Centrifuge and method of loading a centrifuge

A centrifuge and metering device technology, applied in the field of centrifuges, can solve problems such as unfavorable energy and unfavorable centrifuge operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

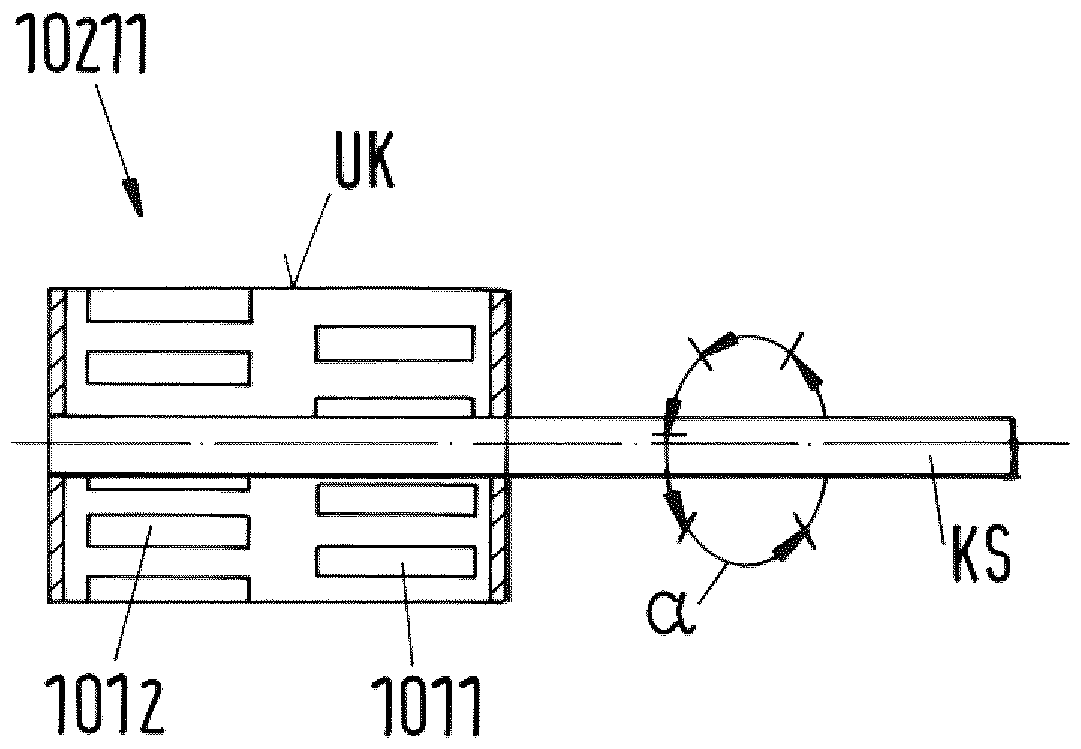

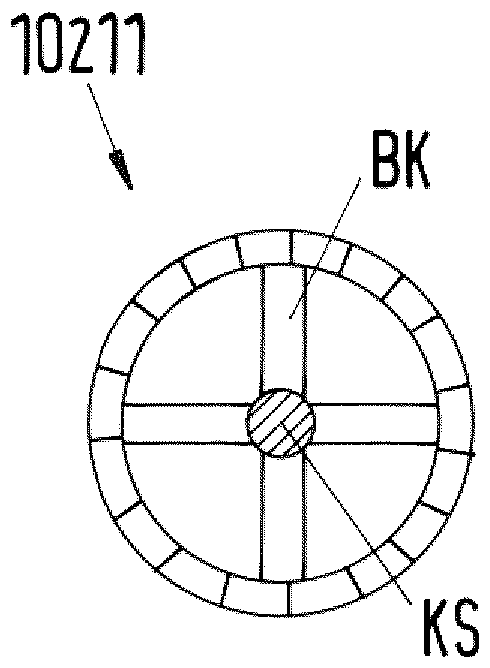

[0086] figure 1 A double-acting impeller centrifuge known from the prior art according to EP1468741A1 is shown, which centrifuge has been described in detail above and, therefore, no further discussion of this centrifuge is required at this point.

[0087] figure 1 A cross-section of a schematic representation of the main elements of a centrifuge according to the invention is shown for the particular example of a double-acting centrifuge generally designated by the reference number 1 in the following.

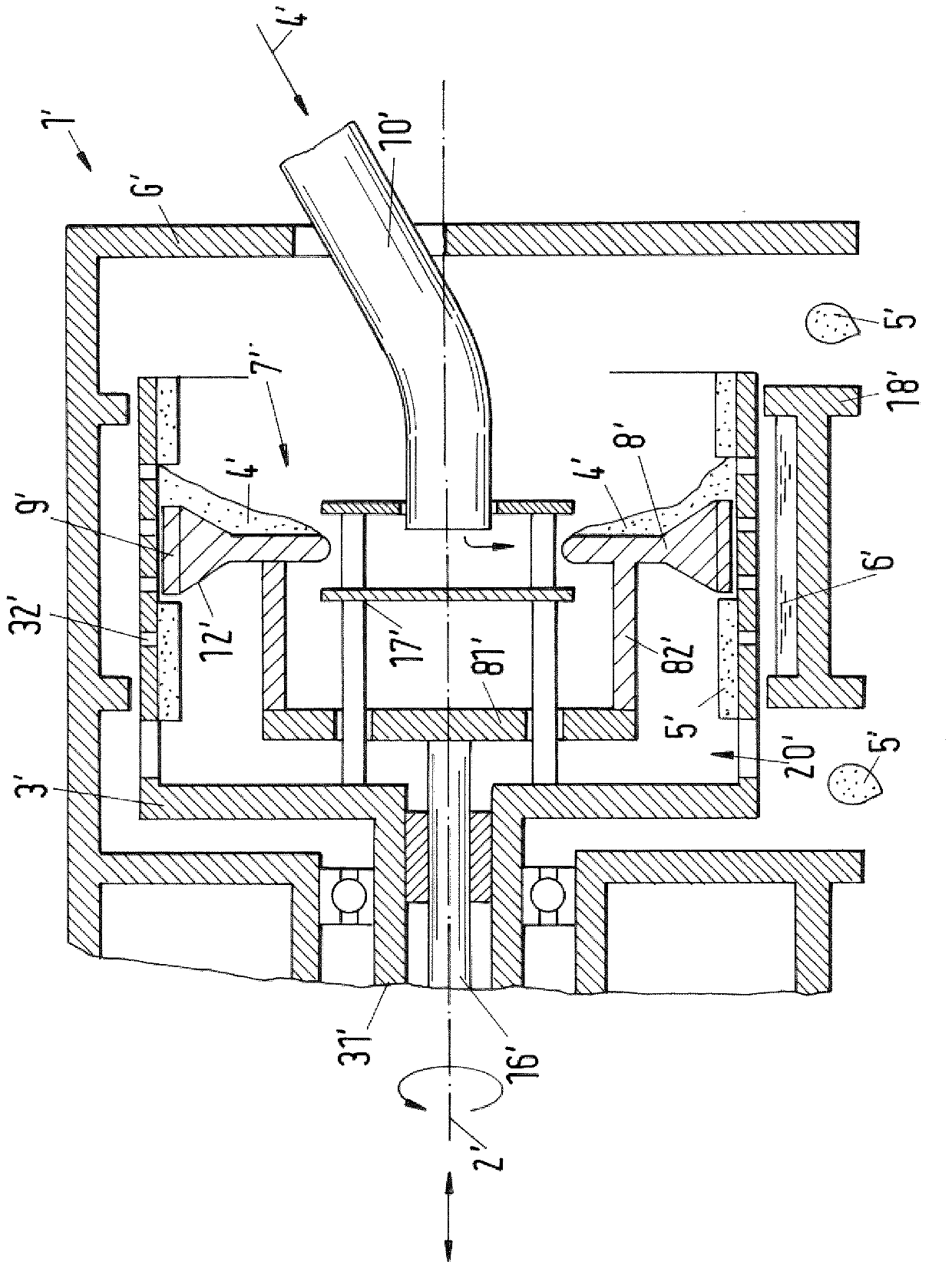

[0088] figure 2 A schematic representation of a first embodiment of a centrifuge according to the invention in one embodiment of a double-acting impeller centrifuge is shown without cleaning products. exist figure 2 The double-acting impeller centrifuge 1 shown in can in principle be a single-stage or multi-stage impeller centrifuge or even a scraper centrifuge with a feed device 100 according to the invention comprising, in a manner known per se: a sieve drum 3, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com