Preparation method and application of MXene-based inorganic particle/PVDF-based polymer composite diaphragm

A technology of inorganic particles and composite separators, applied in nanotechnology for materials and surface science, non-aqueous electrolyte batteries, structural parts, etc., can solve problems such as shuttle effect, achieve inhibited growth, uniform and continuous film formation, and Processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

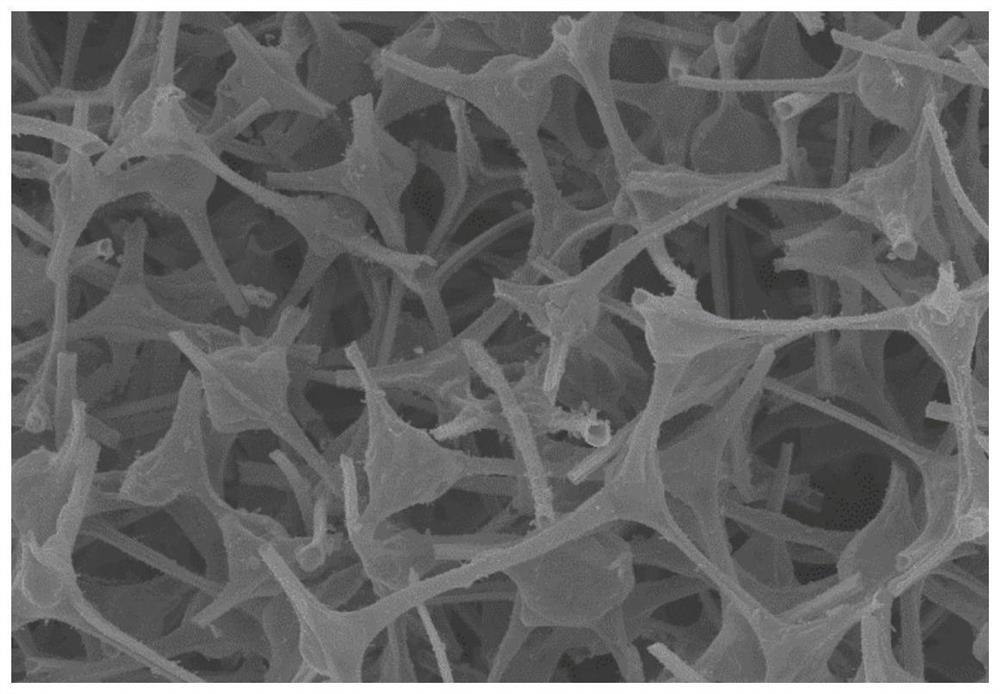

[0030] Embodiment 1: The preparation of the MXene-based inorganic particle / PVDF-based polymer composite membrane of this embodiment is carried out according to the following steps:

[0031] Step 1: Preparation of spinning solution:

[0032] Dissolving the polyvinylidene fluoride-styrene sulfonic acid copolymer in the nitrogen methyl pyrrolidone solution, stirring for a period of time at a certain temperature, adding a certain amount of inorganic substances to obtain a spinning solution;

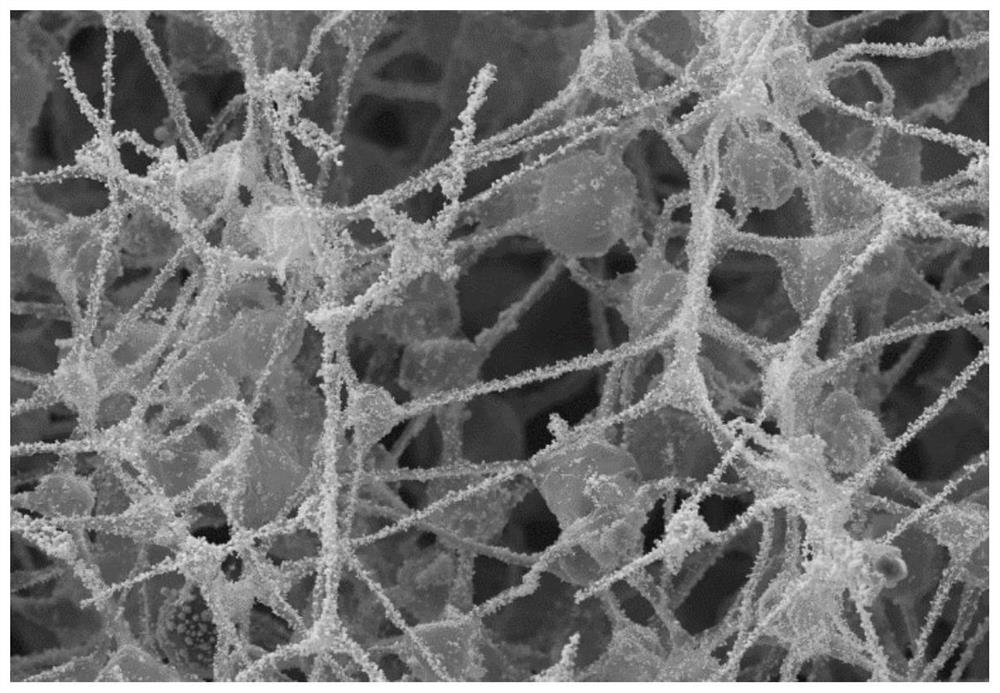

[0033] The inorganic substance is Ti n O 2n-1 -Ti 3 C 2 , Ti n O 2n-1 -Ti 3 C 2 The preparation method is as follows: the Ti 3 C 2 MXene was heated at 200-800 °C for 5-30 min, and then naturally cooled to room temperature to obtain surface-grown Ti n O 2n-1 Ti 3 C 2 Mxene, i.e. Ti n O 2n-1 -Ti 3 C 2 ;

[0034] The polyvinylidene fluoride-styrene sulfonic acid copolymer is polyvinylidene fluoride grafted with polystyrene sulfonic acid, and the graft ratio of styrene sulfoni...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inorganic substance in step 1 is Ti n O 2n-1 -Ti 3 C 2 , Ti n O 2n-1 -Ti 3 C 2 The preparation method is as follows: the Ti 3 C 2 MXene was heated at 200 °C for 30 min, and then naturally cooled to room temperature to obtain surface-grown Ti n O 2n-1 Ti 3 C 2 Mxene, i.e. Ti n O 2n-1 -Ti 3 C 2 .

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the polyvinylidene fluoride-styrene sulfonic acid copolymer in step 1 is polyvinylidene fluoride grafted with polystyrene sulfonic acid, The graft ratio of styrene sulfonic acid was 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com