Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Pusher centrifuge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically for smaller units and hydraulically for larger units to enable separation.

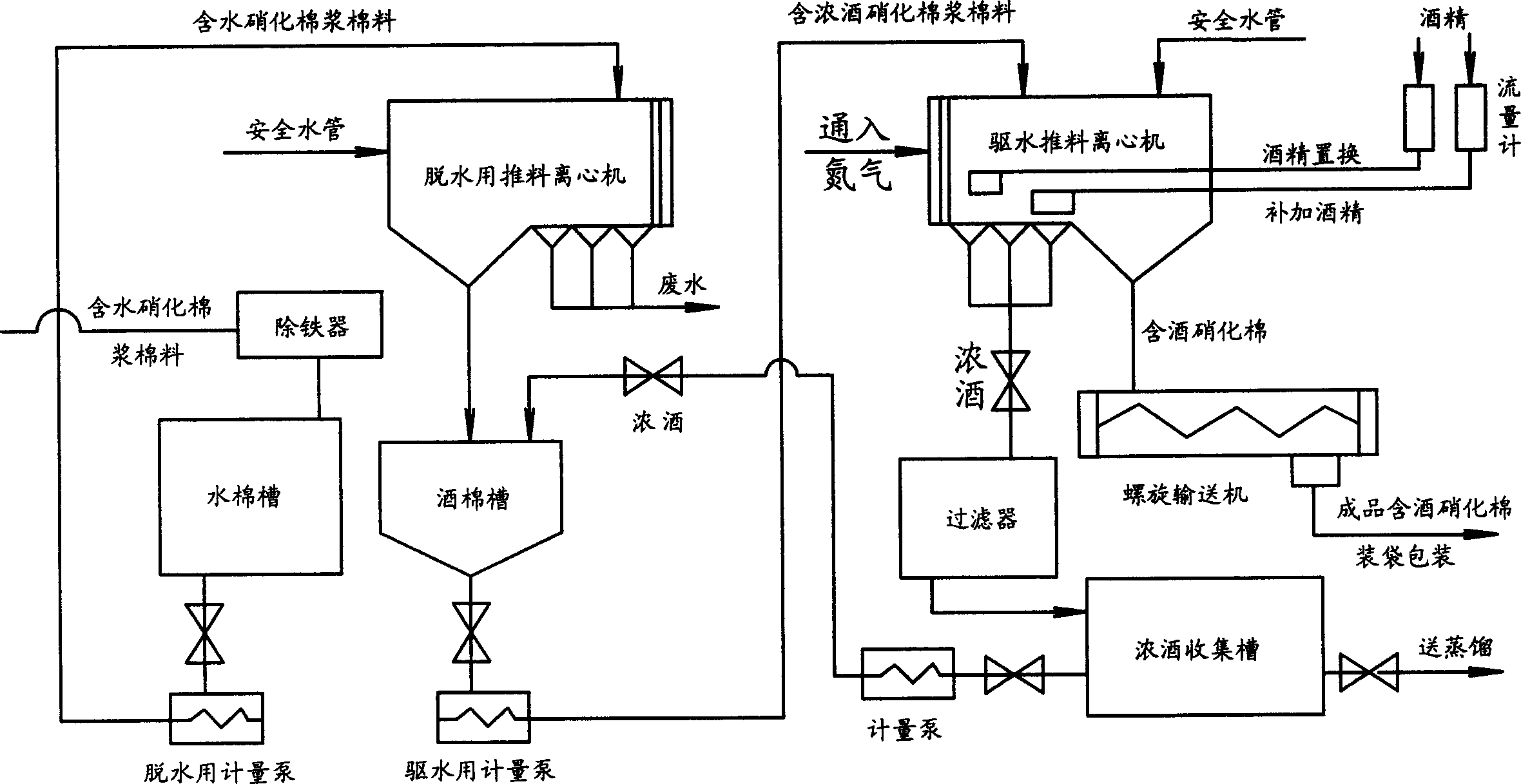

Continuous nitrocotton dewatering process and apparatus

The present invention is continuous nitrocotton dewatering process and apparatus. The continuous nitrocotton dewatering process includes the technological steps of: feeding nitrocotton slurry into dewatering tank; regulating the density of nitrocotton slurry; pumping nitrocotton slurry with metering pump into centrifugal machine to dewatering; soaking with alcohol the dewatered nitrocotton with water content less than 29%; regulating the density of nitrocotton in soaking alcohol tank; pumping alcohol soaked nitrocotton with metering pump into water displacing centrifugal machine for replacing water with alcohol. In the dewatering and water-replacing process, double-stage piston material-pushing centrifugal machine and Neihm pump are used, and during displacing water nitrogen of 0.2-0.3 MPa pressure is introduced into mechanical sealing.

Owner:SICHUAN NITROCELLULOSE CORP

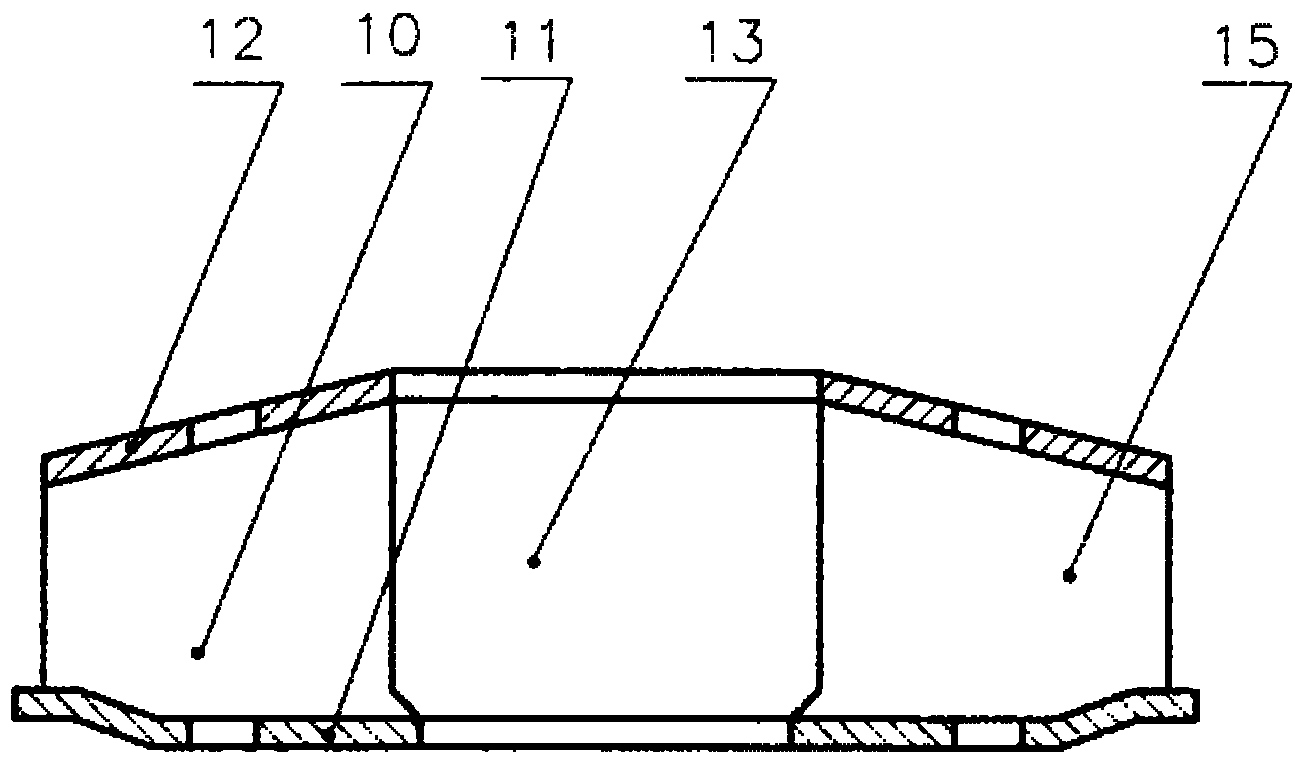

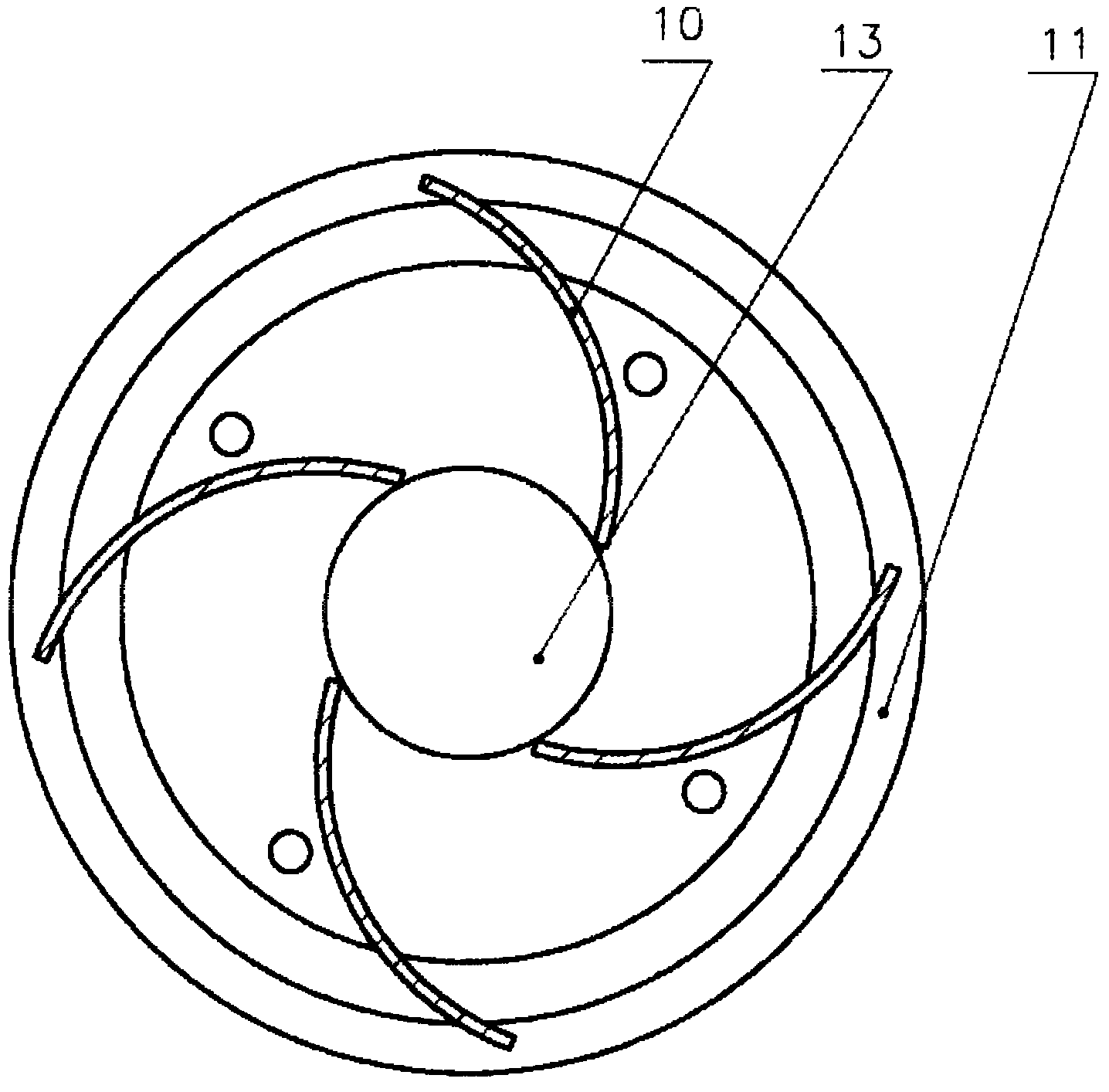

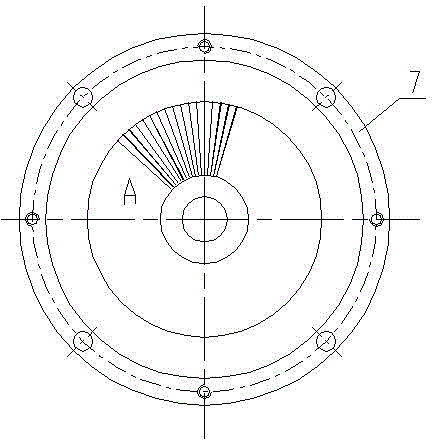

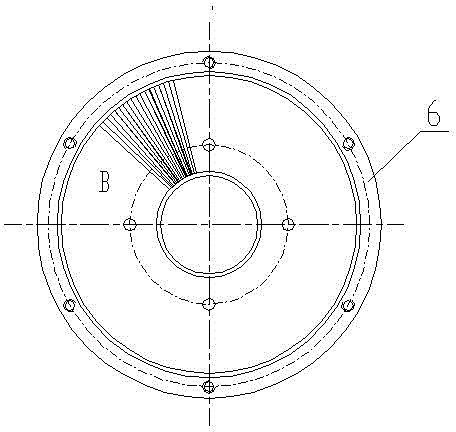

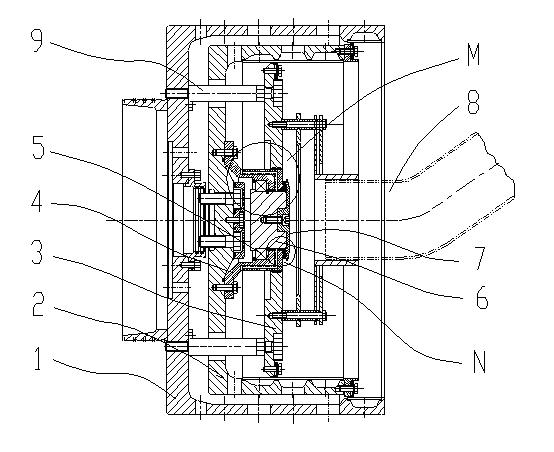

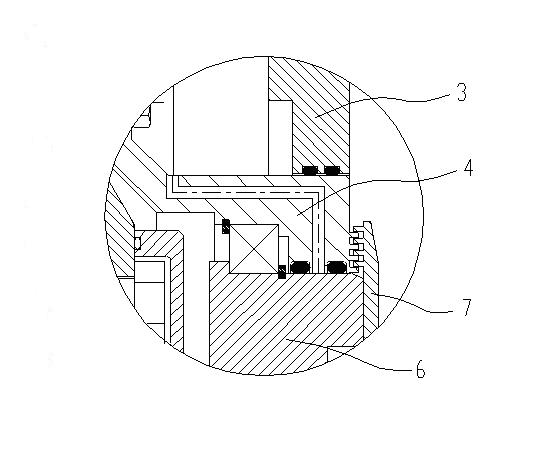

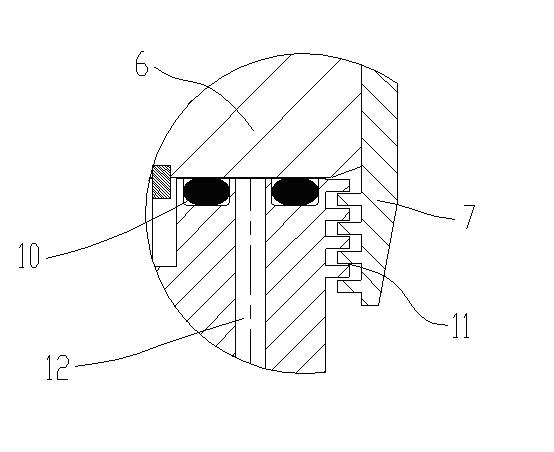

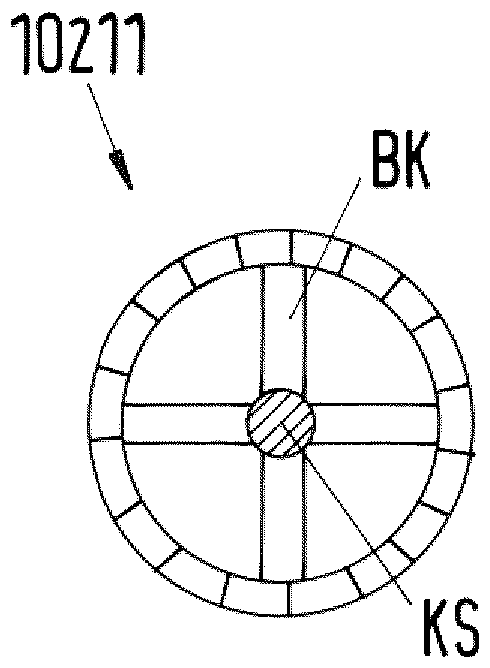

Centrifugal Acceleration Disc Structure of Pusher Centrifuge

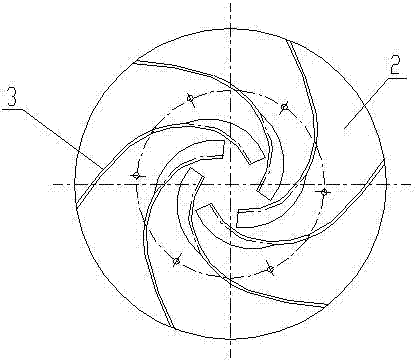

The invention relates to the technical field of centrifuges, in particular to a centrifugal accelerating disc structure of a push-type centrifuge, and solves the problem that impact force applied to a screen by a material is high when the material is accelerated to enter a separation state by the push-type centrifuge. The structure comprises a large circular flat plate and a small circular flat plate which are parallel to each other, and is characterized in that: a plurality of blades are arranged between the two flat plates and are uniformly and radially distributed; the tail ends of the plurality of blades are positioned on the same circumference; the curve of each blade is a turbine centrifugal line; each blade consists of a plurality of sections of circular arcs; the radii of the plurality of sections of circular arcs of each blade are gradually increased from the head to the tail end; and a section of part on the head of each blade is provided with a radial arc surface which inclines to the rotation direction of each blade. The structure greatly reduces the scratch, wear and defect of crystal grains in the material, ensures that the material is fed smoothly and uniformly, canreduce the residual moisture content of the separated material, and can effectively separate a material which is difficult to separate.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

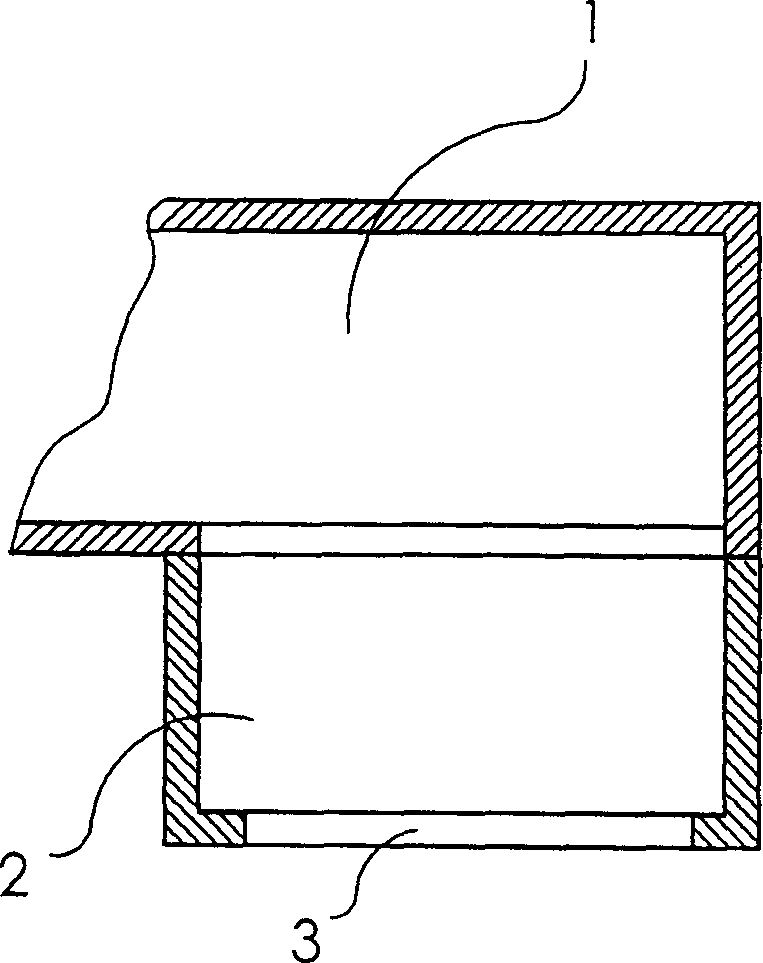

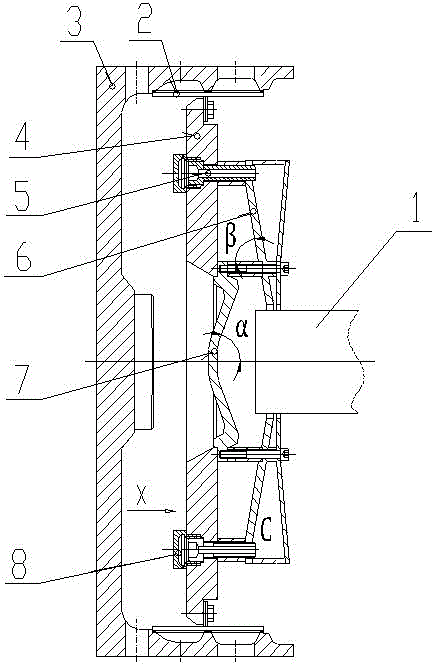

Distributing device of piston-pusher centrifuge

InactiveCN102847616AIncrease the scope of applicationImprove the stability of useRotary centrifugesCircular coneBreakage rate

Disclosed is a distributing device of a piston-pusher centrifuge. Arc-shaped blades uniformly distributed are clamped and mounted between a top plate and a bottom plate, both the top plate and the bottom plate are in the shape of circular cones and form a distributing cone, a hole is reserved in the middle of the distributing cone, an outlet end of a feed pipe extends into the distributing cone, and an outlet end of a flushing pipe also extends into the distributing cone. The distributing device has the advantages of uniformity in distribution, low breakage rate and the like. Besides, even when viscosity of materials is high, concentration of suspension liquid is high, and particle size of the materials is small, the centrifuge can work normally, application range of the double-stage piston-pusher centrifuge can be widened while stability and reliability in use thereof can be improved, and stoppage for treating accumulated filter residues is omitted during running of the centrifuge. In addition, the distributing device in the technical scheme has the advantages of simple structure, convenience in manufacturing and maintenance, reliability in running and low overall price, and is suitable to be used with the double-stage piston-pusher centrifuge.

Owner:蒋立峰

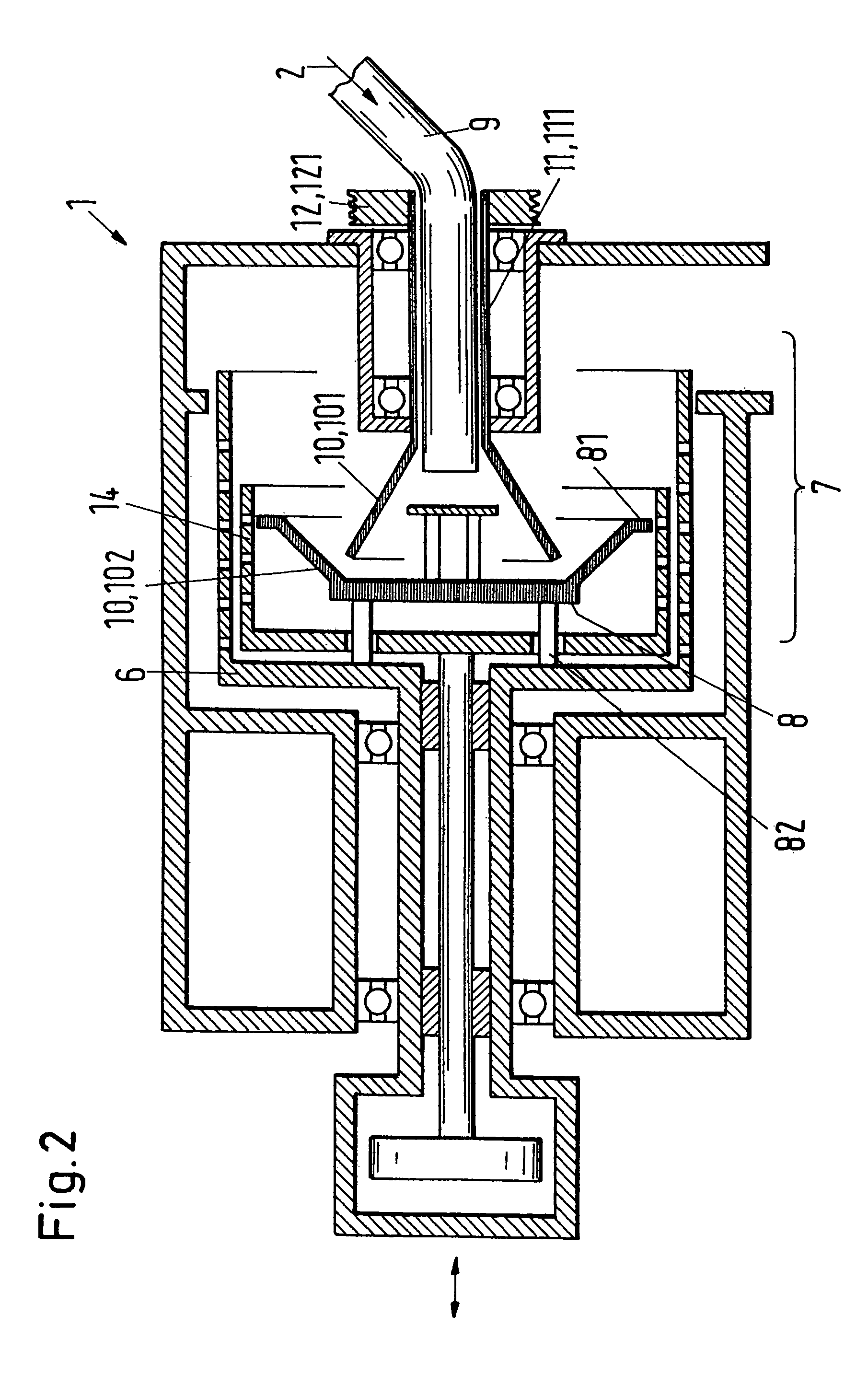

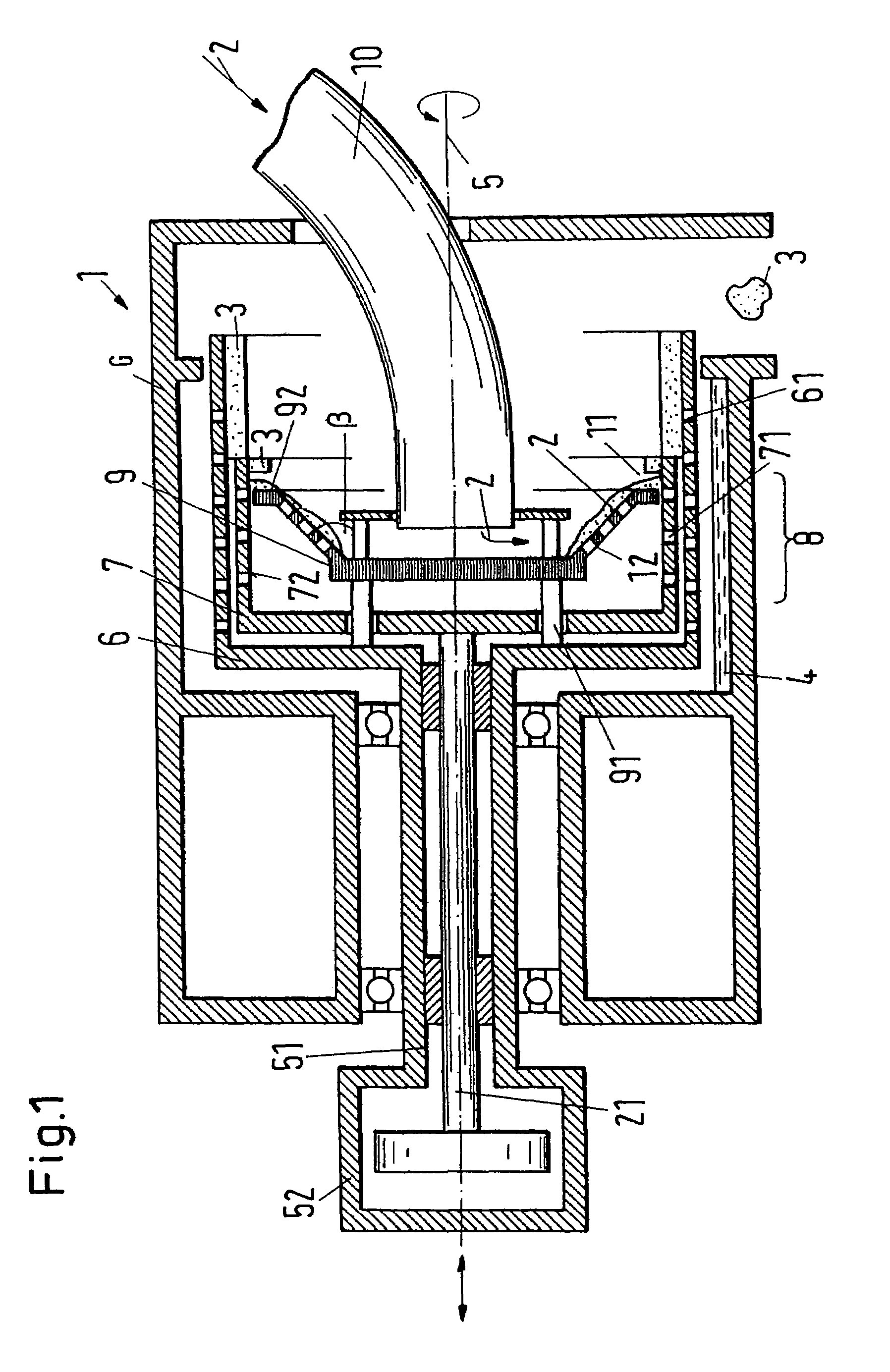

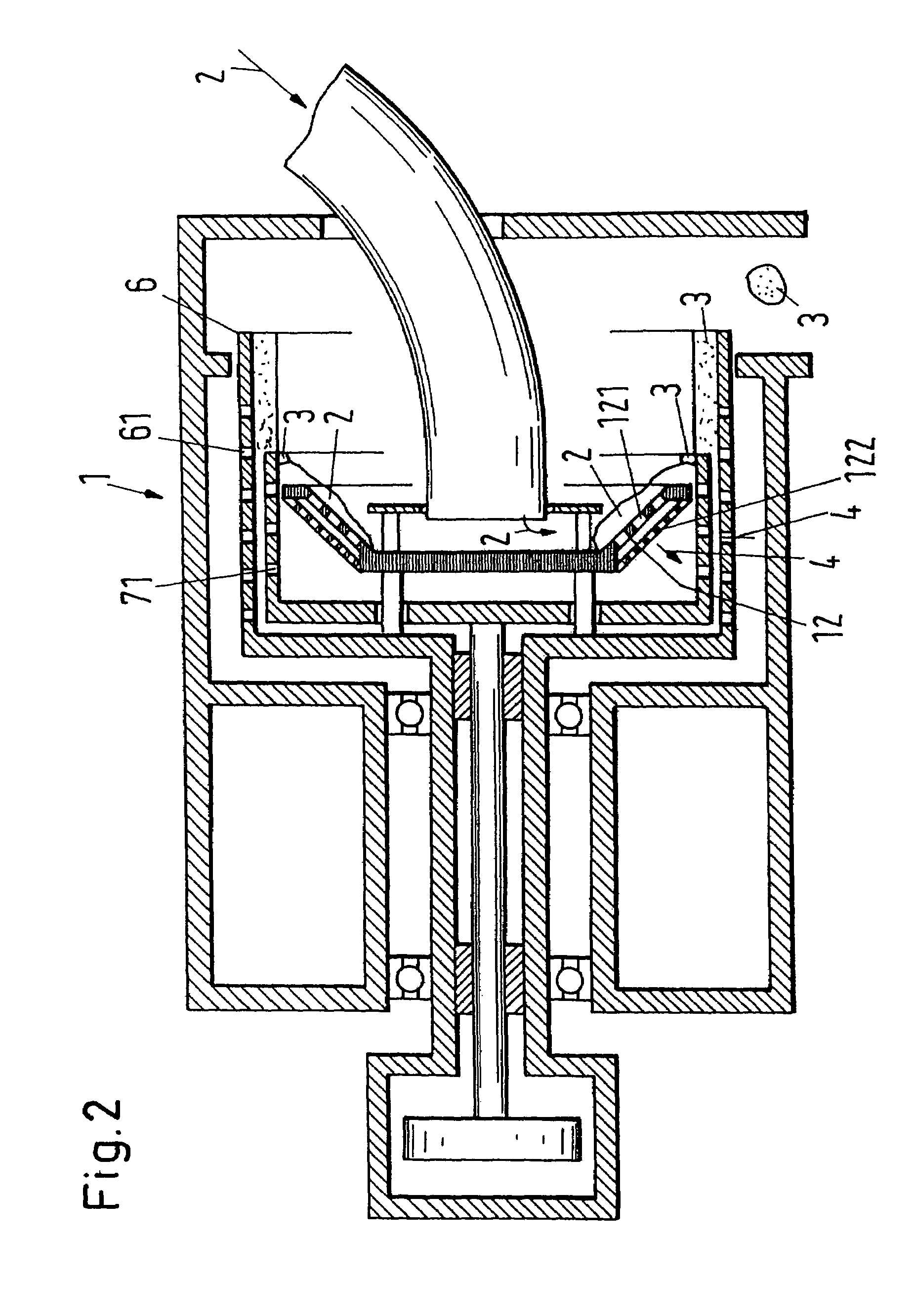

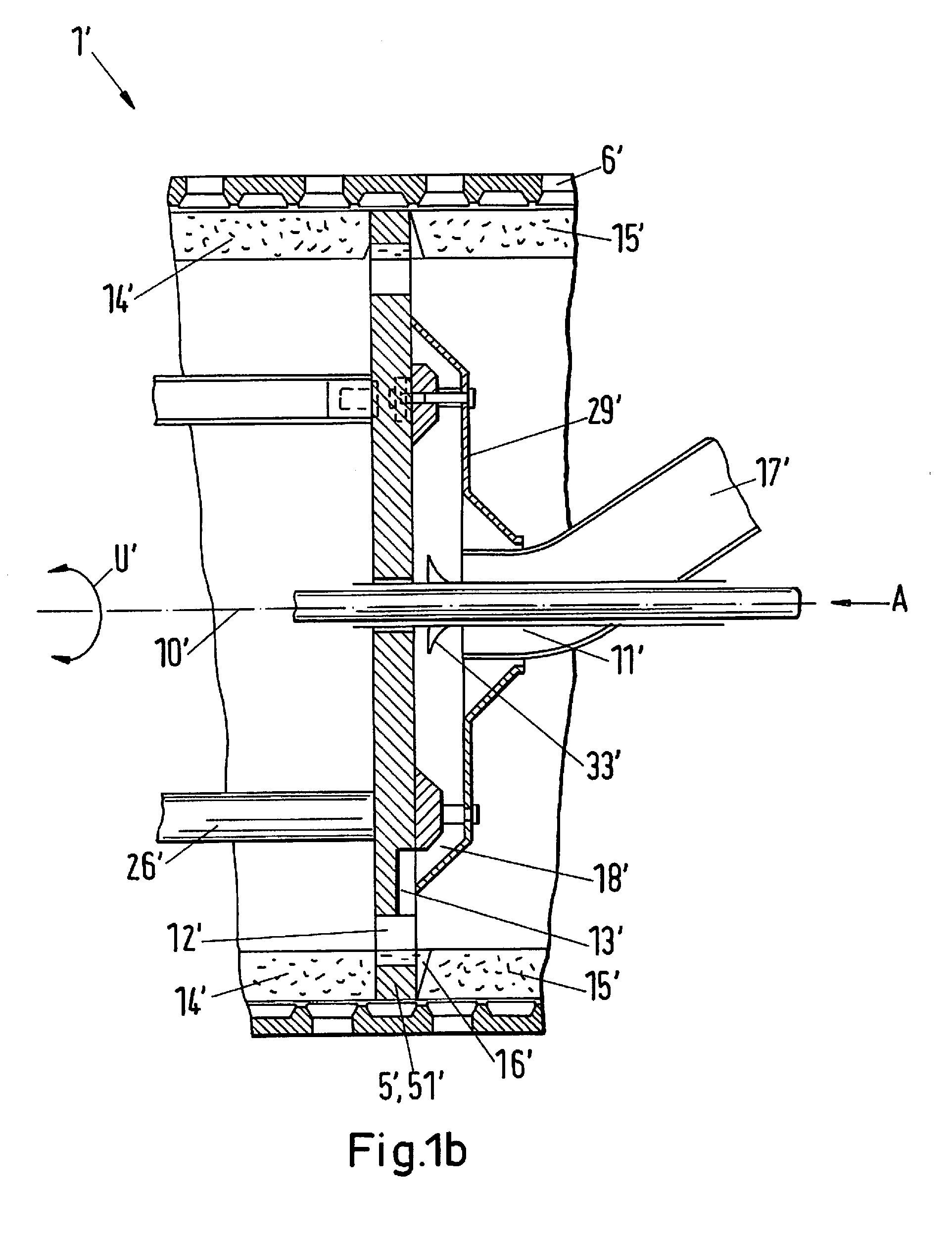

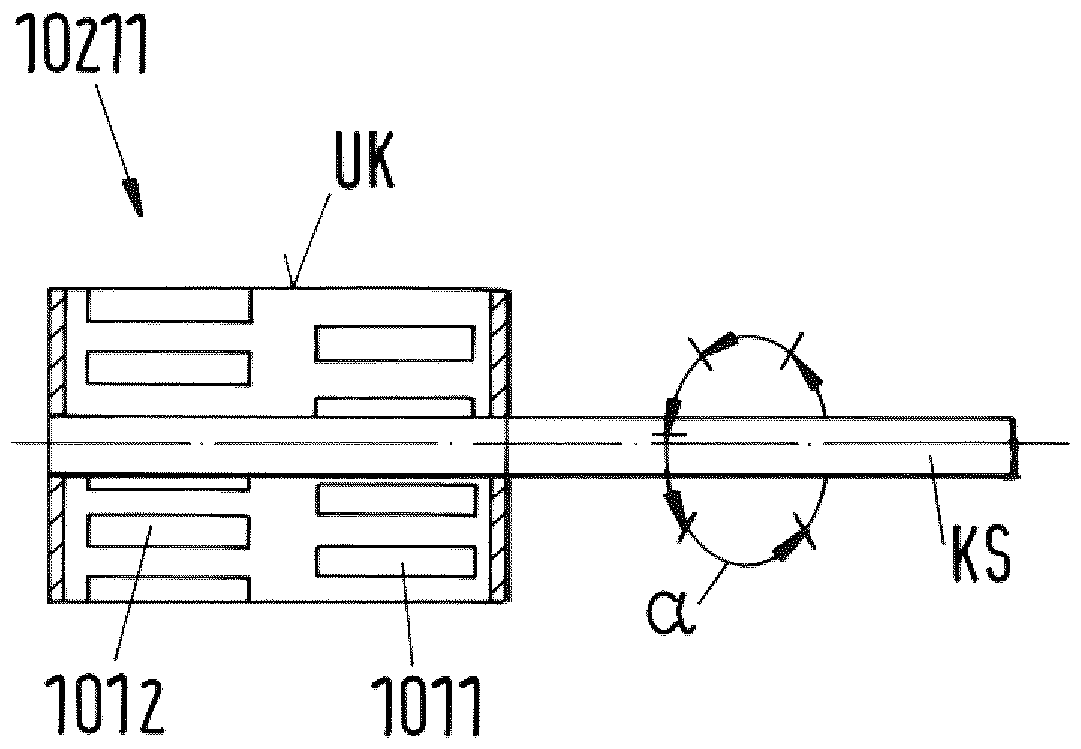

Pusher centrifuge

ActiveUS7032759B2Avoid disadvantagesWater/sewage treatment by centrifugal separationSlip couplingEngineeringPusher centrifuge

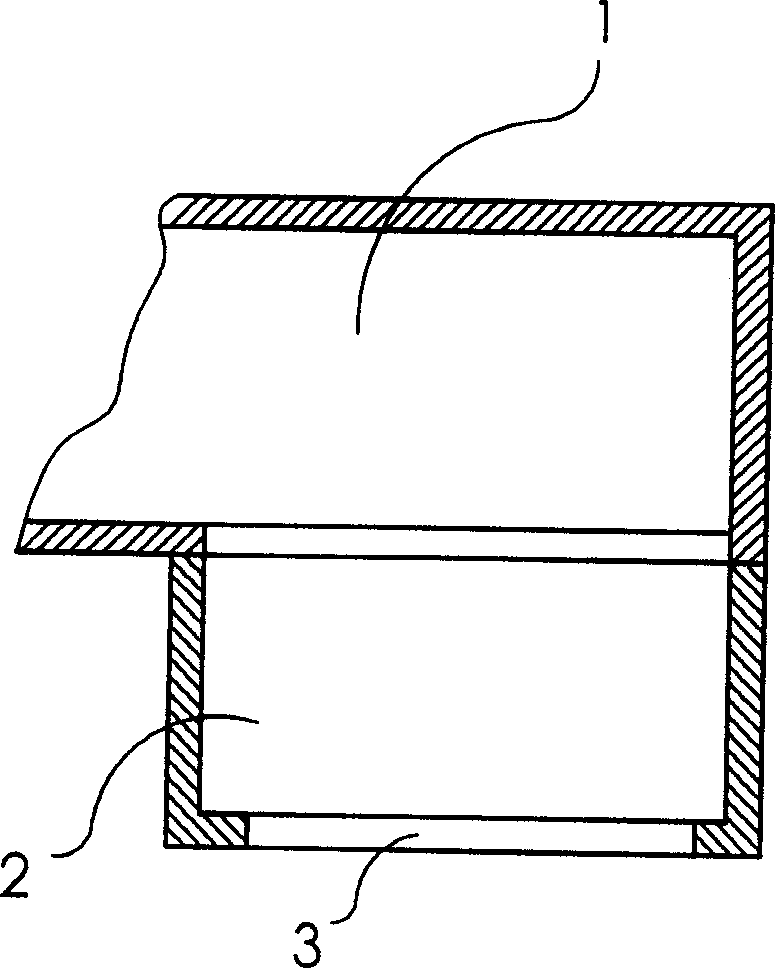

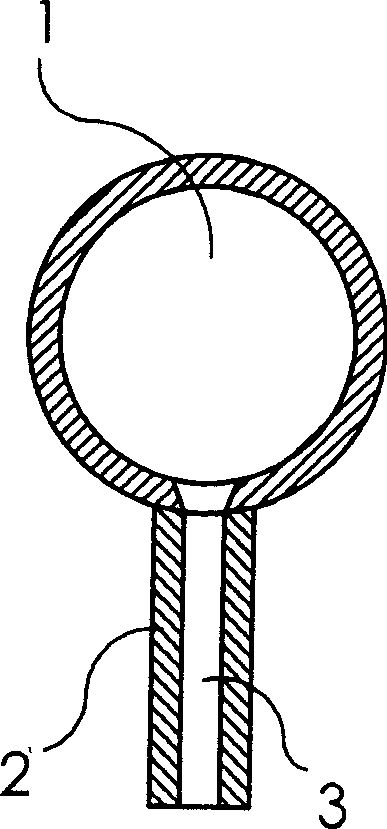

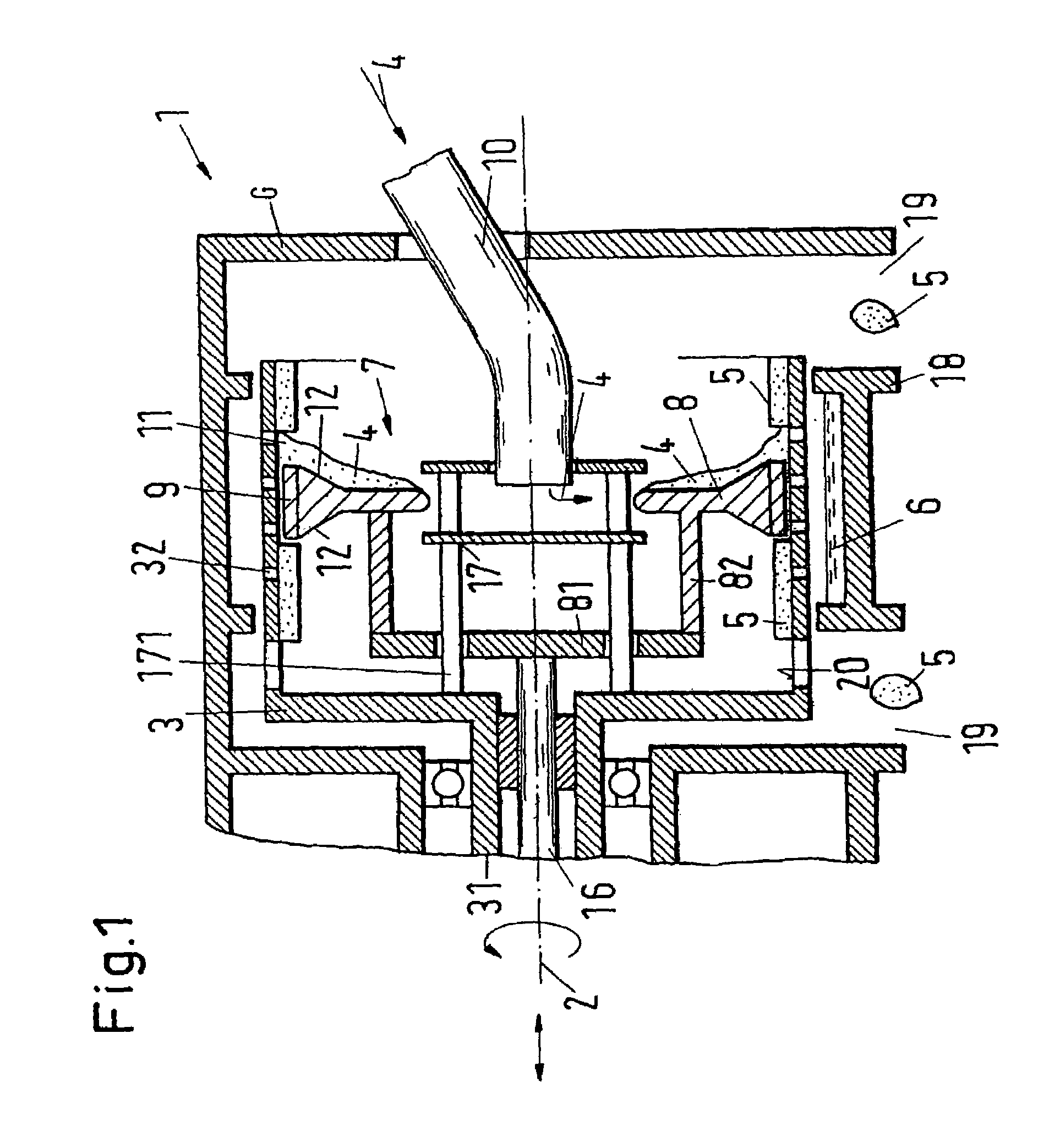

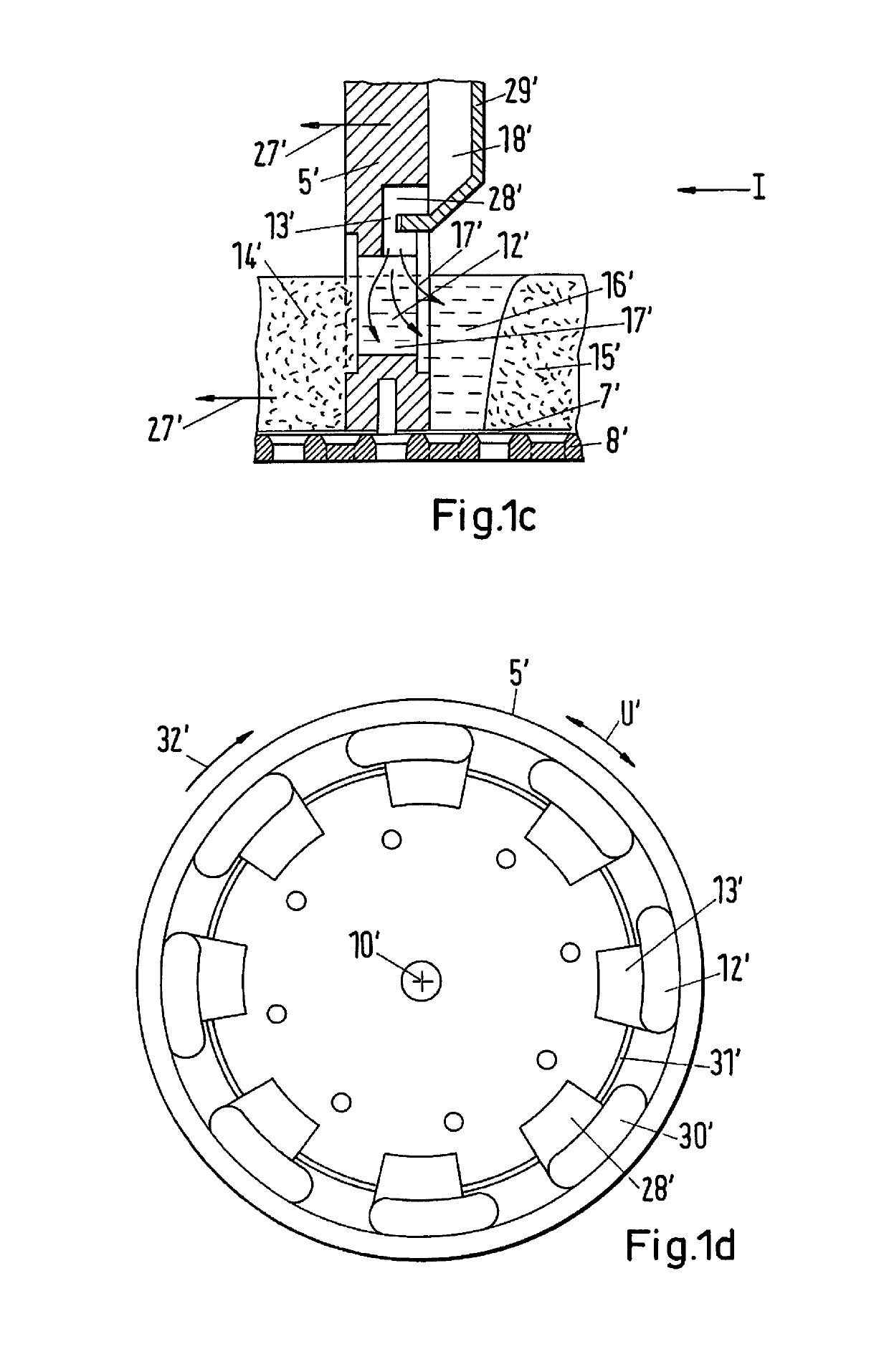

The invention relates to a pusher centrifuge (1) for the separation of a mixture (2) into a solid cake (3) and into a liquid phase (4). The pusher centrifuge (1) in accordance with the invention includes an outer screen drum (6) rotatable about an axis of rotation (5), a mixture distributor (7) arranged in the screen drum (6) with a pusher base apparatus (8) and an infeed device (9), with the pusher base apparatus (8) being arranged and designed such that the solid cake (3) is displaceable by means of the pusher base apparatus (8) and the mixture (2) can be introduced by the infeed device (9) via the mixture distributor (7) into an empty space (R) which arises on the displacement of the solid cake (3) by the pusher base apparatus (8). The mixture distributor (7) includes at least one funnel (10) for the pre-acceleration of the mixture (2), with the funnel (10) being rotatably arranged about a drive axis (11) and being rotatable at a pre-settable speed of rotation about the drive axis (11) by means of a drive (12).

Owner:FERRUM

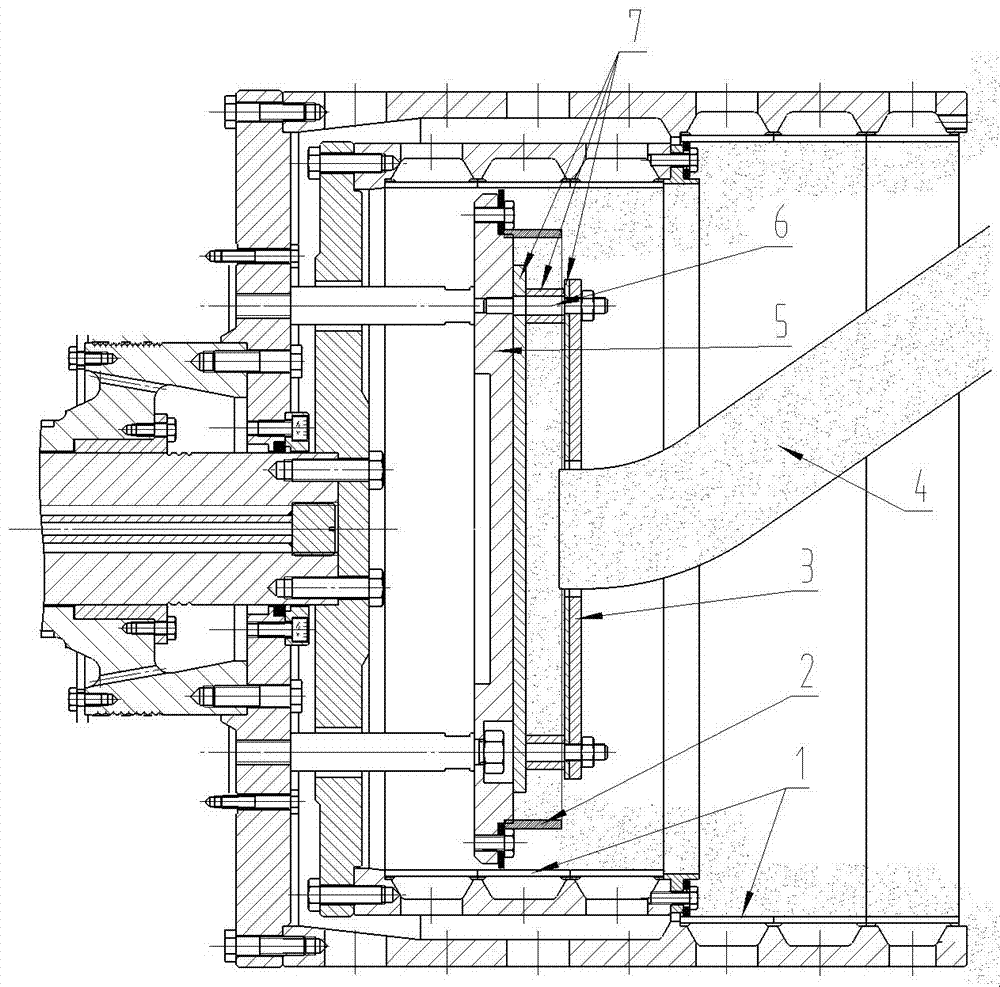

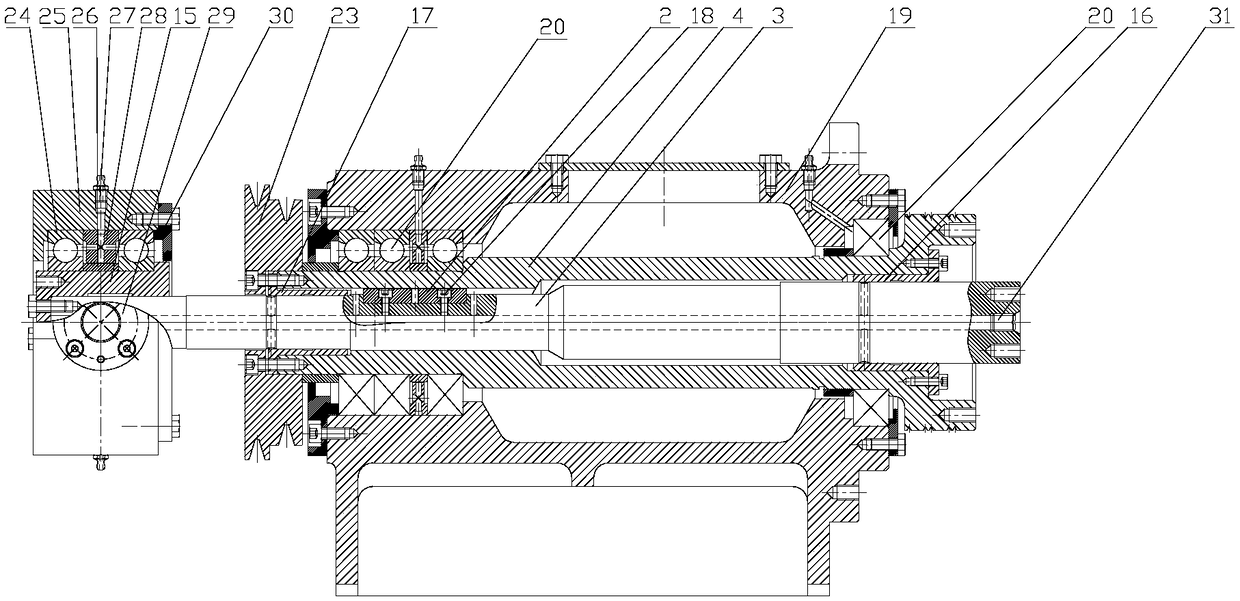

Three-stage piston pushing centrifuge drum device

InactiveCN109499782APlay a buffer roleReduce the amount of running materialRotary centrifugesIsosceles trapezoidThree stage

The invention discloses a three-stage piston pushing centrifuge drum device, and relates to the technical field of mechanical pushing centrifuges. The three-stage piston pushing centrifuge drum devicecomprises a first-stage drum, a second-stage drum and a third-stage drum; the third-stage drum is of a column taper structure, screen cloths in the three-stage piston pushing centrifuge drum device are all made of full-ceramic abrasion-resisting screen cloths; the effective filtering length of the first-stage screen cloth is 300-360 mm, the effective filtering length of the second-stage screen cloth is 360-420 mm, and the effective filtering length of the third-stage screen cloth is 300-360 mm; and a material distributing part in the three-stage piston pushing centrifuge drum device is of a truncated-cone-type structure, and the cross section of a material distributing hopper is in a isosceles trapezoid shape. The three-stage piston pushing centrifuge drum device is simple in structure, capable of conducting equipment maintaining conveniently and lowering the cost, large in drum centrifugal force, good in material dehydration water, large in screen cloth filtering area, capable of prolonging the service life of the screen cloths, and applicable to separation of fine powder materials and low-concentration suspension materials.

Owner:XIANGTAN HUIBO CENTRIFUGE

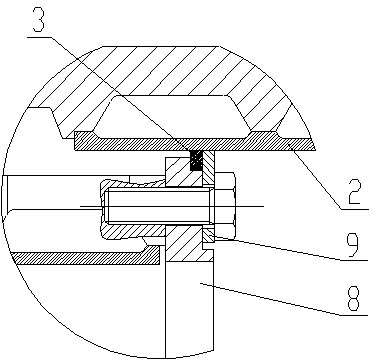

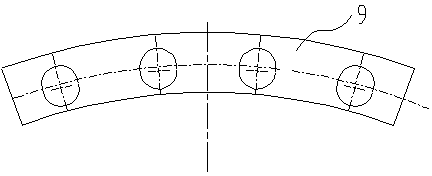

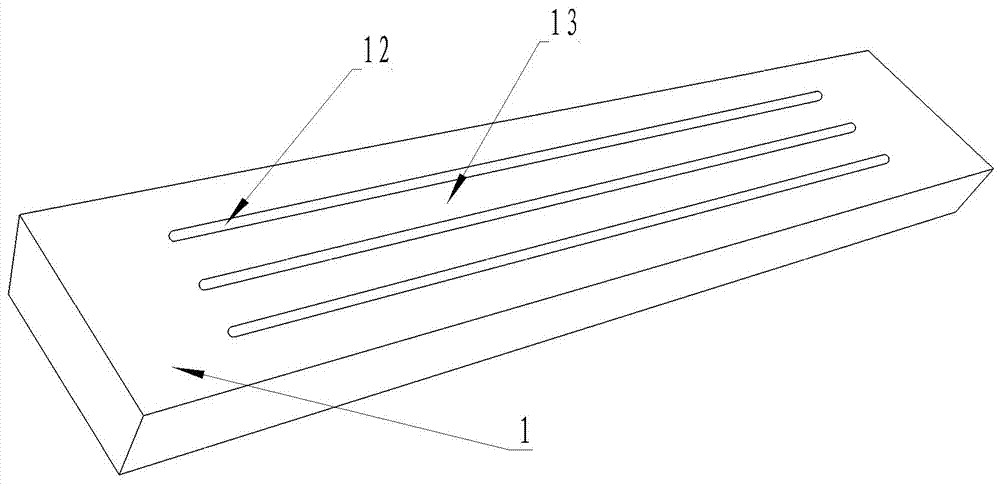

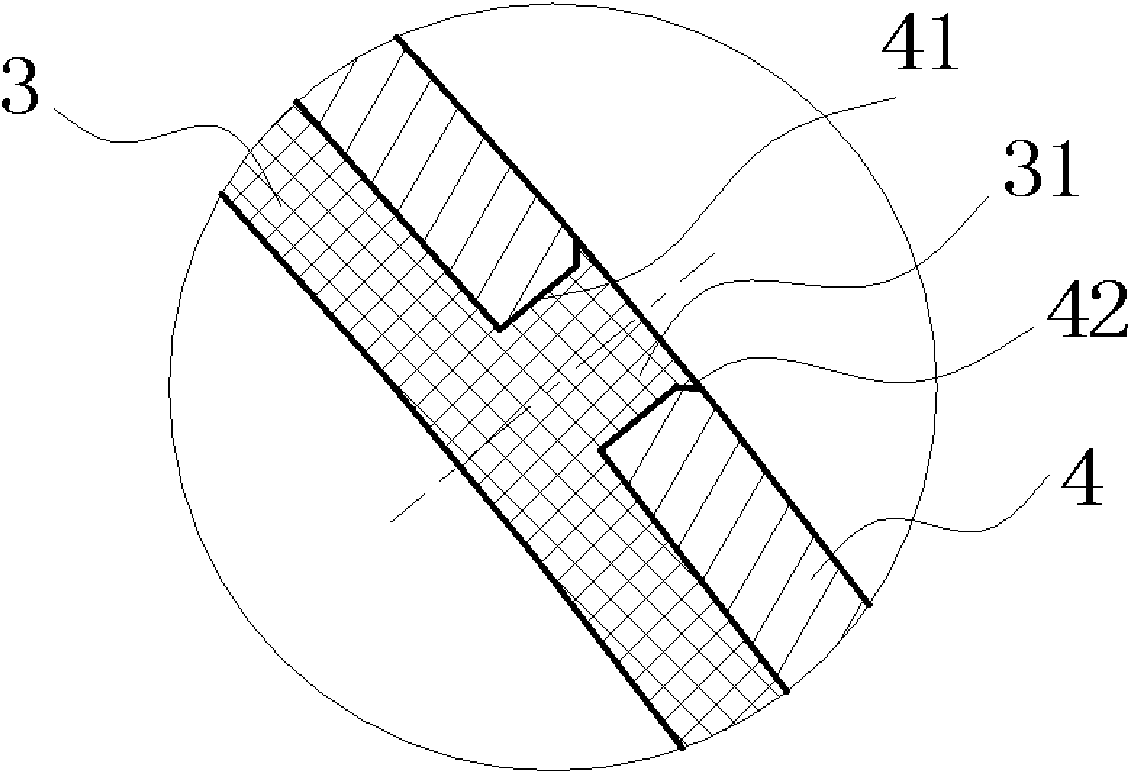

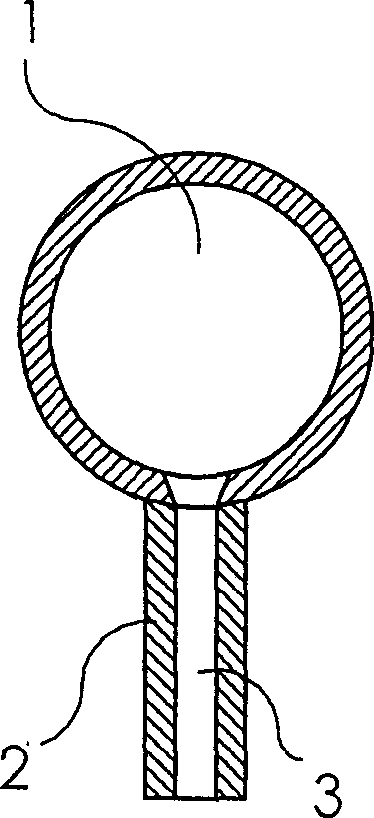

Material pushing piece of drum of material pushing centrifugal machine

ActiveCN103100491AExtended service lifePrevent movementCentrifugesPolyether ether ketoneMechanical engineering

The invention relates to the technical field of centrifugal machines, in particular to a material pushing piece of a drum of a material pushing centrifugal machine. The problems that a material pushing piece and a screening sieve are easily abraded and use cost is high in an existing material pushing centrifugal machine are solved. The material pushing piece of the drum of the material pushing centrifugal machine is characterized by comprising an arc press piece and a nose single piece. The arc press piece is an arc segment of a steel complete round and provided with threaded holes. The nose single piece is provided with an arc segment made of polyether-ether-ketone or polytef materials. Three protruded bodies are arranged on a place facing the center of the arc segment and the size of each protruded body is matched with a groove gap arranged in a material pushing ring of the drum. The arc press piece is matched with the nose single piece in length. During the centrifugal machine works for a long time, the centrifugal machine is tightly adhered to the screen sieve, whereas the screen sieve is not abraded. Materials are prevented from moving to the bottom of the drum and service life of the drum of the centrifugal machine is greatly prolonged.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

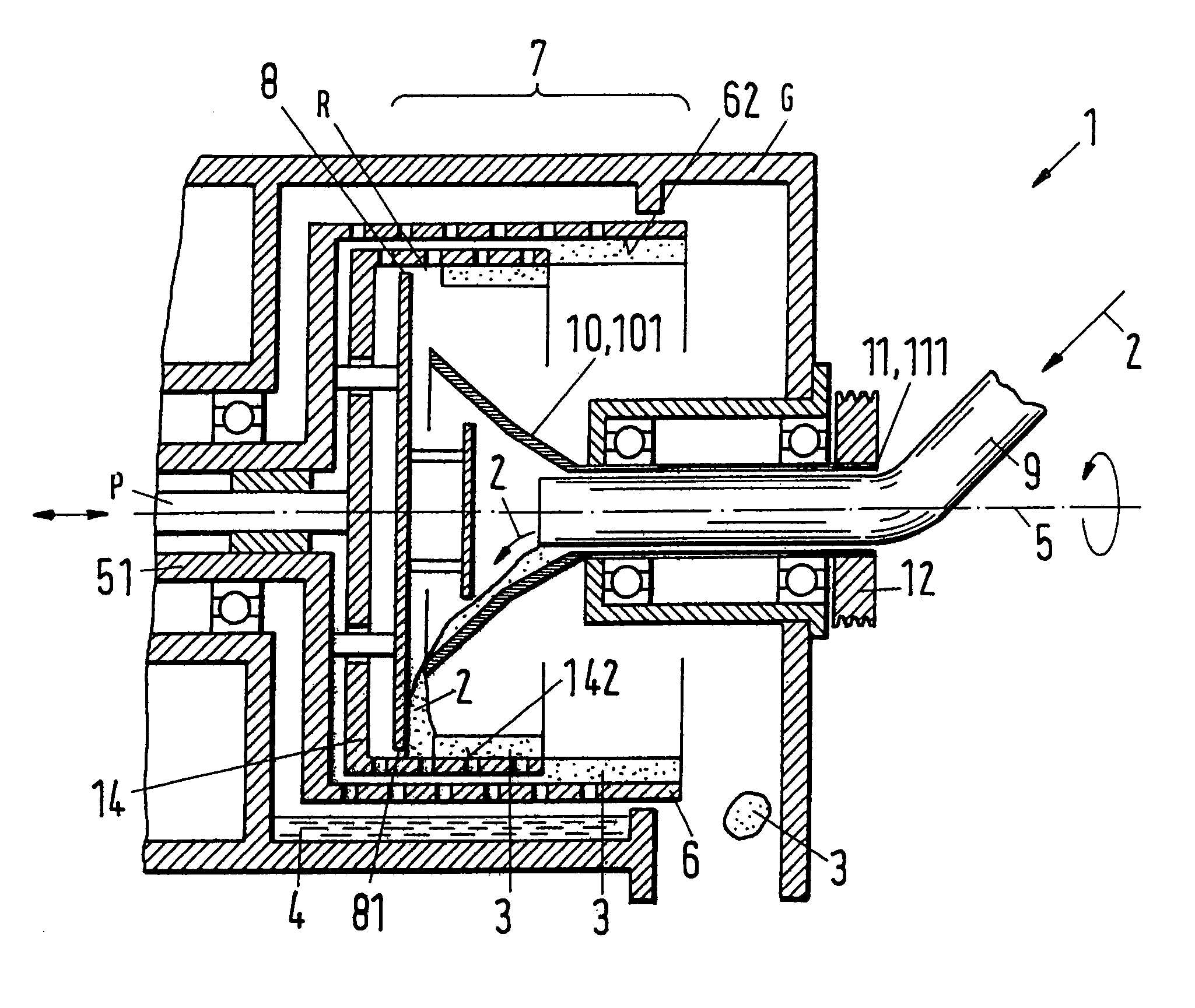

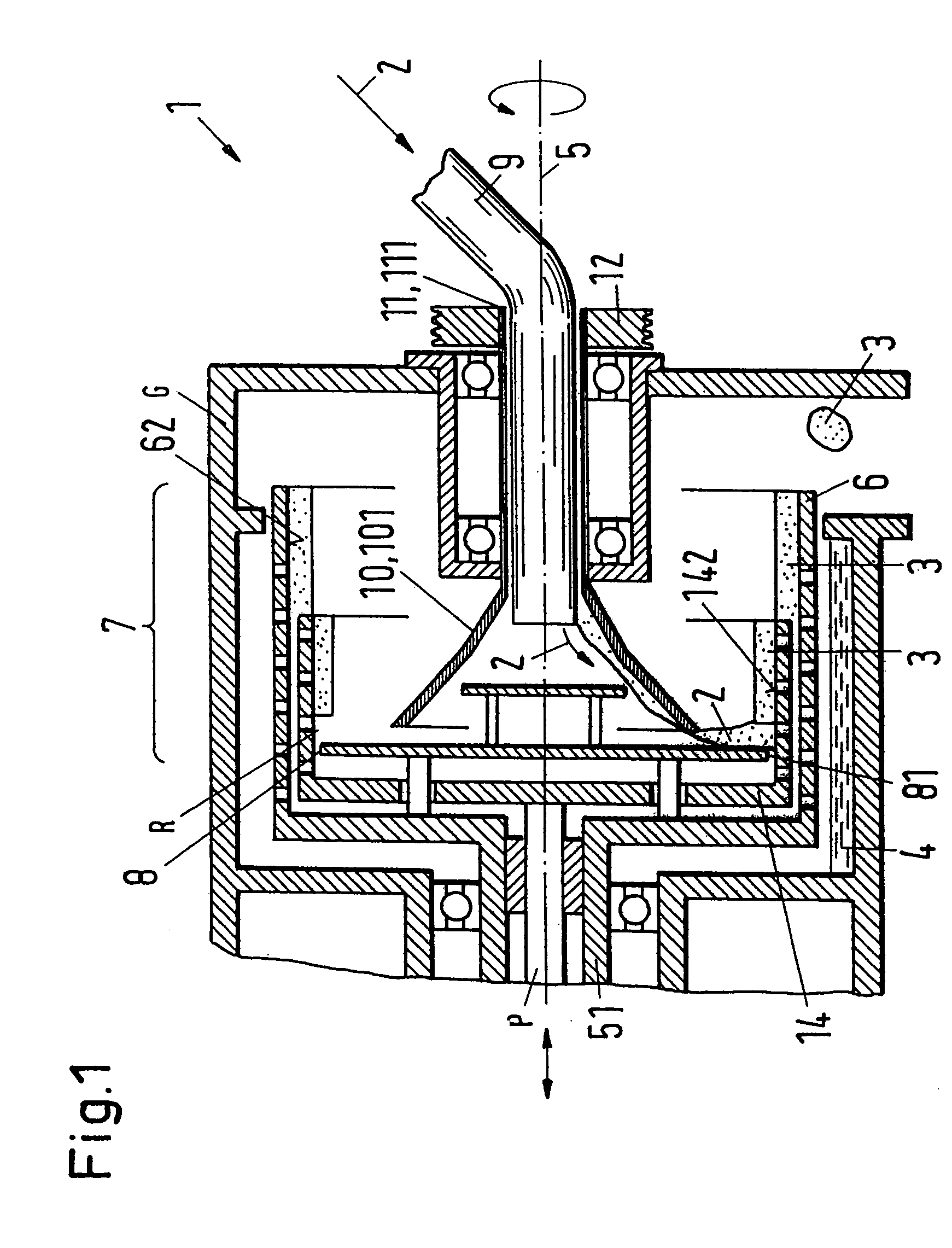

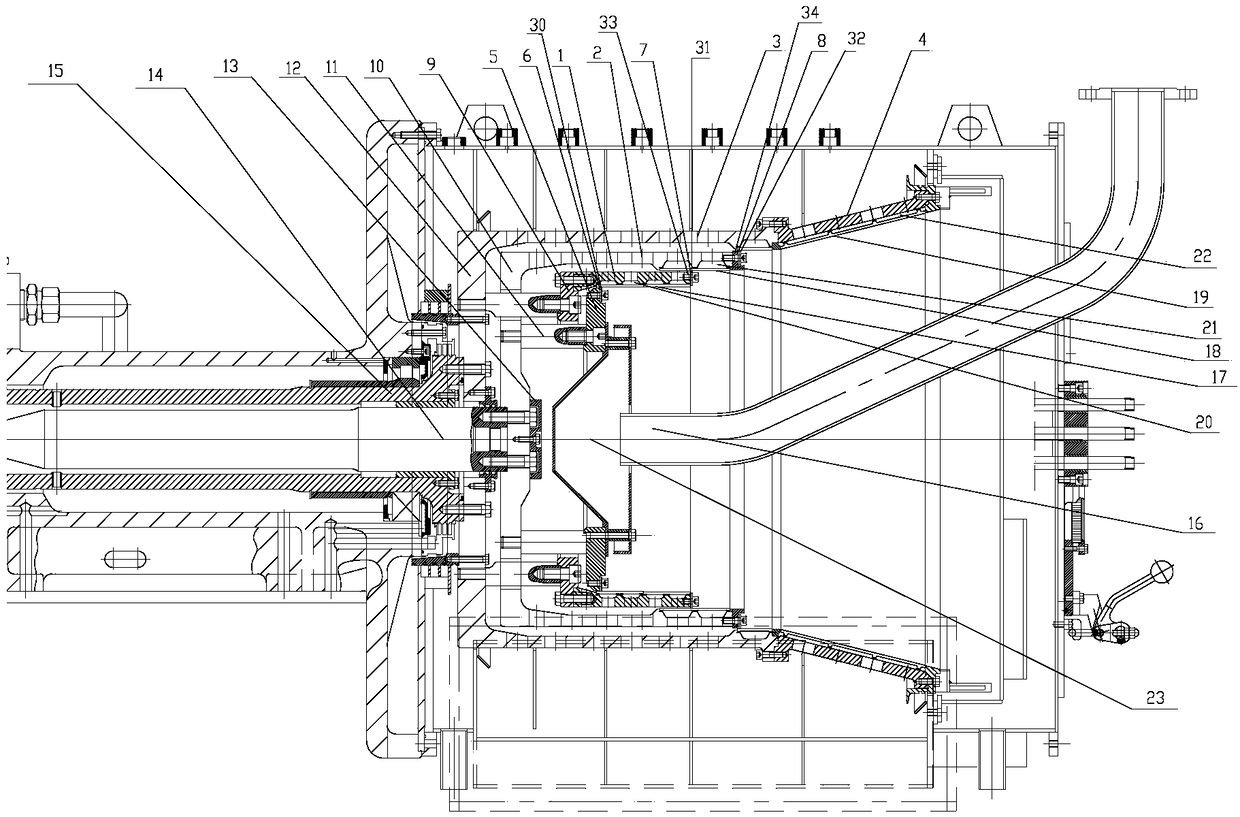

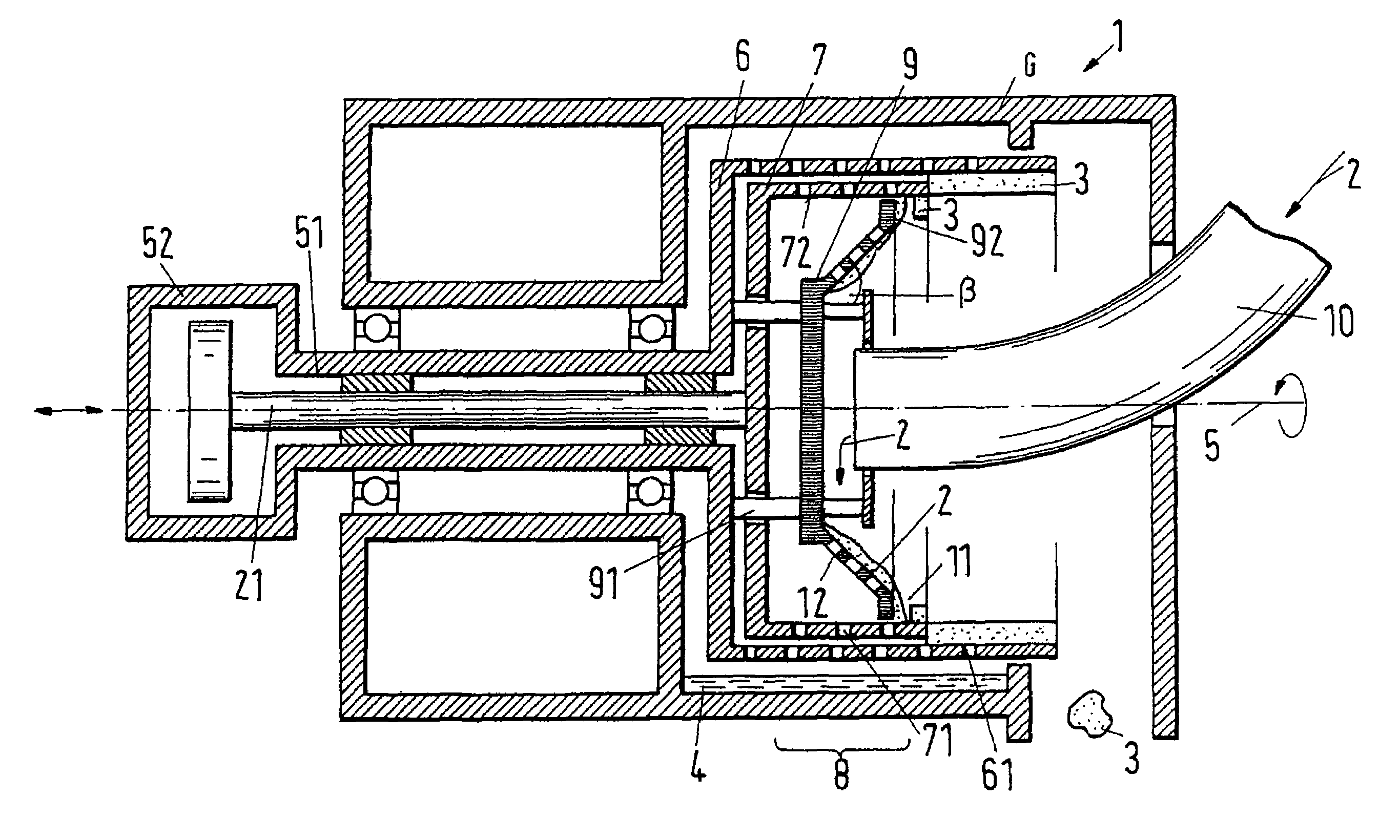

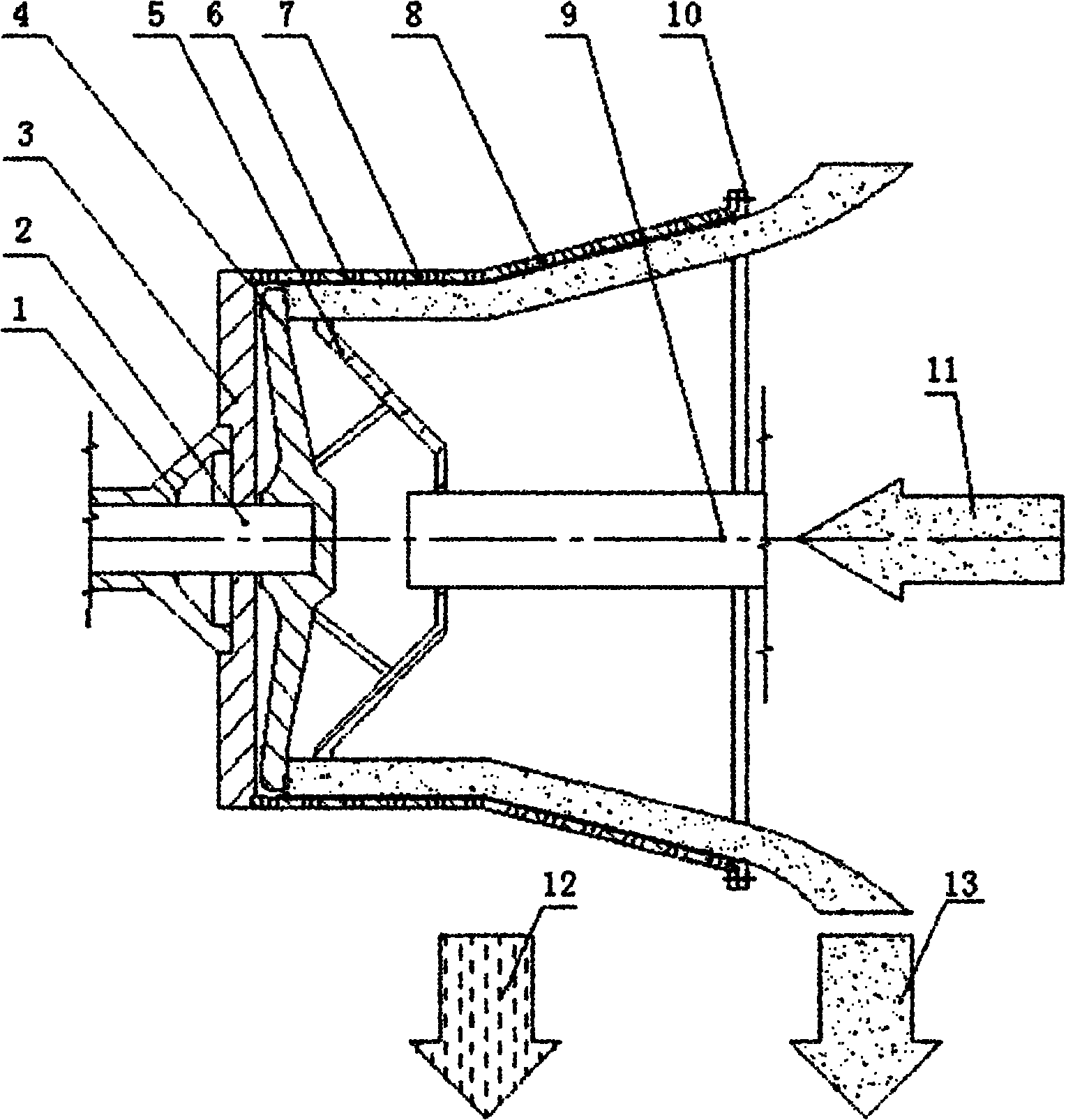

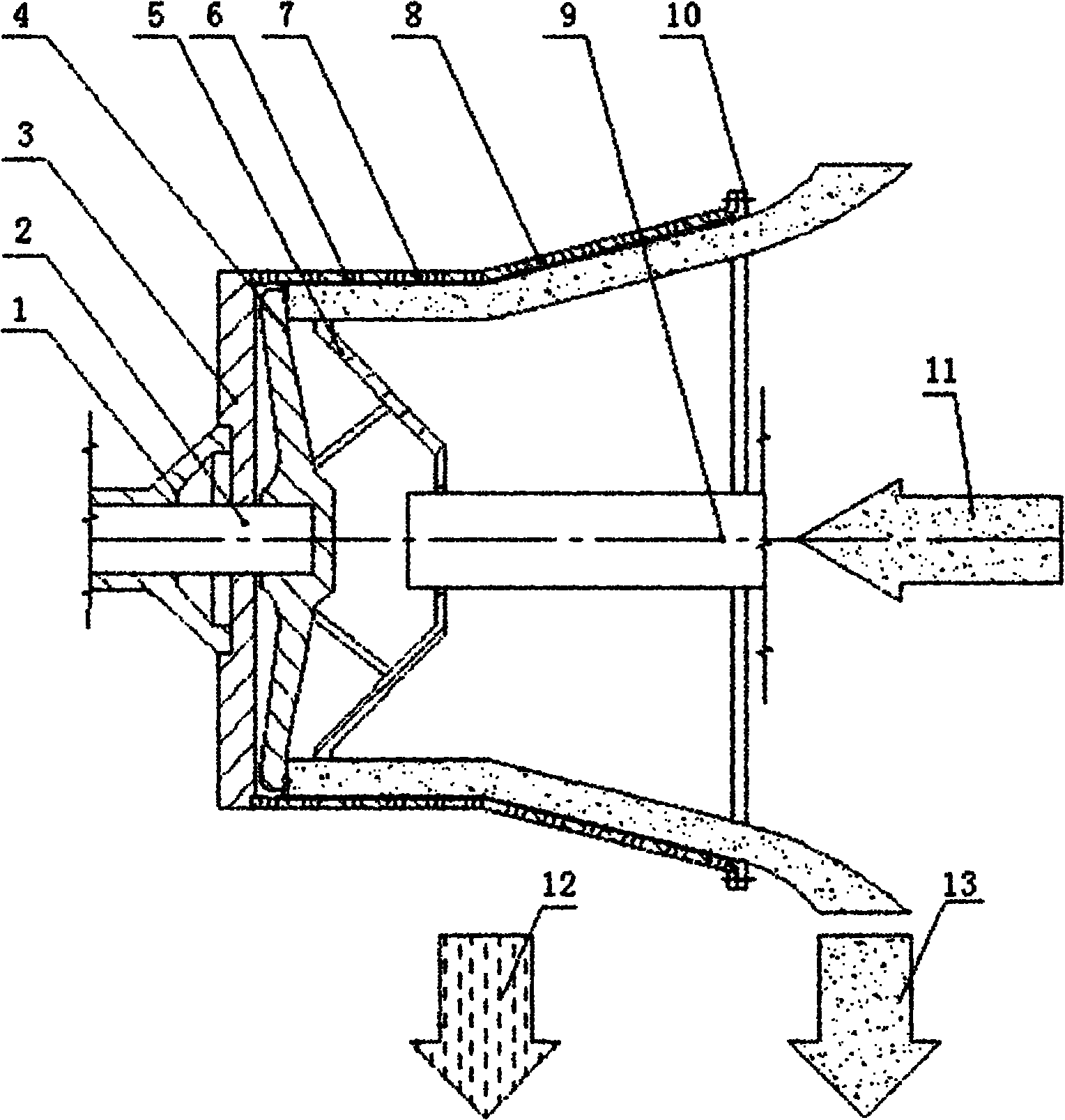

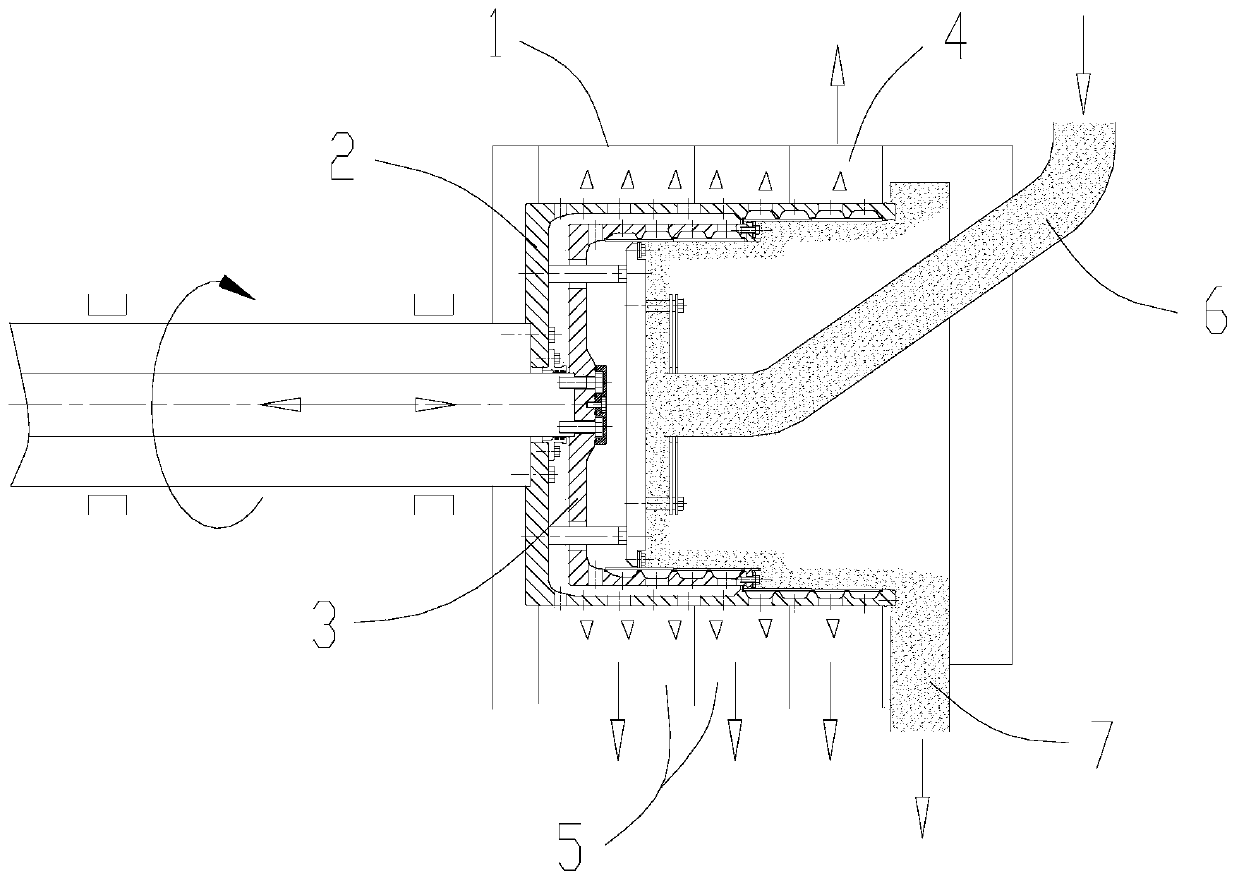

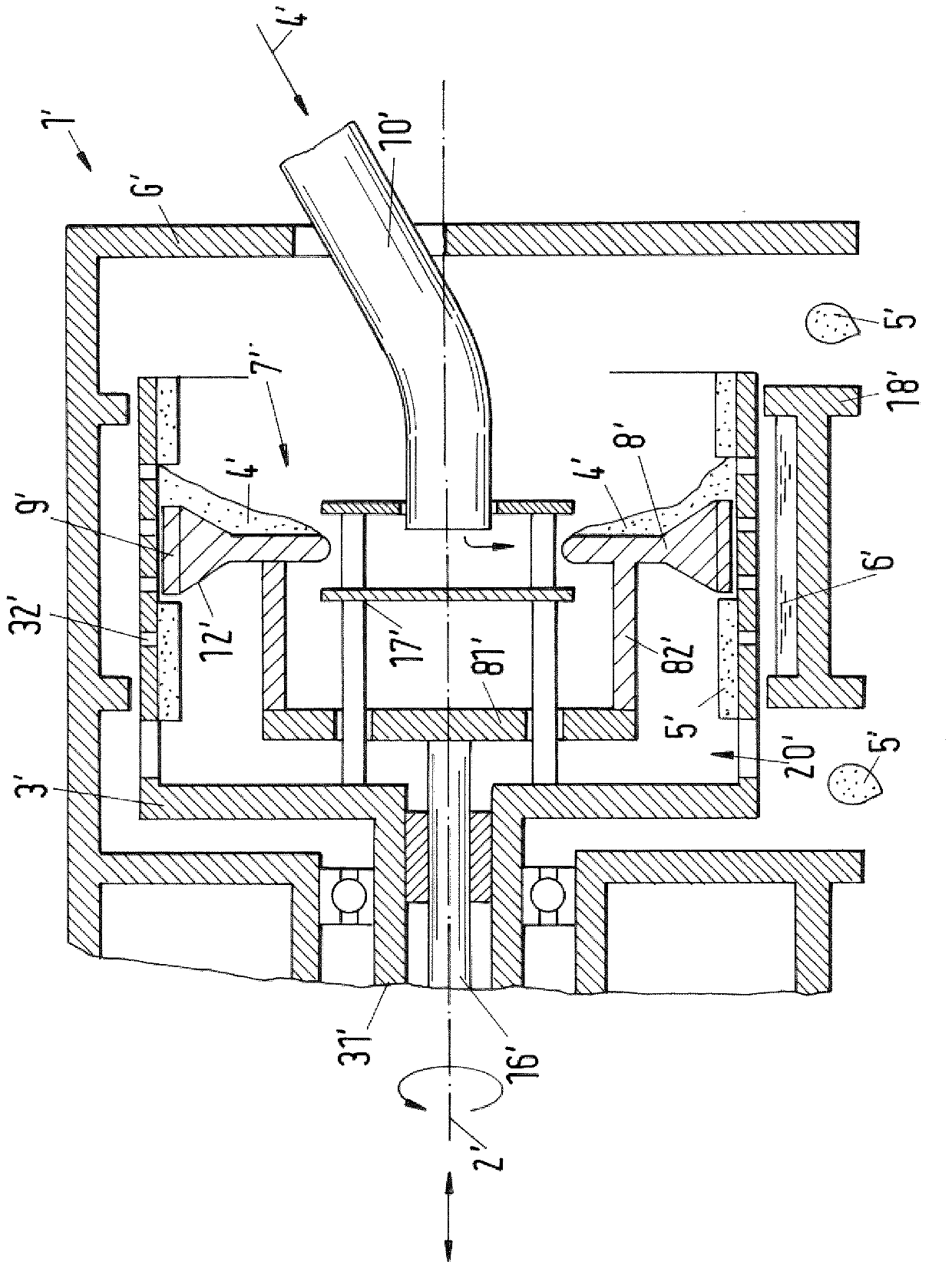

Multi-stage pusher centrifuge

ActiveUS7017756B2Avoid disadvantagesWater/sewage treatment by centrifugal separationSlip couplingPusher centrifugeEngineering

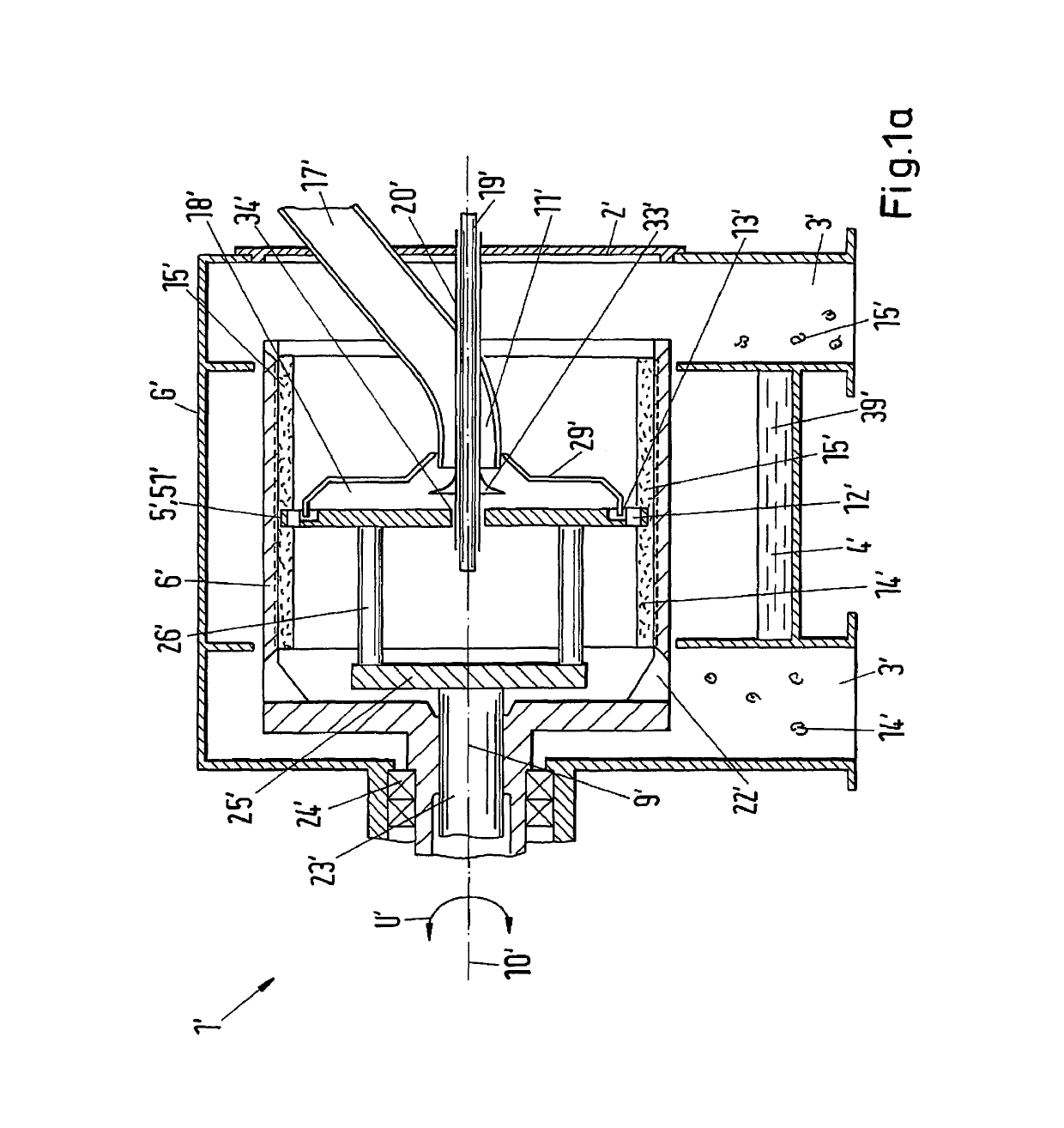

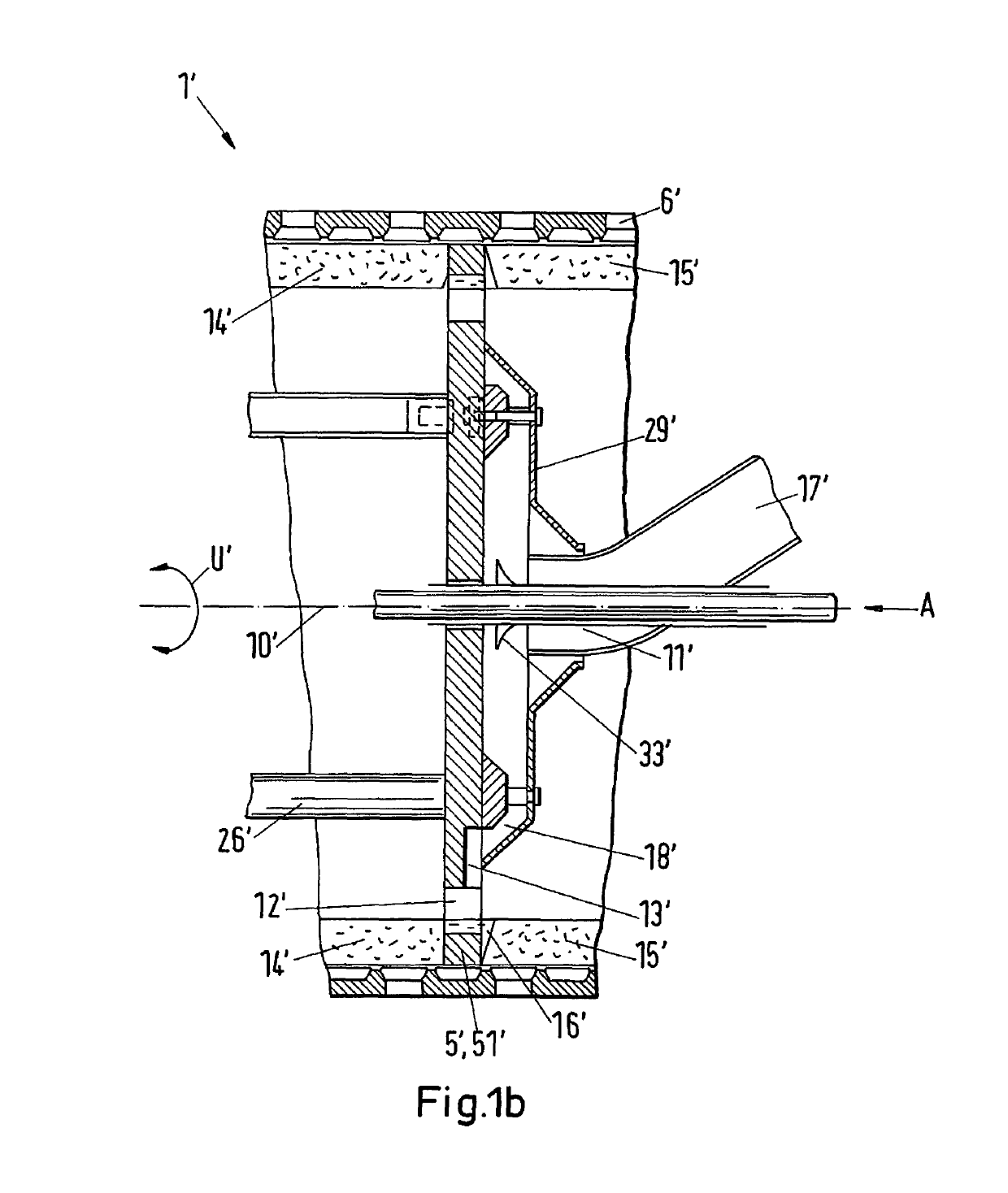

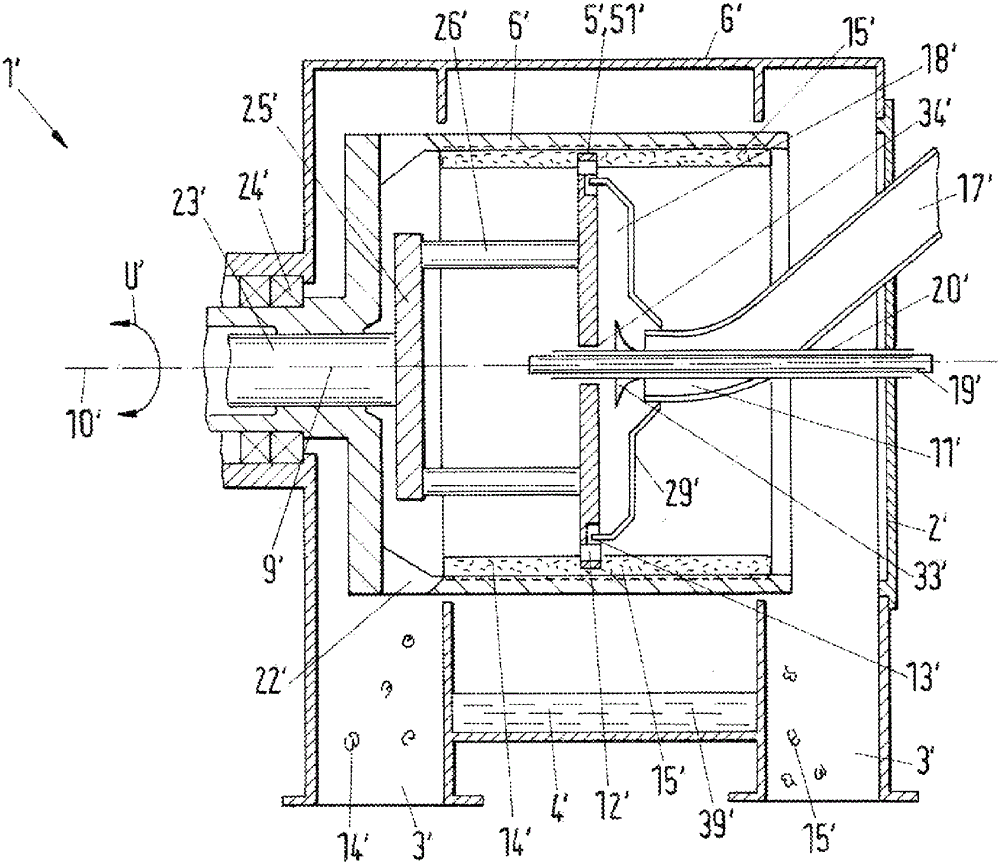

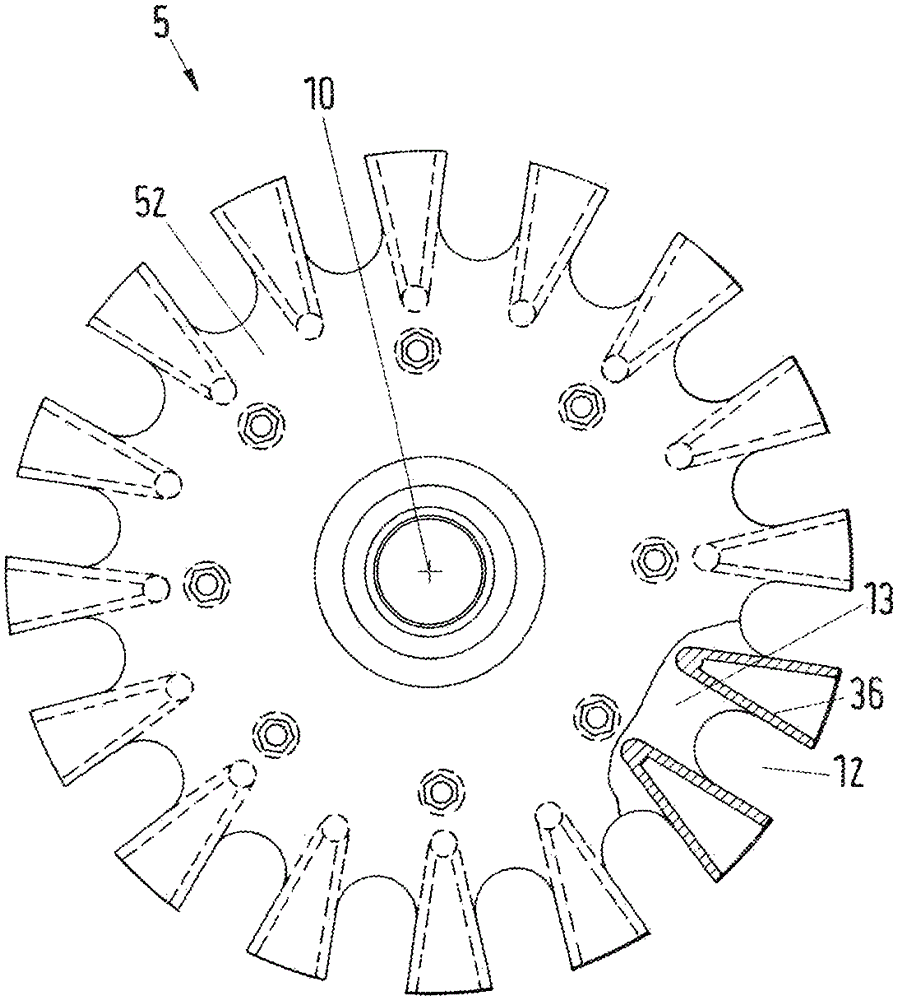

The invention relates to a multi-stage pusher centrifuge (1) for the separation of a mixture (2) into a solid cake (3) and into a liquid phase (4). The multi-stage pusher centrifuge (1) includes an outer screen drum (6) rotatable about an axis of rotation (5) and at least one screen stage (7) arranged in the outer screen drum (6), and a mixture distributor (8) arranged in the screen drum (6) with a pusher base apparatus (9), with either the screen stage (7) or the pusher base apparatus (9) being arranged movably to and fro along the axis of rotation (5) such that the solid cake (3) is displaceable by means of the pusher base apparatus (9). The multi-stage centrifuge further includes an infeed device (10) with which the mixture (2) can be introduced via the mixture distributor (8) into an empty space (11) which arises on the displacement of the solid cake (3) by the pusher base apparatus (9), with the pusher base apparatus (9) including a pre-acceleration funnel (12) which extends in a substantially divergent manner in the direction towards the infeed device (10) and the pre-acceleration funnel (12) being designed as a pre-acceleration screen (12).

Owner:FERRUM PROCESS SYST AG

Cone drum for piston pusher centrifuge

The invention relates to a piston pusher centrifuge, in particular to a novel cone drum for a piston pusher centrifuge. The cone drum comprises a wheel disc connected with a main shaft, and a drum body is connected with the wheel disc by using screws to form the drum of the centrifuge. The drum body is formed by combining a cylindrical barrel and a conical barrel, and screen cloths are laid on the inner circumferential surfaces of the cylindrical barrel and the conical barrel. A pusher disc is fixed on one end of a push rod, the pusher disc and the push rod respectively penetrate in the main shaft and the drum body, a distributing device is connected to the pusher disc through a plurality of ribs, and a material inlet pipe is fixed on a solid and liquid tank of the centrifuge. The invention integrates the advantages of a centrifugal unloading centrifuge and the piston pusher centrifuge, and the centrifuge has the advantages of simple structure, low manufacturing and maintenance cost, large use range, improved centrifugation performance and reduced energy consumption.

Owner:CHENGDU TIANBAO HEAVY IND

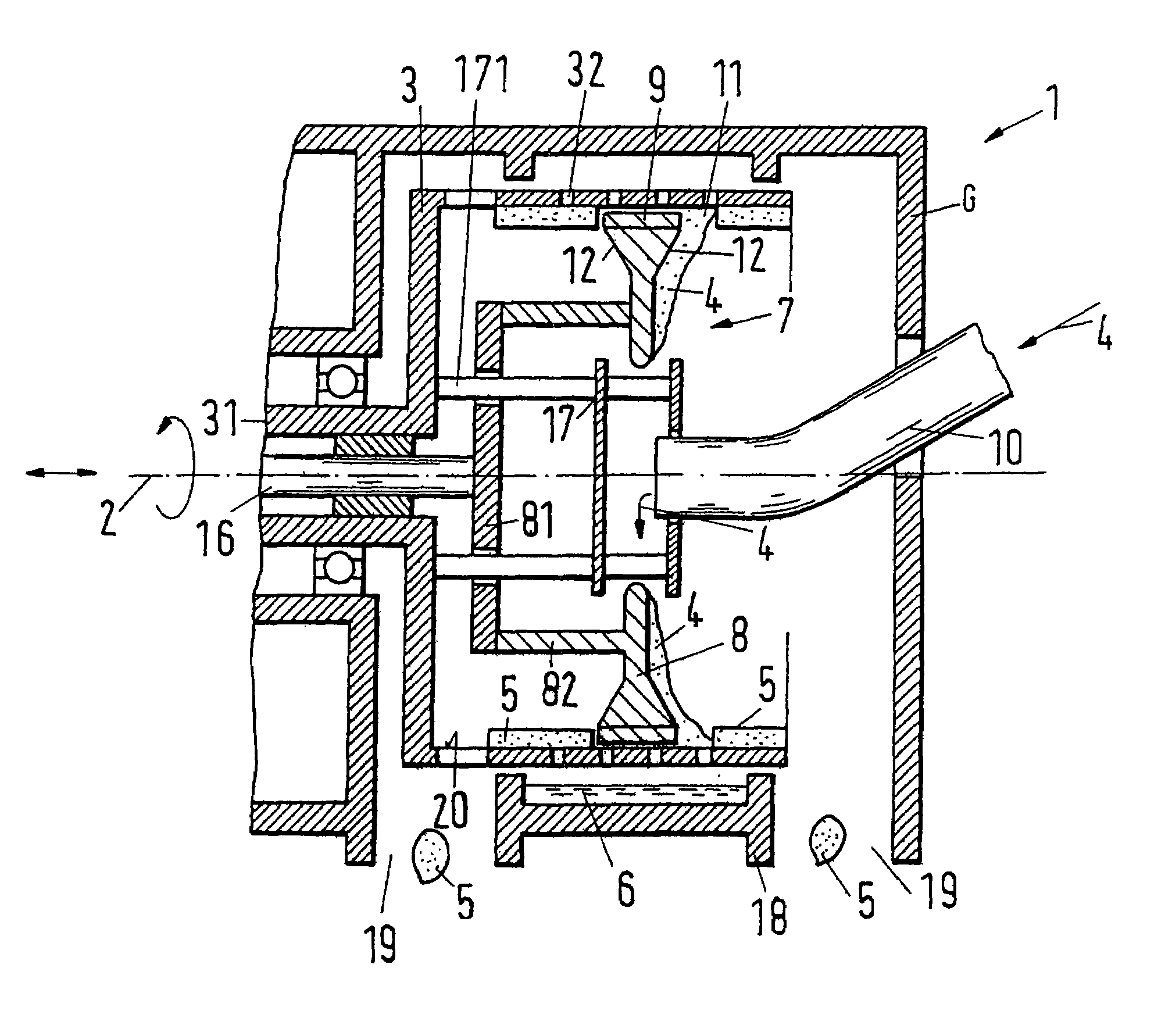

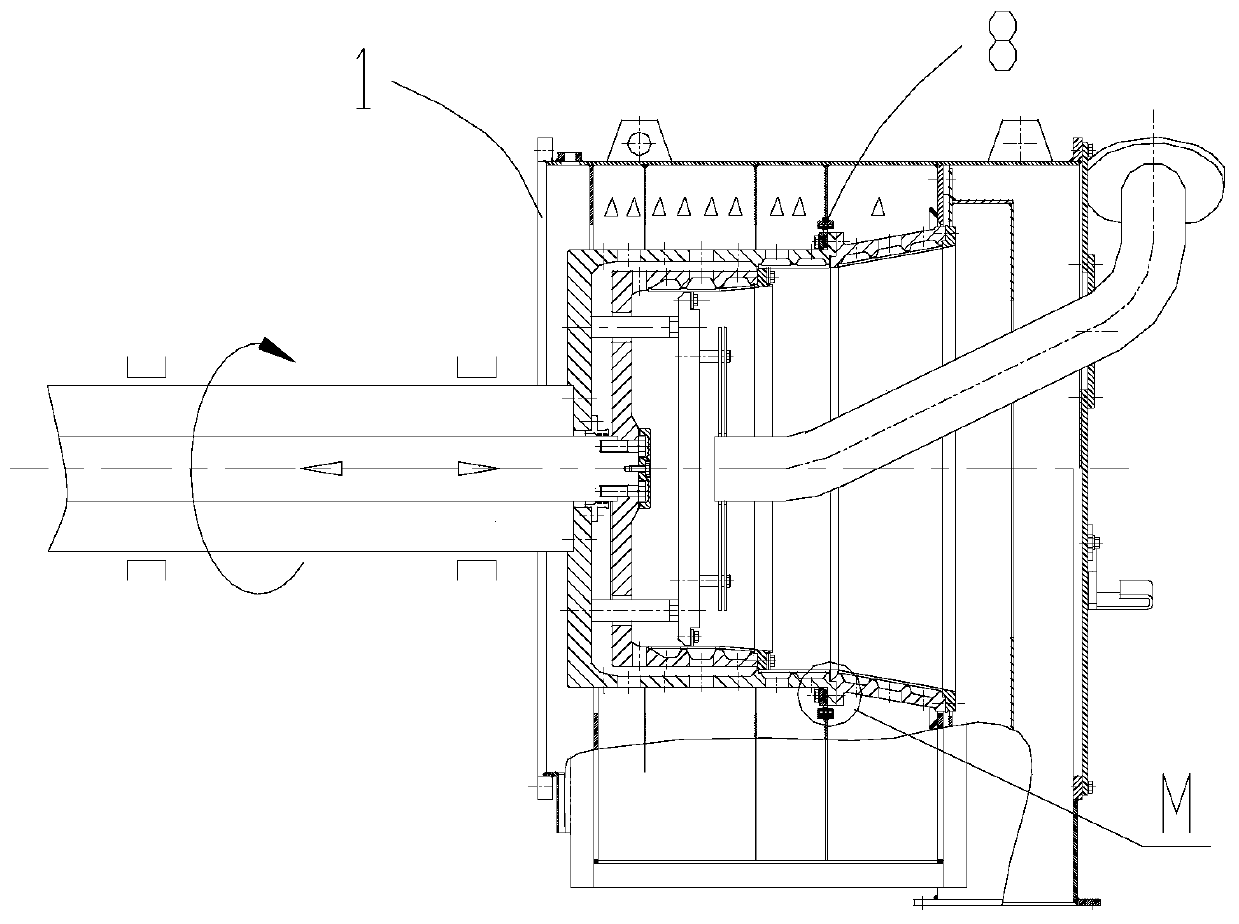

Double pusher centrifuge

ActiveUS7025211B2Varying degree of efficiencyPoor sliding propertyWater/sewage treatment by centrifugal separationSlip couplingEngineeringDistributor

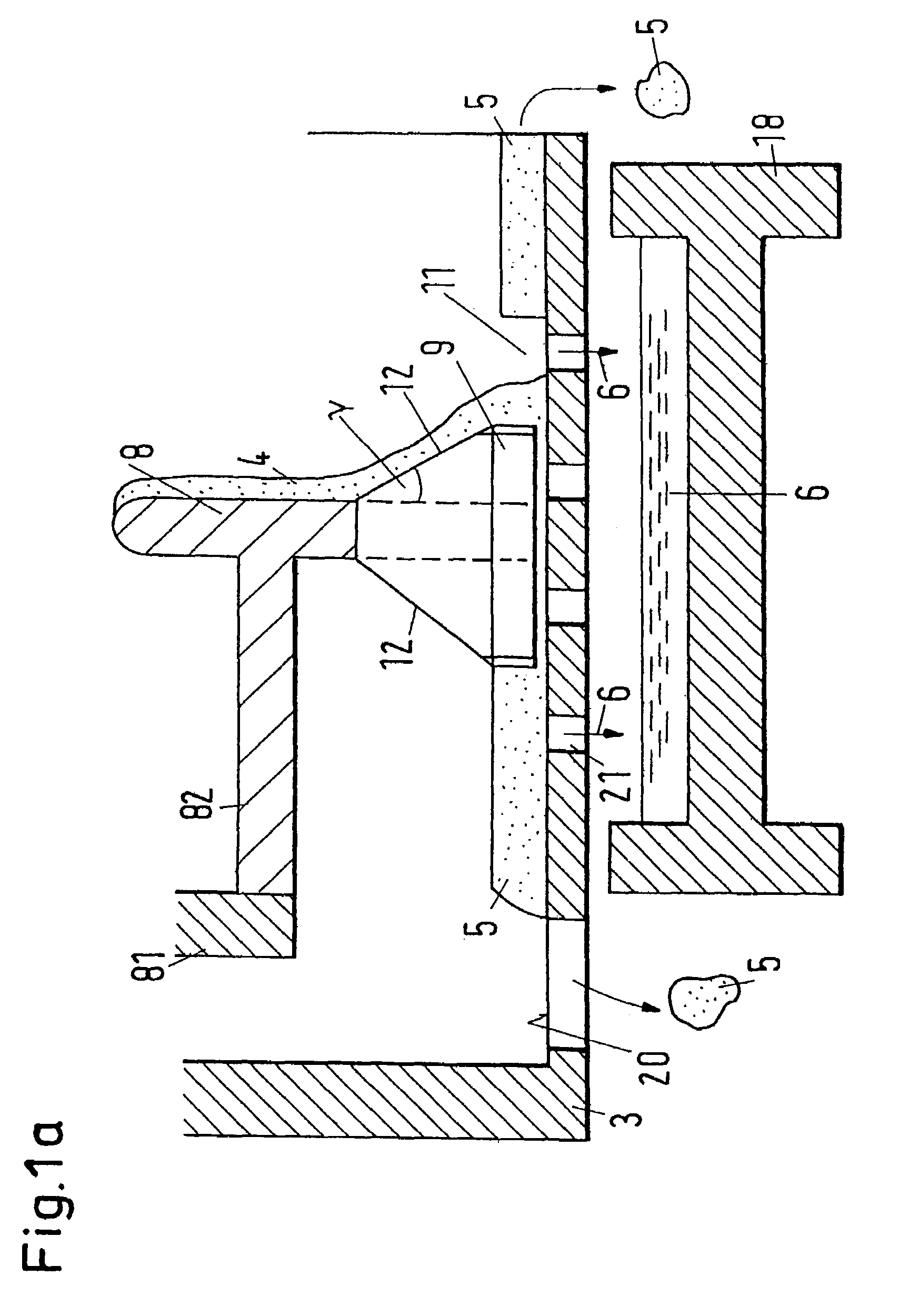

The invention relates to a double pusher centrifuge including a screen drum (3) rotatable about an axis of rotation (2) for separating a mixture (4) into a solid material cake (5) and a liquid phase (6), a mixture distributor (7) arranged in the screen drum (3) and having a pusher base device (8), which is arranged to be movable to and fro along the axis of rotation (2), so that the solid material cake (5) is alternately displaceable with an outer ring zone (9). Furthermore, the double pusher centrifuge includes an infeed device (10) with which the mixture (4) can be introduced via the mixture distributor (7) into an empty space (11), which arises adjacent to the outer ring zone (9) on displacement of the solid material cake (5) by the pusher base device (8). In this arrangement the pusher base device (8) has acceleration surfaces (12) on both sides, which are inclined at a pre-determinable angle of inclination (γ) with reference to the radial direction, so that the mixture (4) introduced by the infeed device (10) can be accelerated to a pre-determinable peripheral speed before reaching the screen drum (3).

Owner:FERRUM

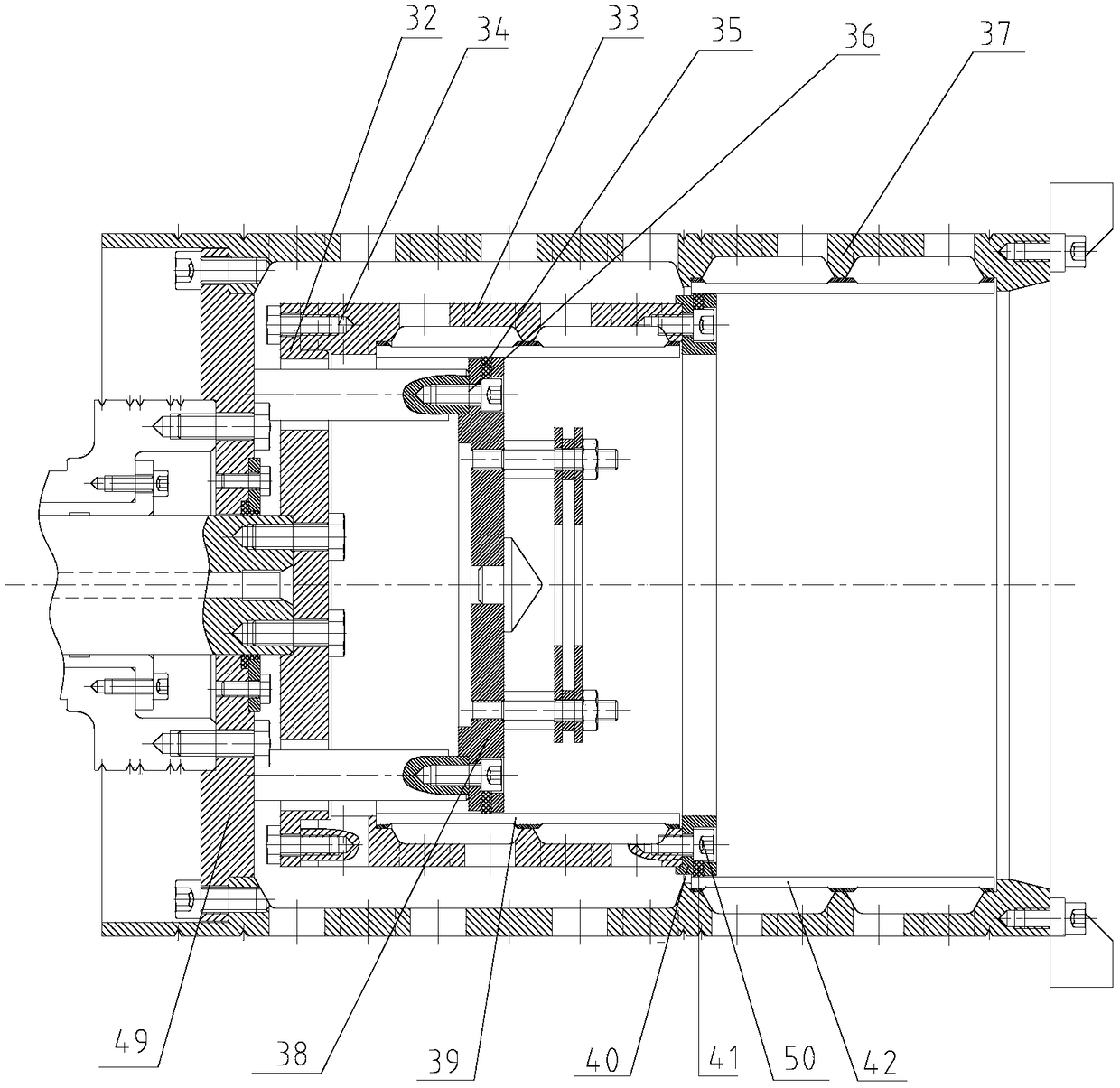

Double-action pusher centrifuge and pusher base device

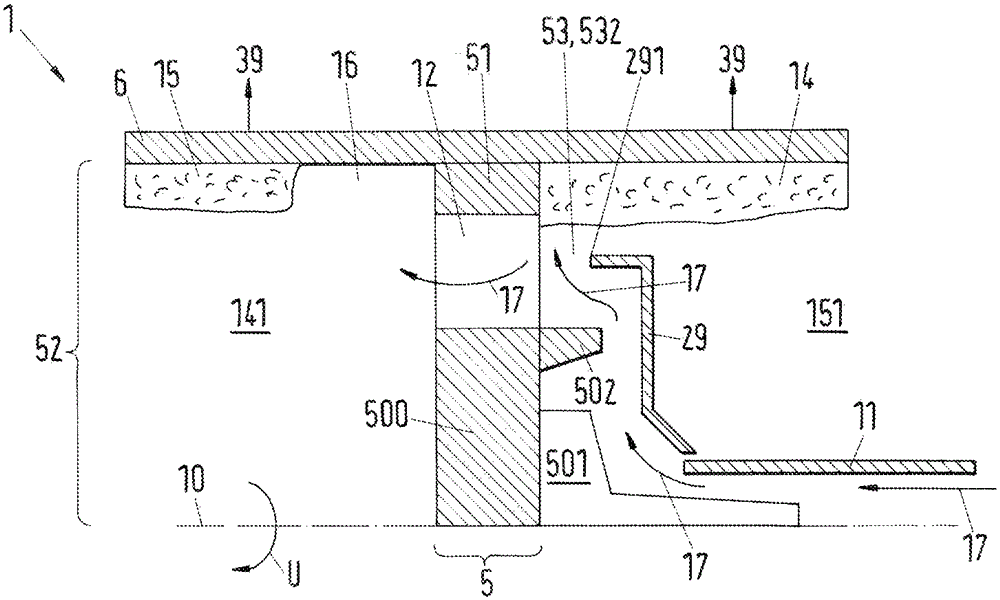

ActiveUS10363500B2Increase heightEasy to wearDispersed particle separationRotary centrifugesEngineeringMechanical engineering

A double-action pusher centrifuge separates a mixture into solid cake and liquid. The pusher centrifuge includes a screen drum rotatable about an axis and in which a pusher base device is arranged to be movable along the axis of rotation. The solid cake is displaced by an outer ring region of the pusher base device. A plurality of axial passage openings are disposed in the outer ring region and connect front and rear regions of the screen drum. A feed unit is arranged at an inflow disk such that the mixture can be introduced via the feed unit and the inflow disk into empty space on the screen drum on displacement of the solid cake. An inflow gap applies the mixture into the empty space, and is between an inflow edge of the inflow disk and a pusher base plate of the pusher base device with an inflow region.

Owner:FERRUM PROCESS SYST AG

Double-action pusher centrifuge and pusher base device

ActiveCN105268562AAvoid disadvantagesAvoid problemsDispersed particle separationRotary centrifugesMechanical engineeringPusher centrifuge

A double-action pusher centrifuge separates a mixture into solid cake and liquid. The pusher centrifuge includes a screen drum rotatable about an axis and in which a pusher base device is arranged to be movable along the axis of rotation. The solid cake is displaced by an outer ring region of the pusher base device. A plurality of axial passage openings are disposed in the outer ring region and connect front and rear regions of the screen drum. A feed unit is arranged at an inflow disk such that the mixture can be introduced via the feed unit and the inflow disk into empty space on the screen drum on displacement of the solid cake. An inflow gap applies the mixture into the empty space, and is between an inflow edge of the inflow disk and a pusher base plate of the pusher base device with an inflow region. The present invention also relates to a pusher base device for the double-action pusher centrifuge.

Owner:FERRUM SEPARATION TECH GMBH

Double-action pusher centrifuge and pusher base device

ActiveUS20150367260A1Wear minimizationEqually distributedWater/sewage treatment by centrifugal separationDispersed particle separationEngineeringMechanical engineering

A double-action pusher centrifuge separates a mixture into solid cake and liquid. The pusher centrifuge includes a screen drum rotatable about an axis and in which a pusher base device is arranged to be movable along the axis of rotation. The solid cake is displaced by an outer ring region of the pusher base device. A plurality of axial passage openings are disposed in the outer ring region and connect front and rear regions of the screen drum. A feed unit is arranged at an inflow disk such that the mixture can be introduced via the feed unit and the inflow disk into empty space on the screen drum on displacement of the solid cake. An inflow gap applies the mixture into the empty space, and is between an inflow edge of the inflow disk and a pusher base plate of the pusher base device with an inflow region.

Owner:FERRUM PROCESS SYST AG

Anti-leakage sealing method of double-stage material push centrifugal machine

ActiveCN110388465AEasy to adjustEasy to controlEngine sealsRotary centrifugesStopped workEngineering

The invention discloses an anti-leakage sealing method of a double-stage material push centrifugal machine. The anti-leakage sealing method is characterized in that negative pressure is generated in aliquid cavity between a housing and an outer rotary drum so that in the process that an inner rotary drum does an axial reciprocating action during work of the centrifugal machine, the pressure of asolid cavity is larger than or equal to the pressure of the liquid cavity all the time; and the part, where the negative pressure is generated, of the liquid cavity is located in a drying area corresponding to an outer rotary drum filter cake concentrating part. In the working process of the centrifugal machine, the phenomenon that liquid in the liquid cavity back flows to a solid collecting cavity through a baffle, and the solid moisture percentage is increased is avoided or reduced, and therefore the solid-liquid separation effect is improved; and when the centrifugal machine stops working,an external negative-pressure pump system does not affect work such as demounting of a centrifugal machine body at all, a dynamic sealing device also retracts to reset under the effect of an elastic part, a certain distance is maintained between the dynamic sealing device and the housing, and demounting of the housing is not affected as well.

Owner:ZHEJIANG QINGJI IND +1

Anti-corrosion and abrasion resisting device of piston material pushing centrifugal machine

PendingCN107442299AAvoid contactHigh hardnessRotary centrifugesMohs scale of mineral hardnessStrong acids

The invention discloses an anti-corrosion and abrasion resisting device of a piston material pushing centrifugal machine. An abrasion resisting plastic lining, an abrasion resisting ring and a ceramic sieve net are arranged on an overflow channel of the centrifugal machine, and therefore high-hardness strong-acid materials are prevented from making contact with a metal component; material impact and abrasion are relieved through the abrasion resisting ring; the service cycle of the sieve net is obviously prolonged through the high hardness (the Moh's hardness 9) and the corrosion resisting character of the ceramic sieve net; the anti-corrosion and abrasion resisting device is mainly applied to quartz sand (the Moh's hardness 7) and strong-corrosivity materials, the corrosion and abrasion overlapping destructive power is reduced to the minimum, and the service life of the machine is greatly prolonged.

Owner:覃湘

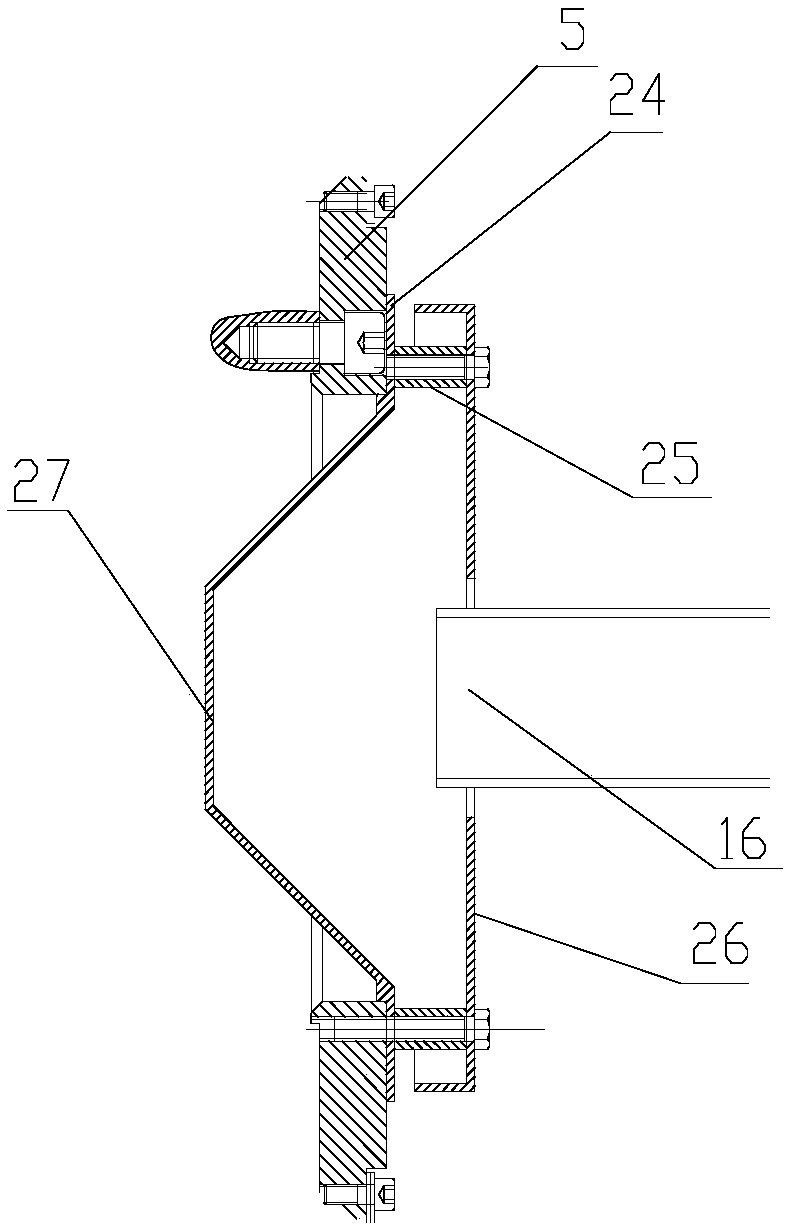

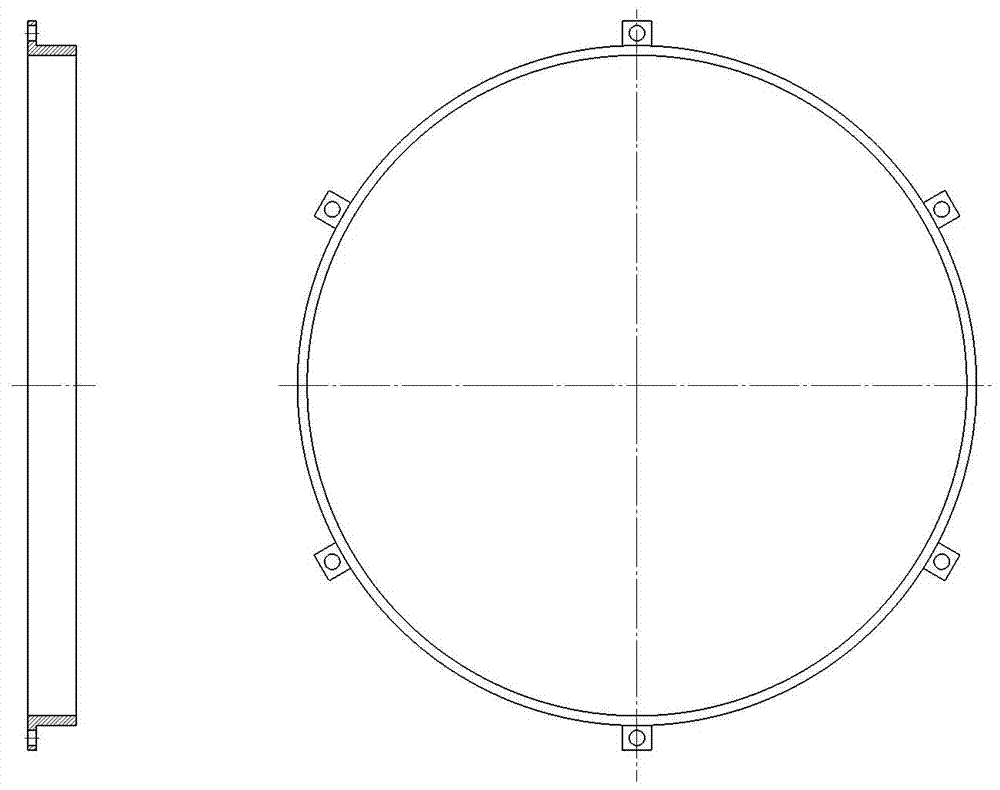

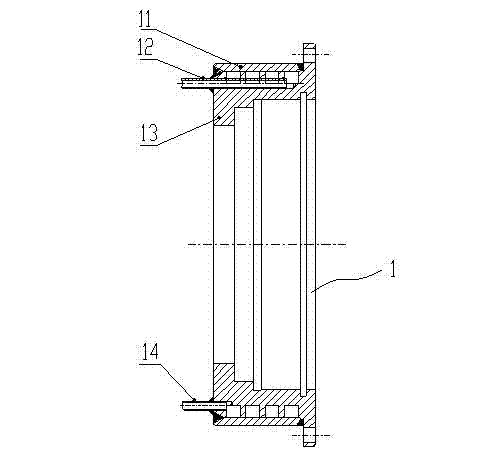

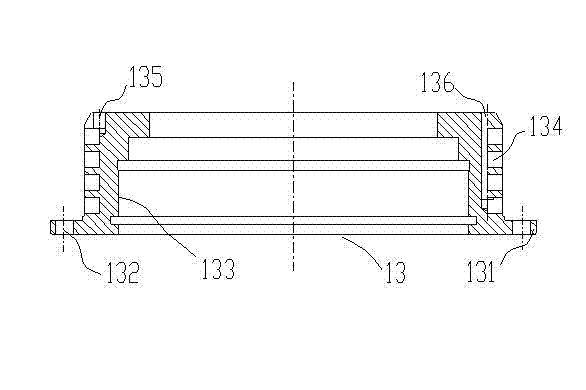

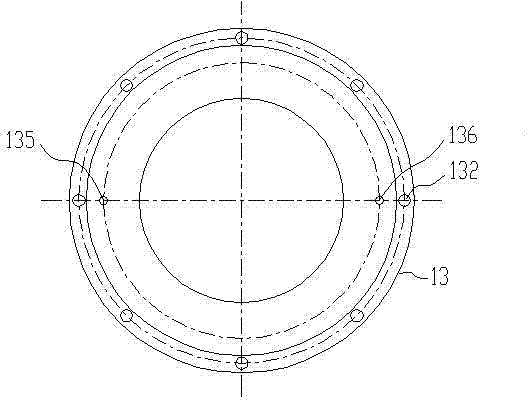

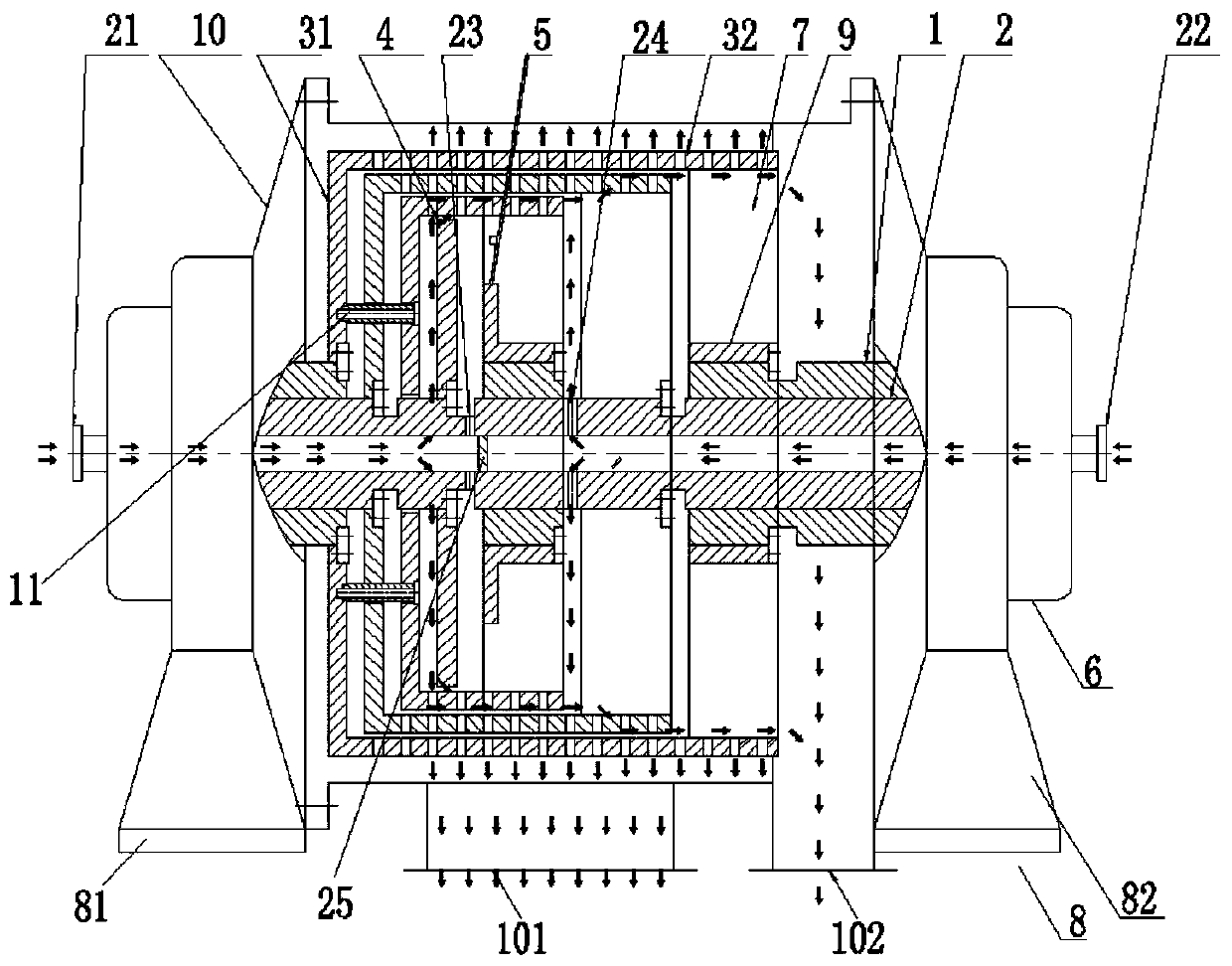

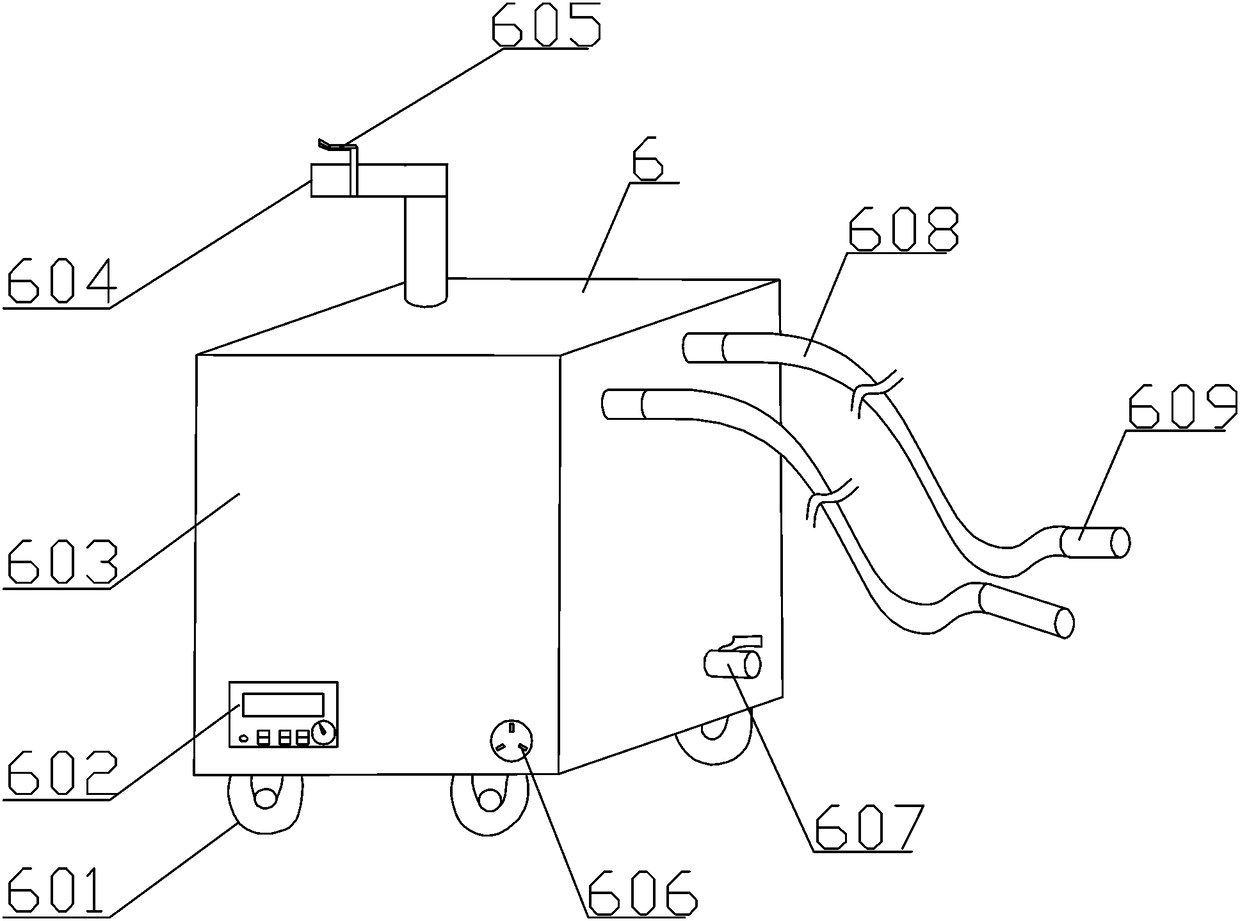

Cooling device for bearing of two-stage pusher centrifuge and manufacturing method thereof

The invention relates to the technical field of bearings of centrifuges and specifically relates to a cooling device for bearings of two-stage pusher centrifuges. The objective of the invention is to solve the problem that when temperature of materials in a two-stage pusher centrifuge is over 100 DEG C, a bearing is damaged because mere utilization of the conventional method of oil cooling can not realize drop of temperature. The invention is characterized in that: a cooling flange is provided in the core part of a deep aperture in a bearing pedestal of a two-stage pusher centrifuge; the cooling flange comprises an outer ring and an inner ring; one end of the head of the inner ring is a flange ring; the bore of the inner ring is provided with a bearing pedestal aperture; a helical groove is formed at cylindrical surface of the inner ring through the setting of helical teeth; processing short tube hole and long tube hole respectively communicate with the helical groove; a short copper tube is provided in the short tube hole while a long copper tube is provided in the long tube hole; the bore of the inner ring matches with excircle of the inner ring where the helical groove is provided, and the two are welded into an integrate part. According to the invention, the contact area between a liquid coolant and the inner ring is guaranteed, and the force received by a supporting bearing can be stabilized.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

Wear-resistant collecting vat of charging centrifugal machine

InactiveCN101549328AReduce breakageSolve serious wear and tear problemsCentrifugesPolyesterSEMI-CIRCLE

The invention relates to a collection system for charging centrifugal machine after severing materials, especially relates to a wear-resistant collecting vat of charging centrifugal machine improved from solid materials collecting vat of charging centrifugal machine, which includes charging centrifugal machine collection system and solid collection apparatus. The feature is indicated that the aforementioned solid collection apparatus is installed in the charging centrifugal machine collection system, there is a collecting vat with the intersecting surface as U type or semi-circle type or rectangle or special-shaped, and there is a wear layer lining in the collecting vat. The wear layer can absorb some kinetic energy carried by part of solid particles deviating from B grade barrate as the wear layer has definite elasticity, which can drives down the particle broken problem, furthermore can effectively account for the problem of abrasion of the solid collecting vat as the wear layer is nano type SY polyene and polyester.

Owner:ZHEJIANG QINGJI IND

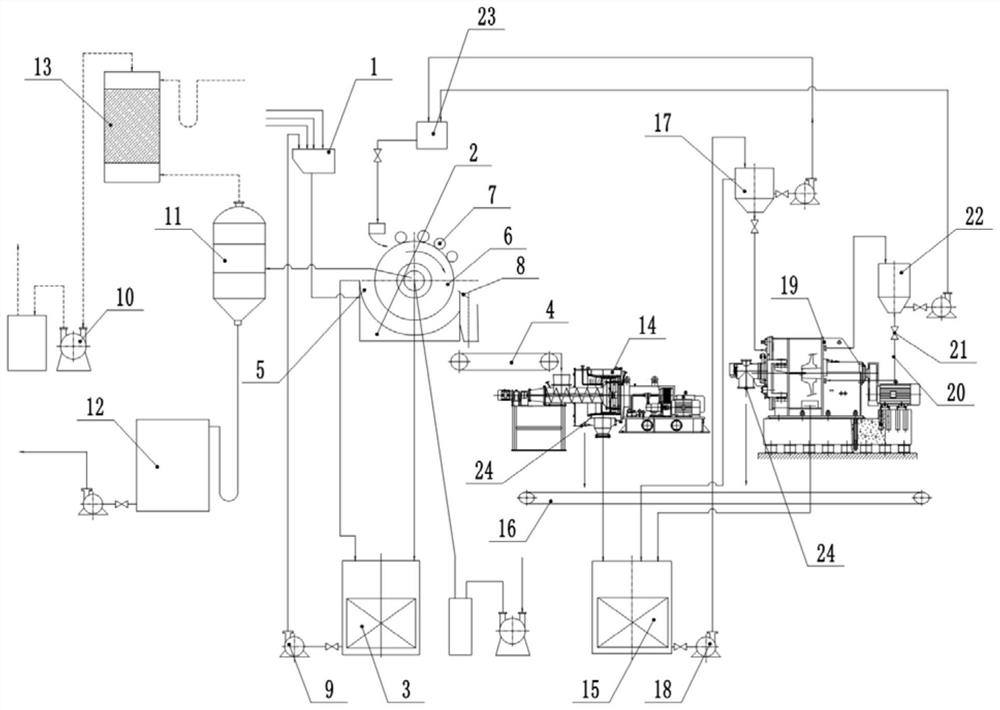

Continuous nitrocotton dewatering process and apparatus

The invention discloses a process and device for continuous water displacement of nitrocellulose. The continuous water displacement of nitrocellulose can be realized by using the method. The invention comprises the following process steps: ① nitrocellulose slurry enters the dehydration cotton tank; ② adjusts the concentration of nitrocellulose in the dehydration cotton tank; ③ the nitrocellulose slurry is pumped into the dehydration pusher centrifuge for dehydration by a metering pump for dehydration; ④ The water content of the dehydrated nitrocellulose is ≤29%, and the cutting material falls into the wine cotton tank and soaked with concentrated alcohol; ⑤Adjust the concentration of nitrocellulose in the wine cotton tank; The pusher centrifuge carries out alcohol replacement and water displacement. In the present invention, the two-stage piston pusher centrifuge used for dehydration and water displacement is a two-stage piston pusher centrifuge, the metering pump is selected from NM90SY02S08V Naimo pump, and the alcohol nozzle in the water-displacement double-stage piston pusher centrifuge is a gap type The flat nozzle and the mechanical seal port of the front bearing of the two-stage piston pusher centrifuge for water driving are connected to the nitrogen input pipe, and nitrogen gas with a pressure of 0.2-0.3 MPa is fed into the mechanical seal during the water driving process. The invention has the characteristics of reliable process and stable product quality, and can meet the quality and safety requirements of nitrocellulose production.

Owner:SICHUAN NITROCELLULOSE CORP

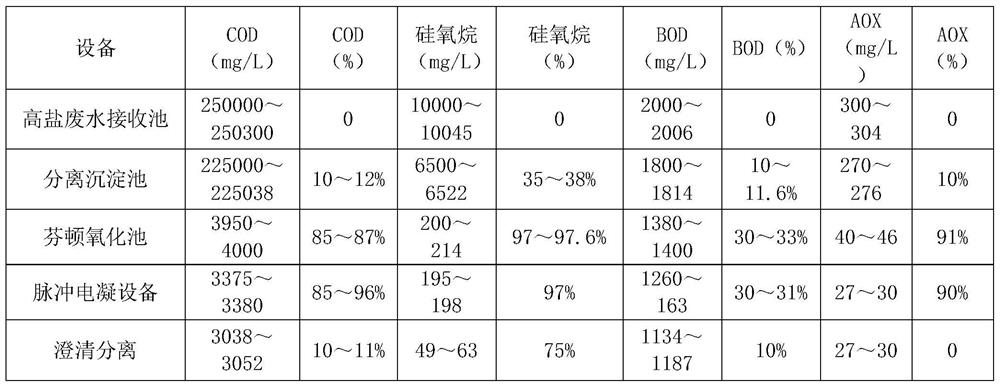

Method for purifying byproduct sodium chloride in organic silicon high-salinity wastewater

ActiveCN113880340AImprove water qualityOptimizing the Purification and Concentration ProcessFatty/oily/floating substances removal devicesWater treatment compoundsSaline waterPhysical chemistry

The invention discloses a method for purifying a byproduct sodium chloride in organic silicon high-salinity wastewater. The method comprises a high-salinity wastewater pretreatment stage and an MVR (mechanical vapor recompression) evaporation stage. The high-salinity wastewater pretreatment stage comprises oil-water separation, Fenton reaction, pulse electrocoagulation reaction and clarification separation; and the MVR evaporation stage comprises the following steps: (1) preheating clarified high-salinity wastewater, (2) carrying out primary evaporation concentration on the high-salinity wastewater to obtain concentrated saline water, (3) carrying out secondary evaporation concentration on the concentrated saline water to obtain a crystal slurry solution, and (4) crystallizing and drying: thickening the concentration of the crystal slurry solution, introducing the crystal slurry solution into a double-pusher centrifuge, carrying out solid-liquid separation, conveying sodium chloride crystals with the water content smaller than or equal to 5% obtained through solid-liquid separation to a drying bed through a spiral conveyor to be dried, and packaging the dried sodium chloride crystals enter a packaging machine to obtain a sodium chloride product. The method is scientific and reasonable, the content of pollutants in the organic silicon high-salinity wastewater can be reduced to the minimum, and the sodium chloride product is high in extraction rate and purity.

Owner:云南能投硅材科技发展有限公司

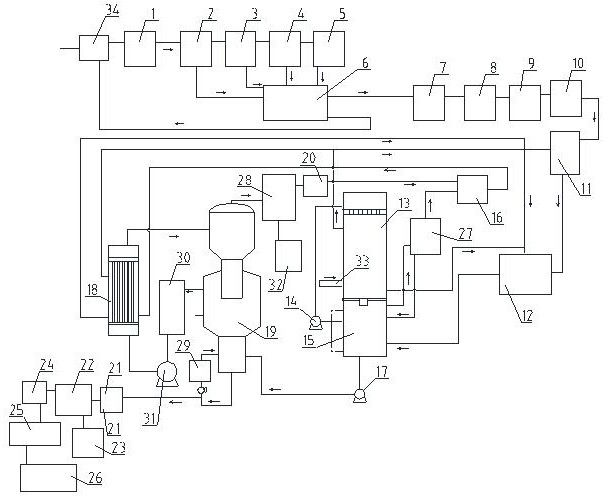

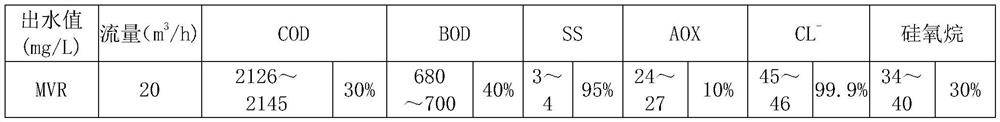

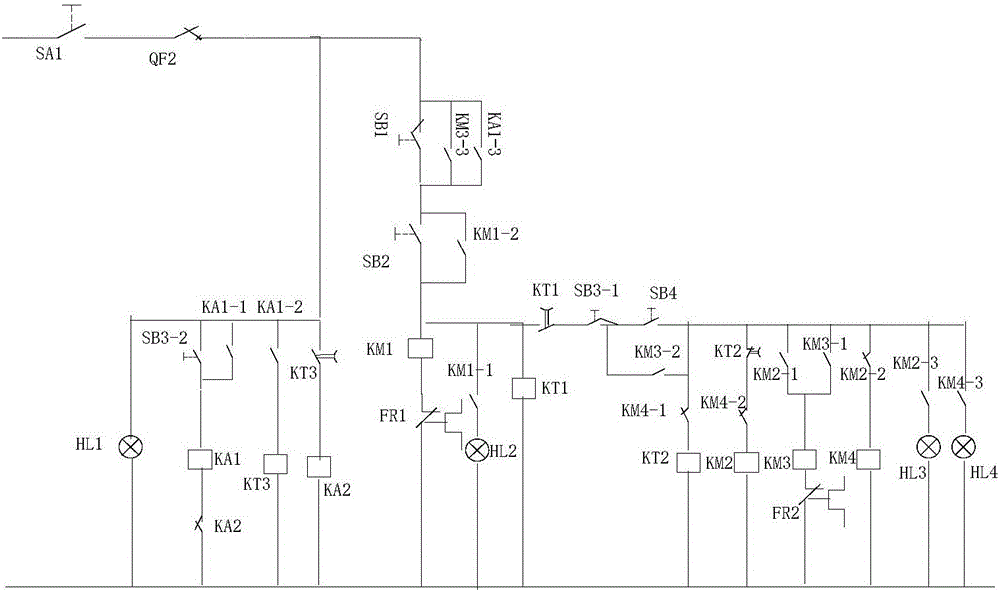

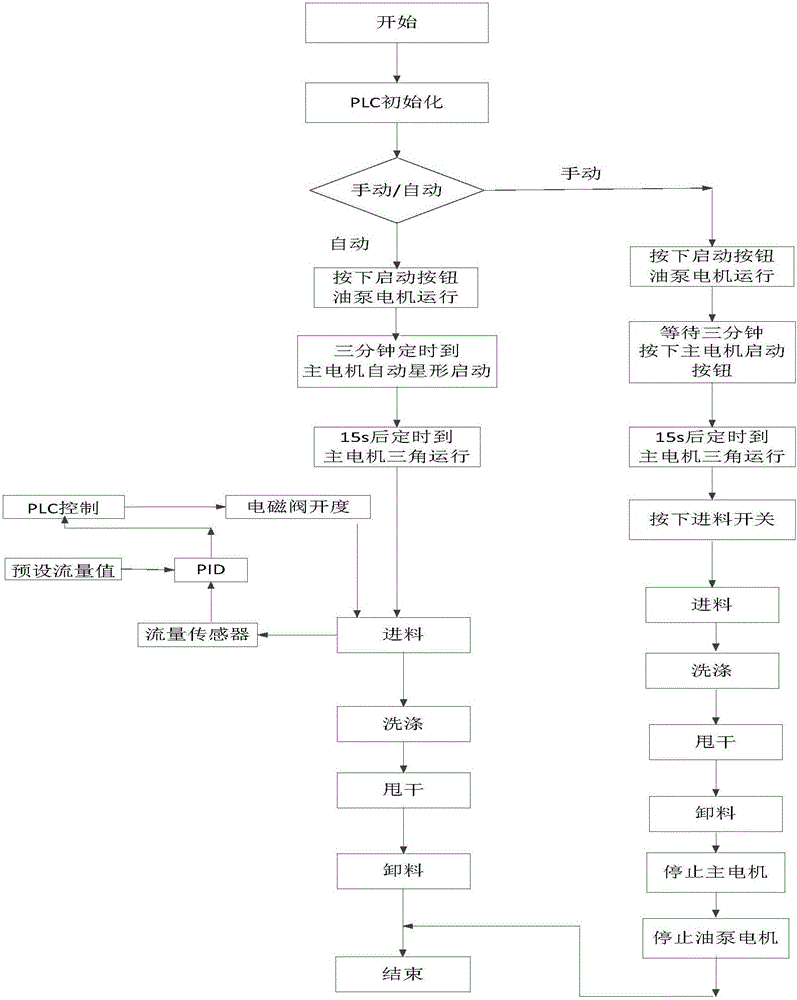

PID-based double-stage pusher centrifuge control device and method

ActiveCN106597986AAvoid shockLow costTotal factory controlProgramme control in sequence/logic controllersFrequency changerAutomatic control

The invention discloses a PID-based double-stage pusher centrifuge control device and method. The device is designed based on the principle of simpleness, practicality, stability and low cost; centrifugal revolution number thereof is lower than 3000r / min; and the device is suitable for separating suspension liquid of crystalline and fibrous material of particles, and is also suitable for materials, which need to the washed and suspension liquid of which is high in solid content. Hardware of the device is formed by a PLC, a main motor, an oil pump motor, a power supply module, a sensor, an electric appliance protection switch and some peripheral circuits. The device is stable to work, is easy to maintain and improves production efficiency and product quality; meanwhile, compared with other control systems adopting the PLC and a frequency converter, the device saves cost, and is easy to operate and maintain; and the device has a manual control mode and an automatic control mode, so that through the flexible control modes, a user can carry out operation very conveniently.

Owner:CHONGQING NORMAL UNIVERSITY

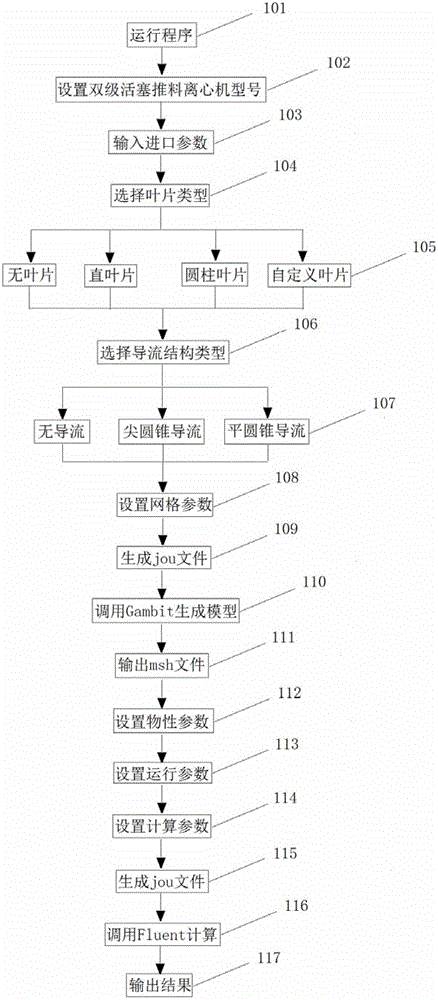

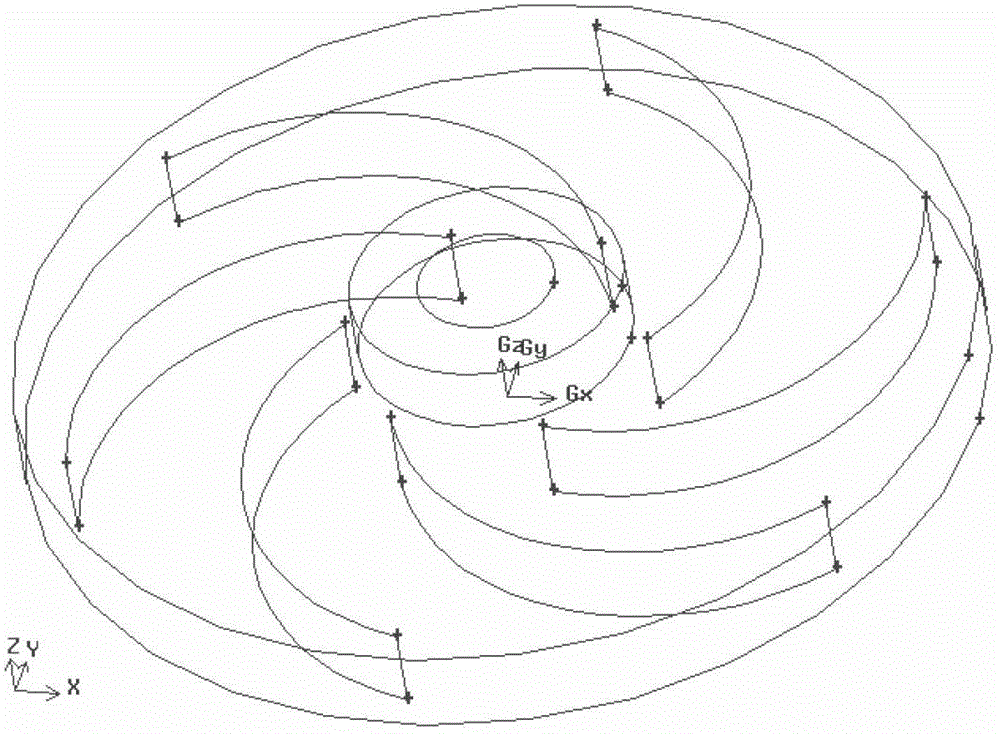

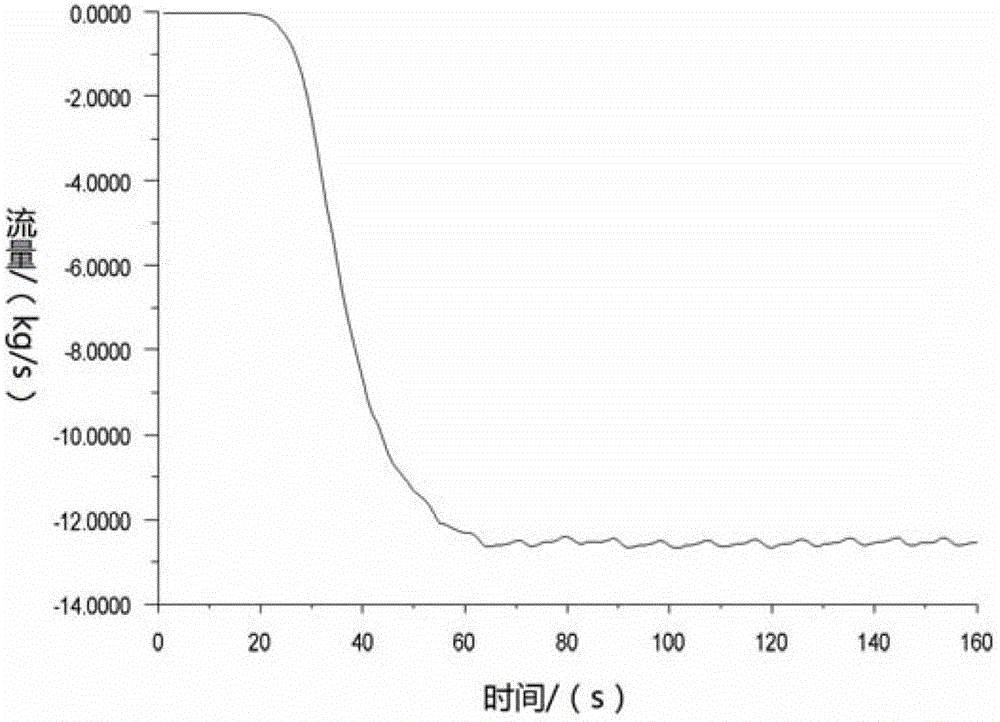

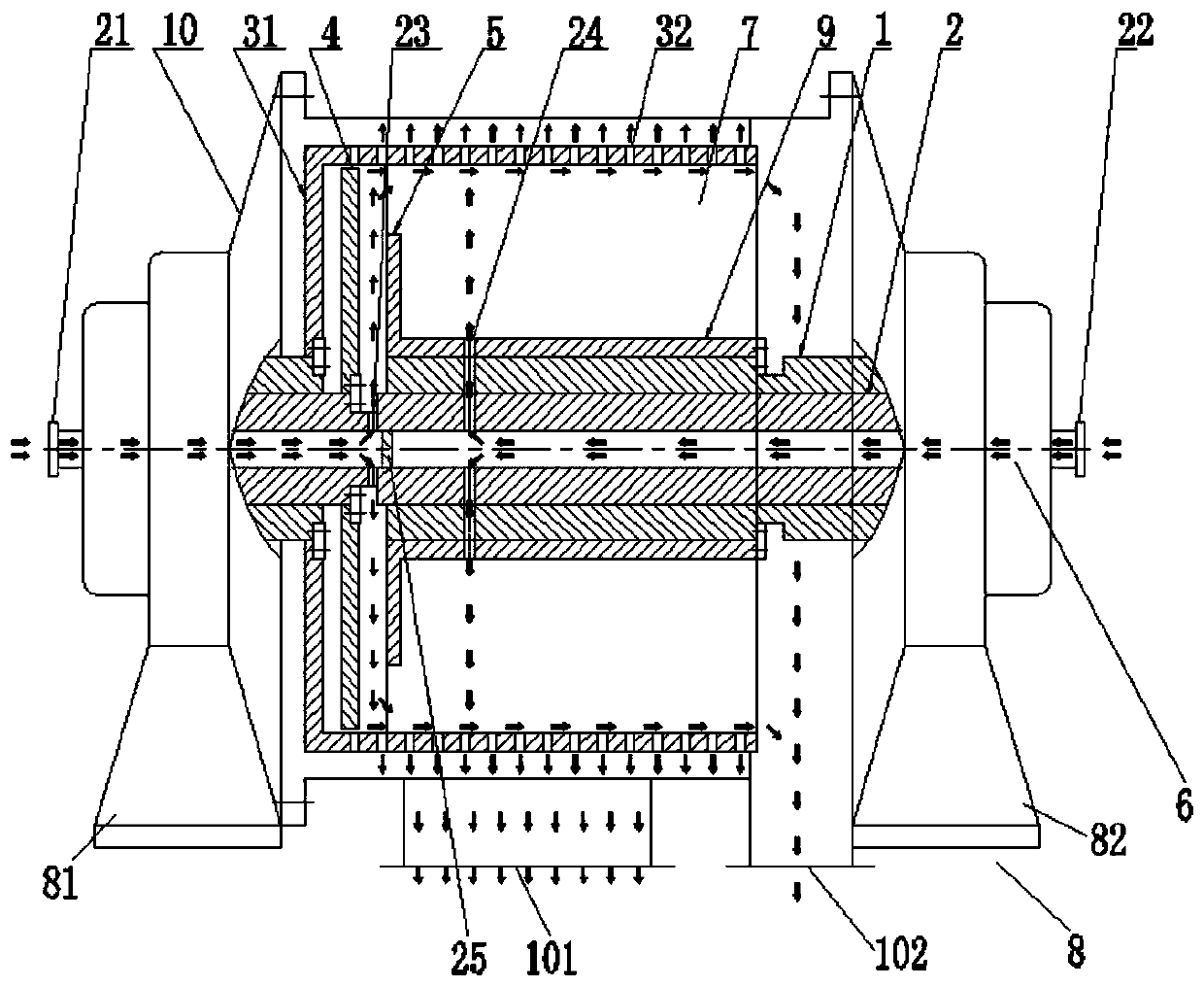

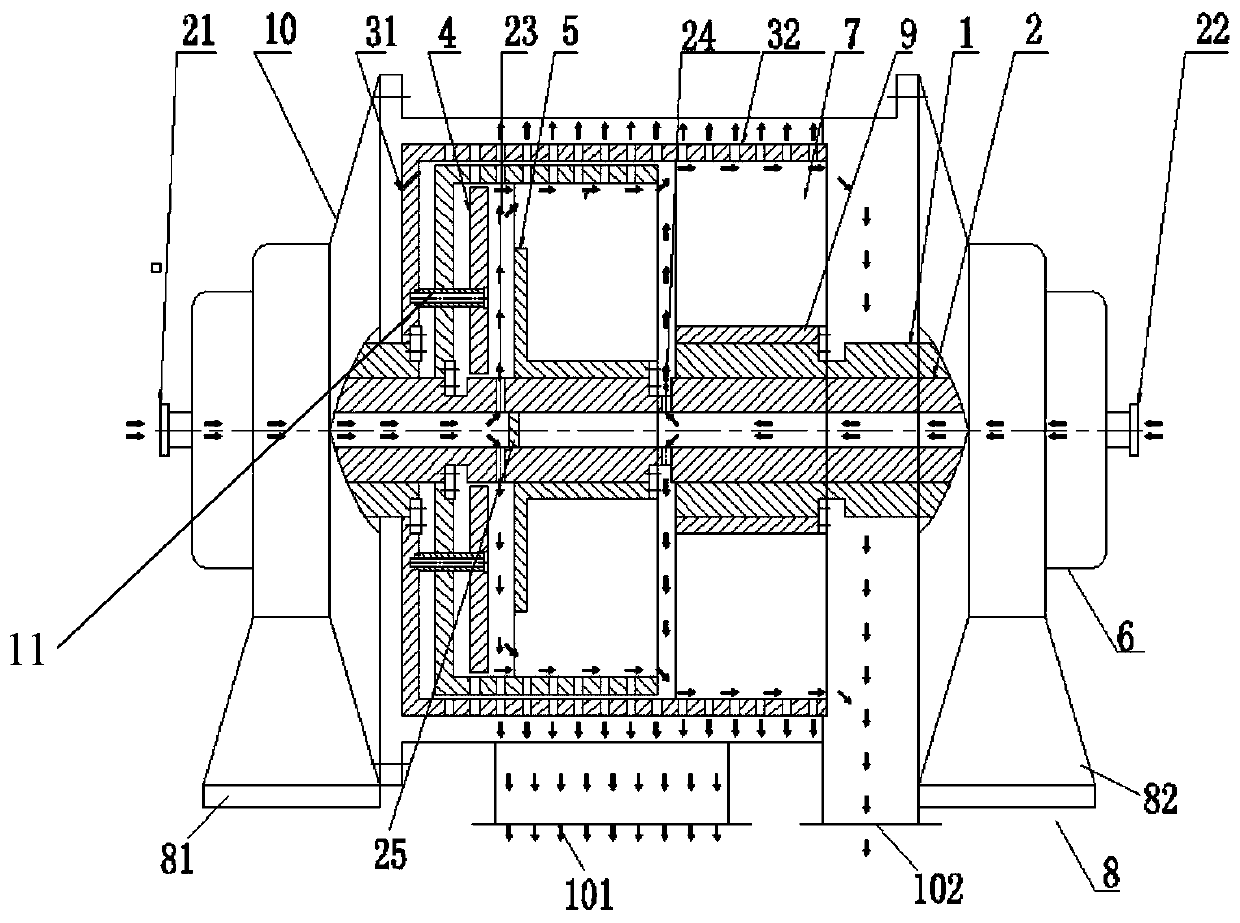

Two-stage piston pusher centrifuge accelerating disc flow field visualization method

InactiveCN102722604AHigh speedQuick buildSpecial data processing applicationsComputer scienceVisualization methods

The invention relates to a two-stage piston pusher centrifuge accelerating disc flow field visualization method. The method comprises the steps that: accelerating disc parameterization modeling and flow field calculation of a parameterization model are realized by using a figure interface and a computer; material motion situations obtained by calculating are outputted; certain design of the accelerating disc can be carried out by a user to form a reasonable accelerating disc structure based on requirements for material motion; basis for analyzing material acceleration effect realized by the accelerating disc is provided by choosing a two-stage piston pusher centrifuge model, choosing a blade type, choosing a flow guide structure, calling Gambit software, automatically carrying out meshing and boundary condition setting, setting material parameters, calling Fluent software and outputting material motion speed results. According to the invention, parameterization setting of various structures of the accelerating disc is carried out, and a plurality of choices for the flow guide structure and the blade type can further be carried out; from the perspective of extensive applicability, a good design platform is provided for common technical staff.

Owner:TIANJIN UNIV

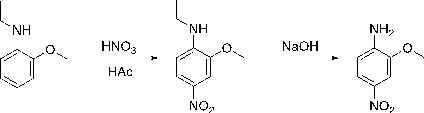

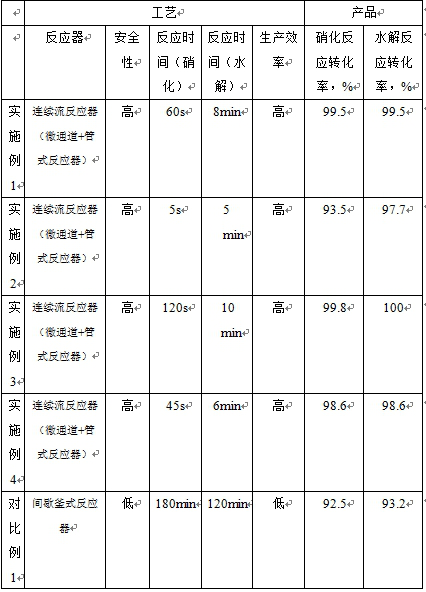

Continuous flow production process of Fast Red B

ActiveCN113185418AReduce usageLow costOrganic compound preparationCarboxylic acid amides preparationOrganic synthesisNitration

The invention discloses a continuous flow production process of Fast Red B, and belongs to the field of organic synthesis. According to the process, o-methoxyacetanilide is taken as an initial raw material, and continuous flow production of the Fast Red B is realized through two-step reaction of nitration and hydrolysis by using a micro-channel reactor / a tubular heat exchanger / a pusher centrifuge / a tubular reactor / continuous cooling and separation equipment. According to the process, common concentrated nitric acid is adopted as a nitration reagent, and continuous reaction and separation equipment is introduced, so that continuous production is realized, the production safety risk is reduced, the production period is shortened, and the blank in the technical field of continuous flow production of the product is filled.

Owner:SHANDONG NORMAL UNIV EXPERIMENTAL PLANT CO LTD +1

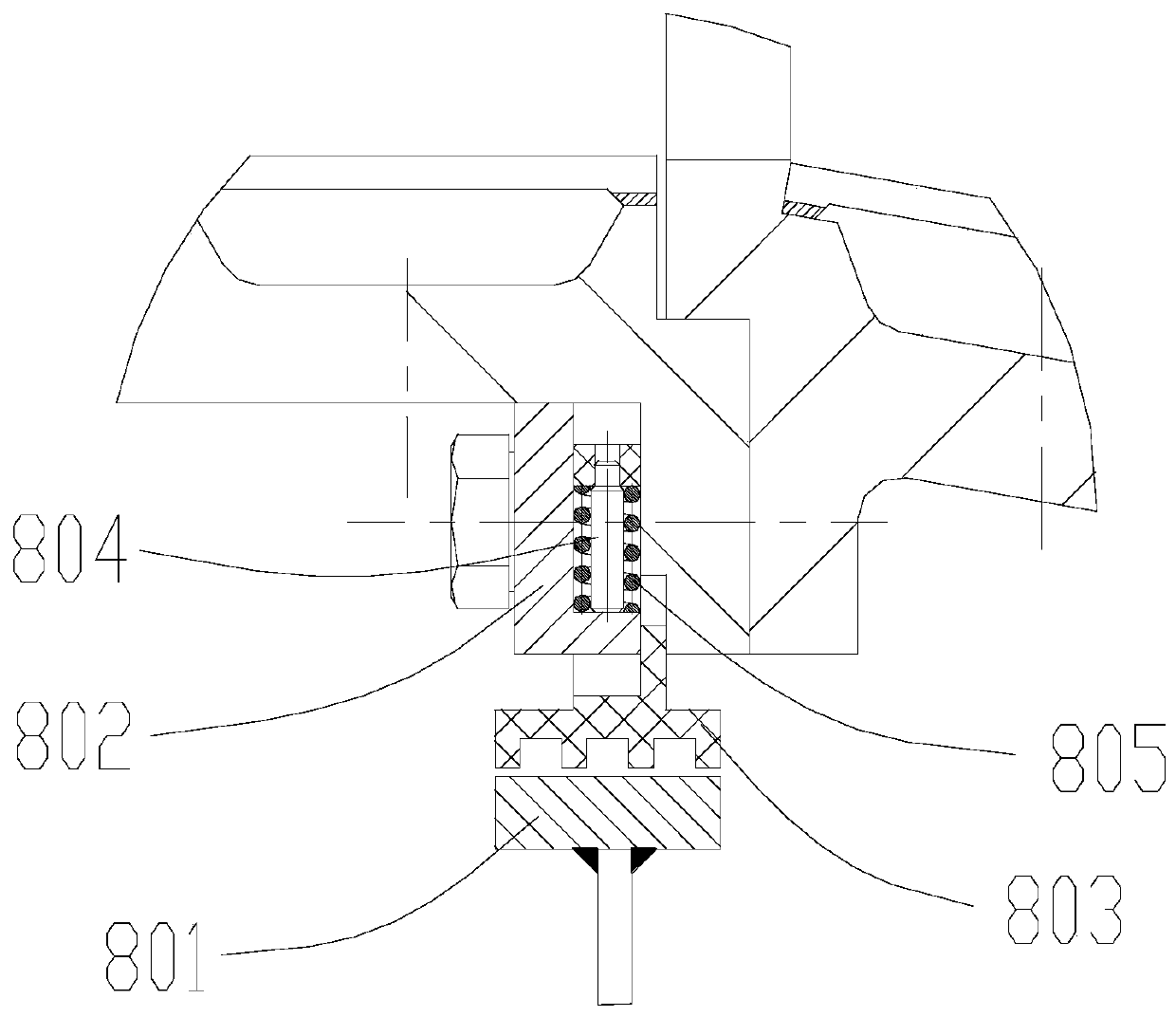

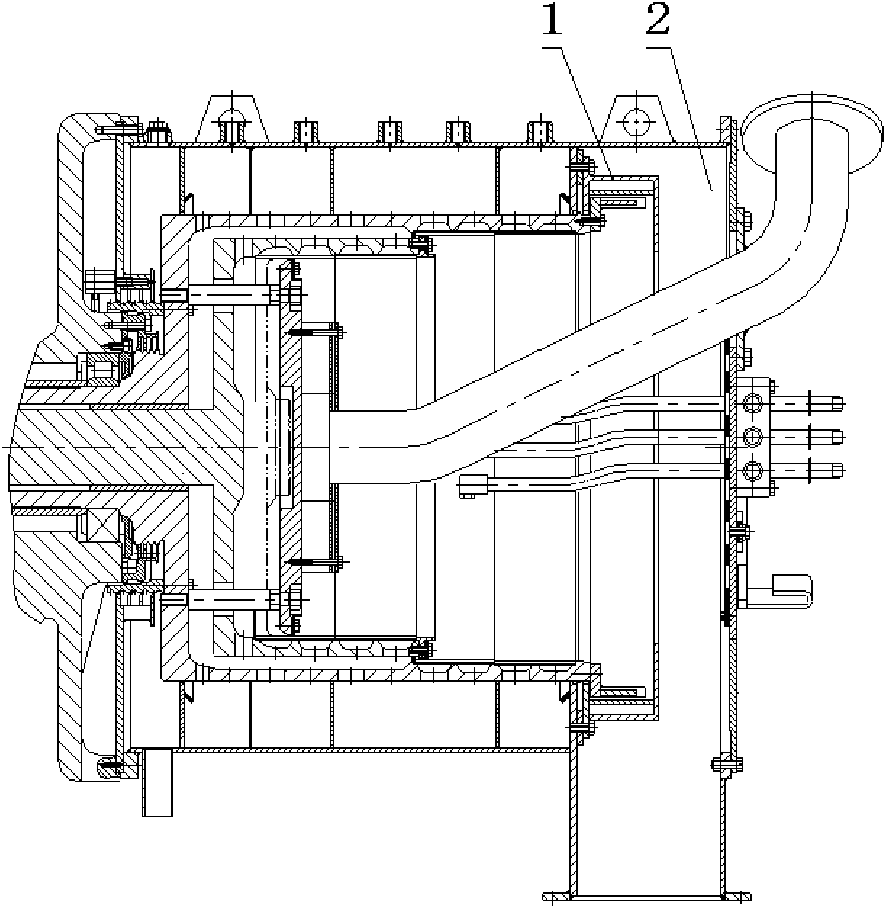

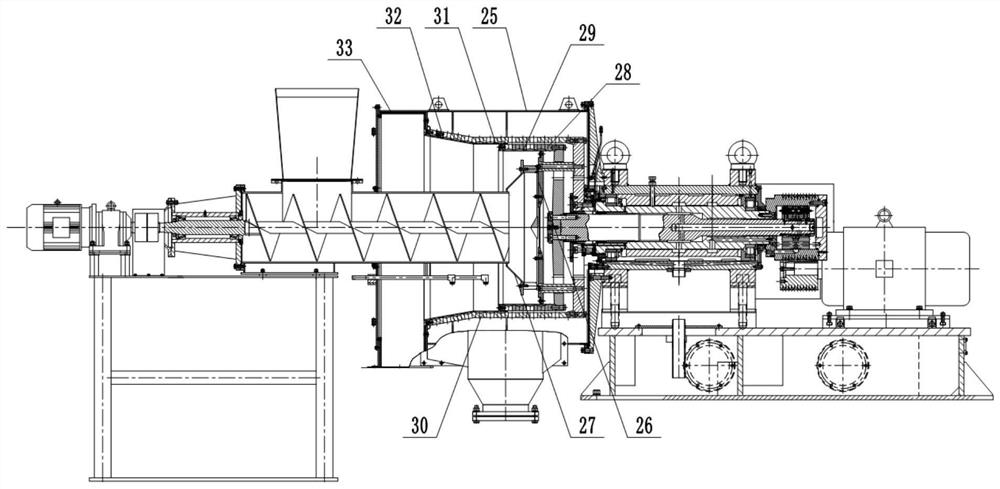

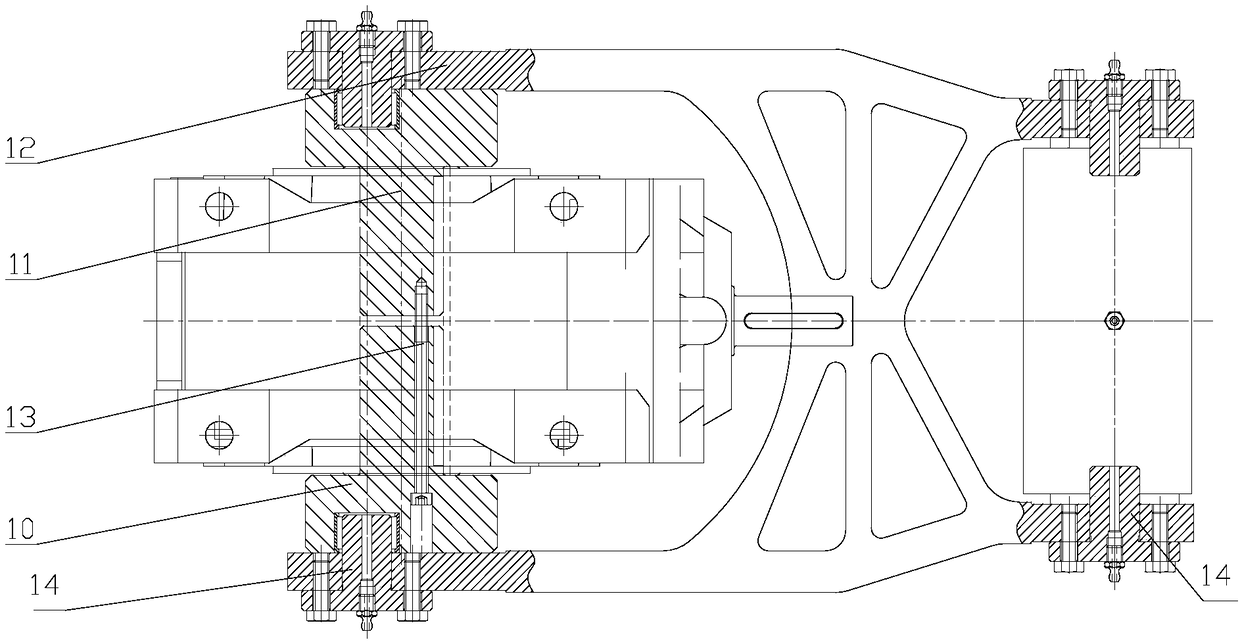

Piston material pushing centrifugal machine and feeding method thereof

PendingCN111054528AMultiple drum stagesLarge diameterRotary centrifugesWash waterMechanical engineering

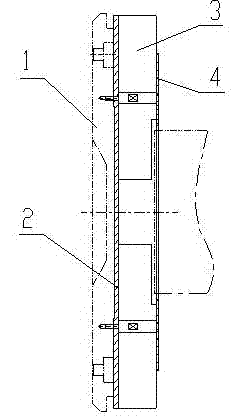

The invention discloses a piston material pushing centrifugal machine. The machine comprises a main shaft, a push rod, a rotary drum, a pusher, a distributor, a driving mechanism, a rotary drum reinforcing structure, a main shaft supporting structure, a sleeve and a machine shell arranged outside the rotary drum; one end of the rotary drum reinforcing structure is fixed to the sleeve, and the other end of the rotary drum reinforcing structure is fixed to the rotary drum wall of the rotary drum; the push rod is of a hollow tubular structure, a material channel communicating with an internal pipeline of the push rod is arranged on the position, between the pusher and the distributor, of the main shaft and / or the push rod, and materials enter a gap between the pusher and the distributor through the material channel and then enter the interior of the rotary drum; and a washing water channel communicating with the interior of the push rod is formed in the middles of the main shaft, the pushrod and the sleeve, and washing water enters the interior of the rotary drum through the washing water channel. According to the machine, through a multi-point supporting structure and an unique feeding method, the rotary drum is large in diameter, high in rotating speed, long in filtering area length, and large in rotary drum stage number, and the advantages that the vibration is not prone to occur, the separation factor is large, the water content of filter residue is low, the water equivalent of the washing water is small, the production capacity is large, and the enlargement is availableare achieved.

Owner:武汉德泽环保科技有限公司

Filtration production line with function of recovering crystals in separation liquid

PendingCN113975893AIncrease production capacityAvoid affecting the dehydration effectAlkali metal carbonatesFiltration circuitsFiltrationPhysical chemistry

The invention relates to the field of sodium carbonate processing, and discloses a filtration production line with a function of recovering crystals in separation liquid. The filtration production line comprises a vacuum filtration unit, a primary dehydration unit and a secondary dehydration unit, the primary dehydration unit comprises a piston pushing centrifugal machine, the secondary dehydration unit comprises a siphon scraper centrifugal machine and a backflushing structure, and the feeding end of the siphon scraper centrifugal machine is connected with the liquid outlet end of the piston pushing centrifugal machine. According to the technical scheme, the piston pushing centrifugal machine and the siphon scraper centrifugal machine are combined for use, secondary dehydration of the sodium carbonate is achieved, the moisture content of the sodium carbonate can be reduced to 10%-12% in a grading mode, and energy consumption of later calcination is greatly reduced. Besides, by arranging a backflushing component, a filter medium of the centrifugal machine can be backflushed, on one hand, the influence on the dehydration effect caused by accumulation of fine grains can be avoided, and on the other hand, recovered fine grains can be directly calcined, so that the sodium carbonate loss is reduced, and the productivity of a sodium carbonate production line is improved.

Owner:重庆江北机械有限责任公司

High-concentration salty wastewater MVR (mechanical vapor recompression) evaporative crystallization treatment system

InactiveCN106630340AReduce energy consumptionImprove qualityEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationCyclone

A high-concentration salty wastewater MVR (mechanical vapor recompression) evaporative crystallization treatment system comprises a raw material storage tank, a feed pump, a plate heat exchanger, a DTB evaporation crystallizer heating chamber, a DTB evaporation crystallizer, a vacuum evaporation crystallizer heating chamber, a vacuum evaporation crystallizer, a first hydraulic cyclone, a sodium sulfate slurry barrel, a double-stage pusher centrifuge, a vibration fluidized-bed dryer, a first mother liquor storage tank, a first mother liquor pump and a mother liquor circulating pump. The high-concentration salty wastewater MVR evaporative crystallization treatment system is characterized in that the raw material storage tank is sequentially connected with the feed pump, the plate heat exchanger, the DTB evaporation crystallizer heating chamber, the DTB evaporation crystallizer and the vacuum evaporation crystallizer heating chamber. The system is low in comprehensive energy consumption, finally obtained anhydrous sodium sulfate quality meets the requirements of GB / T6009-2014 industrial anhydrous sodium sulfate class-II top quality goods, sodium sulfate content is higher than or equal to 98%, and industrial sodium sulfate meets solarized sodium sulfate secondary standard requirements of national industrial sodium sulfate standards (GBT5462-2003).

Owner:HAIZHOU E P GRP CO LTD

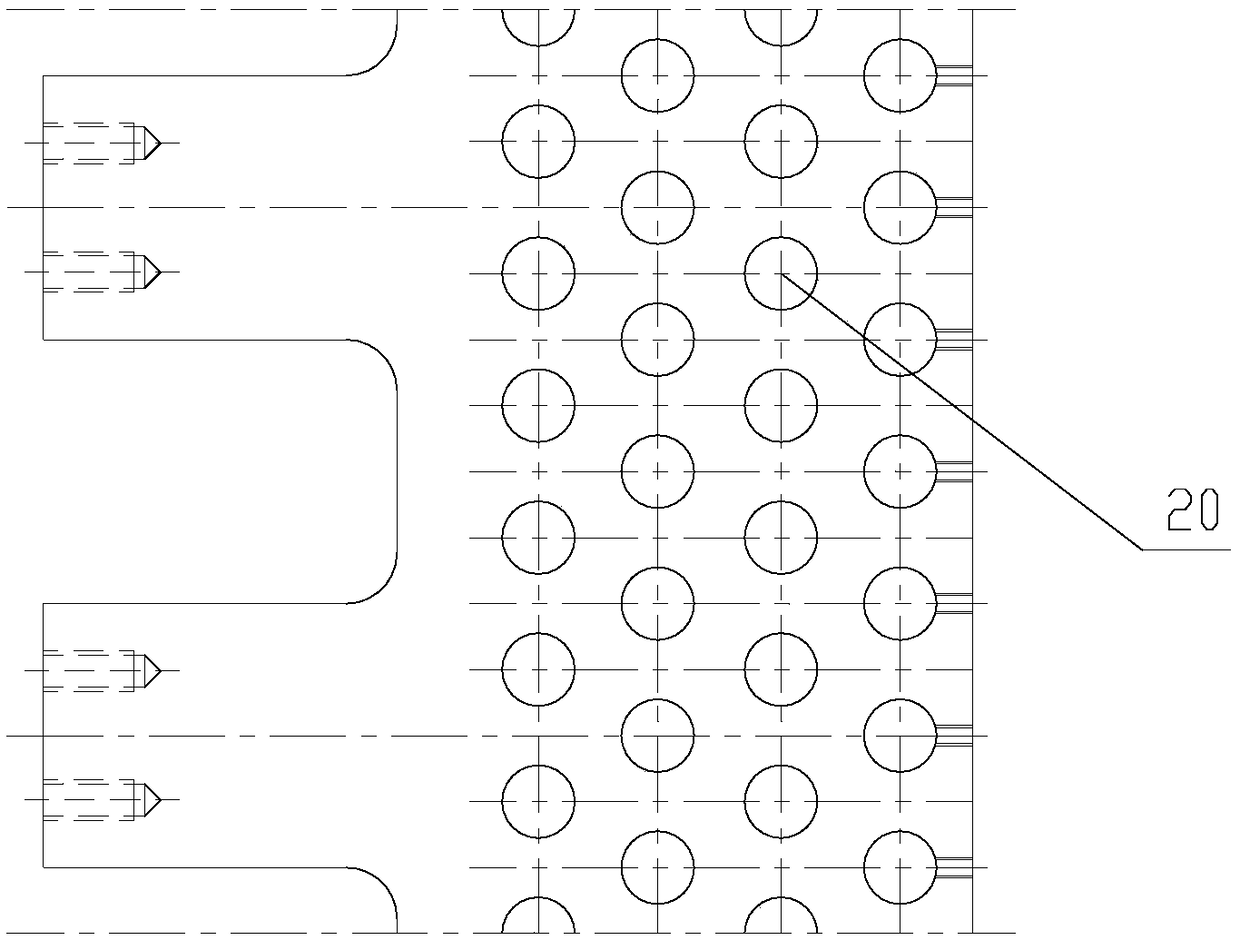

Double-stage material-pushing centrifuge distribution acceleration plate device

ActiveCN104001628AIncrease the solid-to-liquid ratioIncrease flushing functionRotary centrifugesEngineeringDouble stage

The invention relates to a double-stage material-pushing centrifuge distribution acceleration plate device and aims to increase solid-liquid ratio of materials during operation of a centrifuge and use the liquid discharged in advance to wash the screen of a separation section. The device comprises a feed pipe, a primary rotary hub, a material pushing plate located in the primary rotary hub and a primary rotary hub screen assembled between the primary rotary hub and the material pushing plate and is characterized in that a horn-shaped hole is formed in the center of the material pushing plate, an inner distribution acceleration plate is disposed at the horn-shaped hole, an outer distribution acceleration plate is disposed on the outer side of the inner distribution acceleration plate, a sealed space is disposed on the outer side of the outer distribution acceleration plate, a nozzle penetrating the material pushing plate is disposed at the edge of the sealed space, and a screen area is disposed on each of the inner distribution acceleration plate and the outer distribution acceleration plate. The double-stage material-pushing centrifuge distribution acceleration plate device has the advantages that material solid-liquid ratio is increased, the thickening is achieved by the power and containing space of the device, separation effect is increased, and application range of the centrifuge is expanded.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

Intermittent feeding structure of two-stage pusher centrifuge

The invention relates to the technical field of a centrifuge, in particular to a two-stage feeding structure of a two-stage pusher centrifuge so as to solve the problem that intermittent pushing motion is completed by controlling the switch of a feed port, then the synchronism of feeding and pushing can not be accurately controlled. The structure comprises a secondary drum, feeding pipes and a primary drum arranged in the secondary drum, and is characterized in that a guide shaft is arranged on a round end plate of the secondary drum axially towards a tubular body, passes through a round end plate of the primary drum and is provided with a baffle in the primary drum. A baffle shield is arranged on the round end plate of the primary drum. The external diameter of the baffle shield is in sealing match with through holes at the center of baffle. A rotating shaft is arranged in the baffle shield; a sealing plate is mounted at the end part of the baffle shield; and a protective cover matched with the feeding pipes is arranged on the breadth of the baffle. By an intermittent control system, the material pushing time can be set up. When the material is fed, the material is stable and cannot corrode or abrade the baffle shield and the rear part of the baffle.

Owner:ZHEJIANG QINGJI IND

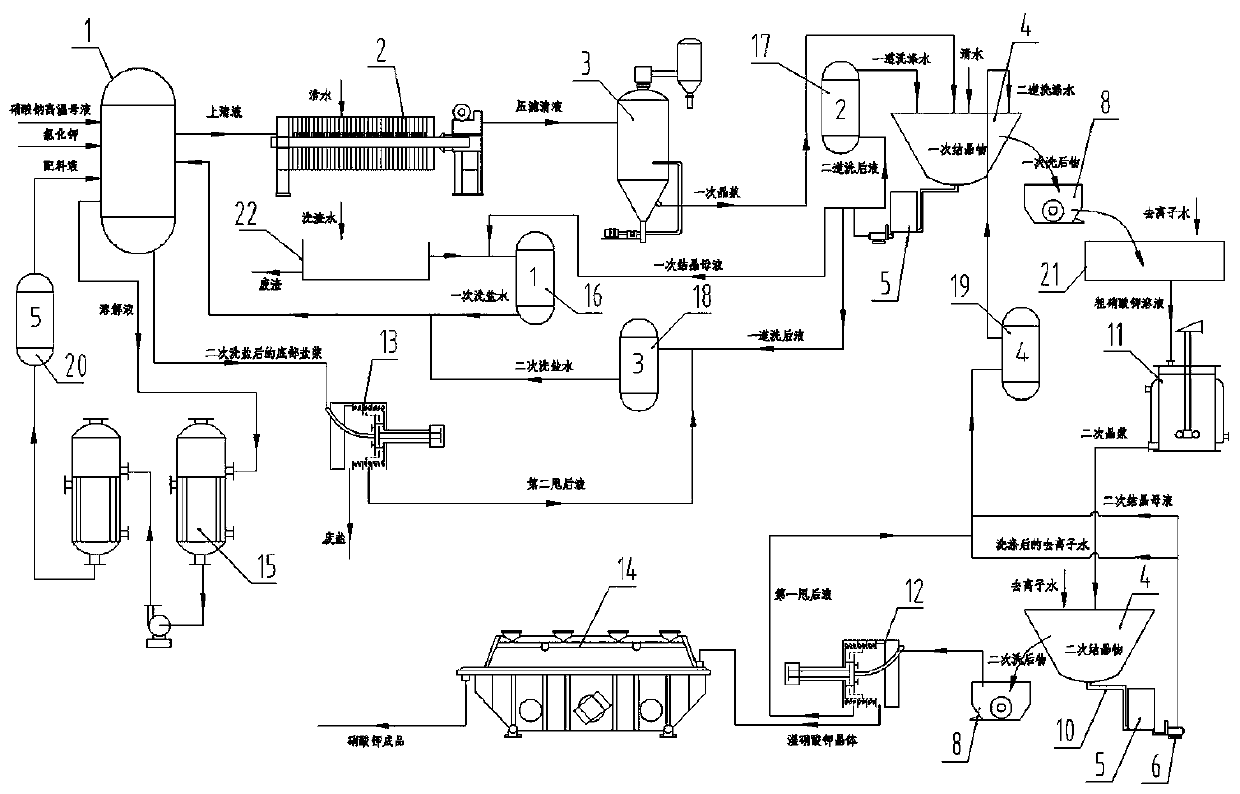

System and method for producing optical glass grade potassium nitrate from sodium nitrate high-temperature mother liquor

PendingCN110963511AReduce consumptionIncrease profitAlkali metal nitrate preparationFluidized bed dryingOptical glass

The invention relates to the technical field of potassium nitrate production systems and methods, and concretely relates to a system and a method for producing optical glass grade potassium nitrate from a sodium nitrate high-temperature mother liquor. The system comprises a batching tank, a plate-and-frame filter press, a vacuum crystallizer, a first filtering and washing device, a dissolving tank, a cooling crystallizer, a second filtering and washing device, a first two-stage material pushing centrifuge, a second two-stage material pushing centrifuge, a fluidized bed drying machine and a two-effect evaporator. Aqueous solutions generated in all production processes can be fully recycled, so the total yield of potassium ions is 95% or higher, the total yield of nitrate ions is 98% or above, no wastewater is discharged, and the water consumption is greatly reduced; and the principle that the solubility of potassium nitrate is greatly influenced by temperature and the solubility of other miscellaneous salts (sodium chloride, sodium sulfate and the like) is slightly influenced by temperature is used to crystallize and wash potassium nitrate twice respectively, so impurity ions in potassium nitrate crystals can be effectively removed, and the optical glass grade potassium nitrate with the purity of 99.9% or above is obtained.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

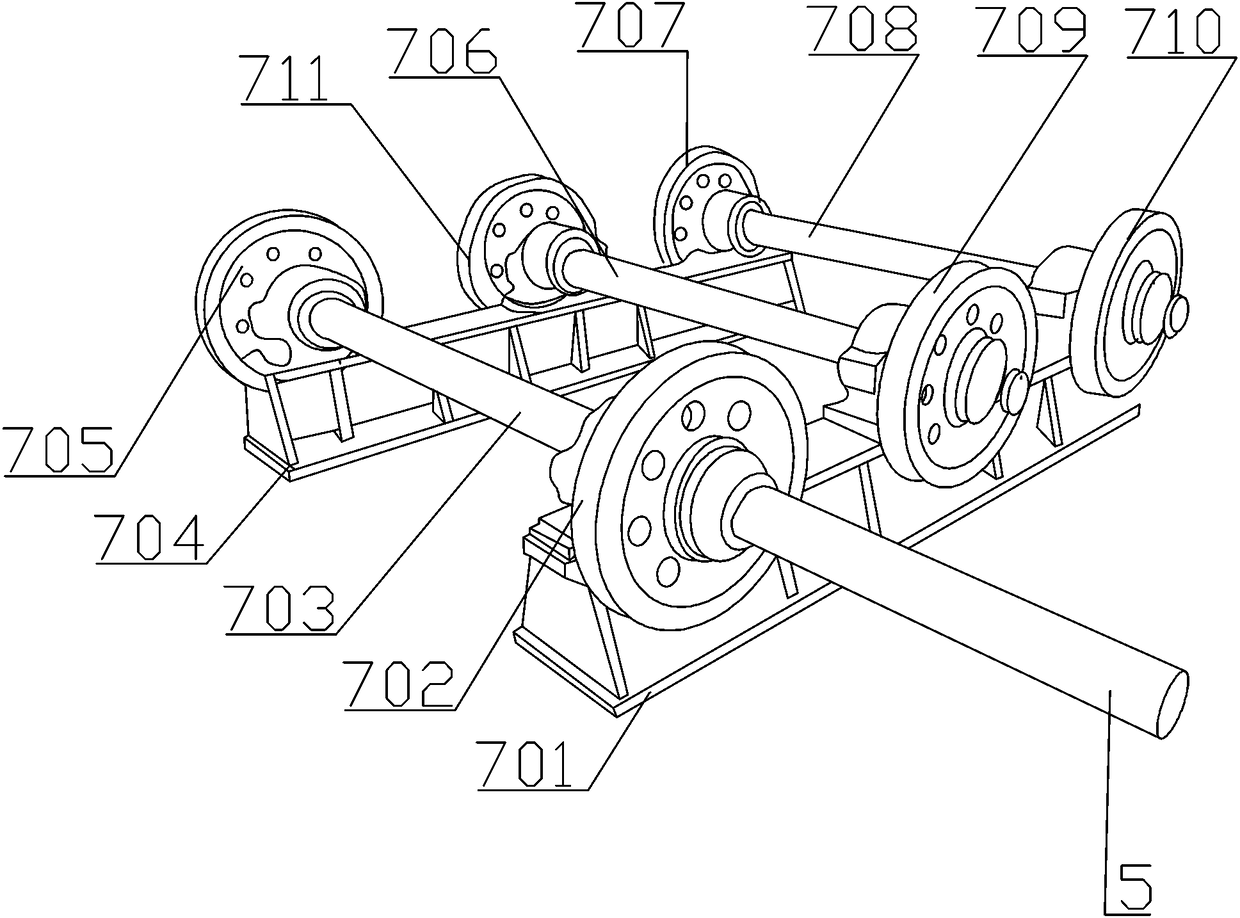

Double-roller electric-pole centrifuge with high-temperature curing function

The invention provides a double-roller electric-pole centrifuge with a high-temperature curing function. The double-roller electric-pole centrifuge comprises a plurality of groups of centrifugal components which are connected in series with one another, wherein a head centrifugal component and a tail centrifugal component are correspondingly connected with two groups of driving mechanisms, and thecentrifugal components are driven to bring two molds to rotate; a high-temperature curing device is arranged on a side bottom plate of the heat centrifugal component; and each group of centrifugal components comprises a first base and a second base, and a first active supporting roller component, a central supporting roller component and a second active supporting roller component are parallellymounted between the first base and a second base. By the adoption of the double-roller electric-pole centrifuge, the two molds can be driven at the same time; accordingly, the centrifugal production of two electric poles at a time can be achieved, the production efficiency can be improved, and the equipment cost can be reduced; and furthermore, the demolding process can be accelerated by adoptingthe high-temperature curing process, the production time can be shortened, and the working efficiency can be improved.

Owner:湖北红业建材科技开发有限公司

Pushing driving device of mechanical pushing centrifuge

ActiveCN109046804AOvercome the problem of easy leakage into the mother liquorConvenient sourceCentrifugesMotor driveReciprocating motion

The invention discloses a pushing driving device of a mechanical pushing centrifuge, and relates to the technical field of mechanical pushing centrifuges. The pushing driving device of the mechanicalpushing centrifuge adopts a motor driving speed reducer to drive a transmission device to move front and back; the transmission device and a connected shaft sleeve are rotated; the shaft sleeve drivesa pushing shaft to slide back and forth; a guide key is arranged between the pushing shaft and a hollow shaft, so that the pushing shaft slides back and forth in the hollow shaft in a path of the guide key; the pushing shaft drives a first-grade rotating drum bottom to drive a first-grade rotating drum to move back and forth; and a pushing piece is of a fan annular structure to stop materials from leaking in mother liquor in centrifugal treatment. The pushing driving device of the mechanical pushing centrifuge is simple in structure, lower in production and maintenance cost and simple in positioning and guide structure of the pushing shaft, prevents the oil leakage phenomenon, can achieve the effects needed by the reciprocating motion of the first-grade rotating drum; the pushing piece issimple in structure; and materials are not easy to leak into the mother liquor in centrifugal treatment.

Owner:XIANGTAN HUIBO CENTRIFUGE

Centrifuge and method of loading a centrifuge

Pusher centrifuges having screen drums rotatable about axes of rotation are used for separating a mixture into solid cake and into liquid phase. Pusher centrifuges may further have pusher bases arranged in the screen drums and arranged to be movable to and fro alternately in a first pushing direction and a second pushing direction along the axis of rotation that are used in order for the solid cake to be alternately displaced along the axis of rotation. The mixture is introduced into a first empty space or into a second empty space using a feed device. The first empty space is established on a displacement of the solid cake by the pusher base in the first pushing direction and the second empty space is established on a displacement of the solid cake by the pusher base in the pushing direction opposite to the first pushing direction.

Owner:FERRUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com