Double-action pusher centrifuge and pusher base device

A double-acting, centrifuge technology, used in centrifuges, jet propulsion units, gas turbine units, etc., to solve problems such as particle breakage and negative impact on solid cake quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

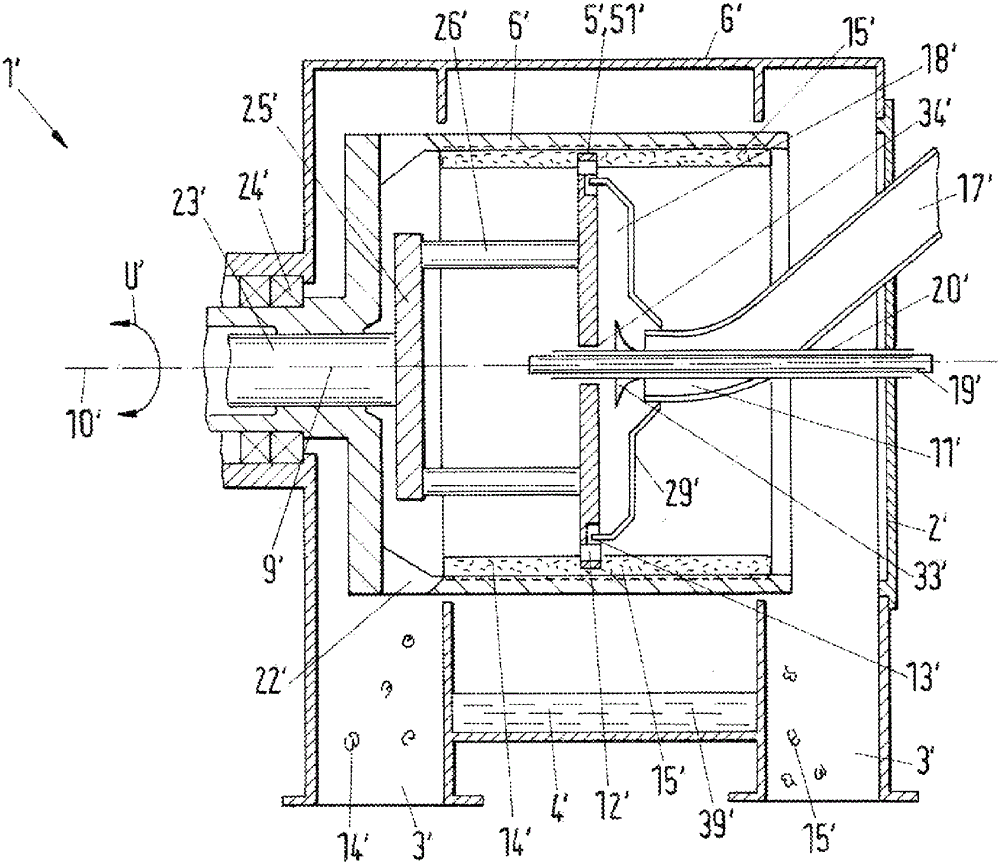

[0046] Figures 1a to 1d An example of a double-acting pusher centrifuge known from the prior art is shown, which was already discussed in detail at the beginning and which therefore need not be discussed any longer at this point.

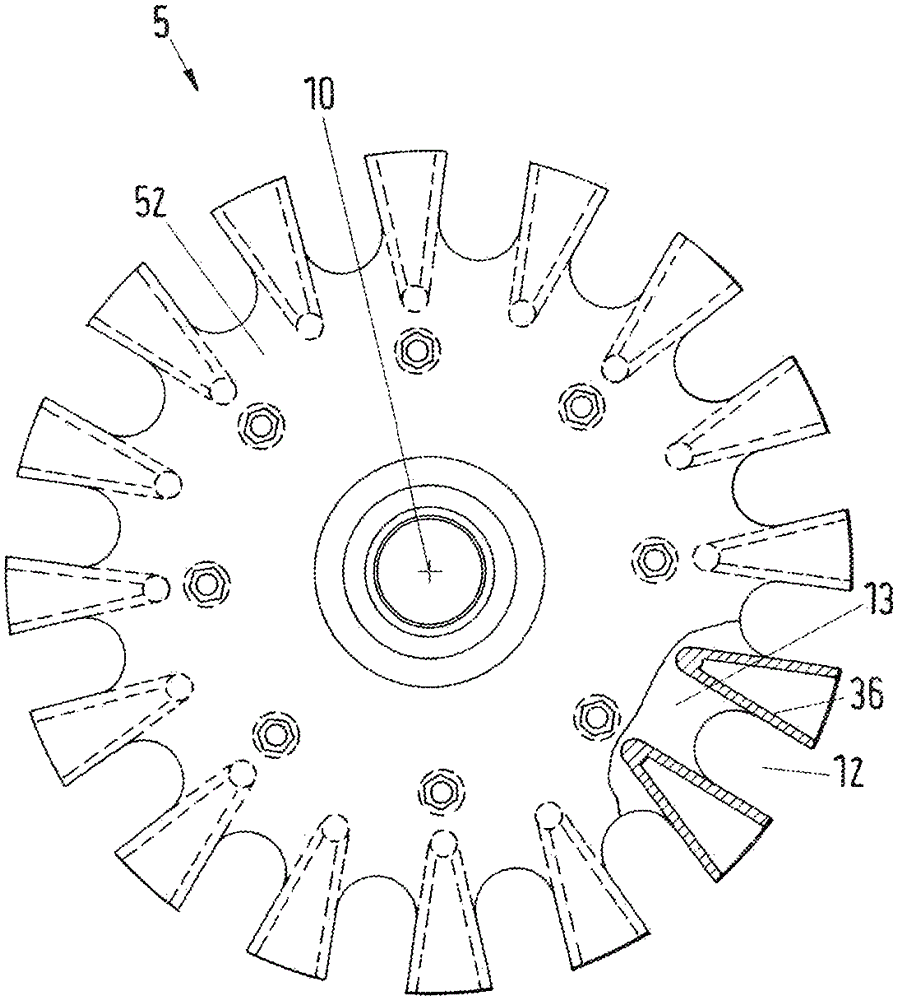

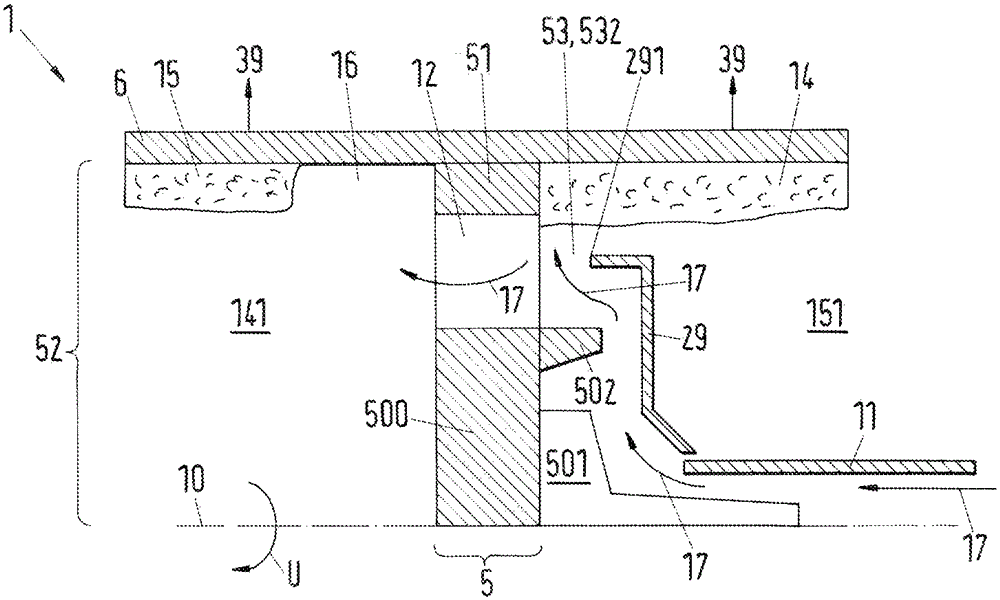

[0047] figure 2 The main components of a first embodiment of a double-acting pusher centrifuge according to the invention are shown in a highly schematic representation in section by way of example. In this regard, at least for particular embodiments, the double-acting pusher centrifuge of the present invention may be considered to be based on Figure 1a-Figure 1d Another development of the known double-acting pusher centrifuge, where the main difference can be seen in the inflow gap, which is not interrupted in the peripheral direction, and this is not present in the known double-acting pusher centrifuge .

[0048] Basis identified generally with reference numeral 1 figure 2 The inventive double-acting pusher centrifuge serves to separate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com