Preparation method of anti-puncture high-barrier co-extrusion film

A high-barrier, co-extruded film technology, applied in the field of packaging materials, can solve the problems of low puncture resistance, poor low temperature resistance, poor tensile resistance, etc. Effect of tear strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a puncture-resistant high-barrier co-extrusion film provided by an embodiment of the present invention includes the following steps:

[0048] Step 1: arranging the composite layer 1, the first core layer 2, the second core layer 3 and the heat-sealing layer 4 in sequence;

[0049] Step 2: Blow molding and co-extruding the composite layer 1, the first core layer 2, the second core layer 3 and the heat-sealing layer 4.

[0050] The preferred material of embodiment one of the present invention when preparing co-extruded film is as follows:

[0051] Metallocene polyethylene: melt index 0.5-1.0g / 10min, density 0.91-0.925g / cm 3 ; Metallocene polyethylene elastomer: melt index 0.75-1.25g / 10min, density 0.901-0.906g / cm 3 ;Polyamide resin: density 1.1-1.15g / cm 3; Compatible extrusion: polyethylene grafted maleic anhydride; low density polyethylene: melt index 0.25-1.0g / 10min, density 0.923-0.926g / cm 3 ;Linear low density polyethylene: melt index 1.0-2....

Embodiment 1

[0061] The process parameter description of embodiment one:

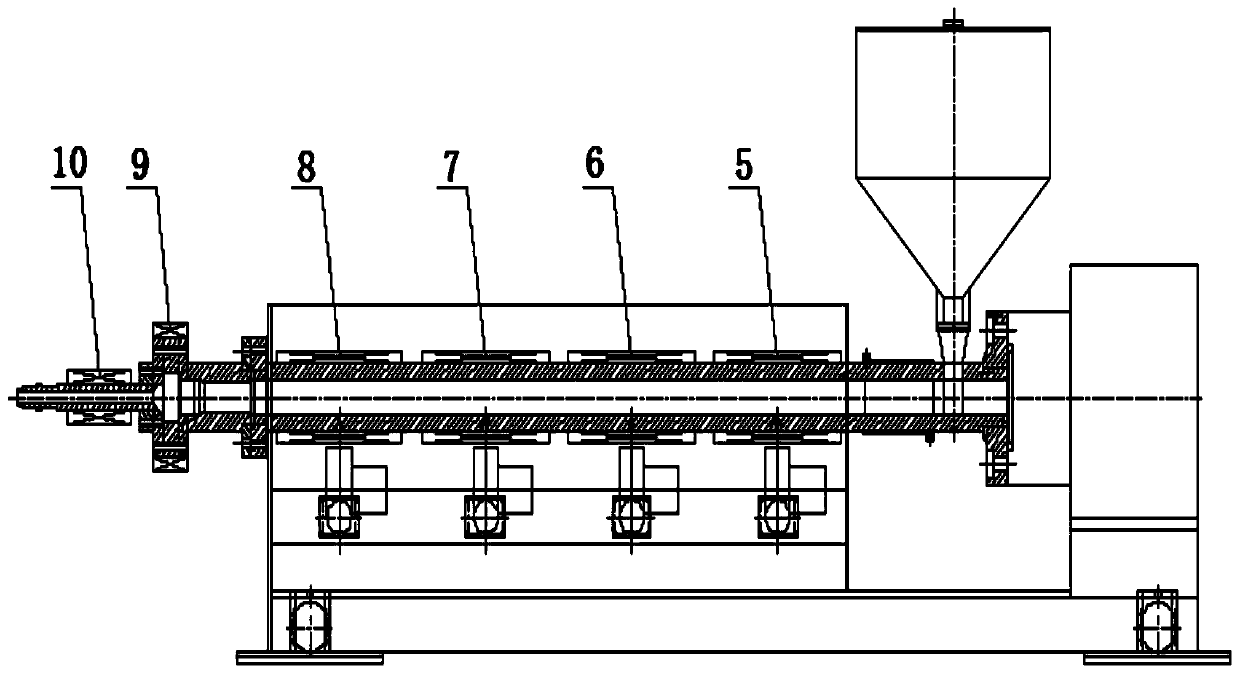

[0062] Please refer to Table 1 for the temperature setting range of the interlayer screw, such as figure 2 As shown, it mainly includes a first heating zone 5 , a second heating zone 6 , a third heating zone 7 , a fourth heating zone 8 , a fifth heating zone 9 , and a sixth heating zone 10 .

[0063] Table 1

[0064] between layers Zone 1 temperature ℃ Second zone temperature ℃ Three zone temperature ℃ Four zone temperature ℃ Five zone temperature ℃ Six zone temperature ℃ composite layer 165-170 170-180 180-200 180-200 180-185 180-185 first core layer 180-185 180-185 190-200 200-210 190-200 180-185 second core layer 195-200 220-230 230-240 230-240 200-210 200-210 heat seal layer 165-170 170-180 180-200 180-200 180-185 180-185

[0065] Please refer to Table 2 Blow Molding Machine Die Temperature Settings:

[0066] Table 2

[0067] Zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com