Piston material pushing centrifugal machine and feeding method thereof

A centrifuge and piston technology, applied in the field of centrifuges, can solve the problems of fewer stages of drums, high moisture content of materials, cracking of drum bottoms, etc., and achieve long filtration area, low moisture content of filter residues, and increase filtration time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

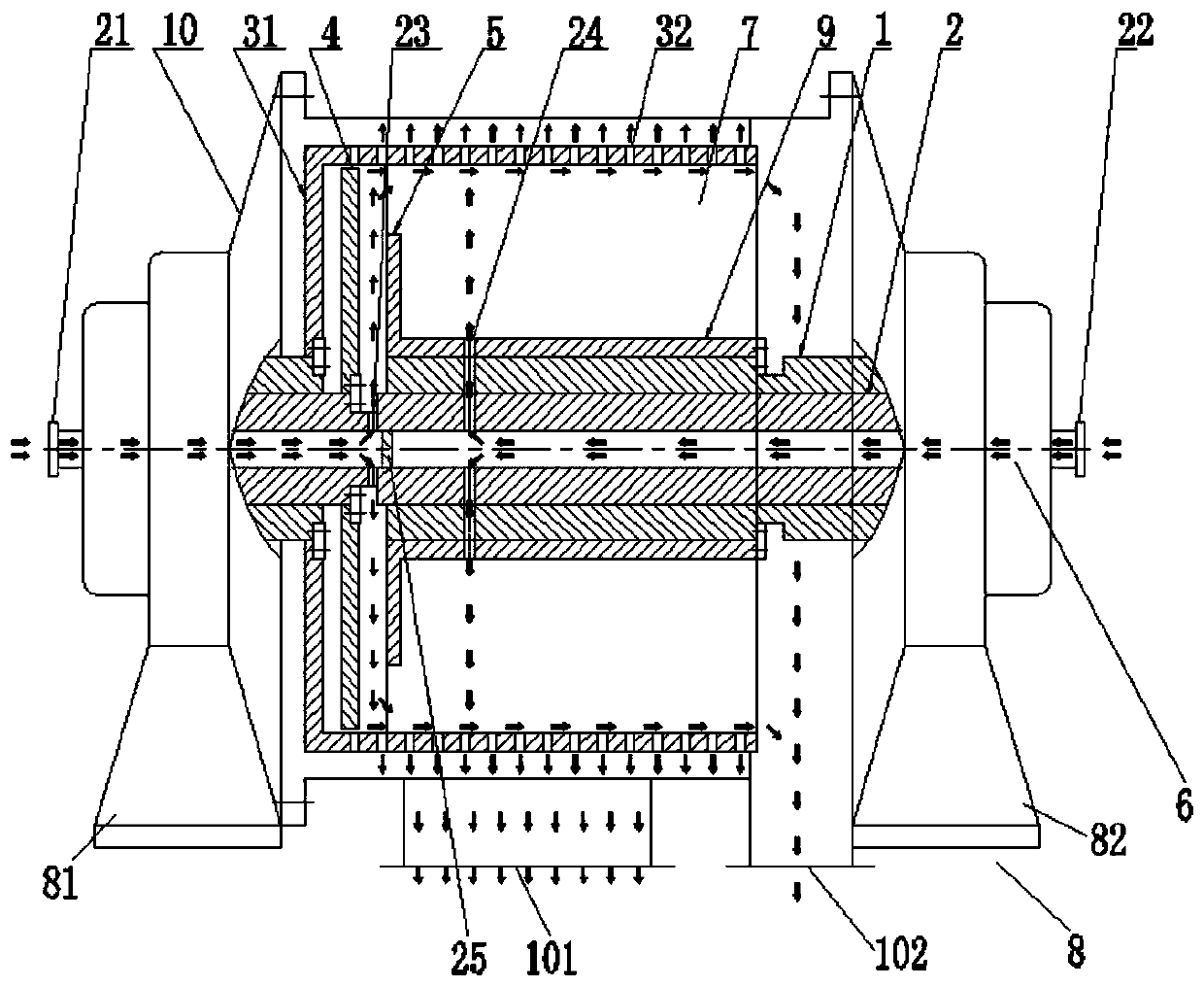

[0036] Please refer to figure 1 , a piston pusher centrifuge, including a main shaft 1, a push rod 2, a drum 3 with one end open and a hole in the side wall, a pusher 4, a distributor 5, a driving mechanism 6, a drum reinforcement structure 7, a main shaft The supporting structure 8, the sleeve 9 and the casing 10 arranged outside the drum 3, the lower end of the casing 10 is provided with a filtrate outlet 101 and a filter residue outlet 102;

[0037]The main shaft support structure 8 includes a left support structure 81 and a right support structure 82 respectively arranged on both sides of the drum; the drum bottom 31 of the drum 3 is fixedly arranged on the main shaft 1 or the push rod 2, and the drum strengthens The structures 7 are all arranged in the circumferential direction of the sleeve 9, one end of the drum strengthening structure 7 is fixed on the sleeve 9, and the other end is fixed on the drum wall 32 of the drum 3;

[0038] The push rod 2 is a hollow tubular s...

Embodiment 2

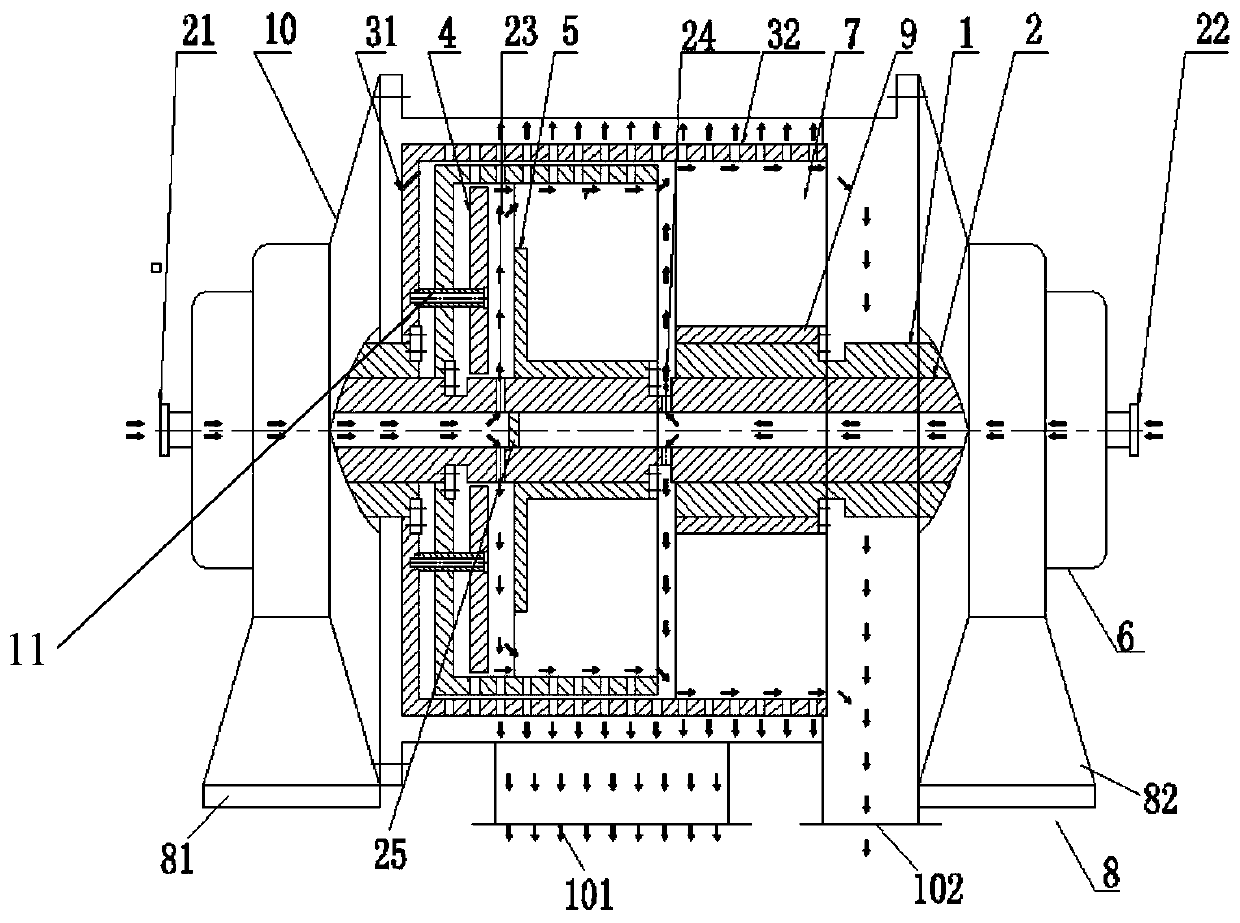

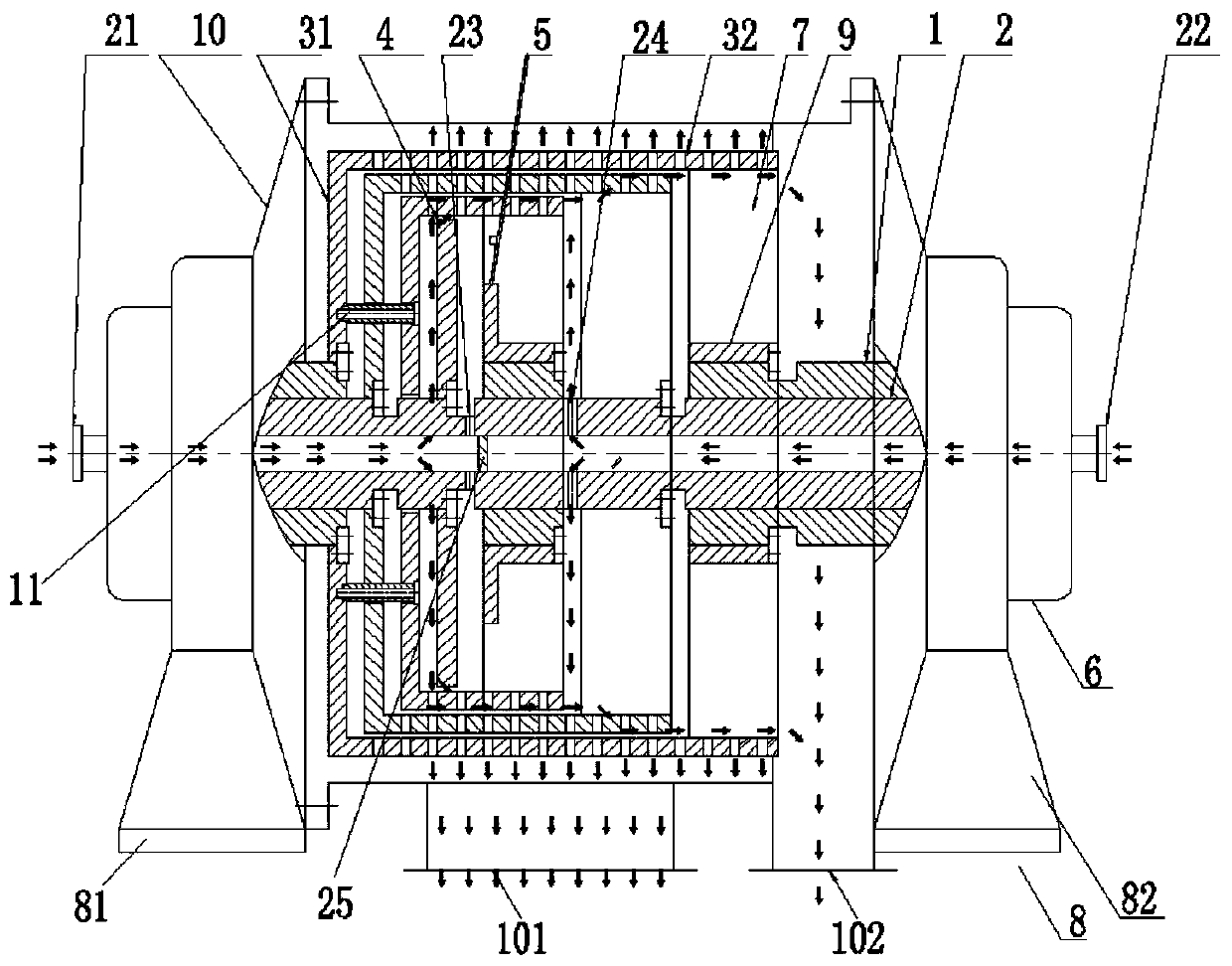

[0043] Different from Embodiment 1, the number of the drum reinforcing structures 7 distributed axially in the drum can be two rows (see figure 2 , image 3 , Figure 5 ), which are respectively positioned at the axial feed end and the discharge end of the drum wall 32, become a simply supported beam support structure supported by double fulcrums; it can be a plurality of more than two rows (see Figure 6 ), which are respectively located between the axial feed end and the discharge end of the drum wall 32, and become a multi-fulcrum support structure.

Embodiment 3

[0045] The difference from Embodiment 1 is that the material channel 23 or the washing water channel 24 is other structural forms such as annular seams on the push rod 2, and the two ends of the annular seams are connected by the connecting structure 11. At this time, the torque of the driving mechanism is Structure 11 transfer (see figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 9 area with connection structure 11). The connection structure 11 can be a combination of a single or multiple fasteners (such as screws, bolts) of a plate, a column, a pipe, or a combination of multiple single or multiple fasteners (such as similar to a joint shaft structure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com