Vacuum brazing welding piece blank material and preparation method thereof

A technology of brazing and soldering sheet, which is applied in the field of soldering sheet blanks for vacuum brazing and its preparation, can solve problems such as easy occurrence of holes in blanks, increased material consumption, and difficulties in blank production, achieving good application prospects and economic benefits, reducing Component segregation, the effect of satisfying the membrane breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

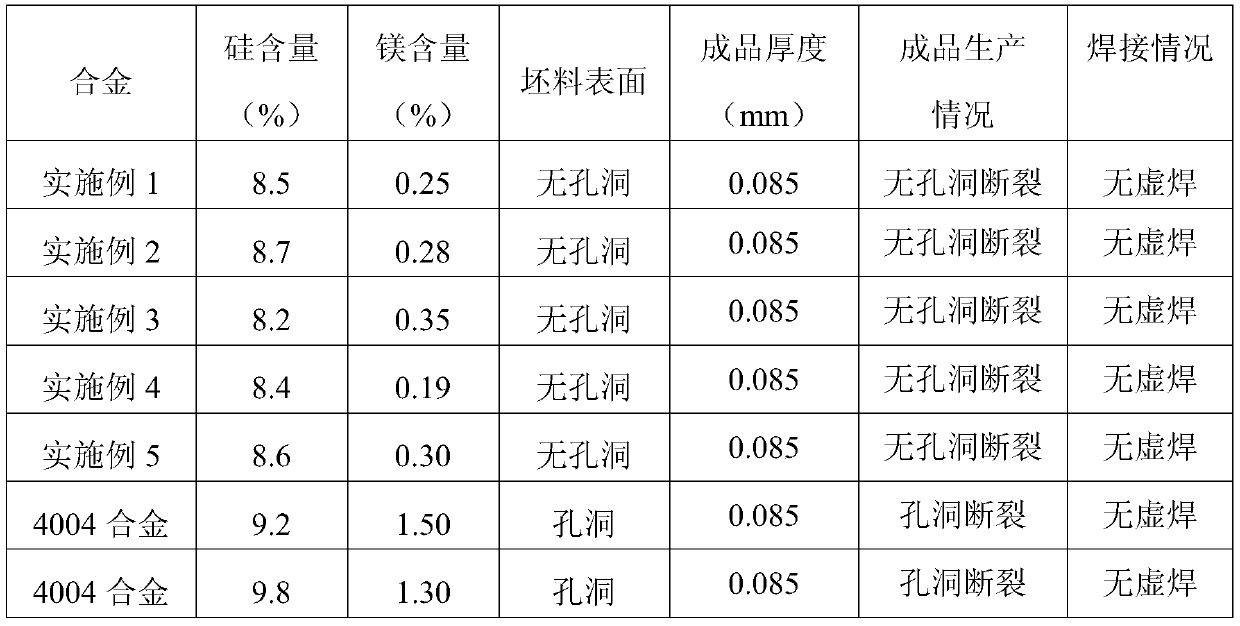

Examples

Embodiment 1

[0022] A method for preparing a welding sheet blank for vacuum brazing, comprising the following steps:

[0023] S1. Raw material preparation: including aluminum ingots, scrap aluminum, aluminum-silicon master alloys and primary magnesium ingots;

[0024] S2. Melting: adding aluminum ingots, waste aluminum and aluminum-silicon master alloy to the melting furnace, igniting and melting;

[0025] S3. Smelting: After the above-mentioned raw materials are completely liquefied into aluminum water, the silicon content is adjusted with the aluminum-silicon intermediate alloy, and then the aluminum water is heated to 720°C and introduced into a static furnace, and an iron cage is used to add primary magnesium ingots in the static furnace , carry out the allocation of magnesium content, after twice component allocation, the silicon content is 8.5%, the magnesium content is 0.25%;

[0026] S4. Casting and rolling. Casting and rolling are carried out at a casting temperature of 640° C. a...

Embodiment 2

[0028] The method described in Example 1 was used to prepare the blank for vacuum brazing. In the S3 step, the aluminum water was heated to 730°C and introduced into the static furnace. After the alloy components were prepared twice, the silicon content was 8.7%, and the magnesium content was 0.28%. ; In step S4, the casting and rolling temperature is 648° C., the casting and rolling speed is 580 mm / min, and the obtained cast and rolling coil has a thickness of 6 mm.

Embodiment 3

[0030] The method described in Example 1 was used to prepare the blank for vacuum brazing. In step S3, the aluminum water was heated to 733°C and introduced into a standing furnace. After the alloy components were prepared twice, the silicon content was 8.2%, and the magnesium content was 0.35%. ; In step S4, the casting and rolling temperature is 645° C., the casting and rolling speed is 620 mm / min, and the obtained cast and rolling coil has a thickness of 6.6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com