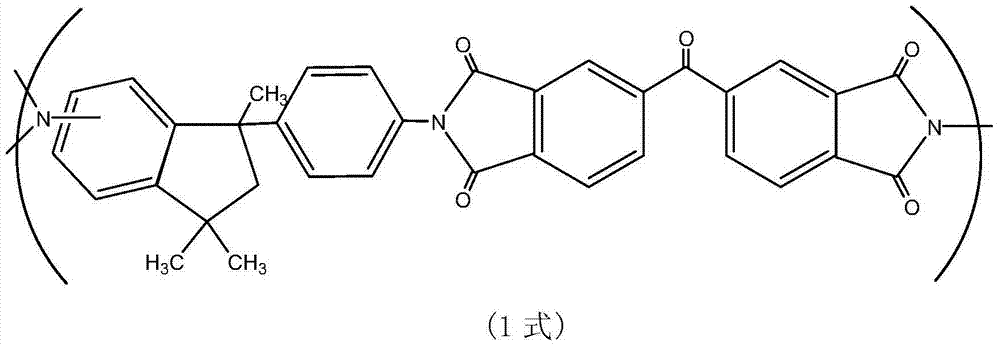

Thermosetting resin composition, b graded resin film, metal foil, copper-clad board and multi-layer lamination substrate

A resin composition and thermosetting technology, applied in the fields of thermosetting resin composition, B-stage resin film, metal foil, copper clad laminate and multilayer laminate substrate, can solve the problem of low resin fluidity, lower reliability than rigid materials, Tg lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

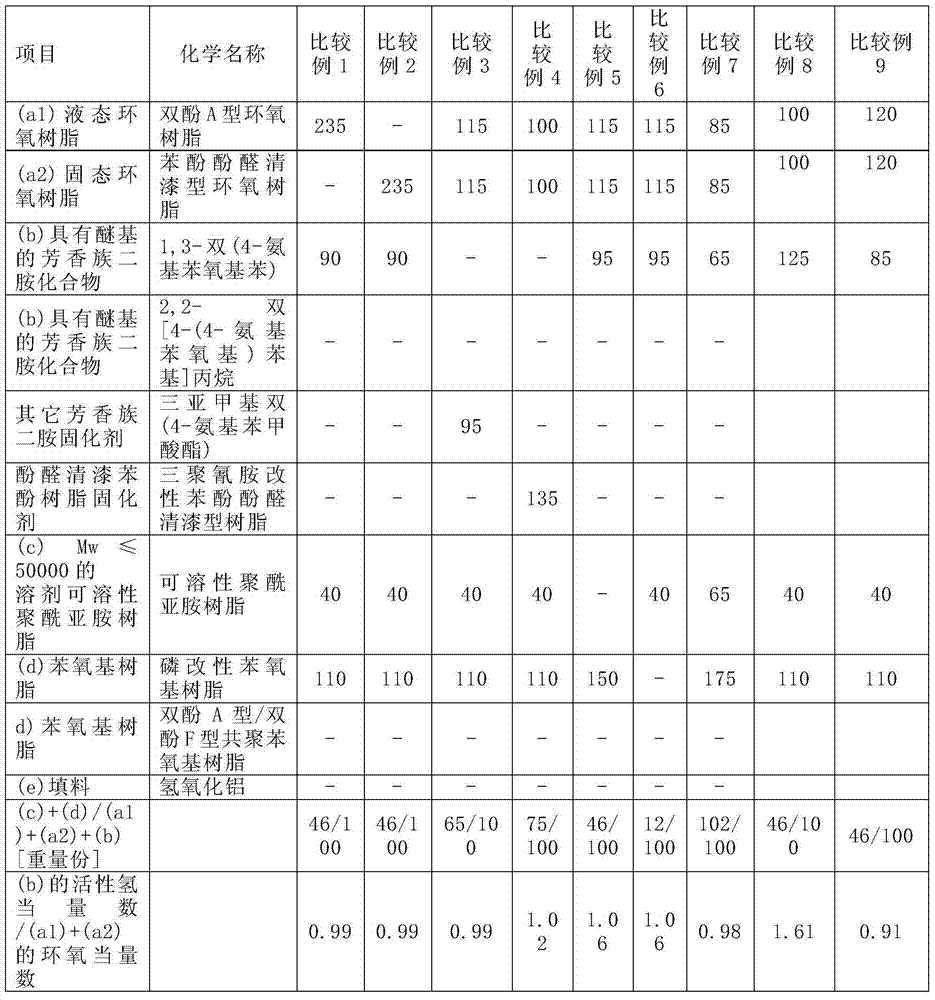

[0070] Prepared by 115 parts by weight of bisphenol A type epoxy resin Epiclon 850-S (manufactured by DIC Corporation, epoxy equivalent 188), 115 parts by weight of phenol novolak type epoxy resin Epiclon N-770 (manufactured by DIC Corporation, Epoxy equivalent 188), 95 parts by weight of 1,3-bis(4-aminophenoxybenzene) TPE-R (manufactured by Xihua Co., Ltd.), 200 parts by weight of soluble polyimide resin Q -VR-X0163 (manufactured by PI Technology Research Institute Co., Ltd., resin solid content 20% by weight), 367 parts by weight of phenoxy resin FENOTO-ERF-001M30 (manufactured by Nippon Steel Chemical Co., Ltd., resin solid content 30% by weight) , 25 parts by weight of HCA (manufactured by Sanko Co., Ltd.) to prepare a resin varnish with a resin solid content of 40% by weight.

Embodiment 2

[0072] Prepared by 105 parts by weight of bisphenol A type epoxy resin Epiclon 850-S (manufactured by DIC Corporation, epoxy equivalent 188), 105 parts by weight of phenol novolak type epoxy resin Epiclon N-770 (manufactured by DIC Corporation, Epoxy equivalent 188), 115 parts by weight of 2,2-bis[4-(4-aminophenoxy group) phenyl] propane BAPP (manufactured by Xihua Co., Ltd.), 200 parts by weight of soluble polyimide resin Q -VR-X0163 (manufactured by PI Technology Research Institute Co., Ltd., resin solid content 20% by weight), 367 parts by weight of phenoxy resin FENOTO-ERF-001M30 (manufactured by Nippon Steel Chemical Co., Ltd., resin solid content 30% by weight) , 25 parts by weight of HCA (manufactured by Sanko Co., Ltd.) to prepare a resin varnish with a resin solid content of 40% by weight.

Embodiment 3

[0074] Prepared by 115 parts by weight of bisphenol A type epoxy resin Epiclon 850-S (manufactured by DIC Corporation, epoxy equivalent 188), 115 parts by weight of phenol novolak type epoxy resin Epiclon N-770 (manufactured by DIC Corporation, Epoxy equivalent 188), 95 parts by weight of 1,3-bis(4-aminophenoxybenzene) TPE-R (manufactured by Xihua Co., Ltd.), 200 parts by weight of soluble polyimide resin Q-VR-X0163 (manufactured by PI Technology Research Institute Co., Ltd., resin solid content 20% by weight), 110 parts by weight of phenoxy resin Fenotto YP-70 (manufactured by Nippon Steel Chemical Co., Ltd.), 25 parts by weight of HCA (manufactured by Sanko Co., Ltd. ) to make a resin varnish with a resin solid content of 40% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com