Distributing device of piston-pusher centrifuge

A technology for distributing devices and centrifuges, which is applied to centrifuges and centrifuges with rotating drums, etc. It can solve the problems of reducing the stability and production capacity of centrifuges, reducing product quality, and unbalanced centrifuges, so as to improve The scope of application and the stability of use, easy maintenance, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the drawings

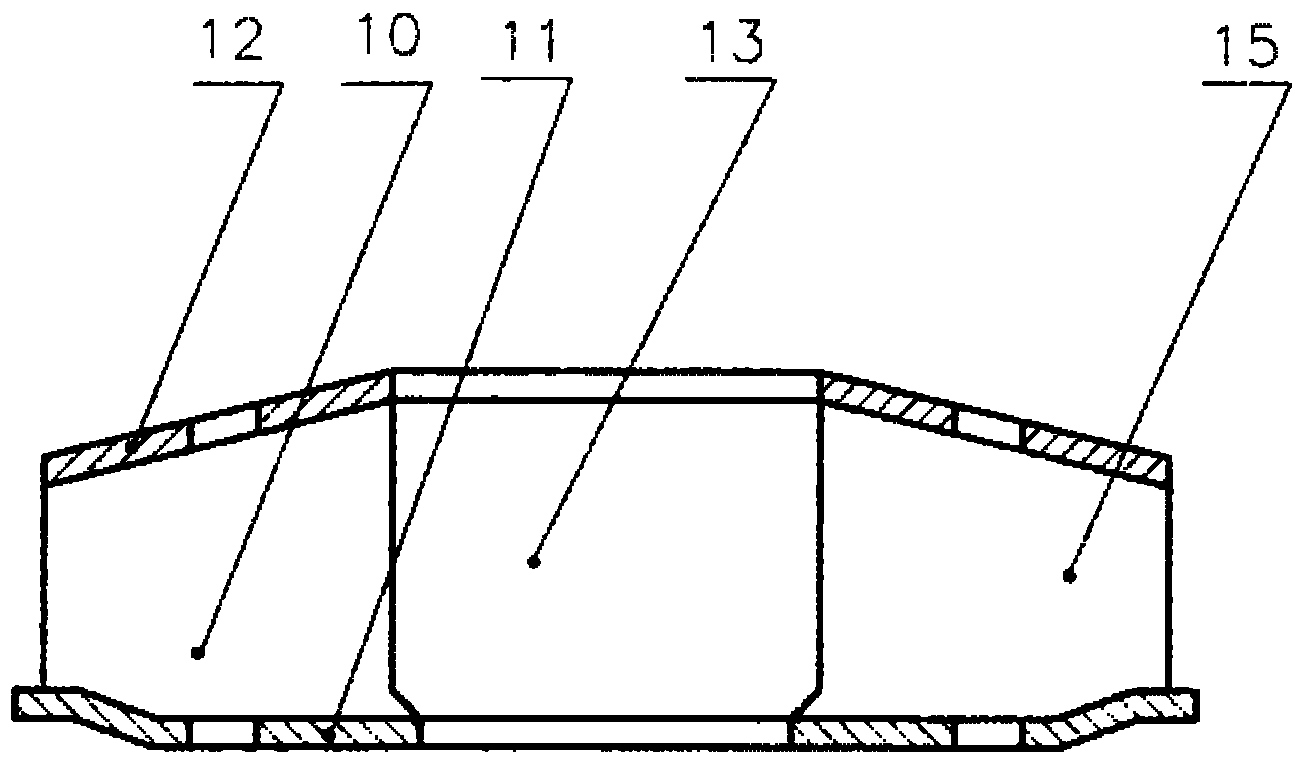

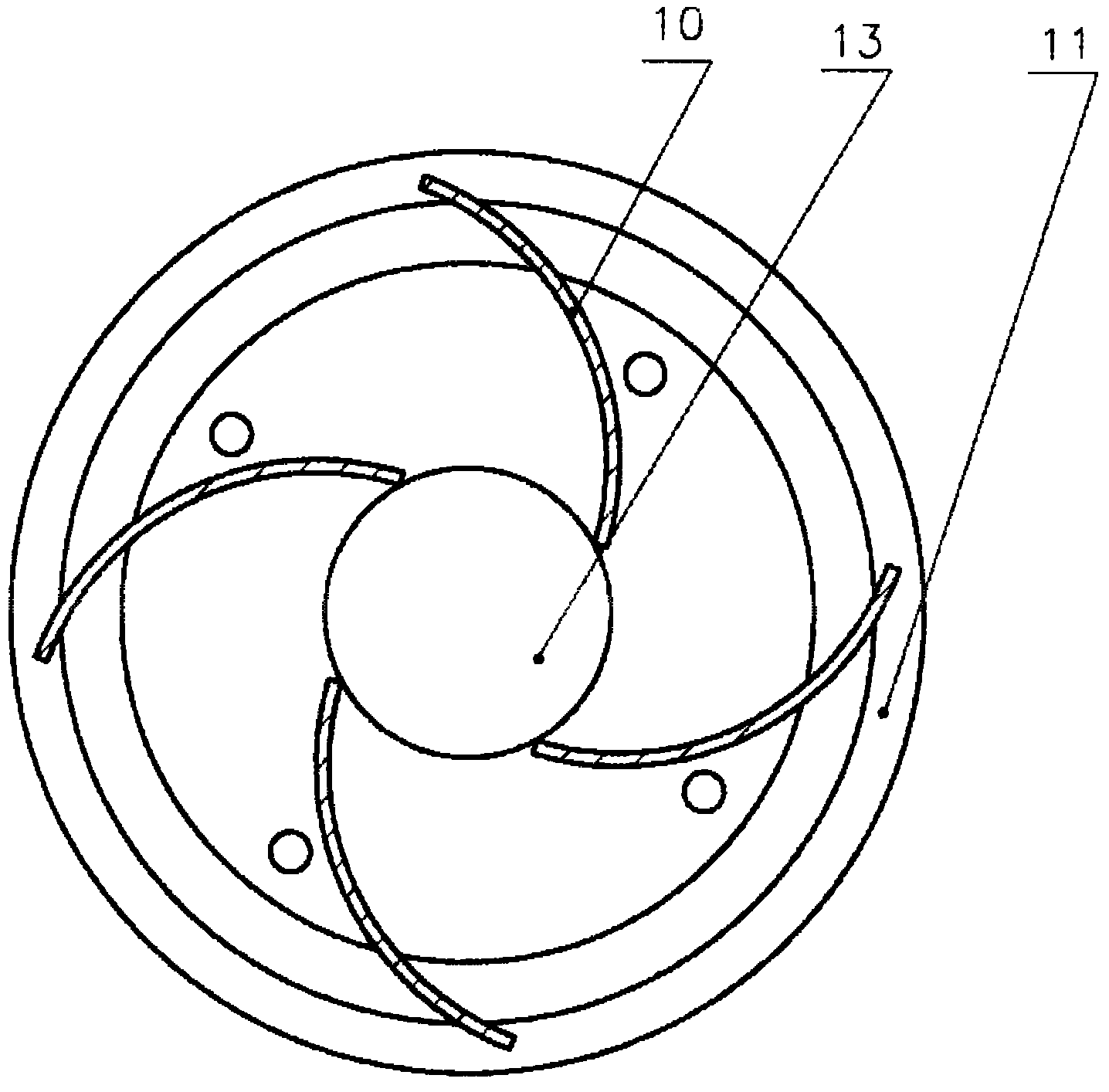

[0013] The bottom plate 11 of the cloth cone 14 is fixedly connected with the pusher plate 5 by welding with screws, and the pusher plate 5 is fixed to the support rod 6. The top plate 12 and the bottom plate 11 of the cloth cone 14 are equipped with four arc-shaped parabolic blades. 10; The upper and lower edges of the blade 10 are welded and fixed to the top plate 12 and the bottom plate 11, respectively. The top plate 12 and the bottom plate 11 are disc cones. There is a hole 13 in the middle of the cloth cone 14, and the cloth cone 14 has a top plate 12 and a bottom plate. 11 and the horn arc cavity 15 surrounded by the arc blades 10, the outlet end of the feed pipe 2 extends into the horn arc cavity from the hole 13, and the flushing pipe 1 is fixed on the centrifuge feeding pipe 2, and The pipes 2 are parallel, and the feed pipe 2 is fixed on the casing to maintain a static state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com