Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Meet concentration requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

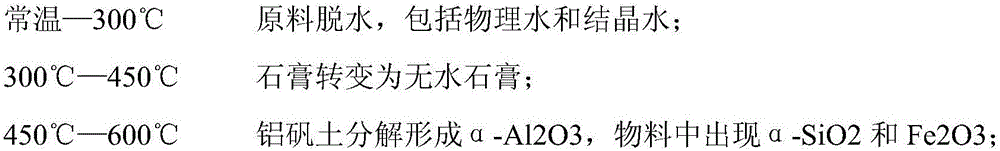

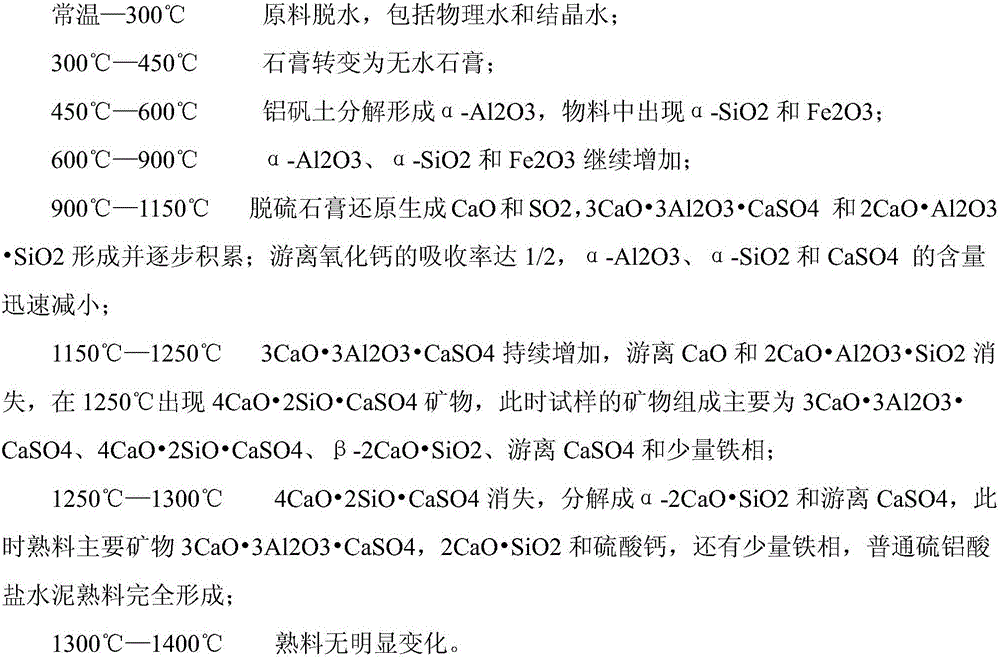

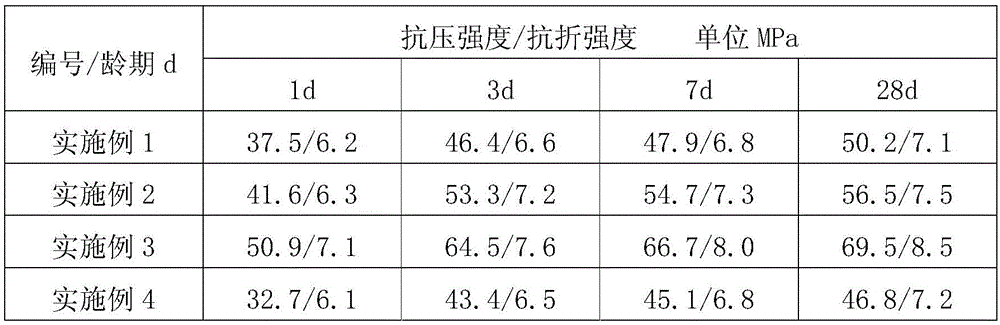

Method for preparing high-strength sulphoaluminate cement and coproducing sulfuric acid

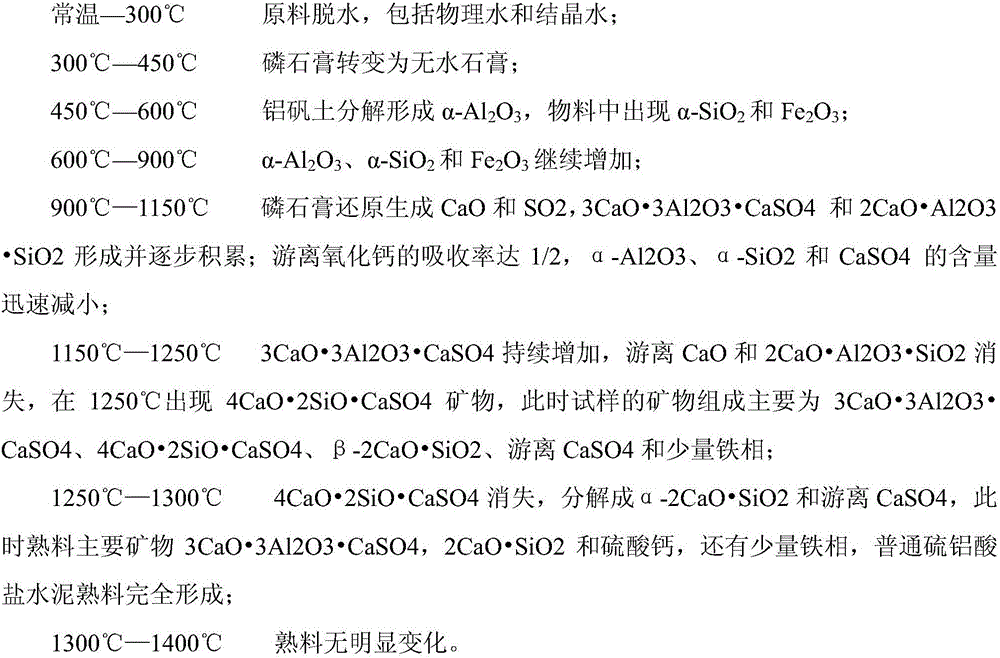

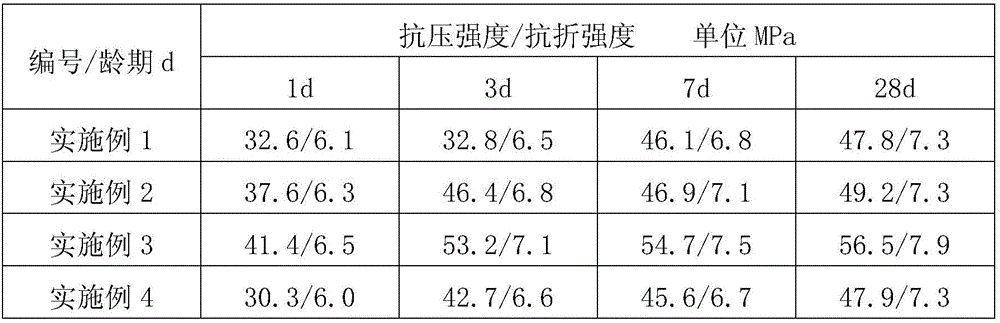

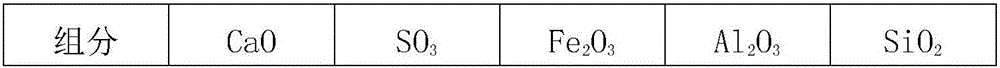

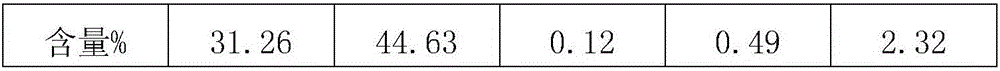

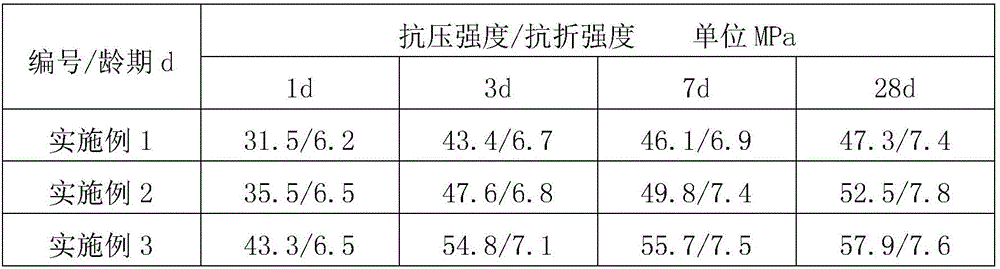

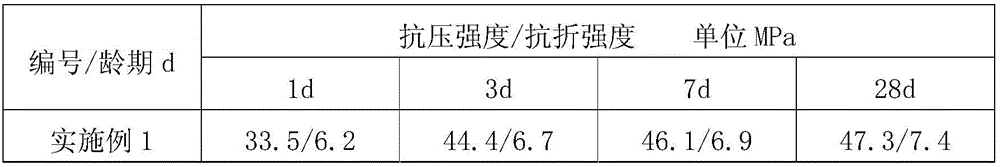

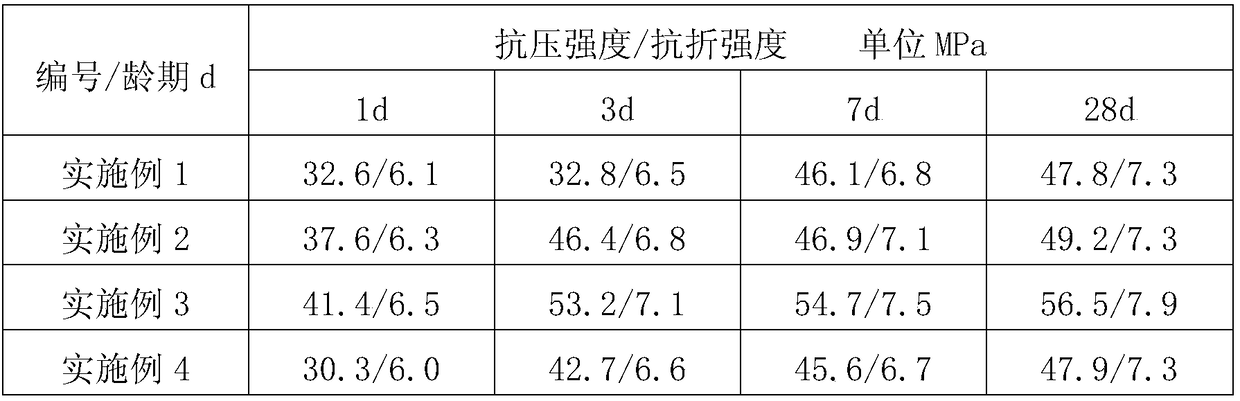

The invention relates to a method for preparing high-strength sulphoaluminate cement and co-producing sulfuric acid. The method comprises the following steps of adopting phosphogypsum for completely replacing limestone and natural gypsum, milling and homogenizing the phosphogypsum, bauxite, steel scoria, silica and pulverized anthracite, and then calcinating the milled and homogenized raw materials at a temperature of 1250-1300 DEG C. The method is capable of greatly improving the phosphogypsum utilization ratio, and high-concentration sulfur dioxide tail gas can be adsorbed to prepare sulfuric acid. The prepared sulphoaluminate cement clinker is high in hardening rate, high in early-stage strength, and stable in later-stage strength increase; performance tests indicate that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the rapid-hardening sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

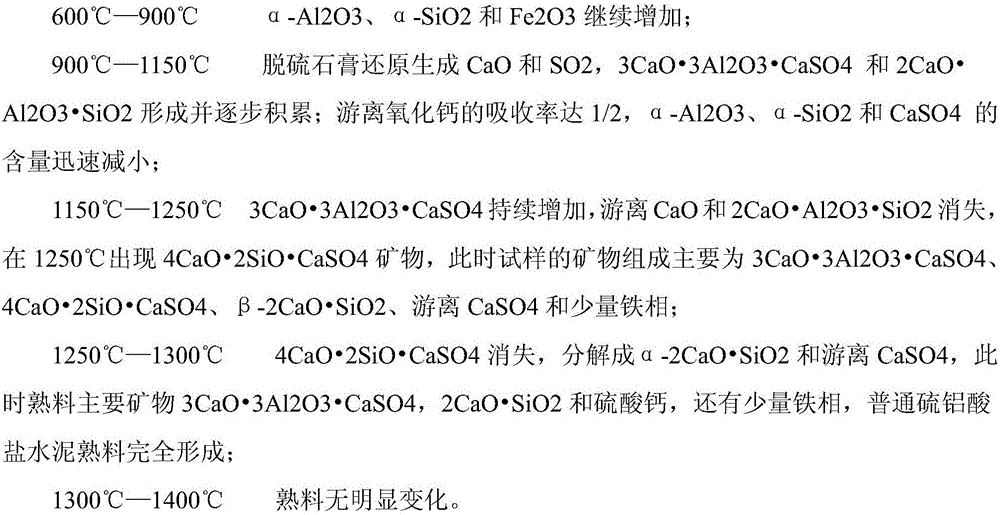

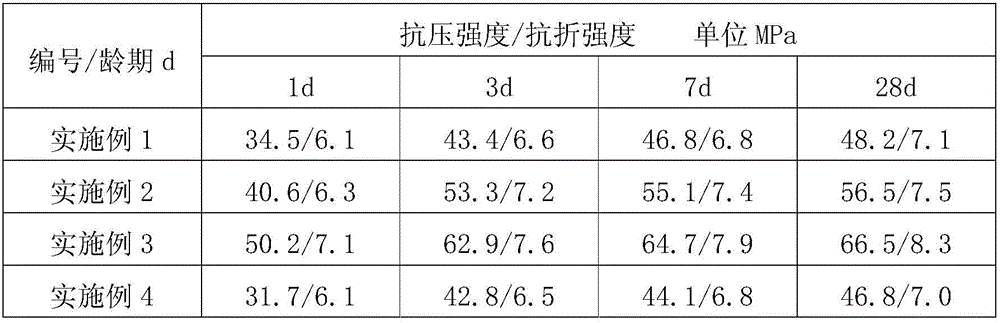

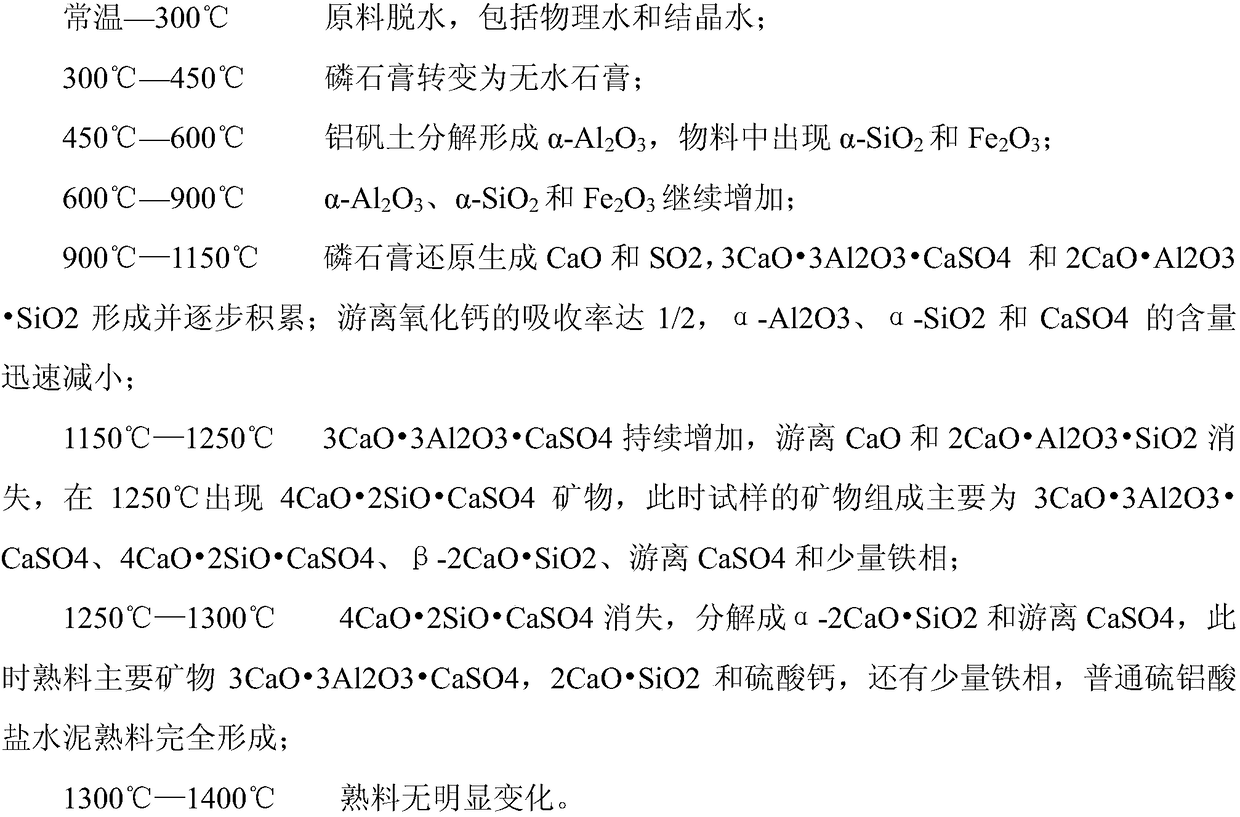

Method for preparing sulphoaluminate cement by calcining ardealite by steps

ActiveCN106630701AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationPolymer science

The invention relates to a method for preparing sulphoaluminate cement by calcining ardealite by steps. Limestone and natural gypsum are completely replaced by ardealite, the ardealite is homogenized with bauxite, solid steel scrap and anthracite duff and then a method for calcining by steps is adopted for preparing the sulphoaluminate cement. According to the invention, the use ratio of the ardealite can be greatly increased and the high-concentration sulfur dioxide tail gas can be absorbed for preparing sulfuric acid. The sulphoaluminate cement prepared according to the invention is high in clinker hardening speed, high in early strength and stable in later strength. A performance test proves that the mechanical strength of the sulphoaluminate cement prepared according to the method provided by the invention meets the sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

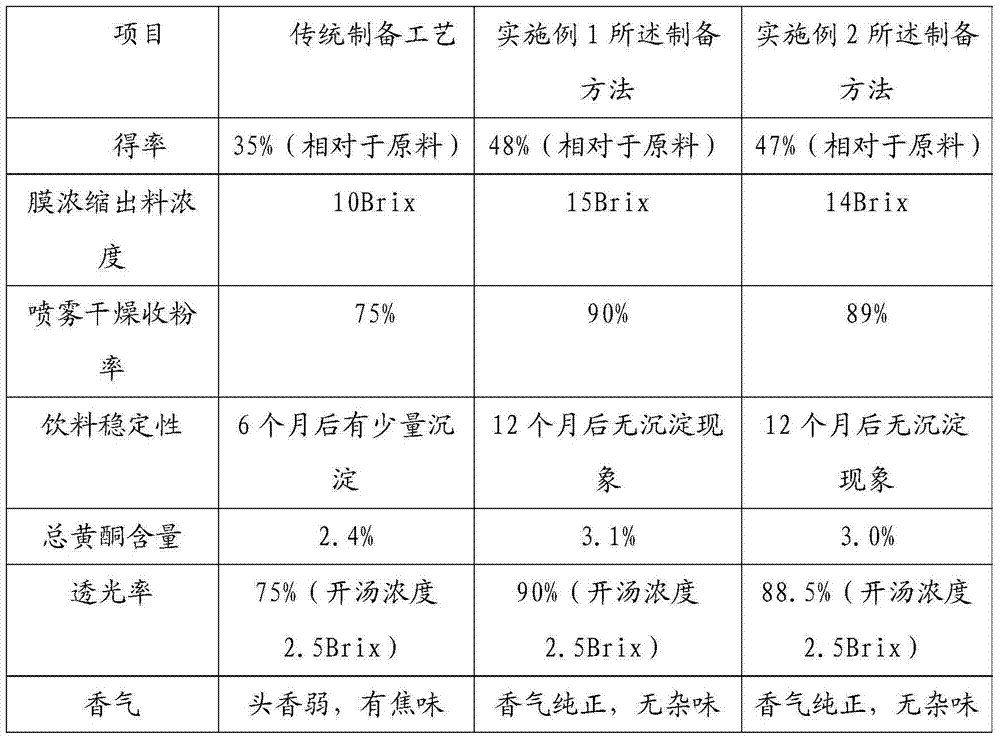

Preparation method of chrysanthemum morifolium extract

The invention discloses a preparation method of chrysanthemum morifolium extract. The preparation method comprises the following steps of 1, crushing: crushing chrysanthemum morifolium as a raw material, 2, extraction: putting the crushed raw material into an extraction tank, carrying out extraction in twice, and treating the chrysanthemum morifolium by combined cellulase and pectase, 3, coarse filtration: carrying out filtration by a vibrating screen to remove impurities, 4, centrifugation: carrying out centrifugation by a disk centrifuge, 5, membrane condensation: carrying out condensation by a polyamide film, 6, sterilization: carrying out superhigh-temperature instantaneous sterilization, 7, blending: adding the condensed juice subjected to sterilization into a blending tank and adding maltodextrin into the condensed juice, and 8, spray drying: carrying out spray drying to obtain chrysanthemum morifolium extract. The chrysanthemum morifolium extract obtained by the preparation method has the characteristics of high total flavone content, high extraction ratio and good clarity. The preparation method can obviously improve adhesion to the tower in spray drying, and has the characteristics of simple operation, low price and no toxicity.

Owner:SHENBAO INDAL CORP SHENZHEN

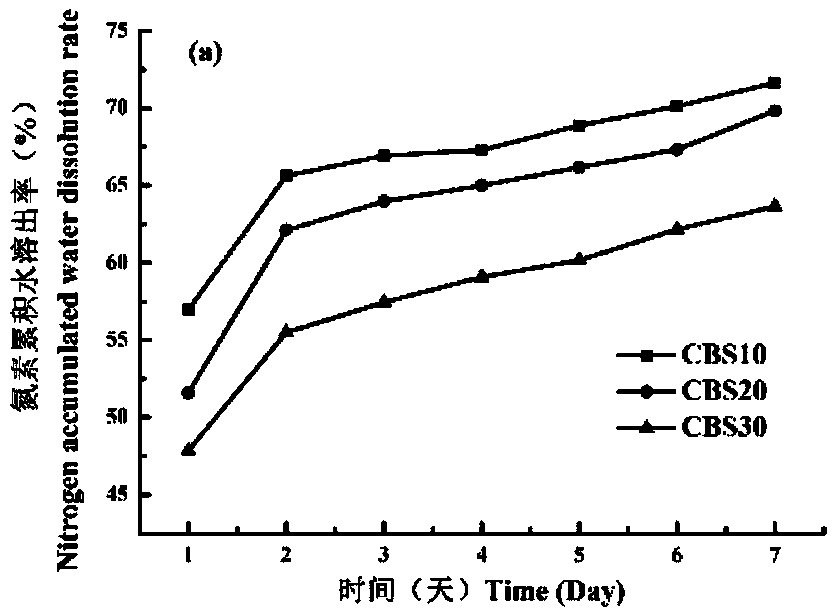

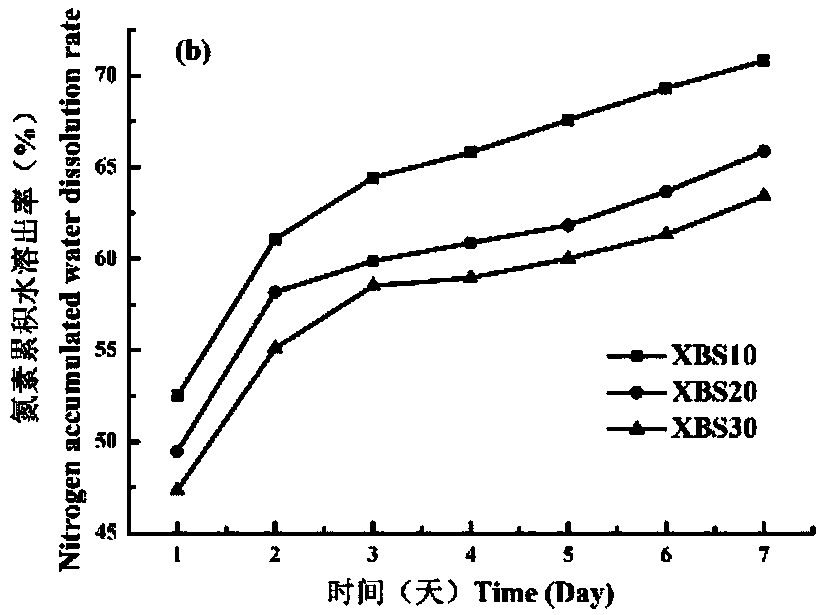

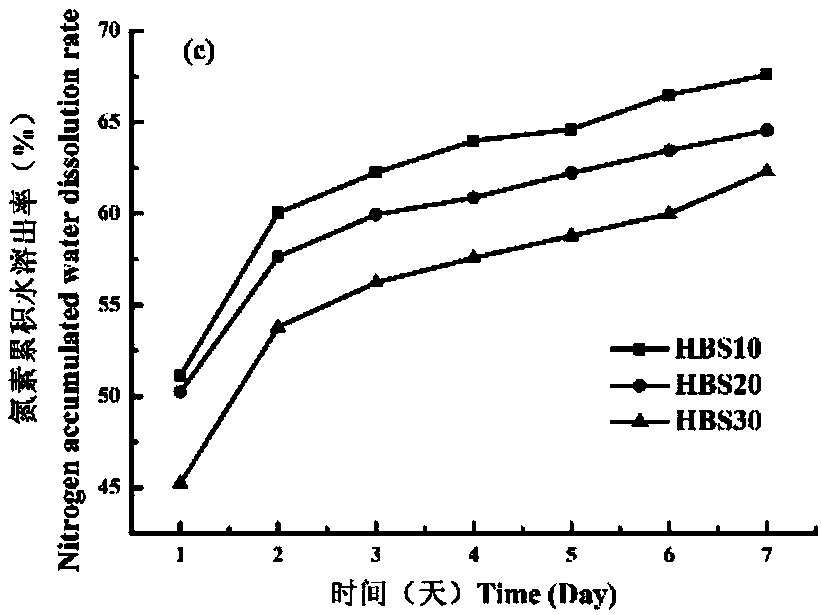

Charcoal-base microbial compound fertilizer and preparation method thereof

InactiveCN107759322AThe process steps are simpleIncrease contentSuperphosphatesCarbon preparation/purificationChemistryNitrogen fertilizer

The invention belongs to the technical field of compound fertilizers. The charcoal-base microbial compound fertilizer is prepared from a microbial compound fertilizer, a coating agent, charcoal and zeolite in a proportion, wherein the microbial compound fertilizer contains a nitrogenous fertilizer, a phosphorus fertilizer, a potassium fertilizer and a nitrogen-fixing microorganism; and the coatingagent contains attapulgite and a polyvinyl alcohol water solution. The invention further discloses a preparation method of the charcoal-base microbial compound fertilizer. The preparation method comprises the steps of putting the microbial compound fertilizer into a coating machine, adding the coating agent, the charcoal and the zeolite, stirring, and drying, so as to obtain the charcoal-base microbial compound fertilizer. The content of the nitrogenous fertilizer, the phosphorus fertilizer, the potassium fertilizer and the nitrogen-fixing microorganism in the charcoal-base microbial compoundfertilizer is relatively high, so that the charcoal-base microbial compound fertilizer has potential application prospects in the regions which are suffered from salinization and are lack of phosphorus; the charcoal-base microbial compound fertilizer contains rich organic elements such as carbon and nitrogen, and the total nutrition content reaches the requirements on the concentration of the fertilizer in the national standards of compound fertilizers; the charcoal-base microbial compound fertilizer has certain slow release effect to nitrogen; and the preparation method is simple in processstep, and existing equipment is easily utilized for production.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

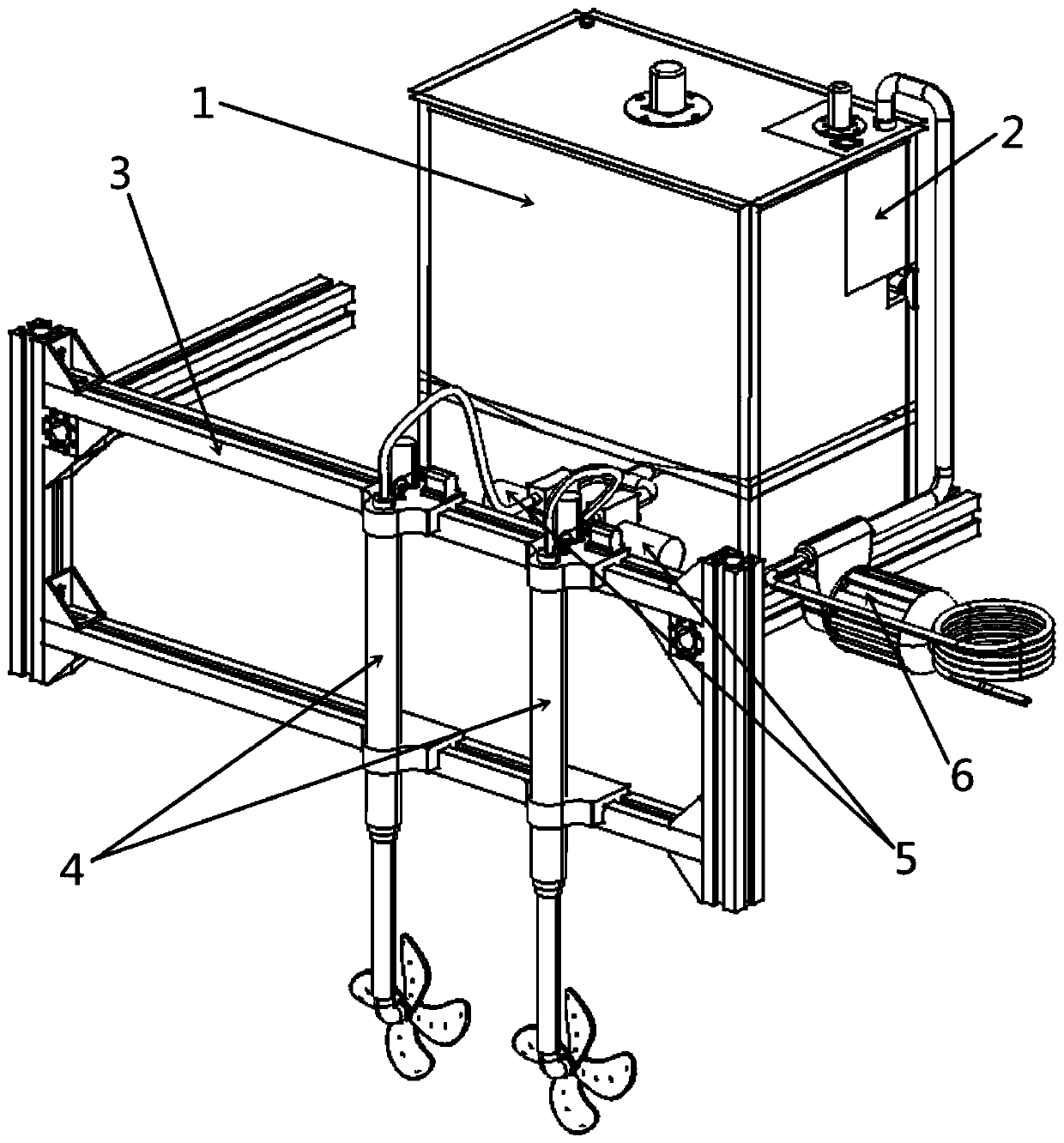

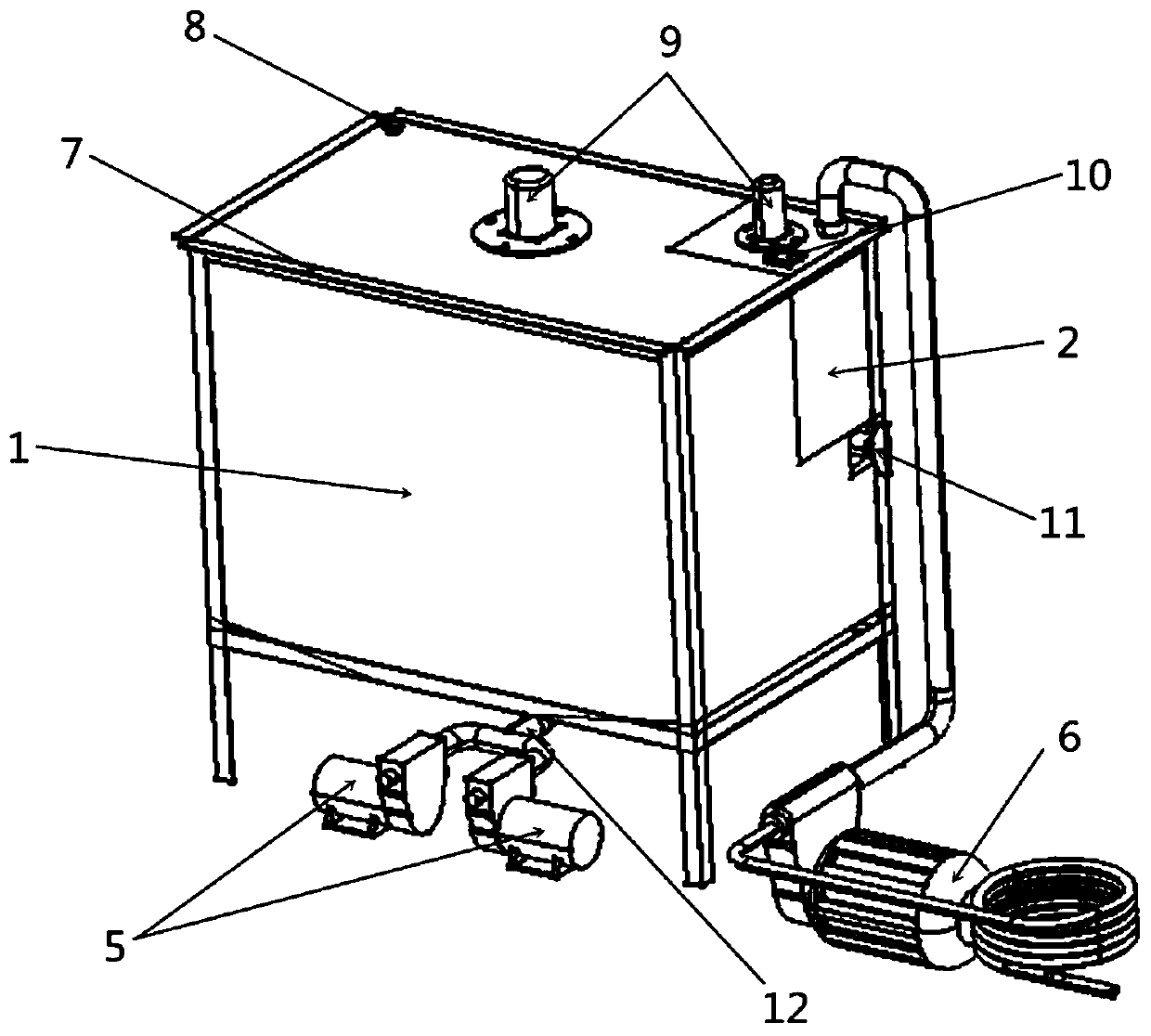

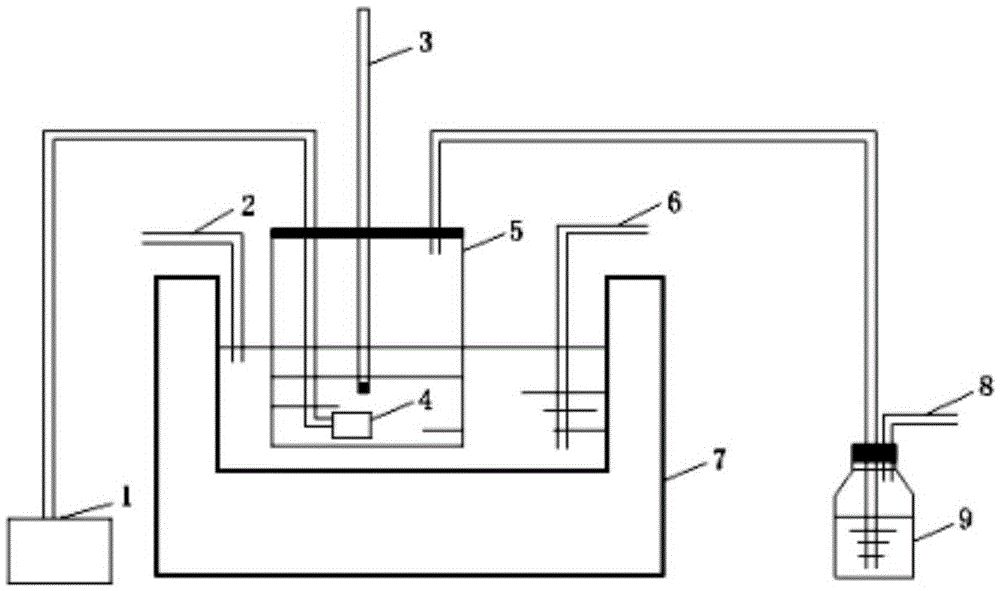

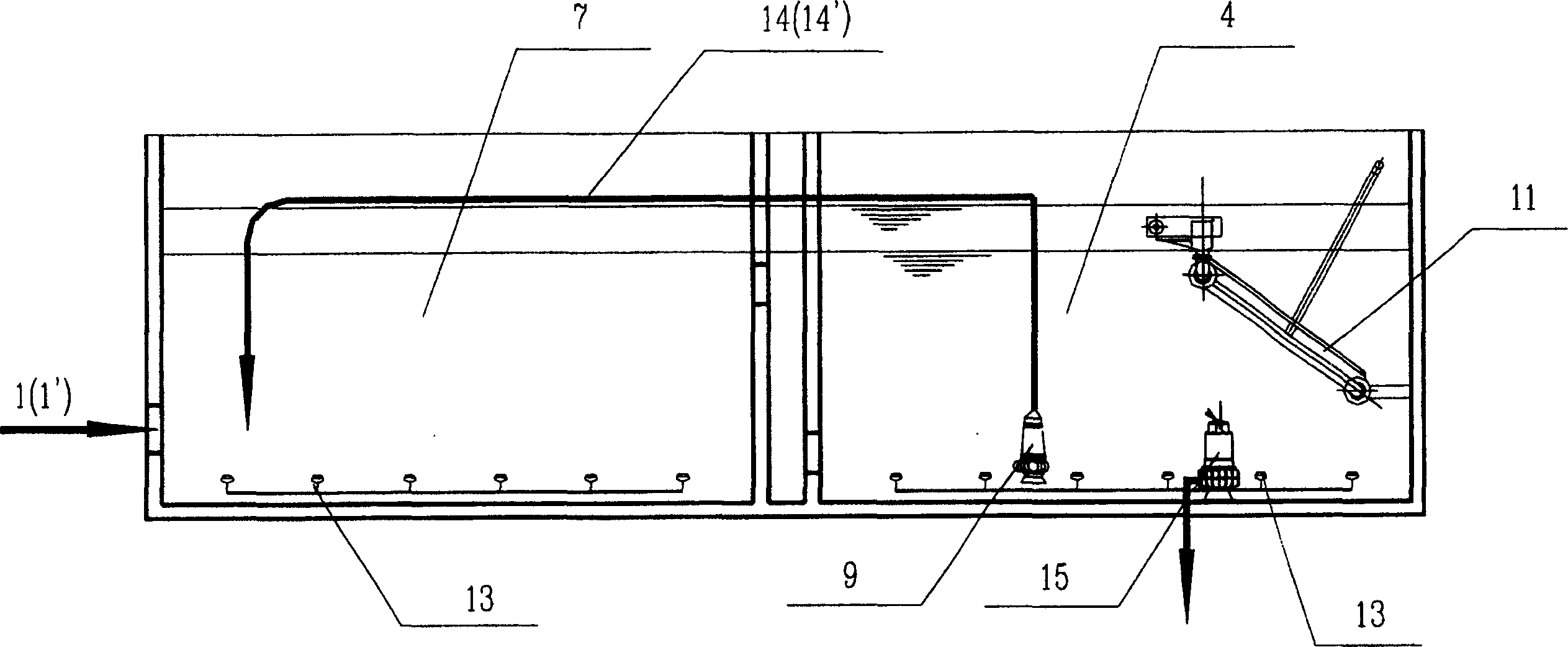

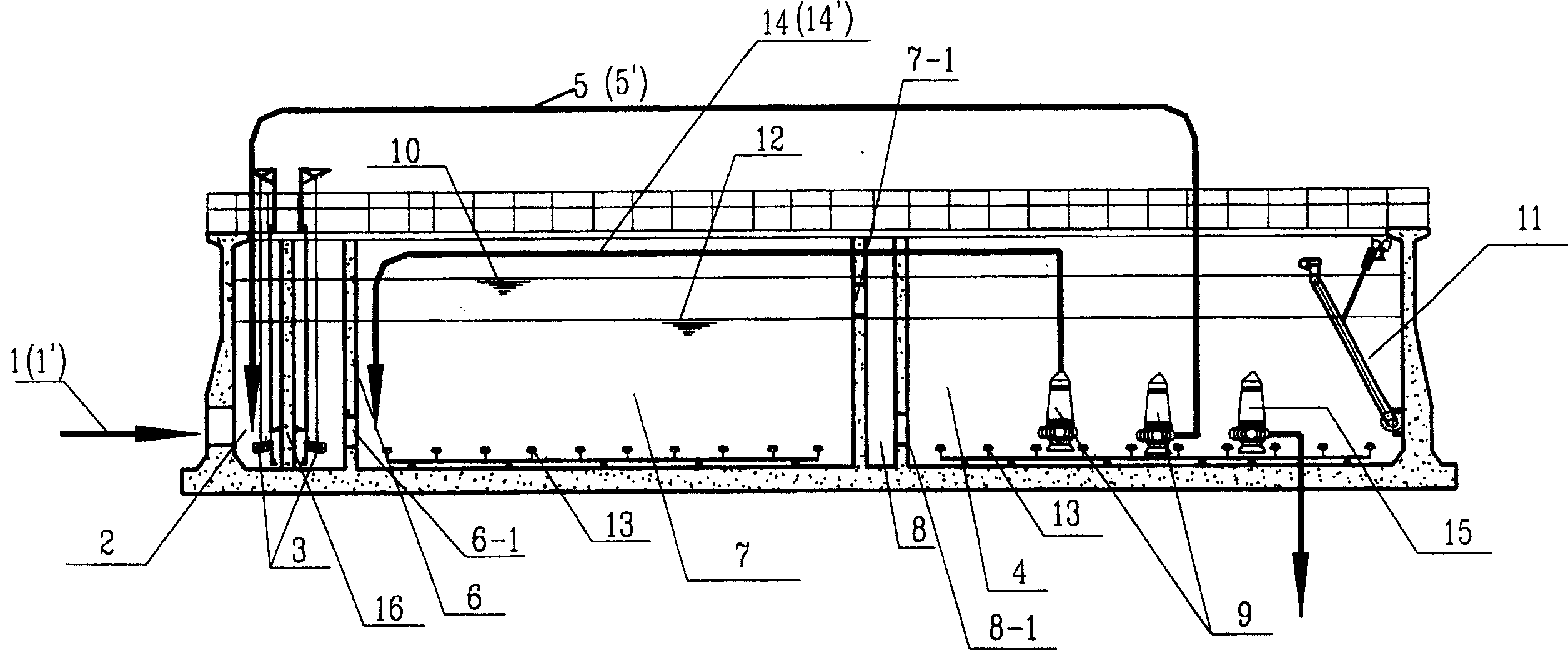

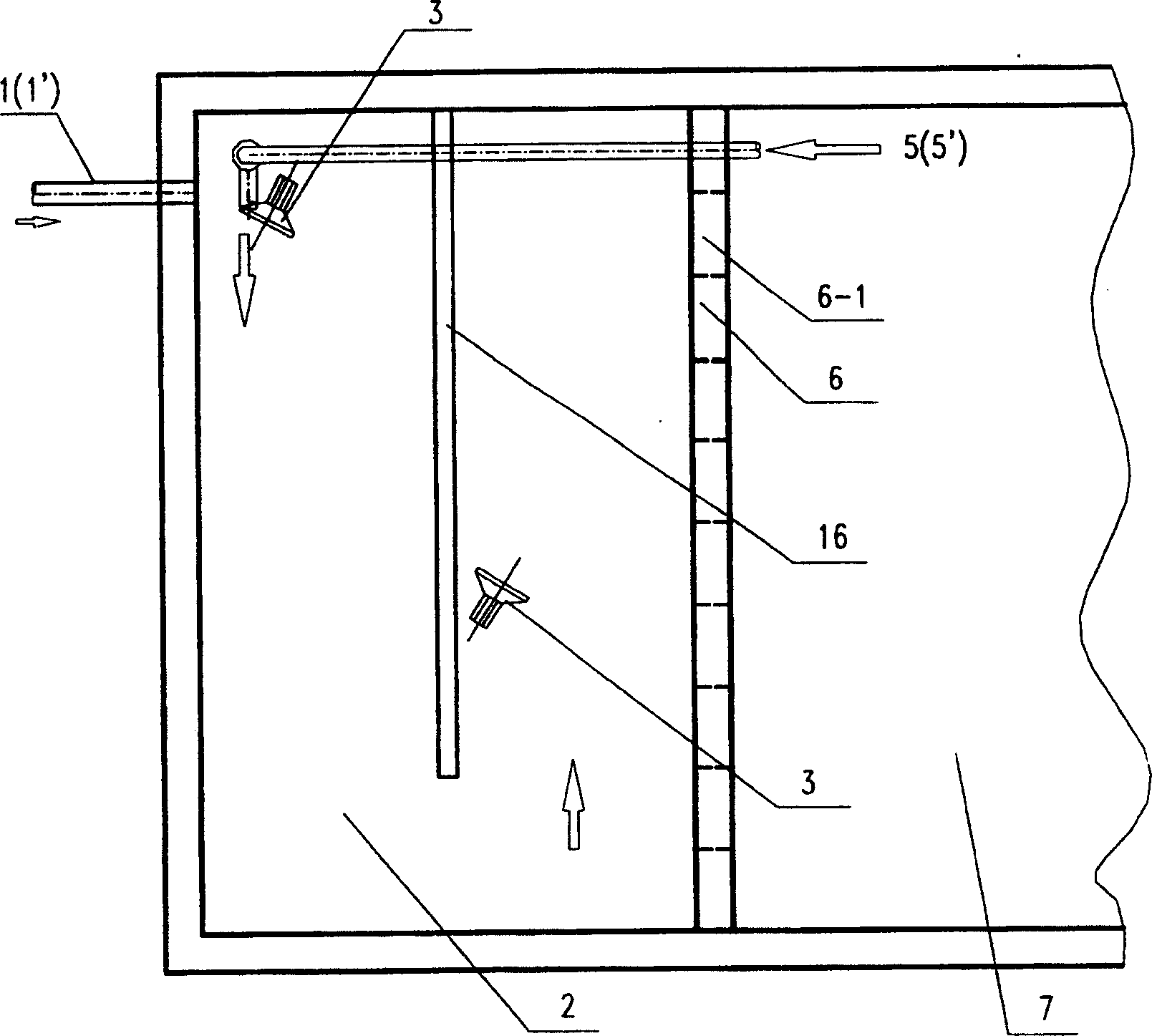

Automatic particle spreading device suitable for towing basin PIV system

ActiveCN110849579AExpand the mixing rangeGood effectTransportation and packagingHydrodynamic testingEnvironmental geologyMarine engineering

The invention relates to an automatic particle spreading device suitable for a towing basin PIV system, and belongs to the field of experimental devices. The automatic particle spreading device suitable for the towing basin PIV system mainly includes a compound particle agitating tank, particle delivery telescopic pipelines, a pressure pump group and a support frame; two particle delivery telescopic pipelines are installed on the support frame and can be moved horizontally, and are connected to the water outlet of the particle agitating tank through two drainage pressure pumps; the pool wateris pumped into the compound particle agitating tank from a water inlet through a pumping pressure pump; after adding an appropriate amount of tracer particles and evenly agitating twice, the pool water is sent to hollow blades at the lower part through the particle delivery telescopic pipelines; and the movement of a trailer causes the hollow blades to rotate and uniformly discharge the tracer particles, so that the discharge position and concentration of the particles can be controlled according to specific test requirements.

Owner:HARBIN ENG UNIV

Phosphogypsum sulphoaluminate cement sulfuric acid coproduction method

ActiveCN106431031AIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a phosphogypsum sulphoaluminate cement sulfuric acid coproduction method; wherein, phosphogypsum replacing completely limestone and natural gypsum, after being ground and homogenized with bauxite and anthracite culm, at 1250-1300 DEG C, calcinating and resulting in the sulphoaluminate cement. The exploitation rate of phosphogypsum in the method is increased to a large extent; high concentration of sulfur dioxide tail gas through absorption is prepared into sulfuric acid. The hardening speed of sulphoaluminate cement clinker is quick, the intensity of sulphoaluminate cement is high during the former and later phase, performance test shows that the mechanical strength of the sulphoaluminate cement prepared by the method accords with the standard of sulphoaluminate cement.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Combined production method for preparing sulphoaluminate cement and sulfuric acid from flue gas desulfurization gypsum

ActiveCN106365476AIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationCalcination

The invention relates to a combined production method for preparing sulphoaluminate cement and sulfuric acid from flue gas desulfurization gypsum. According to the method, flue gas desulfurization gypsum which replaces limestone and natural gypsum completely is mixed with bauxite, silica and anthracite, and the sulphoaluminate cement is obtained after calcinations. The method can improve the utilization rate of flue gas desulfurization gypsum by a large margin, and the tail gas containing sulfur dioxide with a higher concentration can be absorbed to prepare sulfuric acid; the prepared sulphoaluminate cement clinker is fast in rate of hardening, high in early strength and further promotes the stability of later strength; through the performance tests, it is indicated that the mechanical strength of the sulphoaluminate cement prepared by the method meets the standard of rapid hardening sulphoaluminate cement.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

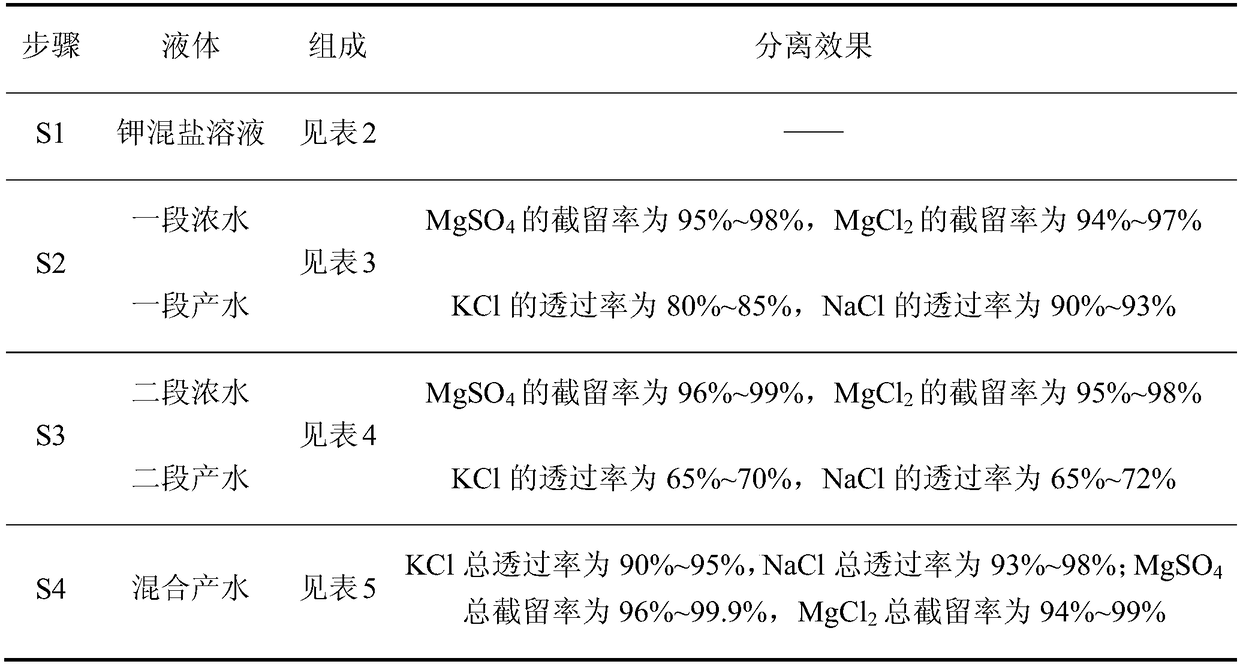

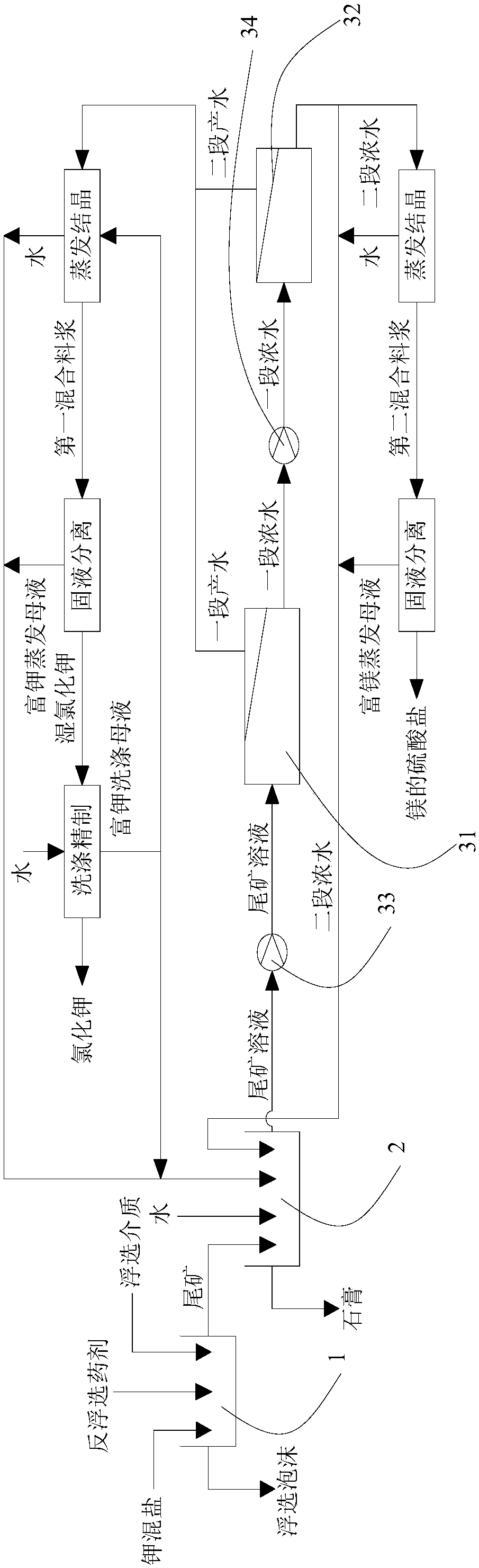

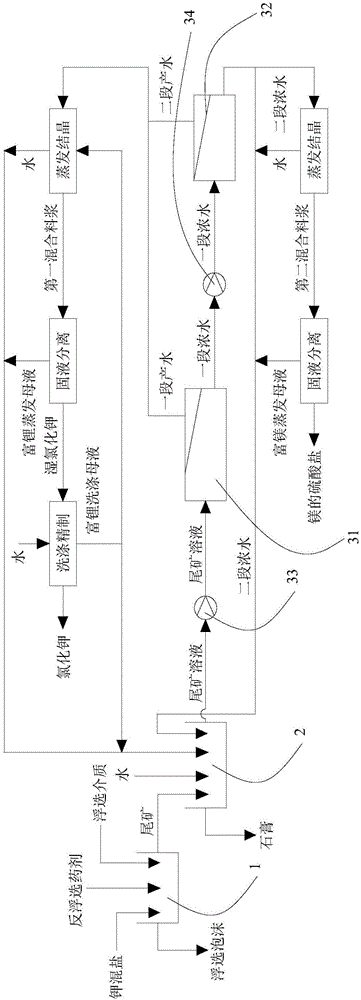

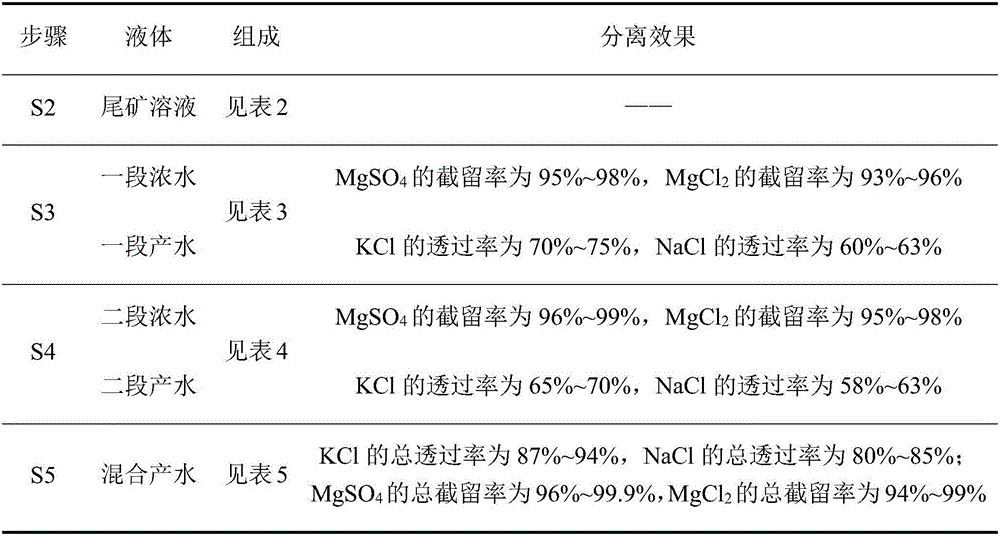

A kind of method utilizing potassium mixed salt to prepare potassium chloride

ActiveCN106517251BHigh purityLarge particlesAlkali metal chloridesAlkali metal halide purificationChloride potassiumChemistry

The invention discloses a method for preparing potassium chloride from potassium mixed salt. The method comprises the steps that the potassium mixed salt is dissolved in water, solid-liquid separation is carried out, and a potassium mixed salt solution is obtained; a first-section nanofiltration step is carried out, wherein a nanofiltration membrane system is adopted for carrying out first-section nanofiltration treatment on the potassium mixed salt solution, first-section concentrated water and first-section produced water are obtained, the nanofiltration system comprises a first nanofiltration membrane assembly, a first concentrated water box and a first produced water box, and the first concentrated water box and the first produced water box are connected to the first nanofiltration membrane assembly; the first-section concentrated water is stored in the first concentrated water box, and the first-section produced water is stored in the first produced water box; the first-section produced water is subjected to evaporative crystallization, and sylvinite ore is obtained; the sylvinite ore is subjected to flash melting crystallization, and potassium chloride is obtained. The novel method is used for producing potassium chloride from the potassium mixed salt and has the advantages of being simple in process, high in product purity, large in particle and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Utilize potassium mixed salt to prepare the method for potassium chloride

ActiveCN106430248BGuaranteed yieldEasy to separateReverse osmosisAlkali metal chloridesNanofiltrationMethods preparation

The invention discloses a method for preparing potassium chloride by utilizing potassium mixed salt. The method comprises the steps that a reverse flotation process is adopted to remove sodium chloride in the potassium mixed salt, and a tailing is obtained; the tailing is dissolved in water, and solid-liquid separation is performed to obtain a tailing solution; a section of nanofiltration step is executed, wherein a nanofiltration membrane system is adopted to conduct a section of nanofiltration treatment on the tailing solution to obtain a section of concentrated water and a section of produced water and comprises a first nanofiltration membrane module and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module, the section of concentrated water is stored in the first concentrated water tank, and the section of produced water is stored in the first produced water tank; evaporative crystallization is conducted on the section of produced water to obtain the potassium chloride. The invention provides a novel method for producing potassium chloride by using potassium mixed salt as a raw material. The method has the advantages of being simple in process, high in product purity and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

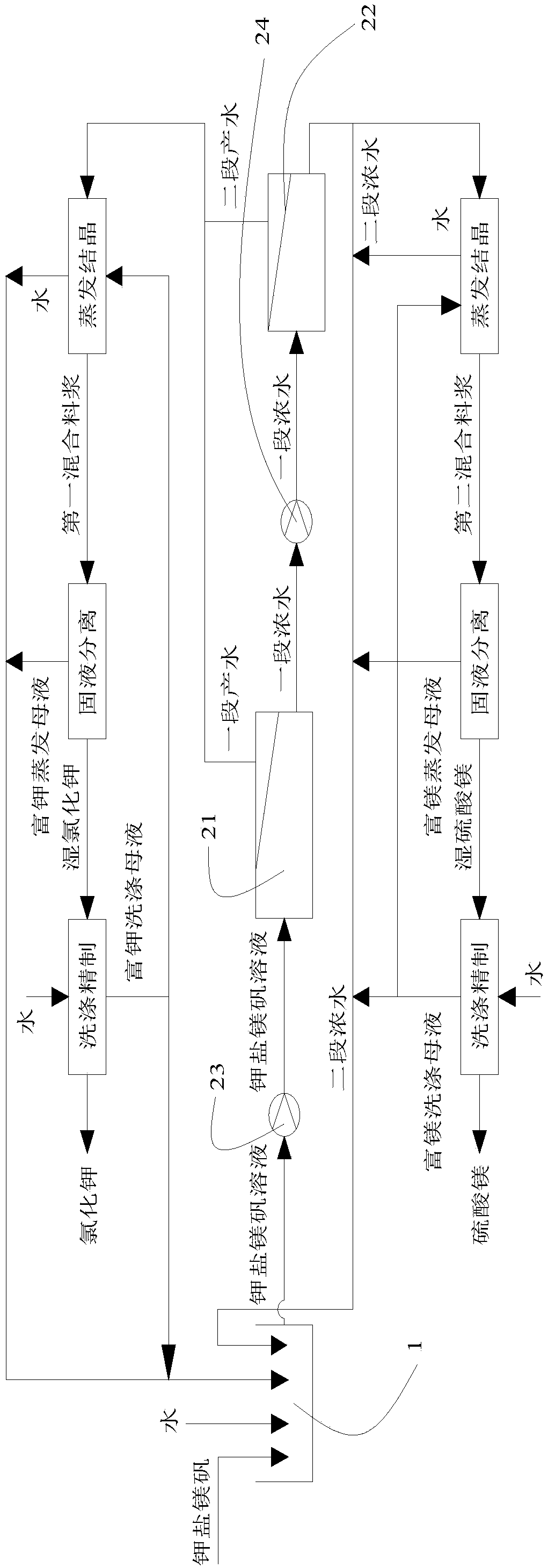

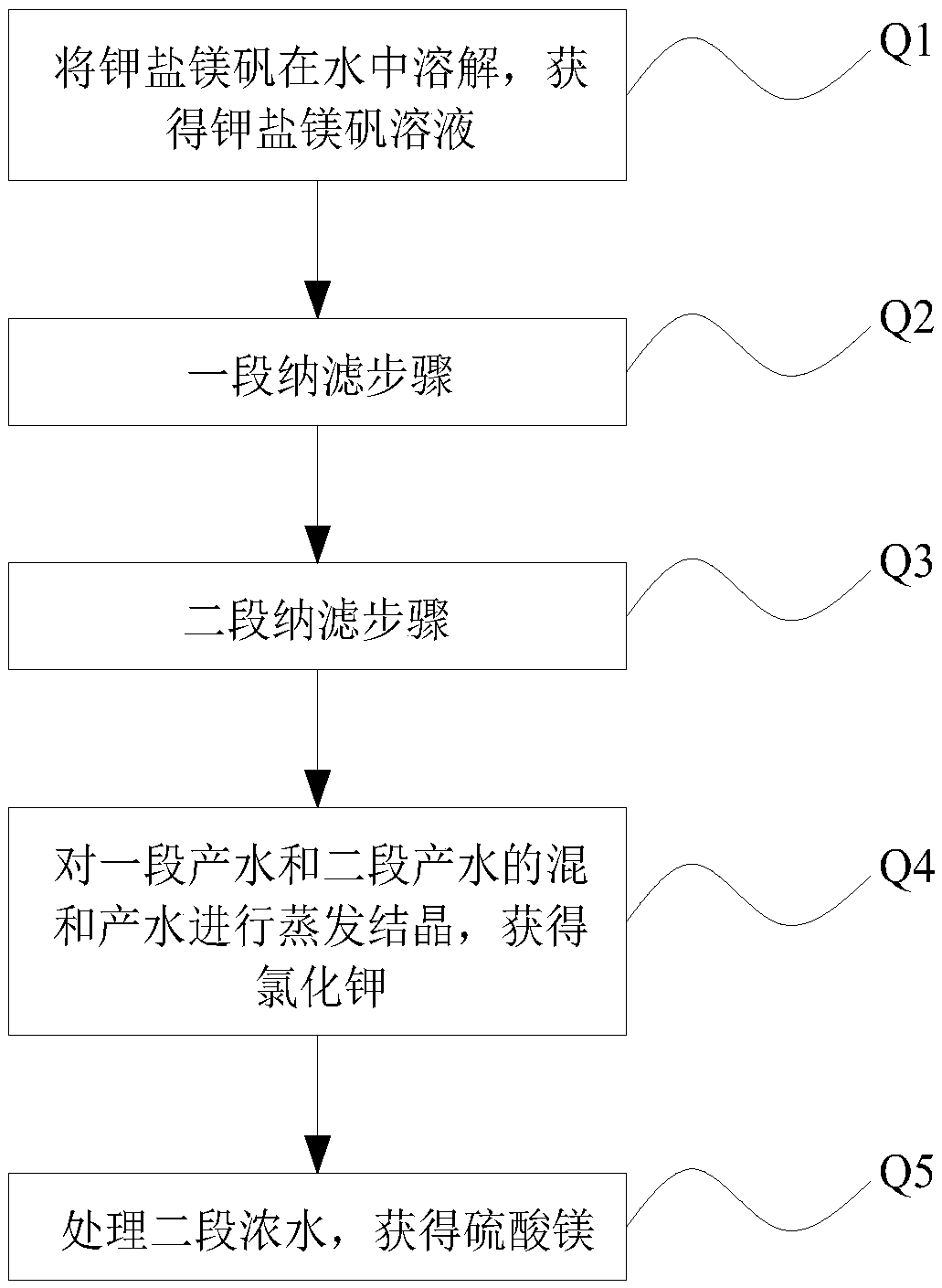

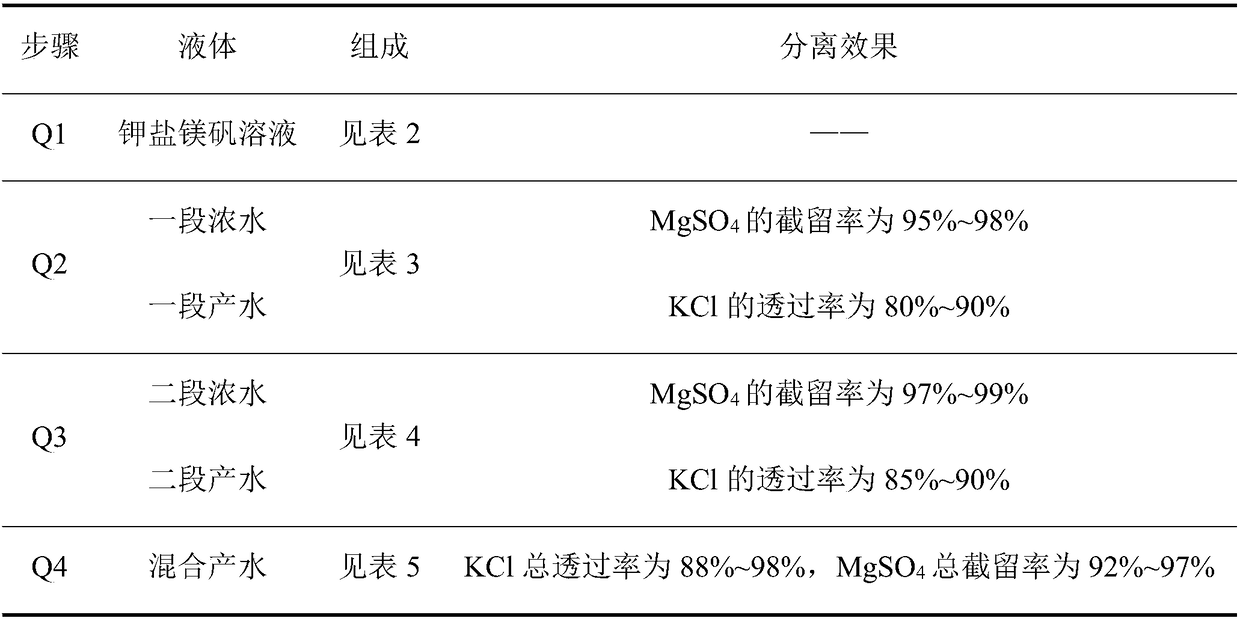

The method for preparing potassium chloride and magnesium sulfate by using kainite

ActiveCN106517250BAvoid excessive consumptionHigh separation yieldMagnesium sulfatesAlkali metal chloridesStrontiumChloride

The invention discloses a method for preparing potassium chloride and magnesium sulfate from kainite. The method comprises the following steps: dissolving the kainite in water to obtain a kainite solution, and performing primary nanofiltration: performing primary nanofiltration treatment on the kainite solution by adopting a nanofiltration membrane system to obtain primary concentrated water and primary producing water, wherein the nanofiltration membrane system comprises a first nanofiltration membrane assembly and a first concentrated water tank and a first producing water tank which are connected to the first nanofiltration membrane assembly, the primary concentrated water is stored in the first primary concentrated water tank, and the primary producing water is stored in the first producing water tank; performing evaporative crystallization on the primary producing water to obtain potassium chloride; performing evaporative crystallization on the primary concentrated water to obtain magnesium sulfate, or performing secondary nanofiltration to obtain secondary concentrated water, and performing evaporative crystallization on the secondary concentrated water to obtain the magnesium sulfate. The invention provides a novel method for producing the potassium chloride and the magnesium sulfate from the kainite serving as a raw material; and furthermore, the method has the advantages of simple process, high product purity and high yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

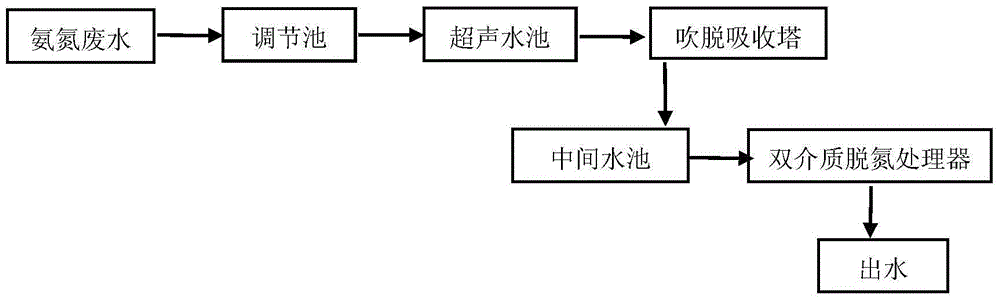

Ammonia-nitrogen removing method for treating high-concentration ammonia-nitrogen waste water

InactiveCN105461173AHigh removal rateMeet concentration requirementsWater treatment parameter controlFatty/oily/floating substances removal devicesHigh concentrationChemical reaction

Provided is an ammonia-nitrogen removing method for treating high-concentration ammonia-nitrogen waste water. The method comprises the steps that two phases are adopted to conduct treatment on the ammonia-nitrogen waste water; for the first phase, namely, a physico-chemical pretreatment phase, the concentration of the high-concentration ammonia-nitrogen waste water is reduced through an ultrasonic stripping method, wherein the water temperature is 65+ / -6 DEG C, and the time is 120+ / -20 min; the concentration requirement of a biological denitrification method to the ammonia-nitrogen waste water is met; for the second phase, residual ammonia and nitrogen in the waste water are removed through a denitrification and nitration biological denitrification method. Due to the fact that ultrasound has the advantages of increasing and controlling the chemical reaction velocity, increasing the yield of reactants and the like, for the ultrasonic stripping method, on the basis of a traditional air stripping method, an ultrasonic degradation technology is combined with a stripping technology, and a novel efficient high-concentration ammonia-nitrogen waste water treatment technology is derived. The ammonia-nitrogen removing rate can reach 90 percent, and limitation of the ammonia-nitrogen waste water concentration in a traditional technology is made up.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG CO LTD

Method for preparing high-strength sulfate aluminum cement co-production sulfuric acid through calcining by steps

ActiveCN106630703AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationSlag

The invention relates to a method for preparing high-strength sulfate aluminum cement co-production sulfuric acid through calcining by steps. The method comprises the following steps: completely replacing limestone and natural gypsum by ardealite, grinding and homogenizing bauxite, slag, silica and anthracite, and preparing the sulfate aluminum cement through calcining by steps. The ardealite utilization rate is greatly improved, and sulfuric acid can be prepared by absorbing high-concentration sulfur dioxide tail gas. The sulphoaluminate cement clinker prepared by the method disclosed by the invention is high in hardening rate, high in early strength and enhanced and stable in long-term strength. The performance test proves that the mechanical strength of the prepared sulfate aluminum cement meets the rapid hardening sulfate aluminum cement standard.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

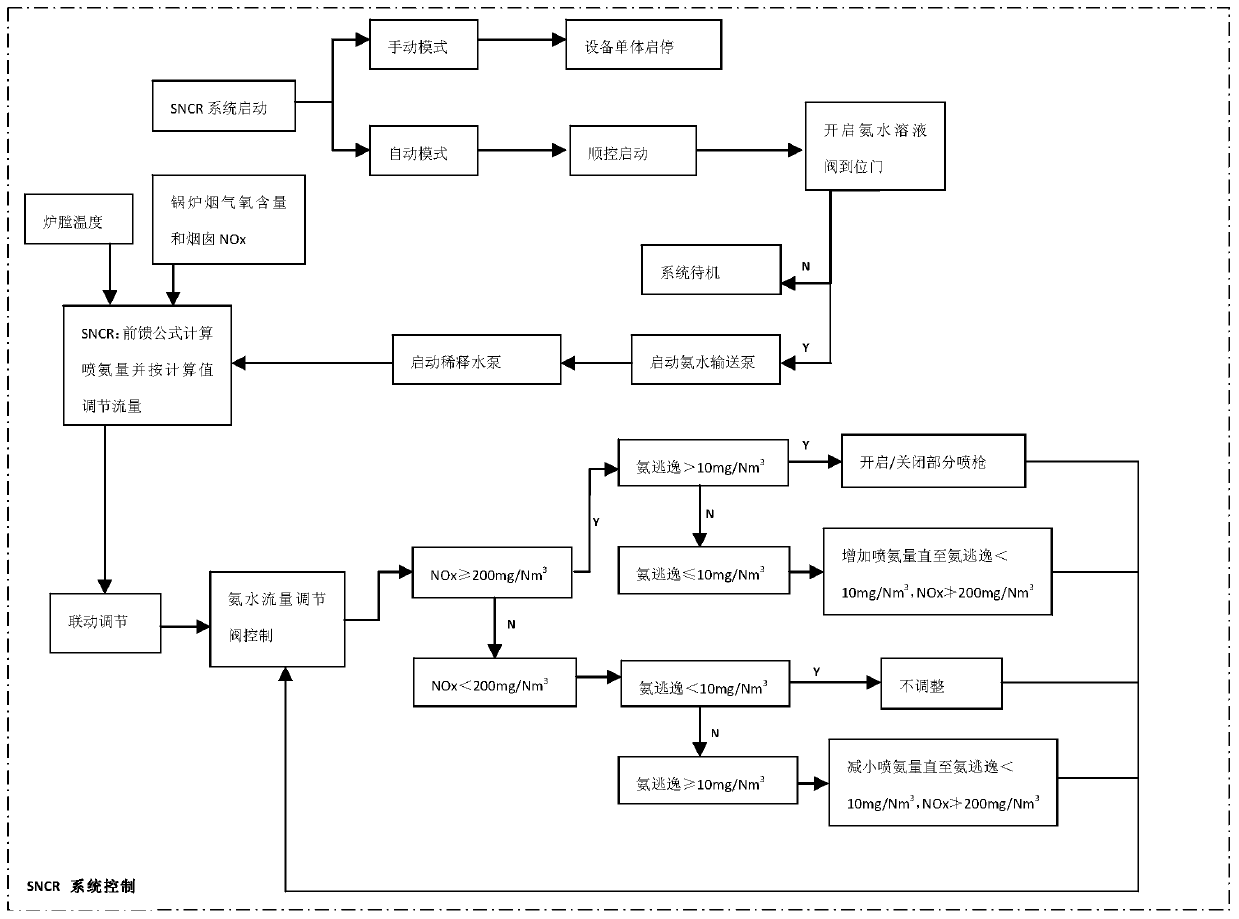

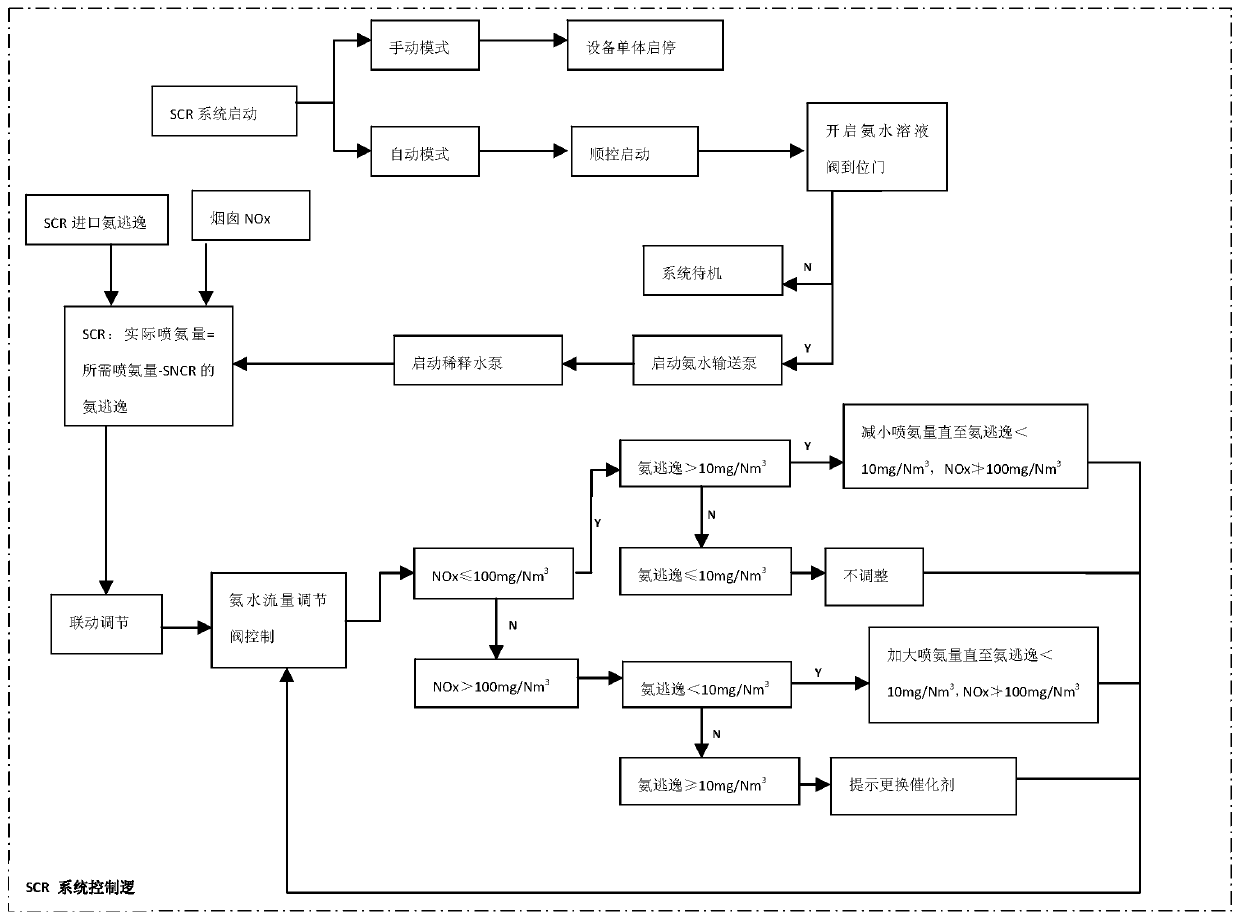

Double-process combined denitration interlocking control system for tail gas treatment of waste incineration plant

PendingCN111026017AImprove denitrification efficiencyRealize a high degree of automationProgramme control in sequence/logic controllersSpectrum analyzerInjection equipment

The invention discloses a double-process combined denitration interlocking control system for tail gas treatment of a waste incineration plant. Control equipment comprises a NOx Fourier transform infrared analyzer, an NH3 laser spectrum analyzer, medicament storage equipment, medicament conveying equipment, medicament injection equipment and a system control unit. SNCR equipment is arranged on theside of the boiler, and SCR equipment is arranged behind the bag type dust collector. The SNCR equipment sprays atomized ammonia water into a hearth of the boiler, redundant ammonia gas after SNCR denitration reaction enters the SCR system and then participates in catalytic denitration reaction, the SCR system needs to adjust and supplement ammonia water through closed-loop control, and the NOx concentration requirement of tail gas emission and the ammonia escape concentration requirement are met. The SNCR equipment introduces an incineration condition feedforward control mode, and is matchedwith a NOx Fourier transform infrared analyzer arranged at an SCR inlet to calculate the required ammonia water injection amount, so that a large amount of ammonia is prevented from escaping and entering an SCR reactor.

Owner:SHANGHAI SUS ENVIRONMENT

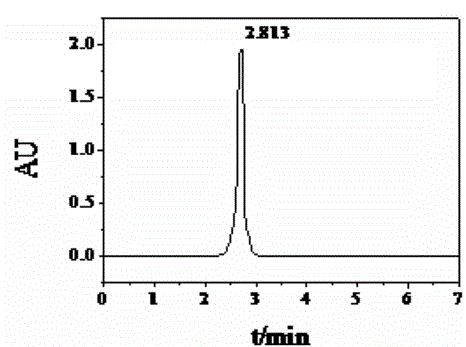

Preparation method of high-concentration acrylamide aqueous solution by microbiology

InactiveCN102776254AIncrease profitMeet concentration requirementsMicroorganism based processesFermentationHigh concentrationAqueous solution

The invention discloses a preparation method of high-concentration acrylamide aqueous solution by microbiology. The preparation method includes strain domestication and screening, free cell preparation, and multistage continuous serial reaction. The preparation method has the advantages that the common one-step intermittent reaction is replaced by the multistage continuous serial reaction, acrylamide is produced from the free cells by microbiological hydration, processes of reactors are controlled, bacteria are separated, utilization of the strain is increased, 60% high-concentration acrylamide can be obtained, the requirements of market for acrylamide are met, and market competitiveness of products is improved.

Owner:江苏南天农科化工有限公司

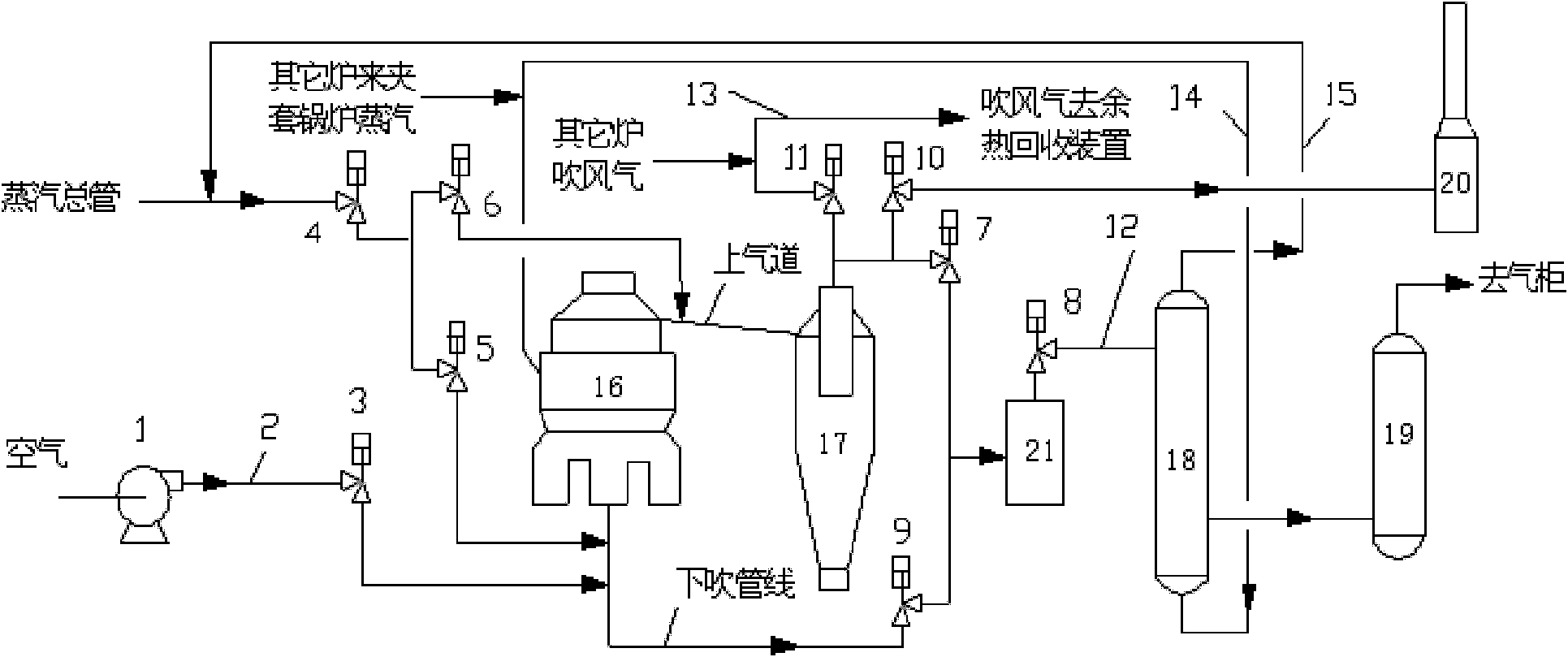

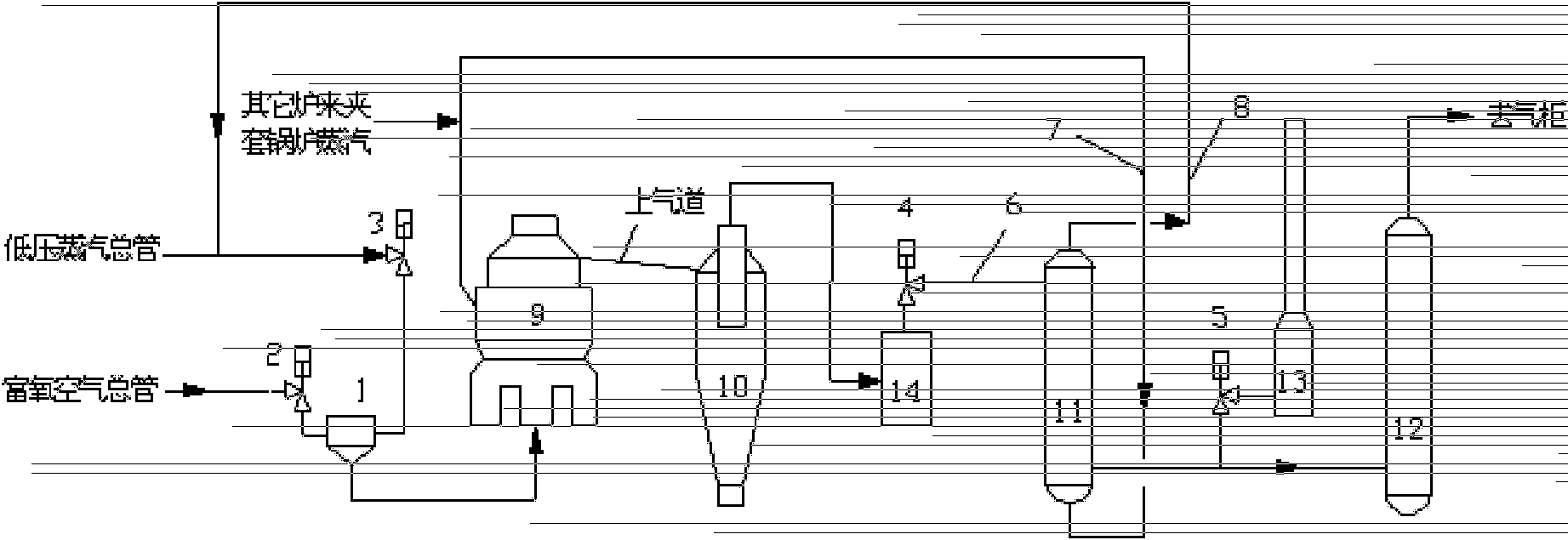

Method for producing synthetic ammonia and methanol raw material gas by fixed-bed intermittent oxygen-increasing natural gasification

ActiveCN102277196AEasy to adjustReduce the difficulty of operationCombustible gas productionProduction rateAlcohol

The invention relates to a method for producing and synthetizing ammonia and methyl alcohol raw material gas by virtue of fixed bed intermittence type oxygenation nature gas, and the method is characterized by improving the concentration of oxygen in charged air of the traditional fixed bed intermittence gasification process to 22-65%. By utilizing the method, the defects of low blowing efficiency, low single-furnace output, high coal consumption, serious environment pollution, unstable oxygen enrichment continuous gasification operation, high gas carbon dioxide and methane and the like of the traditional intermittence gasification process are overcome, and the advantages of high enrichment continuous gasification gas production rate and low coal consumption are carried on, two gasification process advantages are innovatively integrated, and the purpose of playing up strengths and avoiding weaknesses is realized.

Owner:ANHUI HUAIHUA

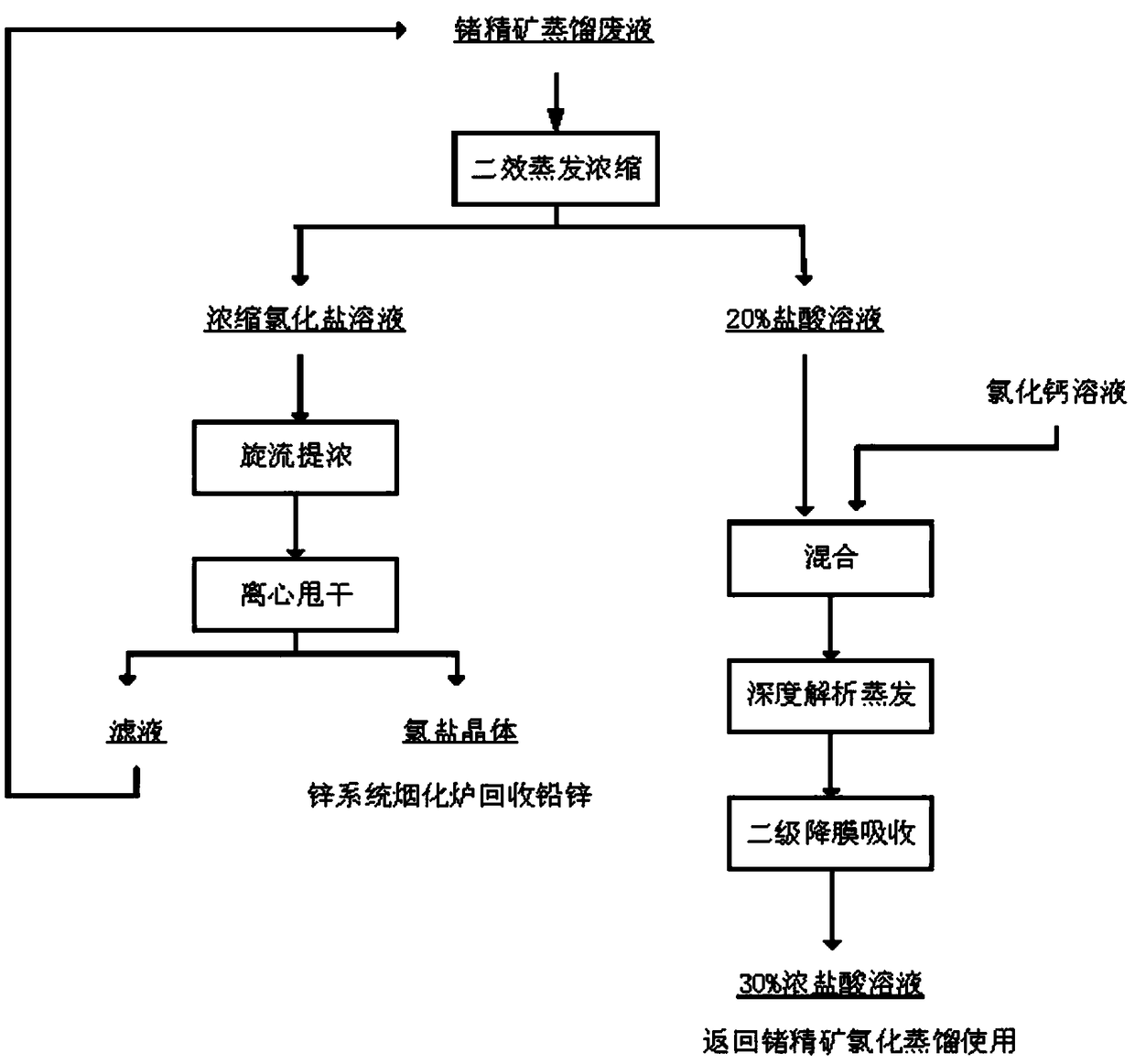

Method for recovering hydrochloric acid from germanium concentrate distillation waste liquid

InactiveCN109207747AAvoid the neutralization processReduce the amount of slagProcess efficiency improvementReboilerBoiling point

The invention discloses a method for recovering hydrochloric acid from germanium concentrate distillation waste liquid. The method comprises the following steps of primarily separating hydrochloric acid and salt solution in the germanium concentrate distillation waste liquid through evaporation and concentration; performing cyclone concentration on the concentrated salt solution; then, performingcentrifuge dripping to obtain crystal products of zinc chloride, ferric chloride, lead chloride and the like; feeding the crystal products into a zinc melting flow process smoking furnace to recover lead and zinc; after condensing diluted acid subjected to evaporation concentration is collected through a collecting tank, conveying the condensing diluted acid into a desorption tower through a hydrochloric acid conveying pump to be mixed with a certain concentration of calcium chloride solution; performing continuous contact reverse flow mass transfer on the high-temperature chlorine hydride gasheated through a reboiler, water vapor and calcium chloride so that the constant boiling point of dilute hydrochloric acid can be broken and the chlorine hydride content of the rise gas is continuously increased; after the cooling by cooling water, returning hydrochloric acid with the concentration being 30 percent or higher subjected to two-stage falling film absorption into the germanium concentrate for distillation and use; conveying the desorption tower diluted calcium chloride solution into a concentration tower to be subjected to evaporation concentration; then, conveying the solution to the desorption tower for cyclic use. The method for recovering hydrochloric acid from the germanium concentrate distillation waste liquid provided by the invention has the advantages that cleannessand high efficiency are realized; the outsourcing hydrochloric acid consumption in the distillation process is reduced; the production cost is reduced.

Owner:云南驰宏国际锗业有限公司

Method for preparing potassium chloride by utilizing potassium mixed salt

ActiveCN106430248AGuaranteed yieldEasy to separateReverse osmosisAlkali metal chloridesReverse flotationNanofiltration

The invention discloses a method for preparing potassium chloride by utilizing potassium mixed salt. The method comprises the steps that a reverse flotation process is adopted to remove sodium chloride in the potassium mixed salt, and a tailing is obtained; the tailing is dissolved in water, and solid-liquid separation is performed to obtain a tailing solution; a section of nanofiltration step is executed, wherein a nanofiltration membrane system is adopted to conduct a section of nanofiltration treatment on the tailing solution to obtain a section of concentrated water and a section of produced water and comprises a first nanofiltration membrane module and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module, the section of concentrated water is stored in the first concentrated water tank, and the section of produced water is stored in the first produced water tank; evaporative crystallization is conducted on the section of produced water to obtain the potassium chloride. The invention provides a novel method for producing potassium chloride by using potassium mixed salt as a raw material. The method has the advantages of being simple in process, high in product purity and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

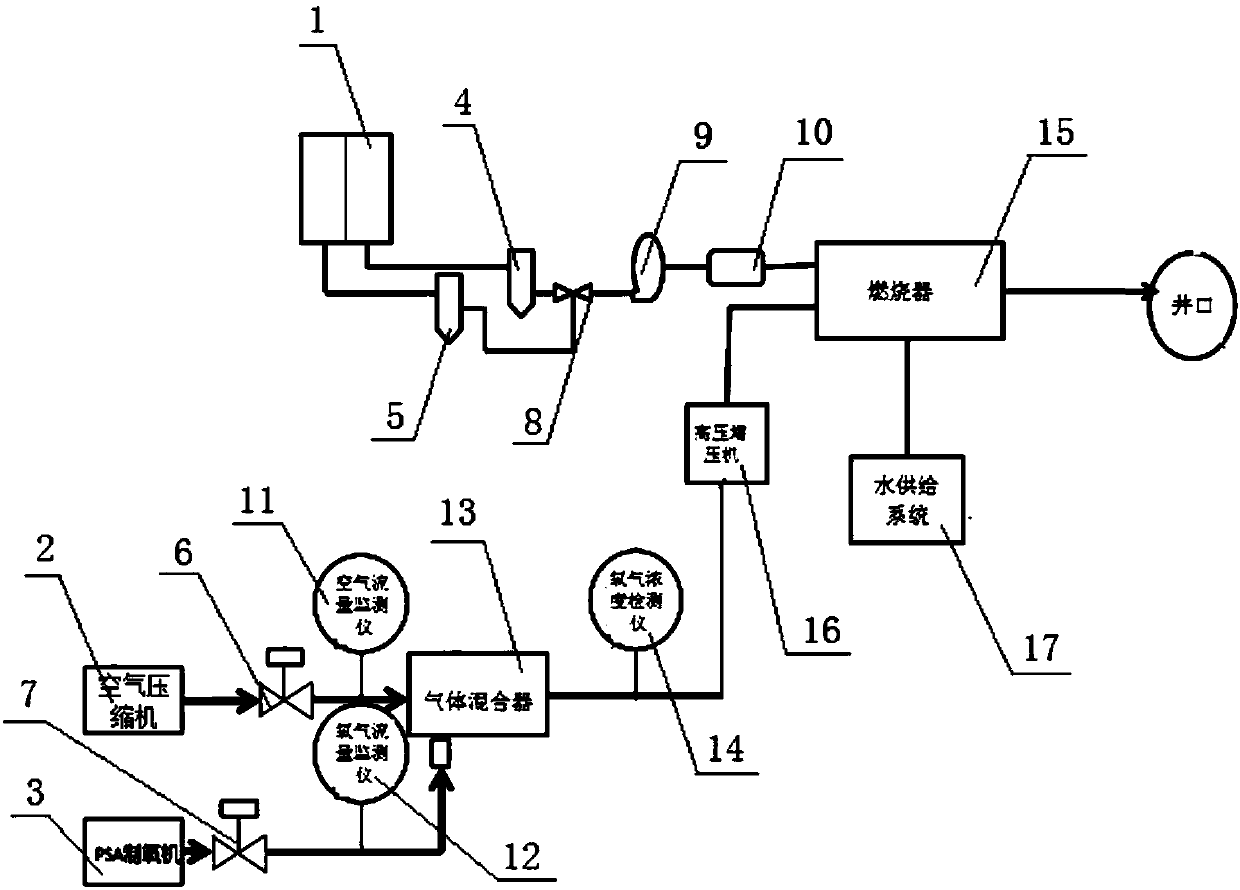

Oxygen-enriched combustion-supporting thick oil well gas injection system and gas injection method

ActiveCN107701159ARealize continuous adjustmentMeet concentration requirementsFluid removalFuel oilOxygen enrichment

The invention discloses an oxygen-enriched combustion-supporting thick oil well gas injection system and a gas injection method. The oxygen-enriched combustion-supporting thick oil well gas injectionsystem comprises a fuel oil pipeline, an oxygen-enriched air pipeline, a combustor and a water supplying system; the fuel oil pipeline comprises a light oil and heavy oil integrated self-heating oil box, a switching valve and a high-pressure oil pump; and the oxygen-enriched air pipeline comprises a gas mixer, an air compressor, a pressure swing adsorption oxygen generator, an oxygen flow electromagnetic valve, an air flow electromagnetic valve and an oxygen concentration detector. According to the oxygen-enriched combustion-supporting thick oil well gas injection system, heavy oil, diesel, light oil and thick oil are used as fuel to be combusted with prepared oxygen-enriched air, in oxygen-enriched air preparation of the oxygen-enriched combustion-supporting thick oil well gas injection system, high-load operation of the gas injection amount under different oxygen-enriched concentrations can be achieved, therefore, the gas injection efficiency of the system can be improved significantly, accordingly the combustion efficiency is improved, the enthalpy value is increased, carbon deposition of the combustor can be reduced, the service life of the equipment is prolonged by a large margin, and the operation cost is reduced greatly.

Owner:WUHAN YUANFANG SCI & TECH CO LTD OF CHINA SANJIANG SPACE GRP

Hydroxylamine nitrate crystal preparation method

A hydroxylamine nitrate crystal preparation method mainly comprises the following several steps: weighing and dissolving raw materials, mixing raw materials and reacting, filtering and concentrating a product, adding a proper organic solvent and freezing, drying the product, sealing and preserving the product. According to solubility difference of HAN and water in two organic solvents, HAN and water can be well separated, and HAN dissolved in an organic solvent can be recovered such that loss of HAN is low. Purity of HAN crystal prepared by the method is high. The HAN crystal prepared by the method can be made into HAN aqueous solutions of different concentrations at any time, and the complicated process of concentration testing of each batch of HAN concentrated solution is omitted. Requirements of a single-base propellant on HAN concentration and purity are met.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Water treatment method for emergency treatment of sudden petroleum pollution to drinking water

ActiveCN104229965AEffective response to sudden pollutionHigh removal rateWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionHigh concentrationPrecipitation

The invention discloses a water treatment method for the emergency treatment of sudden petroleum pollution to drinking water, relates to a water treatment method, and aims to solve the problem of poor elimination effects of a conventional treatment process for a water supply plant on the sudden petroleum pollution to raw water. The method comprises the following steps: performing coagulation sedimentation treatment on raw water, and feeding powered activated carbon in an initial coagulation stage to effectively remove petroleum pollutants. According to the method, the adsorption of the powdered activated carbon is combined before a conventional water treatment process, and effluent is treated by the conventional process, so that the removal rate of the petroleum pollutants in the raw water can maximally reach 86.73 percent, sudden high-concentration petroleum pollution in the raw water can be effectively treated, the petroleum concentration of the effluent is lower than 0.3mgL<-1>, and a requirement for the petroleum concentration of the effluent is met. Compared with an independent conventional water treatment method, the water treatment method has the advantages that the removal rate of the petroleum pollutants in the water is higher than 51.73 percent, and good removal effects are achieved. The treatment method has the advantages of simplicity in operation, high operation efficiency, working reliability and broad popularization prospect.

Owner:哈尔滨工业大学高新技术开发总公司

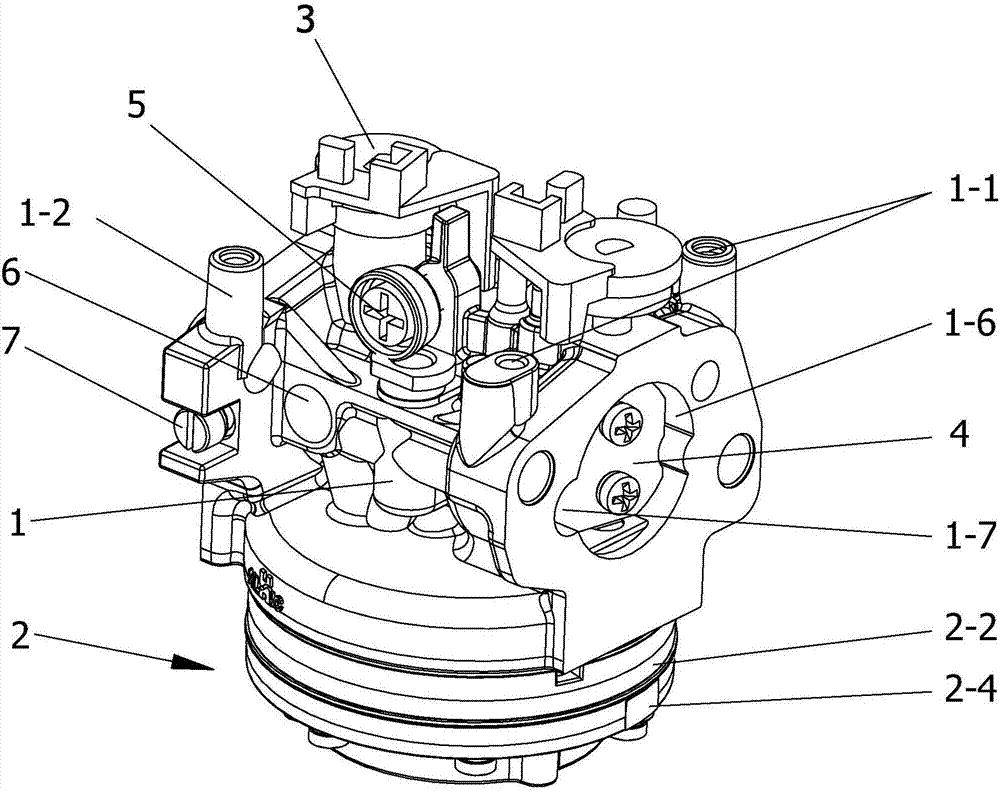

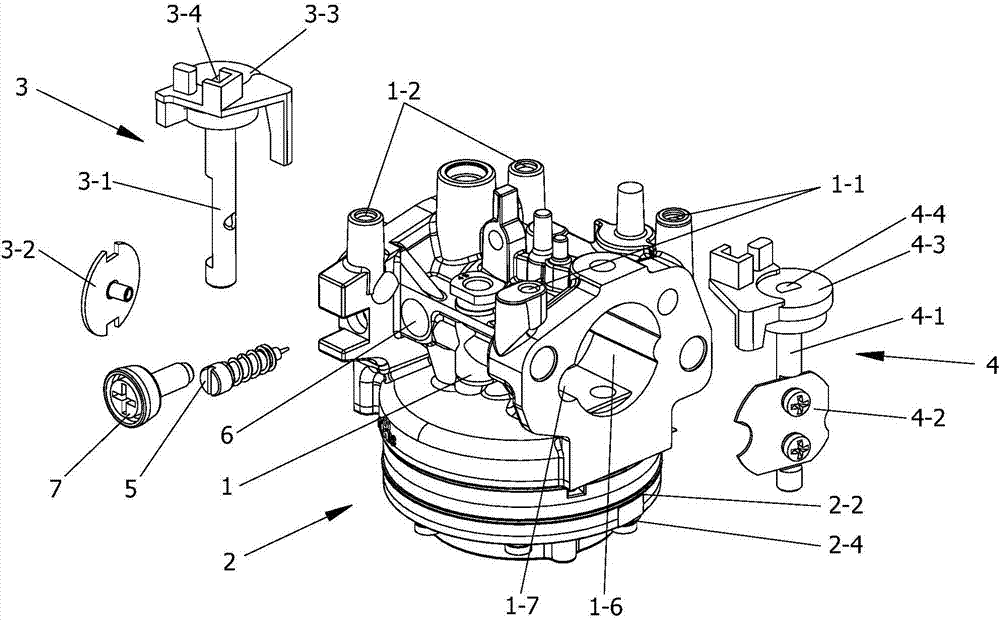

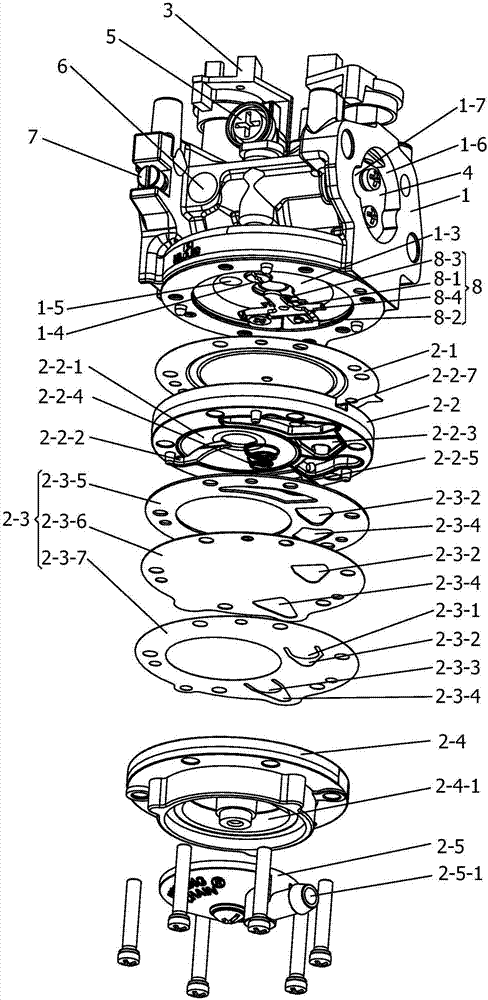

Power-improved diaphragm type carburetor

ActiveCN107461280AAvoid poor quality problems of fuel supplyEasy to controlMachines/enginesCarburettorsFuel tankEngineering

The invention relates to a power improved diaphragm type carburetor. The power improved diaphragm type carburetor comprises a carburetor body, and the upper part of the carburetor body is internally provided with an air inlet passage penetrating the carburetor body; the air inlet passage is internally provided with a choke valve device which can rotate to adjust the air inlet amount, a throat pipe used for accelerating the air flowing speed and a throttle valve device which can rotate to adjust the mixed air amount in the direction of air inlet in sequence; the lower side surface of the carburetor body is provided with a fuel injection cavity for storing fuel, and the carburetor body is internally provided with a fuel injection channel which facilitates fuel in the fuel injection cavity to be injected into the air inlet passage; and the lower part of the carburetor body is provided with a negative pressure regulating device used for controlling the oil tank to feedthe fuel into the oil injection cavity, and the negative pressure regulating device is arranged below the fuel injection cavity. The power improved diaphragm type carburetor adopts the horizontally-arranged negative pressure regulating device, so that a negative pressure elastic membrane is uniformly covered by fuel, severe local damaging caused by different oil corrosion degree of the negative pressure elastic membrane is prevented, and the fact that the problem of poor oil supply quality of the carburetor is generated due to changing of the physical property when the negative pressure elastic membrane is deformed is avoided.

Owner:郑节昭

Method for preparing sulphate aluminium cement through phosphogypsum

ActiveCN106431030ASimple process routeReduce manufacturing costSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a method for preparing sulphate aluminium cement through phosphogypsum. The method includes the steps that limestone and natural gypsum are completely replaced with the phosphogypsum, the phosphogypsum is subjected to powder grinding and homogenized through bauxite, solid waste steel residues and anthracite and calcined at the temperature of 1,250 DEG C to 1,300 DEG C to prepare the sulphate aluminium cement. By means of the method, the using rate of the phosphogypsum can be greatly increased, and high-concentration sulfur-dioxide tail gas can be prepared into sulfuric acid through absorption. The hardening speed of sulphate aluminium cement clinker prepared with the method is high, the earlier-stage strength is high, the later strength is also enhanced to be stable, and performance testing indicates that the mechanical strength of the sulphate aluminium cement prepared with the method meets the standard of the sulphate aluminium cement.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

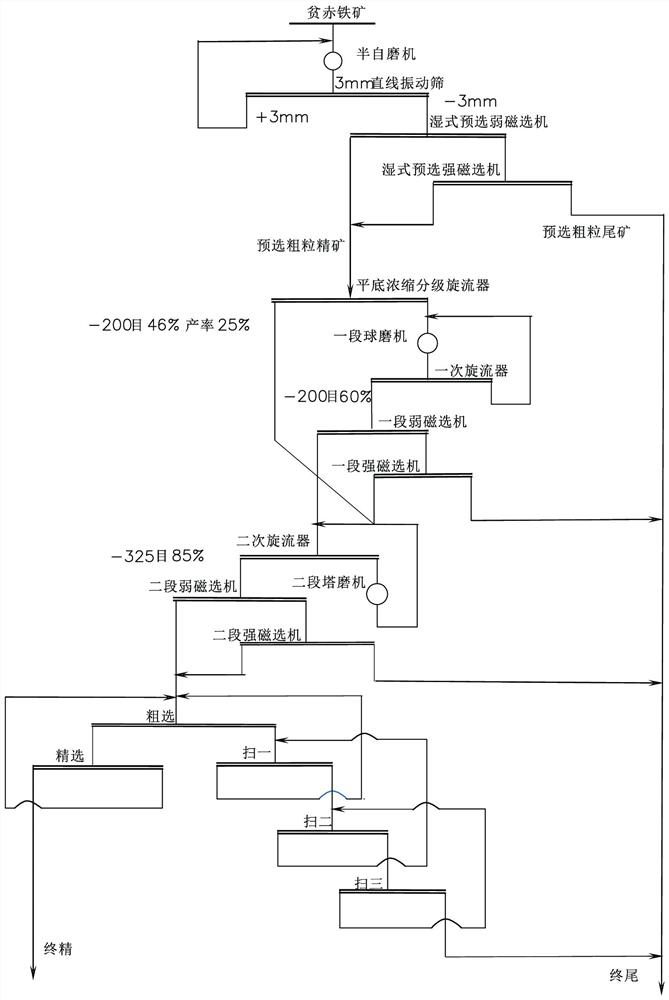

Classification grinding separation process for preselected coarse-grained concentrate of lean hematite

PendingCN112808447AMeet concentration requirementsReduce grinding energy consumptionVortex flow apparatusMagnetic separationProcess engineeringReverse flotation

The invention relates to a classification grinding separation process for preselected coarse-grained concentrate of lean hematite. The process comprises the step of feeding the lean hematite with the grade of 24%-26% into a coarse grain wet type preselection process to obtain the preselected coarse grain concentrate. The process is characterized in that a pre-grading, stage grinding and stage strong magnetic tailing discarding-reverse flotation process is adopted in subsequent treatment, specifically, the process specifically comprises the following steps that 1, the pre-selected coarse grain concentrate is fed into a flat-bottom concentration grading cyclone to be graded in advance, and pre-graded settled sand and pre-graded overflow are obtained; 2, the pre-graded settled sand is fed into a first-section ball mill, and the pre-graded overflow is directly fed into a secondary cyclone; and 3, second-stage bulk concentrate is subjected to reverse flotation, and final flotation concentrate with the grade being 65%-66% and the yield being 25%-27% is obtained through one-time roughing, one-time concentration and three-time scavenging. The process has the advantages that: 1, the concentration requirement of the first-stage mill is met, and the production is stable; and 2, fine grain products are graded in advance, the load of a first-stage mill is reduced, the energy is saved, and the consumption is reduced.

Owner:鞍钢集团矿业设计研究院有限公司

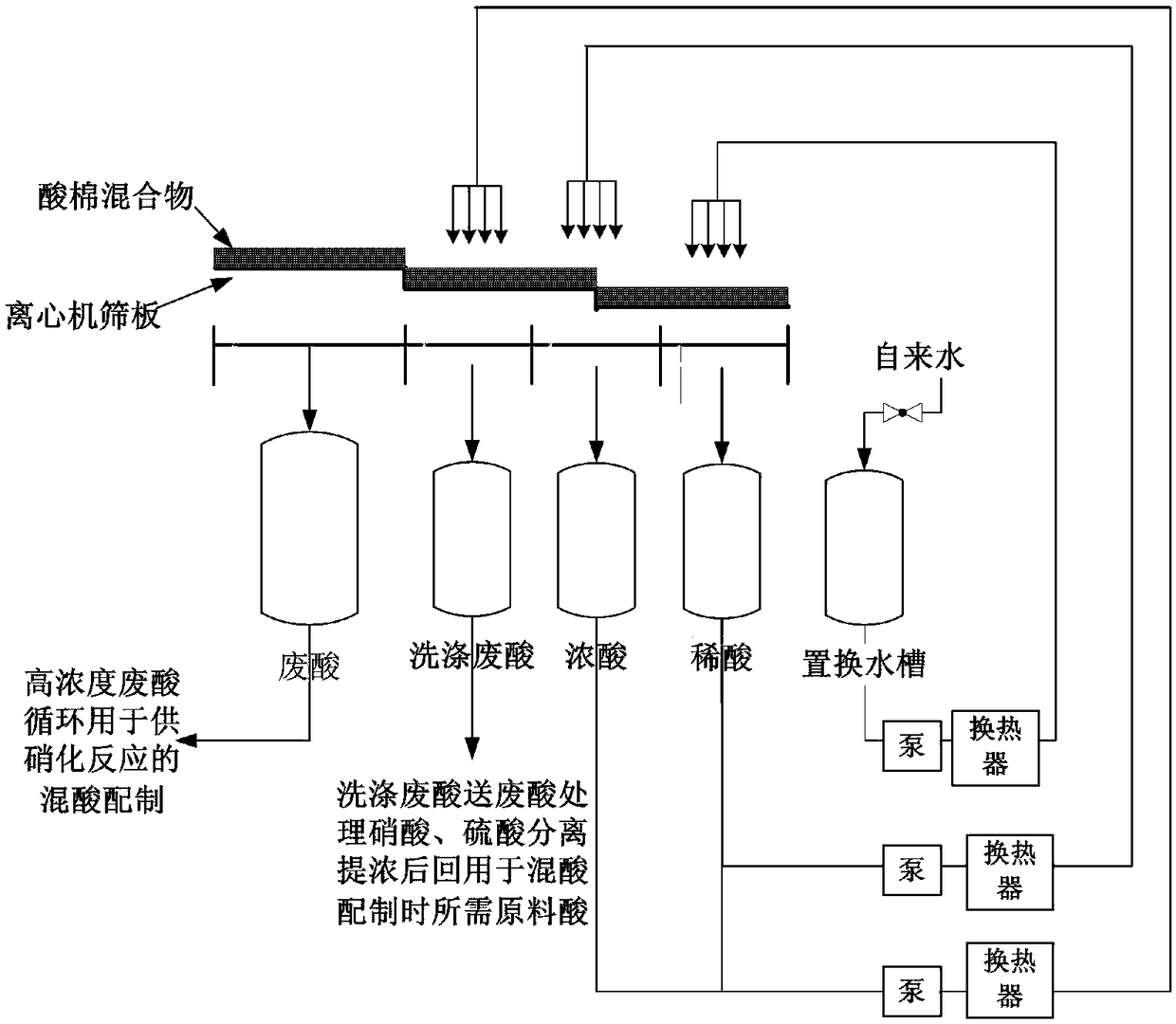

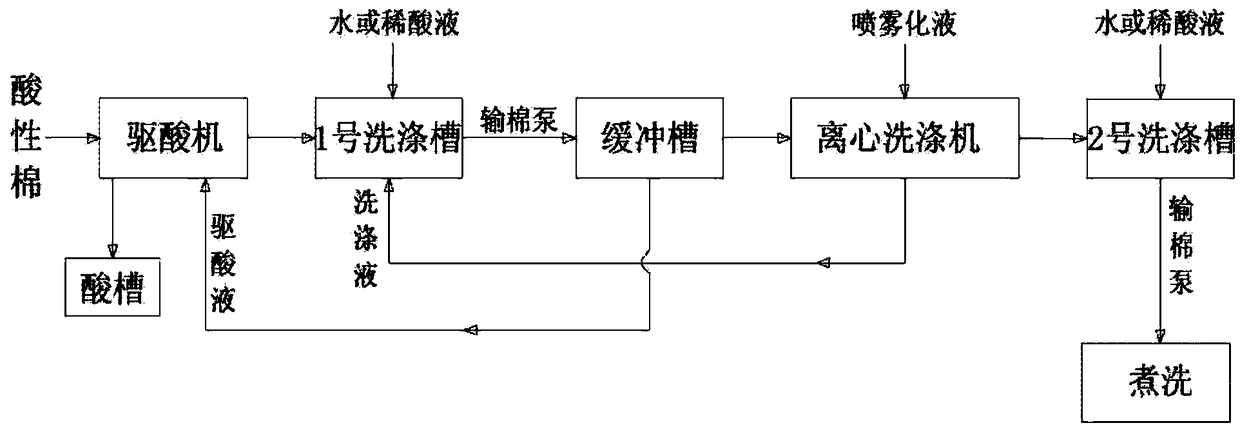

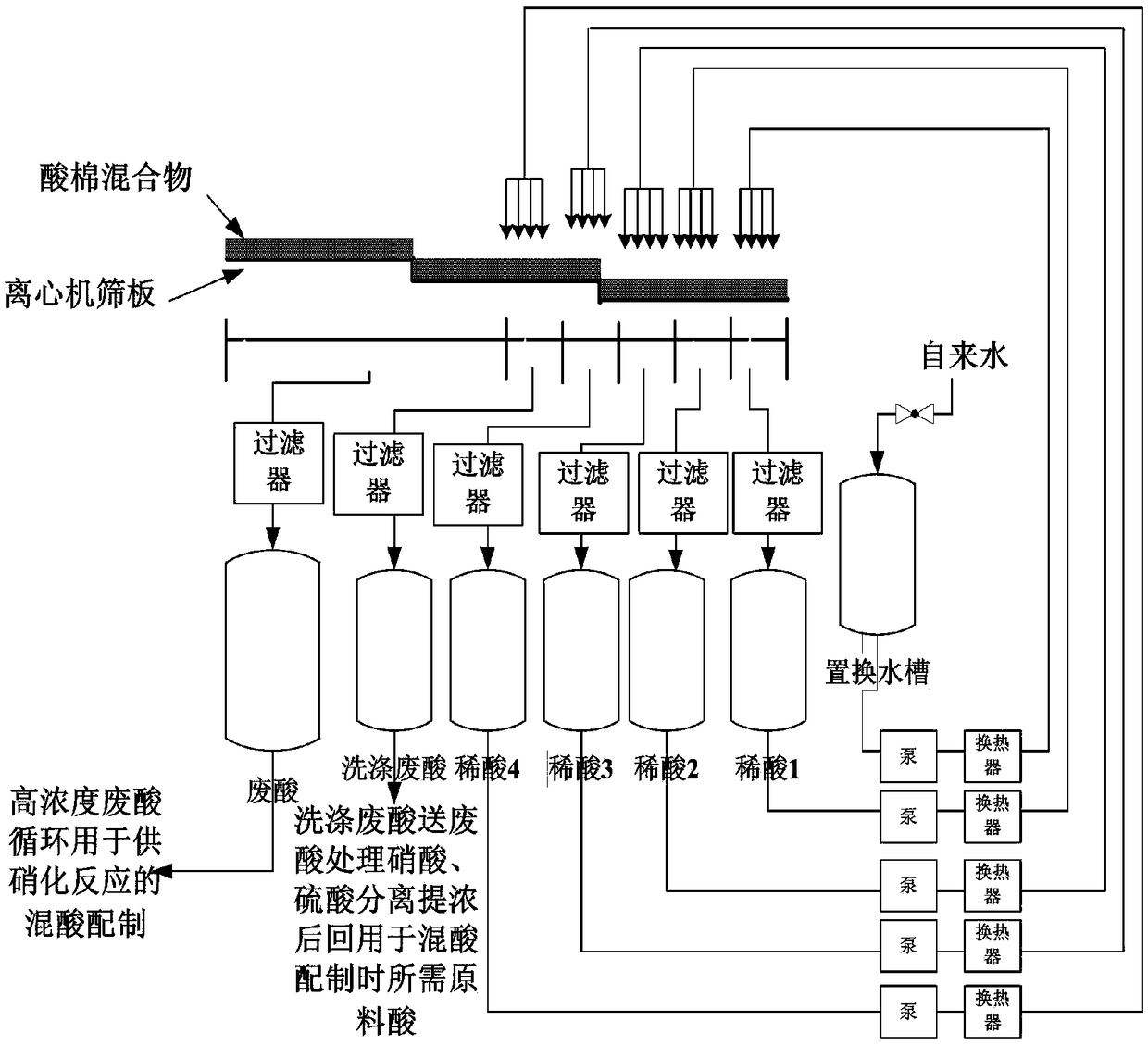

Continuous multi-segment acid displacement washing technological method

ActiveCN109056402AImprove replacement washing effectIncrease the concentration of washing waste acidWashing/displacing pulp-treating liquorsAcid treatmentPusher centrifuge

The invention relates to a continuous multi-segment acid displacement washing technological method, and belongs to the technical field of nitrocotton acid displacement technologies. The method comprises the steps that an acid-cotton mixture subjected to a nitration reaction enters a horizontal type pusher centrifuge to separate acid and cotton, a sieve plate of the horizontal type pusher centrifuge comprises a high-concentration waste acid separation segment and a displacement washing segment, and five-segment countercurrent displacement washing is conducted on the displacement washing segment. The method adopts the five-segment countercurrent displacement washing technology, the acid cotton residua acidity after acid displacement is conducted is controlled below 8%, the residual acidity is greatly lowered compared with a traditional three-segment acid displacement technology, the final concentration of the washing waste acid is high, the washing waste acid contains 18-22% of nitric acid and 47-53% of sulfur, waste acid treatment, separation and concentration increasing is facilitated, and the technological procedure and the operation are simpler and more convenient relative to theacid displacement technology with two centrifuges being connected in parallel.

Owner:SICHUAN NITROCELLULOSE CORP

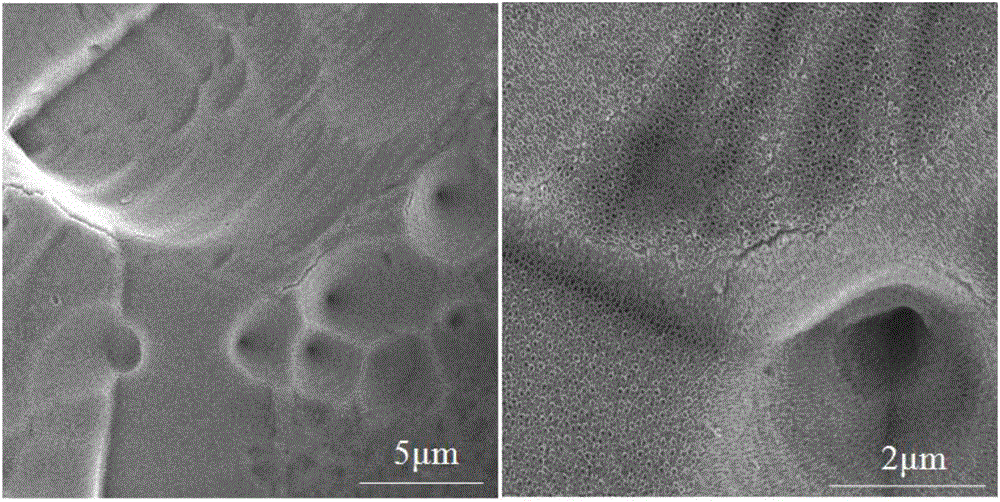

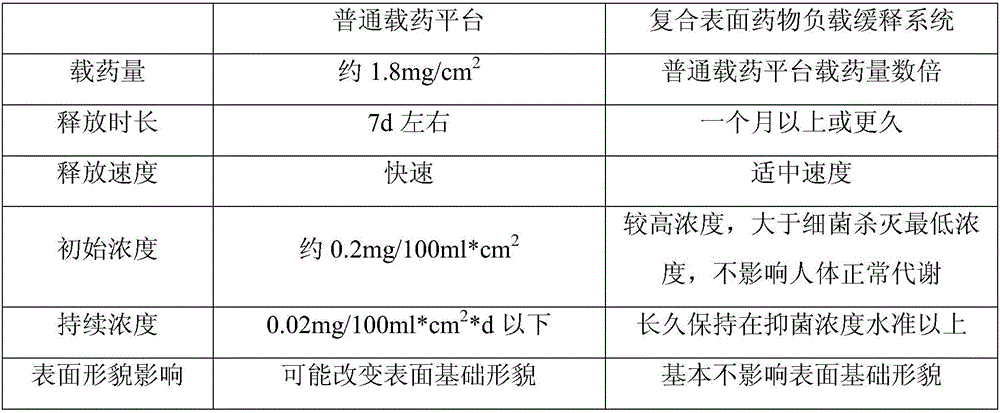

Composite surface drug-carrying slow-release system and preparation method thereof

ActiveCN106377495AIncrease concentrationBoost surface storageAntibacterial agentsInorganic non-active ingredientsMedicineDrug release

The invention discloses a composite surface drug-carrying slow-release system and a preparation method thereof. The composite surface drug-carrying slow-release system comprises a drug carrying matrix, wherein the surface of the drug carrying matrix has a nanotube structure and a micron pore pit structure; nanotubes, tube clearances and micron pore pit drug storage spaces are formed on the surface of the drug carrying matrix; and drugs are carried in the nanotubes, tube clearances and micron pore pit drug storage spaces. The drug-carrying matrix surface of the drug-carrying slow-release system is provided with the nanotubes, tube clearances, micron pore pits and many other different drug storage regions, thereby ensuring the early-stage drug release concentration and prolonging the drug release duration. The preparation method of the drug-carrying slow-release system combines alkali fusion and anode oxidation to obtain the composite surface with the sequence nanotube structure and micron hole pit structure; and the obtained micron hole pits are relatively flat and provide advantages for the formation of the subsequent sequence nanotube structure.

Owner:CENT SOUTH UNIV

Method for preparing sulphoaluminate cement and co-producing sulfuric acid by virtue of segmented calcination of desulfurized gypsum

ActiveCN106630702AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationAnthracite

The invention relates to a method for preparing sulphoaluminate cement and co-producing sulfuric acid by virtue of segmented calcination of desulfurized gypsum. The method comprises the following steps: completely replacing limestone and natural gypsum with desulfurized gypsum, mixing bauxite, silica and anthracite with the gypsum to prepare blocks, and then carrying out segmented calcination to prepare the sulphoaluminate cement. According to the method, the utilization rate of the desulfurized gypsum can be greatly improved, and the high-concentration sulfur dioxide tail gas can be used for preparing sulfuric acid through absorption. The prepared sulphoaluminate cement clinker has high hardening speed, the early strength is high, the later strength is also improved stably, and the performance test shows that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the standard of the fast-hardening sulphoaluminate cement.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Intelligent water and fertilizer regulation and control device and method based on PID (Proportion Integration Differentiation) algorithm

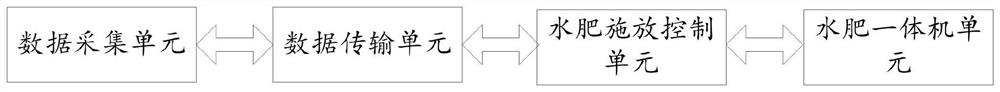

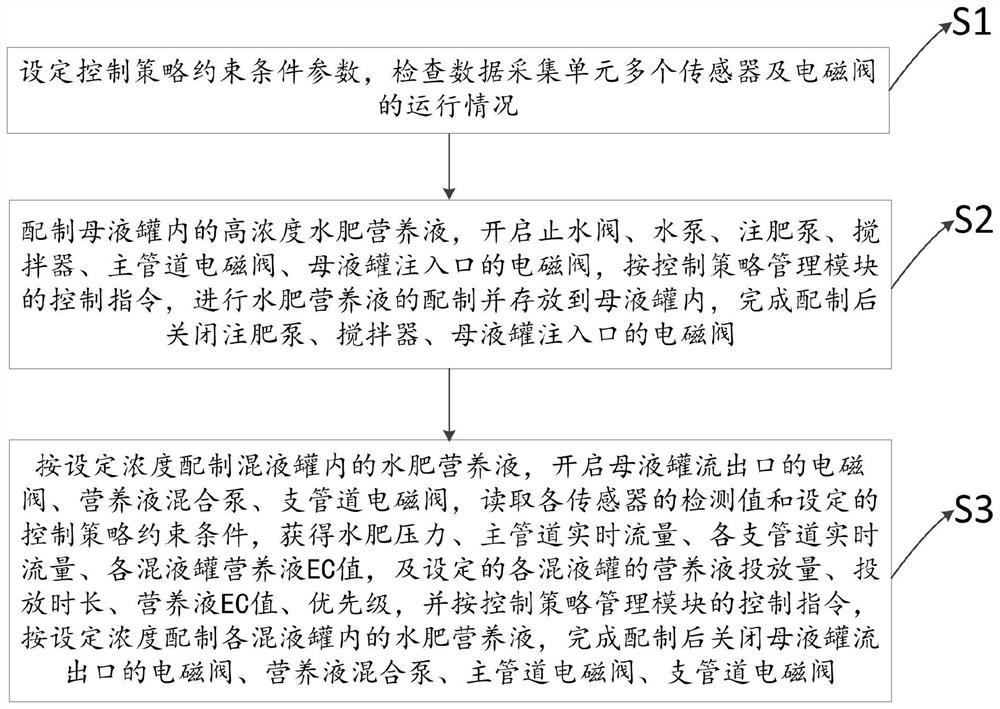

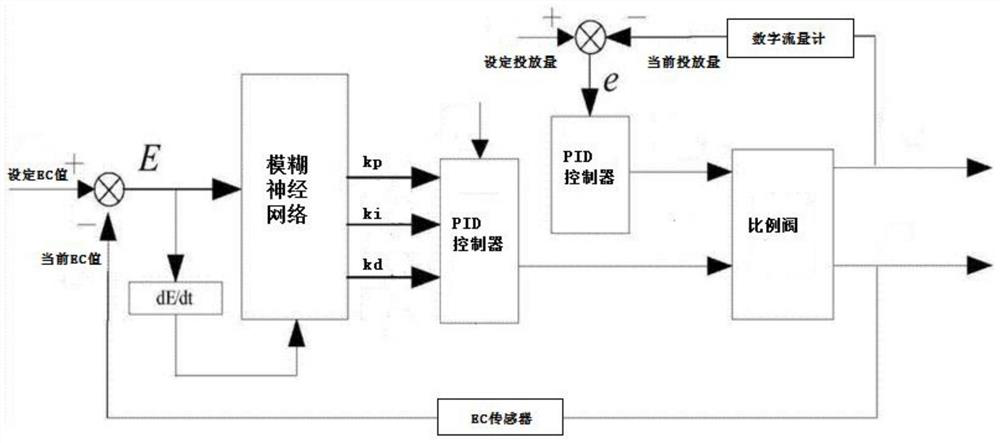

PendingCN114208470AShort lag timeAvoid flow ratio and fertilization ratio mismatchSpraying apparatusPressurised distribution of liquid fertiliserFertilizerData transmission

The invention relates to an intelligent water and fertilizer regulation and control device and method based on a PID algorithm, and the device comprises a data collection unit, a data transmission unit, a water and fertilizer application control unit and a water and fertilizer all-in-one machine unit which are electrically connected. Wherein the data acquisition unit is used for acquiring water and fertilizer flow data of a main pipeline and a branch pipeline, and transmitting the acquired water and fertilizer flow data to the water and fertilizer application control unit at a preset time interval through the data transmission unit; the water and fertilizer application control unit is used for storing and processing the water and fertilizer flow data, constructing a water and fertilizer proportioning model based on a fuzzy neural network PID, and controlling water and fertilizer equipment to complete water and fertilizer application; the water and fertilizer all-in-one machine unit is used for receiving the control instruction of the water and fertilizer application control unit and completing water and fertilizer application work. Through multi-path fertilizer liquid micro-scale proportion control, the delay time during fertilization concentration adjustment is reduced, non-uniformity of water and fertilizers of different plants in the water and fertilizer application process can be prevented, and crop quality difference caused by non-uniform growth vigor of different plants is avoided.

Owner:WUXI KAIYI IOT TECH DEV

A method for preparing high-strength sulphoaluminate cement for co-production of sulfuric acid

ActiveCN106365477BIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationPhosphogypsum

The invention relates to a method for preparing high-strength sulphoaluminate cement and co-producing sulfuric acid. The method comprises the following steps of adopting phosphogypsum for completely replacing limestone and natural gypsum, milling and homogenizing the phosphogypsum, bauxite, steel scoria, silica and pulverized anthracite, and then calcinating the milled and homogenized raw materials at a temperature of 1250-1300 DEG C. The method is capable of greatly improving the phosphogypsum utilization ratio, and high-concentration sulfur dioxide tail gas can be adsorbed to prepare sulfuric acid. The prepared sulphoaluminate cement clinker is high in hardening rate, high in early-stage strength, and stable in later-stage strength increase; performance tests indicate that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the rapid-hardening sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

Sequential batch type method and equipment for treating wastewater by using biologic dephosphorization and intermittent aeration continuously

InactiveCN1218887CGive full play to the function of phosphorus removalPrevention and Control of Eutrophication PhenomenonWater/sewage treatmentTreatment with aerobic and anaerobic processesEutrophicationChemistry

A process for treating sewage by aeration and biologically removing phosphorus includes an aerobic phosphorus releasing stage, continuous aerating and excessive picking-up phosphorus stage, intermittent aerating and organic substance removing stage, and two deposition stages. Its apparatus is composed of the serially connected anaerobic reaction pool, continuous aerating reaction pool and intermittent aerating reaction pool.

Owner:张大群 +1

Method for producing and synthetizing ammonia and methyl alcohol raw material gas by virtue of fixed bed intermittence type oxygenation nature gas

The invention relates to a method for producing and synthetizing ammonia and methyl alcohol raw material gas by virtue of fixed bed intermittence type oxygenation nature gas, and the method is characterized by improving the concentration of oxygen in charged air of the traditional fixed bed intermittence gasification process to 22-65%. By utilizing the method, the defects of low blowing efficiency, low single-furnace output, high coal consumption, serious environment pollution, unstable oxygen enrichment continuous gasification operation, high gas carbon dioxide and methane and the like of the traditional intermittence gasification process are overcome, and the advantages of high enrichment continuous gasification gas production rate and low coal consumption are carried on, two gasification process advantages are innovatively integrated, and the purpose of playing up strengths and avoiding weaknesses is realized.

Owner:ANHUI HUAIHUA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com