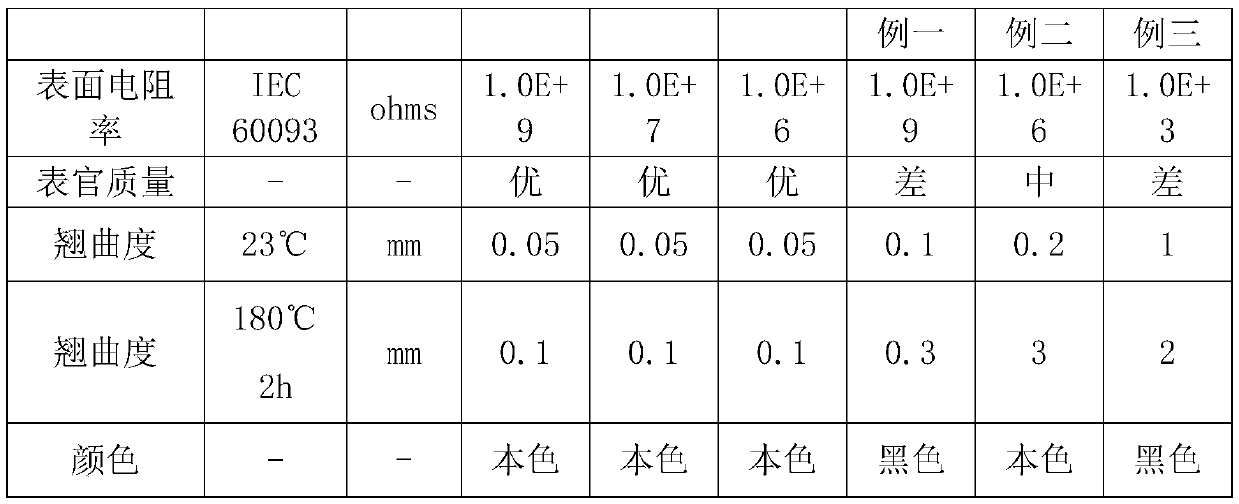

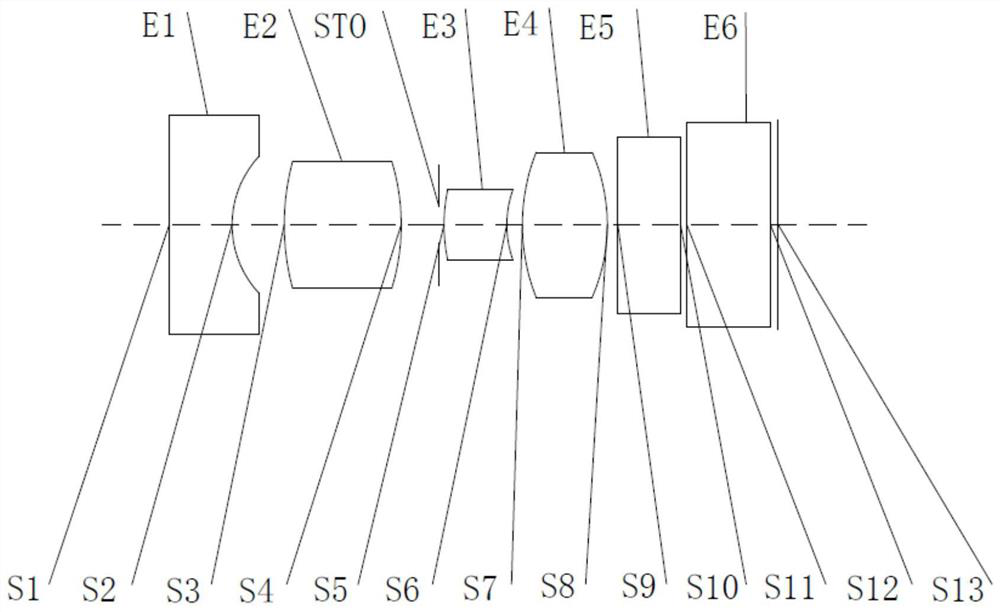

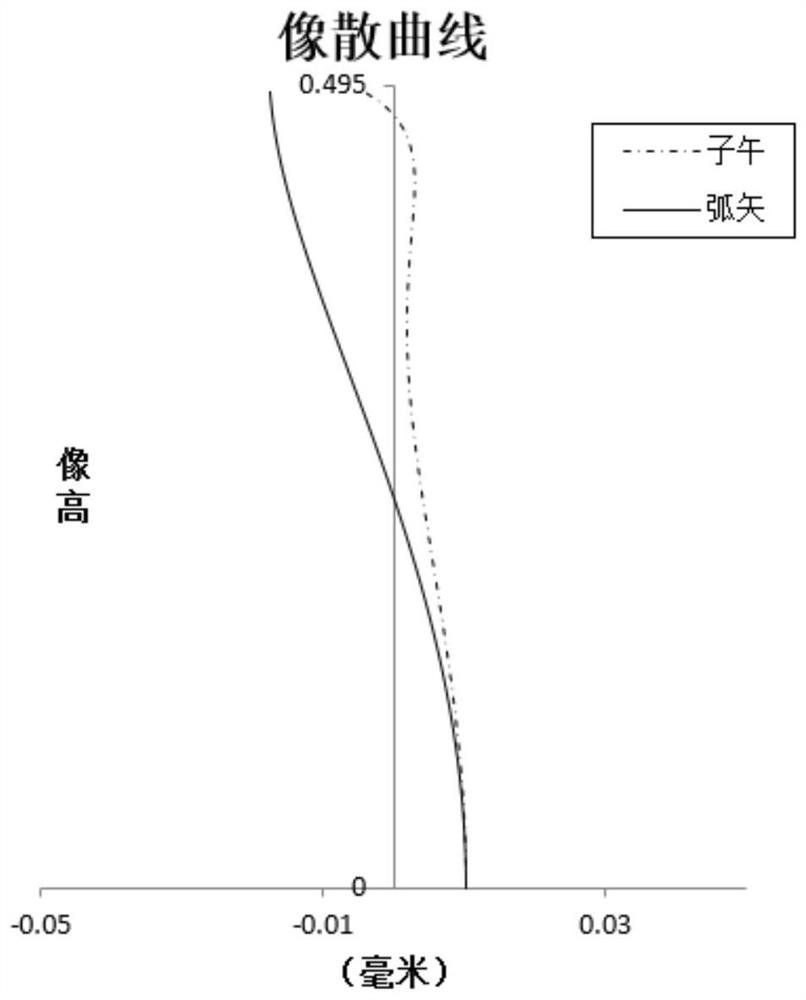

Ultra-thin small-caliber high-resolution endoscopic microscope objective

The invention relates to an ultra-thin small-caliber high-resolution endoscopic microscope objective which comprises a first lens, a diaphragm, a second lens, a third lens and a fourth lens sequentially arranged from the object side. All the lenses are spherical lenses and are separately arranged by taking air as an interval, the first lens has negative focal power, the object side surface of the first lens is a plane, and the image side surface of the first lens is a concave surface; the second lens has positive focal power, the object side surface of the second lens is a convex surface, and the image side surface is a convex surface;the third lens has positive focal power, the object side surface of the third lens is a convex surface, and the image side surface of the third lens is a concave surface; the fourth lens has positive focal power, the object side surface of the fourth lens is a convex surface, the image side surface of the fourth lens is a convex surface, the maximum clear aperture is less than or equal to 0.6, the axial distance from the object side surface of the first lens to the imaging surface is less than or equal to 4.0 mm, and 1.1< f*TAN(HFOV) / T34< 2.3. The endoscopic microscope objective is small in caliber, small in thickness, high in resolution, compact in structure, convenient to machine and install and good in imaging quality, and the requirements for miniaturization and light weight of the medical endoscopic microscope objective are met.

Owner:ZHEJIANG LAB +1

A kind of tension control method for fair drawing and straightening of deep-drawn galvanized steel sheet

ActiveCN103934282BImprove surface qualityGuaranteed surface qualityTension/compression control deviceSheet steelEconomic benefits

The invention belongs to the technical field of galvanized steel sheet production methods, and relates to a finishing withdrawing-straightening tension control method for a deep-draw galvanized steel sheet for guaranteeing the steel sheet performance and the surface quality. According to the technical scheme, the tension set values before and after the finishing withdrawing-straightening are adjusted, and the matching relation between steel plates with different thicknesses and the tension before and after the finishing withdrawing-straightening is adopted, wherein the tension before finishing conforms to the formula: T(strip steel thickness)*(25-30)KN, and the tension after finishing and withdrawing-straightening conforms to the formula: T(strip steel thickness)*(27.5-33)KN. According to the finishing withdrawing-straightening tension control method, the surface quality of the deep-draw galvanized product can be guaranteed, the performance is not greatly affected, the requirement for machining and using performance of a user is met, and the performance aggravating effect brought by increasing the finishing rolling force to guarantee the surface of the deep-draw galvanized product is avoided. The performance judgment amending ratio of the deep-draw galvanized product is greatly reduced, the surface quality and the profit space of the deep-draw galvanized product are greatly improved, the competitiveness of enterprises is enhanced, and considerable economic benefits are brought to the enterprises.

Owner:HEBEI IRON AND STEEL

Method for preparing ternary copolymerized metalize cast polypropylene resin composition

InactiveCN109721808AMeet the processing performanceMeet the optical performancePolymer scienceOptical property

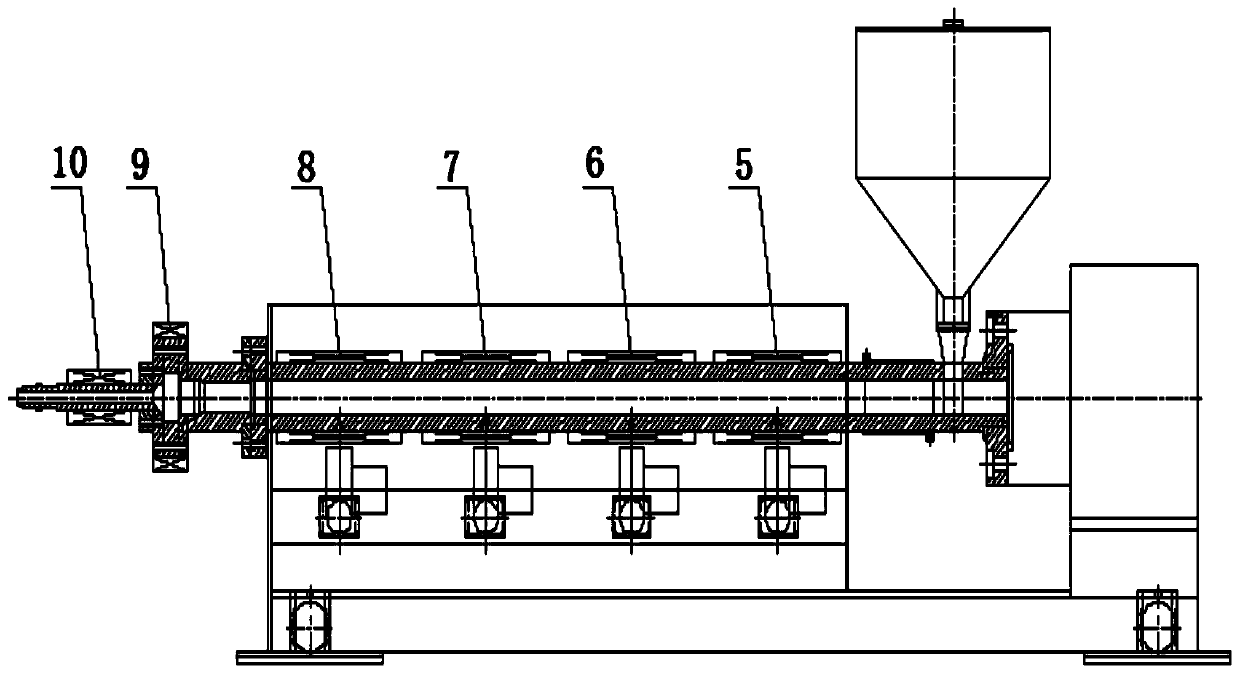

The invention relates to a method for preparing a ternary copolymerized metalize cast polypropylene resin composition, comprising the steps of: 1) preparing a ternary copolymerized polypropylene resinbinder: using propylene as a main reaction material, 1-butylene and ethylene as comonomers to carry out copolymerization reaction in a loop reactor to obtain the ternary copolymerized polypropylene resin binder; 2) mixing the ternary copolymerized polypropylene resin binder prepared in the step 1, an antioxidant 1, an antioxidant 2, and a halogen absorber at ambient temperature and pressure, andthen adding the mixture to a twin-screw extruder for granulation to obtain the ternary copolymerized metalize cast polypropylene resin composition. The ternary copolymerized metalize cast polypropylene resin composition of the invention satisfies the processing property, aluminum plating property, optical property and thermal adhesive property for a food grade aluminized film, and also has excellent impact strength, rigidity and low hexane extract content. The resin composition fully meets the requirements of high-end cast film packaging manufacturers for producing aluminized cast films.

Owner:CHINA PETROLEUM & CHEM CORP +1

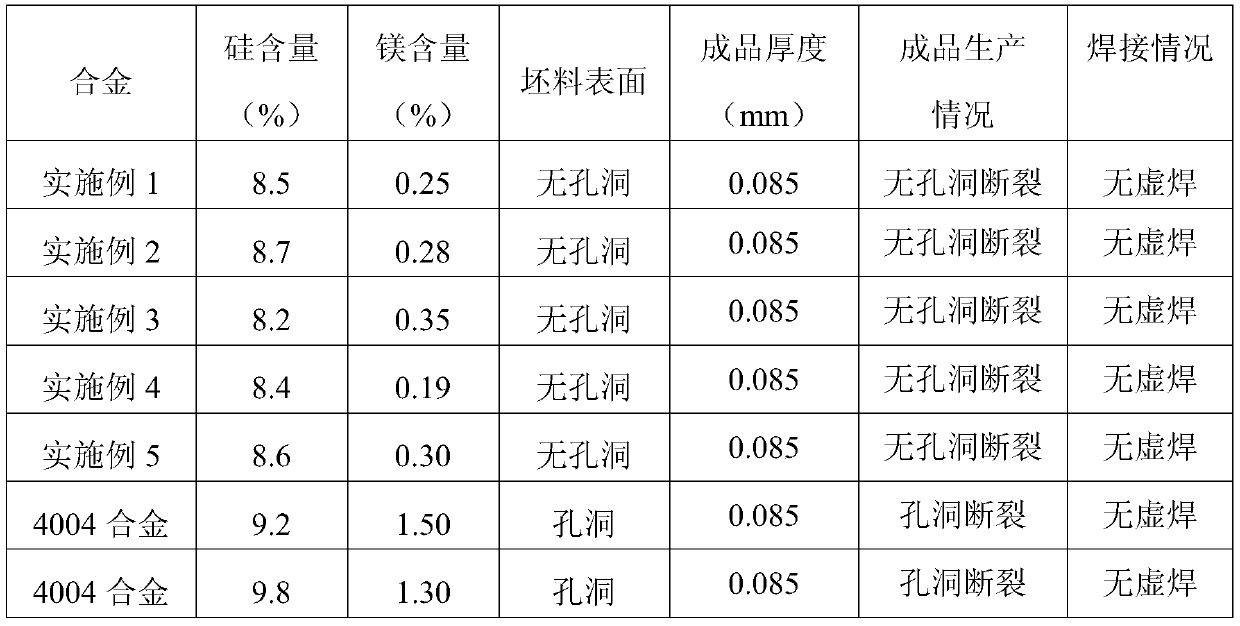

Vacuum brazing welding piece blank material and preparation method thereof

InactiveCN111451667ANo holesReduce consumptionWelding/cutting media/materialsSoldering mediaMaterial consumptionIngot

The invention discloses a vacuum brazing welding piece blank material and a preparation method thereof. The preparation method comprises the following steps that raw materials are prepared, and the raw materials comprise an aluminium ingot, waste aluminum and aluminum-silicon intermediate alloy; the raw materials are added into a smelting furnace and are ignited to be melted; after the raw materials are completely liquefied into aluminum water, silicon content blending is firstly performed, then the aluminum water is guided into a standing furnace to perform magnesium content blending, after the two-time ingredient blending, the silicon content is not more than 9.0%, and the magnesium content is not more than 0.35%; and cast rolling is performed to obtain cast rolling rolls, namely the vacuum brazing welding piece blank material. According to the vacuum brazing welding piece blank material and the preparation method thereof provided by the invention, the production cycle is short, material consumption is low, and the blank material has no holes, is not prone to breaking and is easy to roll.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

An ultra-thin small-aperture high-resolution endoscopic microscope objective lens

The invention relates to an ultra-thin small-caliber high-resolution endoscopic microscope objective lens, which comprises a first lens, a diaphragm, a second lens, a third lens and a fourth lens arranged in sequence from the object side, and each lens is a spherical lens And they are all separated by air. The first lens has a negative refractive power, its object side is a plane, and its image side is concave; the second lens has a positive refractive power, its object side is a convex surface, and its image side is a convex surface; The lens has positive refractive power, the object side is convex, and the image side is concave; the fourth lens has positive refractive power, the object side is convex, the image side is convex and the maximum light aperture is ≤0.6, the first lens object side to imaging The axial distance of the surface ≤ 4.0mm, and meet 1.1

Owner:ZHEJIANG LAB +1

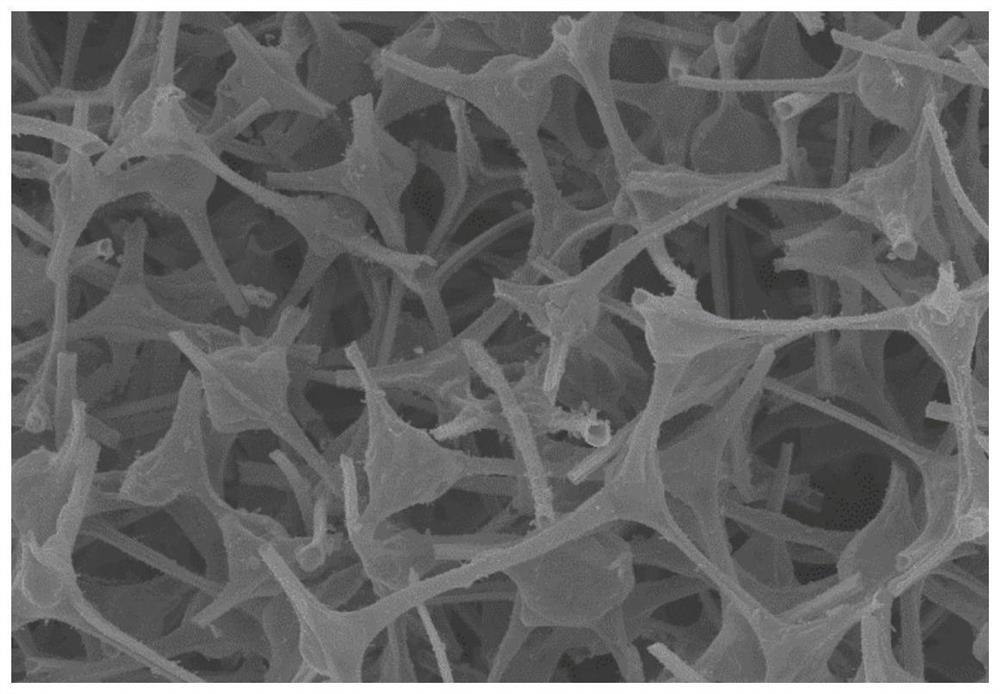

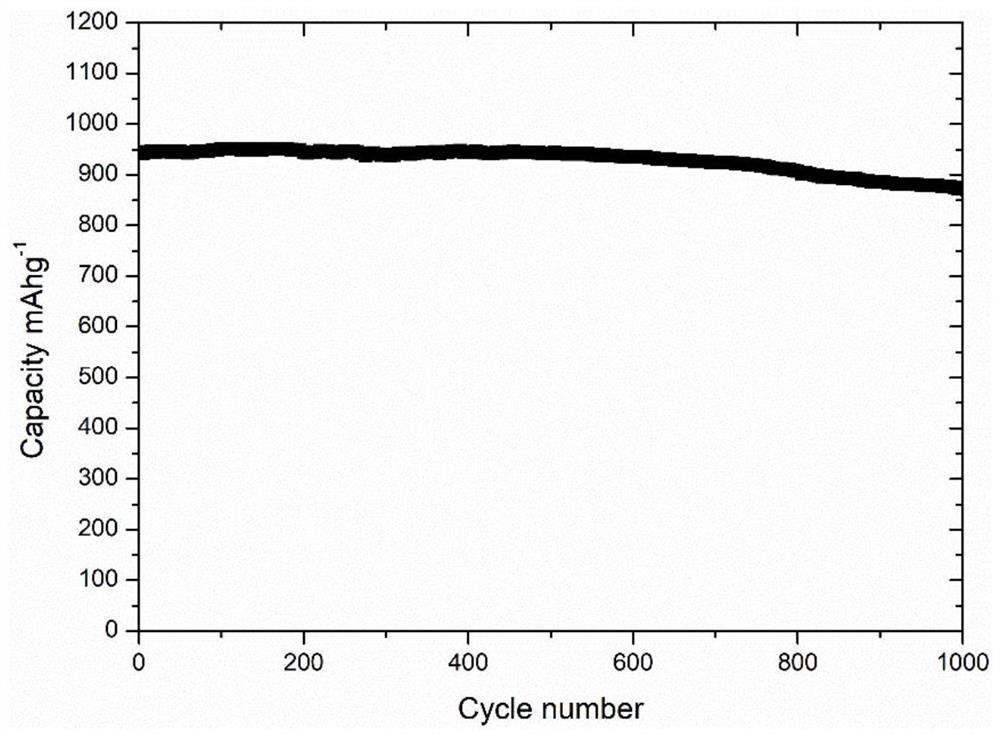

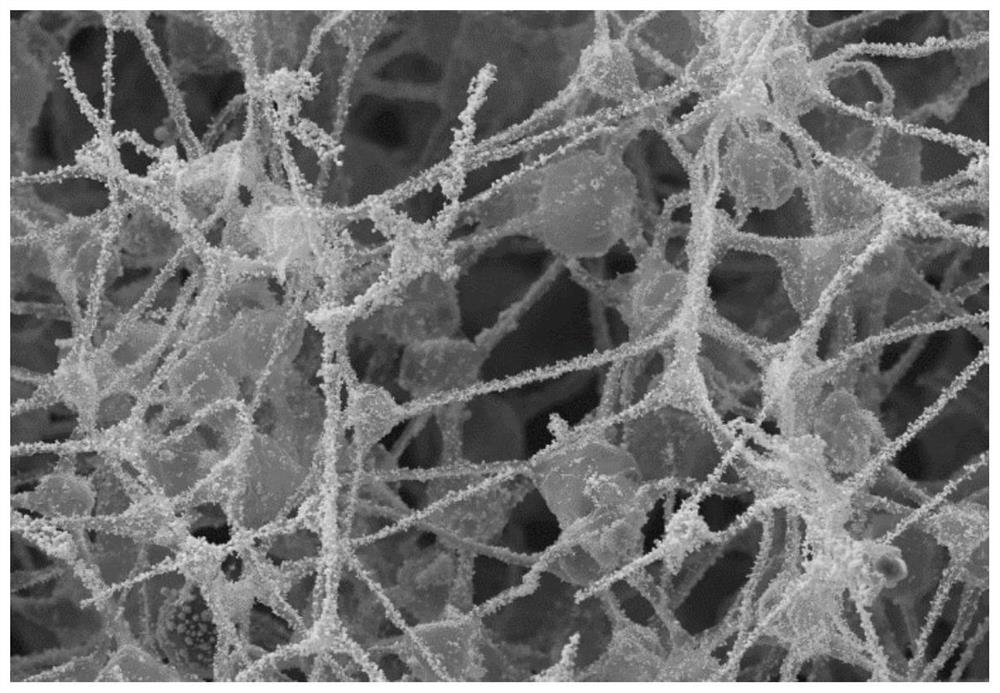

Preparation method and application of MXene-based inorganic particle/PVDF-based polymer composite diaphragm

ActiveCN114865226AImprove performanceInhibit growthMaterial nanotechnologyLi-accumulatorsPolymer scienceSpinning

The invention discloses a preparation method of an MXene-based inorganic particle / PVDF (Polyvinylidene Fluoride)-based polymer composite diaphragm and application of the diaphragm, and relates to a polymer-inorganic composite diaphragm and application. The invention aims to solve the problems of shuttle effect of lithium polysulfide and lithium dendrites. The preparation method comprises the following steps: dissolving a polyvinylidene fluoride-styrene sulfonic acid copolymer in a nitrogen methyl pyrrolidone solution, stirring and adding a certain amount of inorganic matters to obtain a spinning solution; injecting the spinning solution into electrostatic spinning equipment for spinning, and then drying to obtain a polymer composite diaphragm with the thickness of 30-120 microns; an organic-inorganic composite membrane is constructed by utilizing an electrostatic spinning technology, so that the comprehensive performance of the Li-S battery is improved. The space steric hindrance effect of a PVDF-based polymer diaphragm frame and the high-active oxygen vacancy synergistic inhibition shuttle effect of inorganic particles are utilized, and meanwhile, the two-dimensional nanosheet structure of the inorganic particles is utilized to shield large-size pores existing in an electrostatic spinning membrane, so that the mechanical strength of the diaphragm is improved, and the growth of negative electrode lithium dendrites is prevented.

Owner:宁波民光新材料有限公司

A kind of production method of glass fiber SMC yarn

The invention discloses a production method of glass fiber SMC yarn, which comprises the following steps: 1) preparation of an impregnating agent; 2) dosing; 3) melting in a kiln; 4) bushing; 5) coating with the impregnating agent; 6) drawing; 7) drying; 8) roving winding; 9) inspection and storage. According to the method disclosed by the invention, by adopting the complete-performance glass component and the special impregnating agent, the need of the drawing operation is met in the drawing technology while the processability of a later unwinding process is also guaranteed, thus the glass fiber SMC yarn has good acid resistance and water resistance, relatively high strength and good electric properties and mechanical properties.

Owner:JIANGSU ZHONGYA NEW MATERIAL

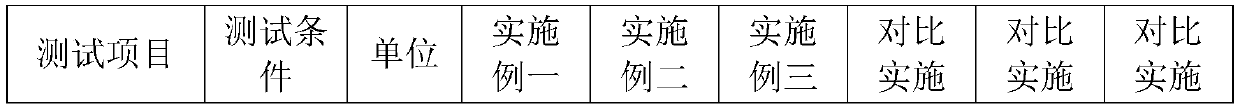

Color-matching conductive polysulfone material and preparation method thereof

The invention discloses a color-matching conductive polysulfone material and a preparation method thereof. The color-matching conductive polysulfone material is composed of the following raw materialsby weight: 43-88.8 parts of polysulfone as a main material, 1-5 parts of nano SiO2 as an auxiliary material, 10-50 parts of nanometer conductive modified TiO2 as an auxiliary material, and 0.2-2 parts of a lubricant as an auxiliary material. The nano conductive modified TiO2 modified PSU material disclosed by the invention has good conductivity, ultrahigh temperature resistance, freely selectablecolors and good warping resistance flatness, and can meet the increasingly developed complex electronic element processability.

Owner:上海普利特伴泰材料科技有限公司 +3

A high-resolution endoscopic optical imaging system with ultra-fine diameter and large depth of field

ActiveCN112255778BImprove image qualityWith ultra-fine diameterTelescopesOphthalmologyImaging quality

The invention relates to an ultra-fine diameter, large depth of field, and high-resolution endoscopic optical imaging system. Chip protection glass, the first lens, the second lens, the third lens and the fourth lens are all spherical lenses and are separated by air. The side is concave; the second lens has positive power, the object side is convex, and the image side is convex; the third lens has negative power, and its object side is convex, and the image side is concave; the fourth lens has positive power , the object side is convex, and the image side is convex; the maximum effective radius of the object side of the first lens is ≤0.5; the lens F number of the endoscopic optical imaging system is 5-8. The present invention has a lens with ultra-fine diameter, large depth of field and high resolution, has a compact structure, is convenient for processing and installation, and has good imaging quality.

Owner:ZHEJIANG LAB +1

Method for manufacturing cable for high-temperature gas cooled reactor

ActiveCN102347110BMeet the processing performanceReduce thicknessInsulating conductors/cablesTemperature controlCopper

The invention discloses a method for manufacturing a cable for a high-temperature gas cooled reactor, and the method the following process flows: material selection-wire drawing-conductor twisting-finished product manufacturing-finished product packaging storage. The method is characterized by comprising annealing-extrusion of an insulating layer-extrusion of an outer sheath, wherein the annealing step means that an annealing silver plating machine is used for plating silver with the thickness of 6-20mu m on a copper monofilament surface; and the extrusion of the insulating layer and the extrusion of the outer sheath mean that screws with a high compression ratio of 3.5:(1-5.0):1 are used, extrusion equipment is provided with a good cooling device, the extrusion processing temperature of the extrusion equipment is controlled between 360 DEG C and 420 DEG C, a pipe-extrusion mould with the high extension ratio is selected as an extrusion mould, and the selected mating extension ratio is 30-50. The cable manufactured by the method provided by the invention has the characteristics of strong ambient temperature adaptability, high conductivity and strong electromagnetic compatibility.

Owner:SICHUAN MINGXING CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com